Value Methodology in Oil & Gas Projects: A Project Management Approach

advertisement

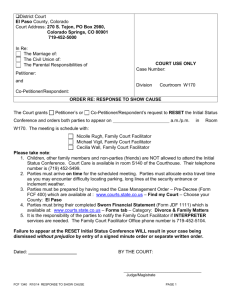

FROM PRODUCT TO PROJECT – FORMING VALUE INTO A NEW SHAPE John G. Downer Penspen Ltd 3 Water Lane Richmond upon Thames Surrey TW9 1TJ United Kingdom BIOGRAPHY John Downer works in the London office of Penspen, a significant hydrocarbon engineering consultancy, where he has contributed to a variety of oil and gas projects around the world. John has championed within Penspen since the late 1990’s 'soft engineering' such as Value and Risk Management prompted by the awareness that such services are being increasingly demand-driven by clients. He is certified as a Professional in Value Management (PVM) to the European Standard BS EN 12973 ‘Value Management’, after qualifying with the highest recorded mark to date in the UK. Other qualifications and professional memberships include a title of European Engineer (Eur.Ing) from the Fédération Européenes d'Associations Nationales d'Ingenieurs (F.E.A.N.I.), B.Sc. (Hons) from The City University, London, Chartered Engineer from the Engineering Council, Member of the Institution of Civil Engineers (MICE), and the Chartered Institution of Water and Environmental Management, (MCIWEM). Contact Details He is also a member and non-Executive Director of the Institute of Value Management (IVM) in the UK and the Editor of the IVM + 00 44 (0) 208 334 2700 tel. magazine ‘Value’ which has a readership in the UK, Europe and + 00 44 (0) 208 334 2701 fax. around the world. j.downer@penspen.com www.penspen.com Although starting out in mainstream engineering design and construction which took him via water projects in south London to the streets of Calcutta, it is working in the milieu of oil and gas that he has developed in-depth project management experience of large capital value projects that combine complexity, quality and concerns about HSE issues. He has facilitated VM workshops to improve the value of projects such as new oil field developments, 100,000 bopd plant enhancements, new infrastructure, mature field power upgrades and offshore life of field engineering option projects, helping workshop teams to identify options with combined potential savings of 5 to 80% of project cost estimate value. John is interested in the development and articulation of sound VM principles that deliver results clients wish for, whilst providing a practical and useful experience for workshop participants and is examining ideas from Operational Research theory to sharpen VM practice and maximise its effectiveness for 21st century projects. SAVE paper rev G.doc This paper is © J Downer 2005 Page 1 of 22 ABSTRACT The development of the Value Methodology from Value Analysis (VA) has carried the imprint of VA from its tools and techniques to a pre-occupation with maximising the value equation. VA was developed to increase the value of manufactured products and it is hardly surprising that applied to major projects there are exposed gaps and demands on the methodology. The growth in project complexities, team size and specialisation, use of consultants have all conspired to confound a VA approach developed for products managed by a stable workforce team. Whilst the number and range of issues facing projects has grown, so inversely has the ability waned to withdraw for a ’40 hour’ workshop. The paper describes how, for a project, the search for value that can be readily translated into tangible improvements in functionality or decrease in cost – or both, are found by mining the ‘unknown’ virtual shape of the project. This shape can be explored by combining systematic open questioning with function analysis. It is then that ideas developed during the creative phase of a workshop can have real significance, resulting in a major increase of value. 1 INTRODUCTION This paper attempts to position the current application of the Value Methodology to large scale oil and gas projects in the context of the development of the Value Methodology from its early beginnings as Value Analysis applied to products within a factory environment. In considering the especial features of such projects and the difficulties they create for a traditional workshop, proposals for the amendment, augmentation and addition of the Value Methodology approach are suggested. Central to this is the development of a workshop body of knowledge fleshed out by open questions that describes a morphology of the project. This virtual shape of the project can be represented in a diagrammatic way, (if workshop time allows) but provides a shared workshop basis with which to generate ideas to add value whilst acknowledging the existence of wide ranging project constraints, risks, assumptions, givens etc 2 VALUE ANALYSIS Value Analysis originated with the pioneering work by Lawrence D Miles (LDM) for General Electric in the 1940’s and Value Analysis has the uncommon trait of possessing a lineage that can be traced to a man, a place and a time. There are numerous sources which record and testify to the work undertaken by Miles and the evolutionary route of development taken by Value Analysis up to the present day, metamorphosing into Value Engineering (VE), and this in turn being subsumed within a bigger framework called Value Management (VM) in Europe and the Value Methodology in the USA. This paper shall refer generically to the Value Methodology and use the abbreviation VMD, and VA when referring to the initial ideas of Miles as represented by Value Analysis over its first 20 years approximately. In order to present in context the main ideas of this paper it is necessary to re-capitulate some of this history, although the review is intentionally selective to counterpoint the issues raised later. SAVE paper rev G.doc This paper is © J Downer 2005 Page 2 of 22 Firstly, it must be noted that although the name of Miles is still well known in the management world, his founding work is not always immediately associated with the methodology that VMD has become. Miles’ own record of his early work captured in his seminal book Techniques of Value Analysis and Engineering (Miles, 1961) testifies to many things, some being so obvious they can be missed from the position that VMD finds itself in today. These are: • • • • The central pre-occupation of Miles’ work is the maximisation of value for a plethora of manufactured products. Techniques of Value Analysis and Engineering is distinguished by copious examples of products which Miles assails with the shock troops of his new VA techniques such as systematic questions, creativity, comparison etc. The location of this activity is within a factory environment (General Electric) Miles presents a fresh idea– that of value - to stimulate new ways of thinking about manufactured products, and postulates what the components of value are made up from. For the first time what an object needs to do, is separated from how that function is provided. Taking each one of these points in turn: • Value Analysis and products Although it is a commonplace in the 21st Century that VMD can be applied to every conceivable situation and scenario, the origins of the Value Methodology are centrally concerned with the improvement of products. Indeed from the founding work of Miles in the mid 1940’s and the specification of VE by US Government Regulations thereafter in Defense Department contracts, there was a prohibition on the application of VE to any construction work (Fowler, 1990). This was not rescinded until the early 1960’s, chiefly through the efforts of Alphonse J. Dell’Isola Although VA jumped the species gap into new terrains of construction projects, did its tools and techniques change sufficiently? • Factory Environment VA was conceived and gestated entirely within a factory environment. At the time of the conception it was an era of relative stability and large factory workforces, with concurrent long average working lives of employees with single employers. Particular features emanating from this and the era (1940’s-1960’s) would include: o Large internal repository of knowledge concerning the factories products and manufacturing methods contained within the factory workforce, a substantial number of which would have a single employer for all their working life. o Information on costs, particularly internal costs available in-house o Larger workforce and less pressures on time making possible the freedom to take time out for activities such as VE To what degree were these factors contributory to the early success of VA and how does their absence for projects affect the application of VMD? SAVE paper rev G.doc This paper is © J Downer 2005 Page 3 of 22 • The importance of the concept of Value Until Miles it is reasonable to think that no one had seriously considered how value was made up in a project. What constitutes value? How are the sediments of value laid down in a particular product? Which bedrocks were they eroded from? - materials, labour, function…. Also, why is someone interested in buying it? Miles introduced the product purchaser as the true judge of value. Miles postulated four components of value for a product as use, cost, esteem and exchange, and defined the keenest value for a product as being the minimum dollars necessary to create the appropriate use and esteem value components (Miles, 1961). The concept of value allowed a new Esperanto of equivalence to materialise and dissolve hitherto artificial walls that separated products and their components. If use and esteem could be provided in some alternative way that was cheaper, then value was improved. Perhaps they could be improved for the same cost of manufacture, or even less cost. This new ‘freedom to dream’ of alternatives organically meshed with the deliberate creative stage inserted into the VA job plan. But are the components of value as conceived by LDM for a product equally applicable to other applications, such as projects, for example? • The idea of function Function similarly permitted the consideration of what it was a product must do, sheared from how that function was currently provided. Again this opened a door to freely considering anew better or alternative ways of providing the function and through the development of function diagramming, investigations of whether some functions were really necessary in the context of appropriate value for a product. Function allows a way of breaking the impassive surround of an existing product into intelligible blocks that can be methodically thought about, when no other technique provides a magic key way of unravelling sufficiently what is tangible to think of new ideas that offer possible value improvements. But in dis-aggregating a product into functions within a workshop there are implicit assumptions that any subject of a VMD workshop can be unpicked to a useful degree within a sensible timeframe and also whilst engaging the whole team. For a project is this true? 3 PROJECTS 3.1 Points of difference between projects and products Since the invention of VA there has been a phenomenal growth in the size and number of projects and at some time in the 1960’s there came a point where the Value Methodology started to be applied to projects, after initially being thought inappropriate. Now it is applied widely and freely, but has what started out as a value improving methodology for products actually metamorphosed sufficiently to be suitable for a project? A key point to which I shall return to at several points is to consider here the timeframe. VMD evolved from VA which was developed to improve products of the 1940’s; its basic format has been applied ever since to a widened area of applications in the world including projects. SAVE paper rev G.doc This paper is © J Downer 2005 Page 4 of 22 Both products and projects have since exponentially increased in complexity – has VMD kept pace, or is it the propeller in the age of the jet? 3.2 Are all projects pretty much the same in the end? In applying VMD to projects there appears to have been little attention paid to differentiation of projects by meaningful metrics within the VMD community. A lack of differentiation leads to construction projects being lumped together and the same uniform techniques and methodology applied indiscriminately. Clearly there are different challenges between say constructing housing or bridges, nuclear power stations or train stations and $100,000 projects or $500m cost projects. Maybe in endeavouring to apply VMD to all of these some deviations can be hidden in a low-key nonconfrontational project that involves building un-contentious houses, or small projects that do not register on any meaningful time or cost ‘Richter scale’. But in progressing in size and complexity to projects of $30, 40, 50m plus, up to the borders of mega projects of $500m plus it is postulated that the VMD methodology that worked well in the former cases starts to creak a bit when applied unchanged to these much larger and more complex projects. Spelling it out – large projects are more difficult since • • • • 3.3 They cost more so a percentage deviation in time and/or money ends up costing considerably more or taking a lot longer They are large enough to warp the social space they border, hence they attract a lot of interest from external parties – a project with a problem often has effects outside of its immediate boundary or envelope Size begets complexity – either by virtue of increased number of interfaces, through a larger number of packages, or as an inherent part of the project involving modern levels of expensive and complicated instrumentation and control, distributed control systems (DCS), programmable logic controllers (PLC’s) to mention only a few possible items that introduce new disciplines, interfaces and critical components etc Size multiplies the numbers of involved parties and team size – which in turn concatenates the divergences and possible points of misunderstanding impinging upon the project manager trying to steer a straight line The type of projects this paper has in mind The projects that this paper has in mind are those within the onshore upstream oil and gas industry. Such projects exhibit all of the foregoing large project characteristics coupled with a much heightened complexity and to mention only a few additional features – extreme sensitivity to health and safety factors, environmental repercussions, comprehensive legalistic constraints on operations, etcetera…The operating environment has followed the modern trend of reducing manpower and increasing remote and more intelligent control whilst complying with ever more stringent health and safety key performance indicators (kpi’s). As just one of many examples, the industry has moved from an acceptance of flaring (burning) gas at wellhead installations towards one of zero flares in the current era, as the environmental and economic arguments have militated against a continuation of the former policy. Such an example is also significant in pointing up the buffered external interests that motivate movements and directions within industries and that these in turn calve large projects (such as turning a large oil and gas installation into a modern zero flaring facility). SAVE paper rev G.doc This paper is © J Downer 2005 Page 5 of 22 Such projects carry with them some special characteristics that make them immune to many of the normal approaches of a ‘standard’ VMDC workshop, due to factors such as: • • • • • • • 3.4 Large teams required to represent the mix of numerous disciplines, project stakeholders and other parties Intense pressures on time due to the size of the team, the teams’ own personal project commitments, and the monetary value of their time The degree of specialisation within the project team members and depth of their experience and knowledge The familiarity of highly educated team members with complex pictorial and textual ways of describing the systems and relationships comprising the project The highly leveraged engagement of individual elements of plant and equipment forming the project building blocks The complicated design of each individual item of equipment that itself is enmeshed into a larger whole A highly redundant web of legislation, codes and standards interposing on the design from technical, health, safety, environmental and other sources. Can VMD help such modern projects? During VMD workshops for large/complex oil and gas projects, if one tries to apply VMD in ways little changed from the founding ideas of VA some questions can arise such as: • Is there actually a quorum of knowledge, shared and agreed with which to commence the workshop? o Do all the specialists gathered understand the overall project ‘big picture’? In order to jolt project team members out of a comfortable complacency and start to question the project anew the inclusion of outsiders may mean that a reconstituted picture of the project needs to be formed by the team prior to any further advancement into the workplan stages. • Does functional analysis, within the available usually short workshop time, allow the assembled team to come to a clearer understanding of what it is the project is doing and where value can be added? o Again this should be considered in the context of a group of intelligent engineers who have in most cases agonised over a project conceptual design probably staying on for the Front End Engineering Design (FEED) for more detailed development and in this time would have sat through a number of intensive design reviews, operability analyses, HAZOP’s etc. Many such reviews encroach on the fertile terrain of VMD by such activities as looking at energy costs and conducting optimisation studies to consider different development scenarios and select a best option that offers the most advantages or cost/benefit. • How can one find what the catalysts are for persons in a workshop to tap into areas of real value adding ideas that have a capacity to improve value radically? SAVE paper rev G.doc This paper is © J Downer 2005 Page 6 of 22 o If for whatever reason the central attack of functional analysis is thwarted then for a large and complex project how is the team to find a way of coming up with value adding ideas? Also for engineers can they be obliged to think truly creatively and not just regurgitate preconceived thoughts during a limp brainstorming session? • What does the project promoter consider to be of most value for this project? o The VMD practitioner may have in his mind the mantra ‘Value=function/cost’ but it would seem a good idea to ask the promoter what his ideas on value are and what value to him is made up from. o From a better understanding of what is of most value for the project then it may be possible to come up with more directed ideas of value adding potential by awakening the assembled team to a wider concept of value for the project. Whilst the special combination of elements that together constitute the main parts of the Value Methodology including team approach, use of workplan, sequential varied techniques, functional analysis make a formidable team, there has arisen since the inception of VA a dizzying array of techniques which could be summed up as focussed on doing things more intelligently to yield bottom line profits. The techniques within operational research particularly have been taken up and spread to areas where they now adjoin the discrete patch left to VMD. This starts to provoke questions about what it is that VMD retains that itself is of value to client bodies; why is VMD still relevant to contemporary large scale projects and are there necessary changes or improvements to the methodology that make it more effective in improving the value of a project? 4 ISSUES WITH APPLYING ‘TRADITIONAL’ VMD TO PROJECTS 4.1 Overview Concerning some of the issues highlighted in the above sections, what follows is an attempt to describe some possible solutions that could constitute the basis of a theoretical solution to the problems raised. 4.2 The components of value – do they need updating? Since the proposition by LDM that Value was formed out of just four components for a product, there appears to have been little further thought given to whether these are fixed or varied in relation to the VMD study subject matter. In considering this question one particular example was noted of a multibillion dollar oil and gas development in the Caspian Sea area where the client defined its value components as follows: • • • • • Cost Schedule Quality Safety Environmental impact SAVE paper rev G.doc This paper is © J Downer 2005 Page 7 of 22 • • • • Risk mitigation Project location Field life expectancy And other company/shareholder requirements These items appear to be confirmed from a high-level analysis of oil and gas projects facilitated by the author, noting that these components are often necessarily subjective. However, it would appear that the components of value for large scale oil and gas projects could be summarised generically as follows: USE Value Expressed in terms of meeting the minimum output requirements of the project design. These could be expressed as a mixture of qualitative, quantitative and other elements. COST Value Expressed in a preferred way such as meeting or coming in beneath the sanctioned project cost estimate or achieving a corporate KPI e.g. an outturn cost within a specified percentage of the estimated cost. TIME Value Expressed again in a preferred way such as meeting schedule key dates or a corporate KPI for project timeliness RECIPROCAL RISK Value The riskiness of the project measured in terms of risk impact for the most serious high impact/high probability risks identified arising typically from safety, environmental, social, legislation etc either directly on the client or via stakeholders including third parties, shareholders etc. The reciprocal risk value implies that a decrease in project risk delivers an increase in value. OTHER Values – as suggested by the client or exposed during the information stage of the workshop. As one may expect it also appears that for projects outside the oil and gas project sphere, the components of value change in response to the type of project. Use and cost are still critical value components but esteem and exchange are absent. There may be residual amounts of these components still present in an oil and gas project but the above elements are nominated as of more concern to the client, who with LDM’s promotion of the importance of the purchaser, for the project assumes this role in defining what it is that is of value to them. SAVE paper rev G.doc This paper is © J Downer 2005 Page 8 of 22 4.3 Pre-Workshop Phase – does it need augmenting? 4.3.1 Usual Elements Pre-workshop preparation is recognised as being an essential phase without which the workshop success is immediately thrown into doubt. Most elements of the Pre-Workshop phase whether for a project or some other subject tend to include the following: • Agreement of o workshop programme o workshop attendees o workshop aims and objectives, no-go areas, constraints etc o materials to be copied and passed out at the workshop and materials to be issued for briefing purposes ahead of the workshop o workshop practicalities such as precise dates, venue, facilities, food and drinks etc • Review of information concerning the workshop subject in order to brief the facilitator; usually this includes information related to costs such as the current cost estimate (used to identify via the 80:20 rule the main elements which cost the most on the project). Interviews by facilitator with key persons or a joint meeting Preparation of Pre-workshop briefing pack of materials to issue to the attendees, including in addition to items above, a welcoming letter, workplan and information on costs • • 4.3.2 LDM and the injection of new information LDM exhorted the VA practitioner through his approach, tools and techniques to: • • • • Always be prepared to seek out and find specialist knowledge use information from only the best source use industry specialists to extend specialised knowledge utilise and pay for vendors skills and knowledge It is worth reflecting on why LDM advised such an approach. Within the walls of even a large factory there is insulation from the outside world. This can retard innovation and evolution of products which new information from outside can go some way to redress. When a product has been replaced by a project as the subject of the workshop, what then is the place and purpose of seeking out information, specialists and knowledge? It is relatively easy to imagine specific information being targeted for a product; but for a large project where precisely is one to start? 4.3.3 Adding new ideas to a familiar project A chief problem with many projects is the familiarity that builds and becomes inevitable when the team has been working together which for a large project could be several years. The project terrain then becomes known and the thought paths through the project incised to the point where the possibility of new thinking of the type that fosters creative value adding ideas becomes ever more SAVE paper rev G.doc This paper is © J Downer 2005 Page 9 of 22 remote. This process appears to be intensified by the growth of specialisation within project teams where literally different languages are spoken and an assumption of understanding and comprehension made based usually on the fact that the project is shared between all. In attempting to inject new thinking during a VMD workshop one of the reasons for seeking out information from the best source, from specialists, can be to show members of the team how others from around the world have faced similar project issues and the solutions that have been worked out. Other examples can be shown of new equipment that has recently been developed that promises advantages in terms of efficiency, reduced costs etc. Or even tangential ideas that may not seem directly relevant but may be sufficient as catalysts for the next stage of provoking further ideas in the minds of team members during the creative part of the VMD workplan. Typical sources of ideas to present to team members can be drawn from the huge amount of information found on the internet, as well as periodicals and other magazines, (subject to obtaining the necessary permissions for reproduction) plus techniques like TRIZ etc. The best combination of information to present to workshop team members usually comprises an amalgam of detailed summaries of comparable projects with a similar theme, selected equipment and manufacturer information on themes directly related to the project and as the seasoning some parabolic items about ideas that could be linked to the project if only in a marginal way. The ‘lack’ of relevance works in favour of provoking the sub-conscious to form new links and it is these that can become the grit in the oyster during the creative session of the VMD workplan. 4.4 Workshop Phase – does it need changing? 4.4.1 The importance of the Facilitator As a facilitator there is an understandable wish often to retreat behind the well prepared structure of the VMD workplan and avoid the sometimes awkward interaction with a group of individuals who on a project as an external facilitator, often one has not worked with or met before. But for the same workshop, two facilitators of differing abilities will be able to draw out completely different responses which in turn will affect what can be achieved through the remaining VMD techniques and ultimately how the workshop will be judged at its conclusion. By abilities what is meant are the ‘soft skills’ inherent and learnt by the facilitator to interact in a responsive and controlled manner with the group forming the VMD workshop team. The expansion of interest and understanding in group facilitation skills over the same period as the development of VMD since the 1940’s has revealed just how important soft skills are in allowing a group to overcome innate passivity and inertia and pass into a new phase of a cohesive team leveraging individual contributions towards a common goal, which in VMD terms could be formulated as finding new ways to add value to an existing project. To expand on just what may constitute a 21st century soft skilled VMD facilitator would require a separate paper in its own right but the essential point to be emphasised is that in facilitating a modern VMD workshop for a complex project, it is essential that the VMD facilitator is fully aware of both the theoretical basis of group interaction and evolution and can in practice enact the practices necessary to: SAVE paper rev G.doc This paper is © J Downer 2005 Page 10 of 22 • • • Catalyse the process of a group overcoming its inertia and inhibitions prior to reforming into a cohesive unit Interject with the group to re-orientate it when it becomes off-balance due to reasons emanating from internal frictions between members, digressions, personal agendas etc. Manage the group to progress through all the VMD workplan stages against the allotted agenda time, whilst taking account of the need to exhaust subjects of particular interest Whilst it is recognised that some persons have an innate pre-disposition to be able to acquire such skills, in facilitating a complex project with its numerous discipline segregations, redundant complexities and limited workshop time, it is ever more critical that the VMD facilitator evinces soft skills in order to maximise the chances of completing all workplan items to a depth sufficient to allow during the creative phase ideas of real value adding worth to come forth. 4.4.2 The use of structured questioning and dis-aggregating the project deliberately Intimately linked with the display of soft skills by the VMD facilitator is a VMD workplan that will deliberately cause the workshop team to confront congenital fault lines within the workshop team. Why should one wish to expose internal disagreements within a team? Every team will have – whether recognised or not – issues within a project where there are disagreements over particular points due to facts, methods of approach or analysis or due to misunderstandings, wrong assumptions or false and sometimes incorrect information. When it is recognised that all of these areas themselves constitute extremely fertile mulch for value adding ideas then it becomes an imperative to quickly dig into the project to permit the workshop participants to begin a process of building up a commonly agreed picture of the project, where all the disagreements have been pruned or clarified. From this process, a number of ‘value seed’ ideas will be accumulated by the team ready to kick start the creative phase. Some commentators (Male and others, 1998) on Value Management consider that a team coming together for a project workshop have a common body of consistent knowledge that needs negligible further work. It is a contention of this paper based on workshop observations that even for a team that has worked together for a long time there will be mis-alignments of perceptions and viewpoints and it is precisely these areas that need to be discovered and explored as they invariably are potential source areas of adding value to a project. By observation, a team coming together will always have issues to discuss even when they have themselves been on the project for a lengthy period. To avoid the re-treading of familiar views two particular approaches are advocated: • Endeavour to select a widely sourced team Team selection is recognised as a critical Pre-Workshop activity; for a VMD workshop on a complex project it is strongly advised that the workshop team should include members drawn from the immediate client project team with representatives from the main disciplines plus project and engineering managers operations and maintenance staff who operate the current plant or will most likely end up operating the project plant when constructed SAVE paper rev G.doc This paper is © J Downer 2005 Page 11 of 22 engineering peers from the same organisation but not directly working on the project or alternatively (and usually better) peers drawn from a different organisation but working in the same project field (though issues to do with confidentiality may have to be confronted) specialist consultants engaged by the project promoter to undertake particular activities e.g. conceptual engineering, cost management representatives from construction contractors of the type who may end up having to construct all or key elements of the project Representatives from major equipment or package suppliers which are envisaged for the project. It is acknowledged that for external contractors and suppliers there are often contentious issues to do with confidentiality and concerns about providing unfair advantage prior to tendering, but from experience if the client is enlightened enough to overcome these restraining factors one encounters a useful source of expert knowledge that directly adds value and promotes positive feedback from the external party in relation to being involved and having their experience valued. The advantages to a tenderer for a professionally bid and evaluated two envelope tender are in practice extremely marginal for the majority of projects. The main problem appears client procedural policy. If followed as advocated then a team is compiled that will contain a number of layered fault lines or ‘unexploded bombs’ that the facilitator will allow to go off, or if things go too quiet in the workshop, deliberately step on. The detonator for such an occurrence can be a particularly contentious question. • Prepare a list of project specific and generic questions about the project A well composed team may with little prompt by the facilitator and the assembled project information, begin a dialogue which quickly rises in temperature as issues and points of faith are exposed and questioned. This process can be catalysed by the use of deliberate questions prepared ahead by the facilitator and this preparation becomes critical if for whatever reason the workshop team is unduly quiet or discussing issues that are of peripheral interest in the pursuit of value e.g. considering at length an item that constitutes only a small cost fraction of the project cost estimate. During the Pre-Workshop phase the information provided to the facilitator in the form of items such as the project brief or scope of work together with drawings should be sufficient to allow a range of questions to materialise. The facilitator’s naiveté (assuming he is an external facilitator) actually is of great use as fundamental questions will often arise, which may have been by-passed, ignored or missed. Coupled with project specific questions, most projects will also have a range of generic questions which will also apply such as clarifying what the project objectives, risks, constraints, assumptions, givens are. A full list of such questions usually number at least 60 for a large project and can be shown on screen as well as handed out in the form of question prompt sheets. It appears useful for the facilitator to present such questions to the team unannounced but not immediately with the beginning of the information/identification phase of the VMD workplan. Again paying attention to the soft skills of the facilitator, a period following initial introductions of the team is usually necessary so the facilitator can gauge the ‘temperature’ of the team, any principal personalities or major issues. If thereafter discussions SAVE paper rev G.doc This paper is © J Downer 2005 Page 12 of 22 between team members begin to generate useful debate about the project, the facilitator can judge when a suitable time may arise to deploy the pre-arranged questions. Naturally many of these may be covered in the preceding debate but the use of formal pre-arranged questions usually introduces a phase in the workshop when the facilitator senses the team is beginning earnestly to think anew about the project; and this is reason enough to use formal questions with the team. For a workshop considering a complex project it is noted that workshop time is limited particularly when covering all the VMD workplan stages. Two to three days are the usual maximum lengths of workshops and it is therefore critical to ensure that debate and discussions cover as a minimum those questions that are fundamental to the project rather than the facilitator just hoping ‘someone’ will ask the appropriate question. In this way, a predetermined list of questions for the project promotes the efficient use of workshop time to yield the most amount of information to workshop participants and ensure the project is looked at from a number of questioning viewpoints. A final unifying point is that notwithstanding the prepared questions, the facilitator will listen to the discussions in response to the questions and will often detect from what was seemingly an innocuous question, a supplementary question or issue arising which may quickly emerge as a fundamental point which ignites the team into vigorous debate. In such circumstances the facilitator may simply step back until the debate is exhausted whilst capturing all the essential points about the project which materialise on a flip chart. From the workshop team discussions and consideration of the open phrased questions, a body of information will start to be compiled by the facilitator which collectively gives a subjective shape to the project under consideration. This morphology of the project can in turn become a prime source and motivation of ideas for improving the value of the project. 4.4.3 Issues to do with Functional Analysis for projects Functional Analysis (FA) is a defining attribute of VMD and traces back to the LDM process of identify the function – evaluate the function by comparison- cause value alternatives to be developed. But with a project the size and complexity presents immediate problems: o What may for a product be broken into identifiable functions and displayed in a functional diagram such as FAST within the time constraints of a workshop suddenly becomes for a project, an inordinately difficult task. This is on account of the vast project complexity whereby complex components are interweaved and linked into a vast array that is often itself part of a bigger whole. To capture individual functions that may lend themselves to creative ideas for alternatives pre-supposes an unavailable amount of workshop time. To consider the project at a high level of functionality in order to save workshop time leads to gross simplifications that offer little useful insights for an intelligent team of qualified engineers. It is worth stating that for all oil and gas projects there will exist, amongst many other such documents and drawings, a complete pictorial representation of the project in drawings such as Piping and Instrumentation Diagrams and Process Flow Diagrams known colloquially as ‘P&ID’s’ and ‘PFD’s’. These portray the project system as linear representations of all pipe and equipment items (P&ID’s) and at a higher level the overall processes interconnected throughout the SAVE paper rev G.doc This paper is © J Downer 2005 Page 13 of 22 project (PFD’s). In many ways they are similar to detailed FAST diagrams. The creation by the facilitator of a new FA diagram therefore suffers from being an abridgement of mostly what exists already plus, due to the necessary simplification in order to produce a result within the pressing time constraints, can turn the workshop team against the facilitator as their perception of its usefulness and worth appears at odds with the facilitator. o What is the implication of even successfully accomplishing a FA diagram? Due to the intense interconnectivity of project components on a complex oil and gas project and the almost interminable HSE and other implications of changing one item without following through the complete links, the notion of coming up with new ideas of performing functions is at best highly optimistic. o Compiling a FA diagram that will conceivably be of use will take a considerable amount of time. This means that with the large workshop teams common for projects, there will inevitably be a percentage of the team unable or unwilling to join in with a shared compilation of a FA diagram and this can have serious implications for the interaction of the team throughout the remainder of the workshop. The paper by Alphonse J. Dell’Isola (1993) describes the application of VE to the process industry and is notable for the complexity of the function diagram it contains which represents only an air separation facility. Most oil and gas facilities are much more complex than this example. 4.4.4 From questions to feeling the shape of the project – Project Morphology If functional analysis for projects becomes becalmed due to the project size, complexity and issues to do with team involvement and interaction, then to what can the facilitator turn to so as to provide a tangible representation of the essential project requirements? This latter definition perhaps summarising what a FAST or FA diagram at best portrays. The use of open questioning allows a team to start to build a shared understanding of the project and this is doubly important where there may be a number of external parties represented at the workshop perhaps considering the project for the first time. In metaphorical terms it could be suggested that each project - until questioned - has a form that is superficially ‘solid’ and could be represented by a cube, as illustrated in Figure 1. SAVE paper rev G.doc This paper is © J Downer 2005 Page 14 of 22 Conceptualising the shape of an ‘unknown’ project prior to the workshop team subjecting it to open questions The shape of a project that has not been questioned WHO WHERE HOW WHY WHAT Starting to ask open questions of the project and challenging its assumed shape WHEN An idealised perfect value shape of the project to meet the clients requirements for value and value criteria determined by open questioning of the project WHO WHERE HOW WHAT WHY Figure 1A, B and C The assumed and modified shape of a project Functionality added WHEN CAPEX/OPEX reduced The solidity of the cube is inversely proportional to the amount of questions the project has been subjected to. The VMD workshop provides a special opportunity on account of the deliberate mix and invitation of persons connected and unconnected with the project. This causes long held views, opinions, assumptions and limitations to be subjected to the cross-fire of new interrogators, not particularly beholden to the well established mores of the core project team. SAVE paper rev G.doc This paper is © J Downer 2005 Page 15 of 22 Open questions constitute verbal probes of the assumed project boundaries and the resulting outputs from team discussions captured by the facilitator provide partial, but as they build up in number, an increasingly complete picture of the project morphology as laid out on an axial grid composed of the six fundamental open questions: what, why, where, when, who and how. Three of these will be familiar to VMD practitioners who have compiled FAST diagrams, namely how, why and when. By conjecturing the remaining questions as being on the opposite poles of axes containing how, why and when, the six sides of the project cube assumed in the beginning can each in turn be challenged. Thus the questioning permits the hitherto solid cube of the project to be modified and mutate into a more subjective shape peculiar to the project under workshop consideration. It is then this modified more particular, more subjective project shape that can form the basis for the team to suggest ideas to add value to the project during the creative phase. WHY HOW WHEN WHERE WHAT WHY HOW WHO WHEN Figure 2A and 2B – Open Question Axes as an extension to those in traditional FAST construction SAVE paper rev G.doc This paper is © J Downer 2005 Page 16 of 22 5 PUTTING IT ALL INTO PRACTICE 5.1 Pre-Workshop 5.1.1 The importance of undertaking research on the project theme However familiar the team with the project it is imperative to undertake both specific and wide ranging research concerning the project theme and key attributes during the Pre-Workshop phase. This permits an up to date infusion of information and ideas to be tapped into from anywhere in the world where similar work and problems have been faced. This information interrupts the thought patterns established about the project to date and if, even only to reject an idea, requires an active thought process to be established. Apart from information on similar projects, new developments of techniques and equipment can be uncovered, some of which may have not existed when the project commenced and therefore legitimately were never taken account of. As an example, for an offshore conceptual study in the Middle East of diverse engineering options considered to sustain a plateau oil production level for a 25 year period, information was gathered on the following subject areas: • • • • • Comparable project problems being addressed somewhere else in the world – reports on extension of field life in the North Sea and a renovation project offshore in the East Indies. Novel technique not being considered in the current project – two summaries of the use of 4D seismic imaging to manage production from a maturing oil field and enhance and extend the oil production. New information concerning the oil field – information in the form of geological paper abstracts recording details of mathematical and other models constructed to understand the behaviour of the reservoir; also information concerning another related project for modernisation of control and instrumentation being undertaken for the same field. New technologies being introduced around the world and not considered – a summary of new technology that provides intelligent management of wells using downhole equipment. Reminder of critical issues – abstract on the importance of life cycle costs (LCC) restating that the sustaining costs can be 2-20 times the initial acquisition costs and a summary item on the principal means of enhancing oil production in use around the world. This information together with other items was sent out two weeks ahead of the workshop to all participants in a Pre-Workshop Pack of information. 5.1.2 The Pre-Workshop Pack The pressures on time coupled with project complexities, team specialisations and team size raise the importance of adequate and substantial preparation for all participants attending the workshop. Whilst the facilitator must judge the correct proportions and levels of detail to be included, the pre-workshop pack of information must achieve the following objectives: SAVE paper rev G.doc This paper is © J Downer 2005 Page 17 of 22 • • • • • • To inform the participants of the essential practical information regarding the workshop such as timings, location and what the reasons for the workshop are together with what is expected of them To outline the workshop agendas and activities and inform the participants of the sequence of VMD phases to be passed through. To relay the clients views on what the components of value are for the project To provide information concerning the project design, options considered sufficient to give a general understanding of what the project is trying to achieve and the way this is intended to be carried out To give information on costs and this is particularly valuable if the facilitator manipulates the cost information using Pareto’s principle to expose the 80% of cost resident in 20% of the project items. To include the best elements of pre-workshop information research to provide hopefully the elemental yeast for ideas during the creative session of the workshop 5.2 Workshop 5.2.1 Questions to stir up the team Questions need to be prepared ahead of the workshop but not distributed as their power is enhanced by their sudden appearance and the workshop team having to confront them live in the middle of the workshop. If the workshop is already approaching a high level of productive interaction, there should occur a lot of useful debate concerning the general themes of what are the project objectives, constraints, risks and assumptions prior to a slight slackening which is usually a sign that the introduction of questions is due. Some deliberate redundancy and repetition in questions is not altogether a bad thing as sometimes the same question differently phrased may attract different answers and the reason for the different responses may unearth further issues. A formal matrix structure to the questions helps as does questions that follow on from the preceding one. All the questions posed begin with one of the key open question words how, why, when, who, where and what. From experience ‘what’ questions tend to be more numerous. An example of such a prompt list of questions is given in Figure 3. Value Management Workshop 06th-08th October 2002 Information Phase – Questions etc WHY? WHAT? WHERE? WHEN? WHO? HOW? Is there an increase in client staffing now? (Who is going to fill the new building?) Have this number of lifts? Choose this HVAC system? Is the programme? What happens if it isn’t completed on time? Is the predicted increase in staff numbers the only project driver? Are the floor areas/person etc and other self-imposed constraints? Are the floor plans? Construction details? Materials? Slowest/ most expensive construction details implied by the design and construction methods? Are all the people coming from? Might an alternative location be found? Will raw materials come from? What needs to be imported? Does it need to be ready? Do long lead items need to be ordered? Will contractor need to mobilise? Are the stakeholders? The 3rd parties (particularly consents) Will be invited to tender (what process?) Has the client managed without this building to now? Do floor areas compare with the current ones provided? Can we improve construction productivity? Will success on this project be judged? Figure 3 – Example of open questions used to interrogate a team about a project Page 18 of 22 SAVE paper rev G.doc This paper is © J Downer 2005 The information captured in responses to these questions is critical information and the facilitator must remain alert – whilst managing the flow and interaction of the workshop – to writing down on flip charts the participant answers to questions, points and issues raised. This material collectively defines the shape of the project – the project morphology. 5.2.2 Trying to find a relevant form of FA The fact that large oil and gas projects are inherently complex, coupled with the existing body of information that exists in the form of drawings such as P&IDs/PFD’s and the constraints on workshop time mean that the use of FA has to be considered with care. Rather than attempting to construct a full FAST model of the entire project or even key elements, a more participative and quicker method such as using the ladder of abstraction has been found to be generally more beneficial. Functions revealed by the ladder of abstraction combined with the information captured from the formal questioning during the information phase can be combined to illustrate a morphology for a project which is useful to a workshop team in representing their composite shared knowledge of the project assembled during the workshop. 5.2.3 Looking at the shape of the project – the cube versus the ideal value added shape A presentation of a complex green oil field development project estimated at over $500m cost is given in figure 4. It should be noted that the information captured during the first stages of the workshop have been greatly reduced in the figure for presentational clarity reasons. In total in excess of 85 items of project information were recorded. Similarly the functional hierarchy diagram summarises the indented functions of which one example is shown (‘acquire information’). The project morphology particular to the project is inferred by the team from the composite of information and functions captured. It should be noted that all the information is generated by the project team alone, although the facilitator has a key role in drawing out as much information as is possible in the available time. Trying to structure the information obliges the team to consider links and raises further questions all of which promote definition of the project. In conceptualising the project morphology information model and considering the equation of value = function / cost, an increase in value by virtue of increased function, decreased cost or both, can be considered in project morphology terms as creative responses that enlarge the models functionality or decrease cost, stretching and compressing the models shape farther away from where it started as an idealised cube. These creative responses are observed typically as developing ideas revealed in the team answers to the questions posed and arising out of issues manifested as a result of questioning the project. SAVE paper rev G.doc This paper is © J Downer 2005 Page 19 of 22 WHERE WHERE Pipelines may be placed on embankments to avoid high water table (-0.7m) in corrosive areas WHERE Power to come from offsite generation (National Electricity supplier) Basis of selection on account of economics, reliability and minimum impact on environment Only 1 access/causeway to well locations Proximity of human habitation to new operations Routing of flowlines & transfer lines in common corridors and parallel to exisitng pipeline in order to minimise footprint WHERE WHERE WHERE WHEN CO2 injection may be considered for Phase 2 WHEN Phase 2 of project – timing of +2015 for expansion to in excess of 200,000 BOPD Cost estimated at double Phase 1 FEED caters for Phase 2 concepts Transfer lines do not allow for Phase 2 Power lines do allow for Phase 2 Lead times – compressors 12-14 months; 10 compressors required <12 months for other equipment (hence in EPC SOW) WHEN WHEN WHEN Roads & causeway need to be in place before construction of surface facilities Time – completion of new facilities by 3Q 2005 WHEN Time for tendering process July 2002 issue of tender January 2003 – approval for EPC contract award sought from shareholders WHAT Satisfy Operational requirements Achieve Shareholder objectives Preserve Environment Recover Fluids Achieve oil specification Meet Process Requirements Enhance oil recovery Gather Data Meet HSE & design life requirements WHY WHAT WHAT WHAT WHAT WHAT WHO WHO WHO HOW 160 new wells to be drilled; estimate of 3-5 months per well; 4 rigs mobilised 70-80 production wells; rest are water injection and disposal wells Crude production will achieve 5.7psi RVP due to original destination of Refinery B c. 10psi acceptable at Refinery C Dehydration of gas is for pipeline protection 1 unit at site X 2 units at site Y EPS (early production system) designed for 3-5 year life and will be made entirely redundant by new project (no re-use) Recent relaxation of specification for crude of 0.05% to 0.10% for BSW Additional staffing requirements for new facilities estimated at +120 new persons; Issues to do with recruitment and training in time for start-up (24 months estimated), hence needs to commence no later than 3Q 2003 for 3Q 2005 completion of works Electricity sub-station + overhead lines – construction by National Electricity body 2 years to construct: due for completion by October 2004 Third Parties identified: National Electricity supplier- supply of water and electricity Local population Roads department for highway crossings City Town planning department National gas supplier for possible alternative make-up gas National oil body for pipeline crossings WHO SAVE paper rev G.doc This paper is © J Downer 2005 Deliver Utilities WHEN Provide phase 2 forecasts; improve drilling department forecasts; monitor injection programme Maximise recovery; increase life of reservoir; data for phase 2 To achieve main objective; new field development; data for phase 2 Reservoir maintenance; drilling department requirements Manage reservoir; data collection; improve efficiency & control; evaluate well performance CAPTURE DATA MANAGE RESERVOIR MANAGE UNCERTAINTY MONITOR WELLS TEST WELLS Instruments; sampling; online data (dedicated server/LAN system for well monitoring) Install gauges; acquire data; control & analysis of data Allow contingency; prequalify bidders; make-up gas; electricity utility power; design margins Test wells; downhole gauges; interface signals’ wellhead control panels Test separators; test lines and manifolds; metering; I&C; remote test sequence; power; piping bunds Figure 4 – Oil field development project example of the components of project morphology derived by workshop team. Note – For the sake of clarity Information Tables and function expansion are abbreviated samples of workshop material Page 20 of 22 5.2.4 Obliging engineers to think creatively From the assembly of revealed information coalesced from responses to questions and derivation of project functions from the ladder of abstraction, there still remains the critical stage of deriving ideas to add value to the project. The project morphology representing the summation of the workshops team understanding of the project only provides the starting point for coming up with ideas that due to the initial work have the possibility of adding value without prima facie being deemed unacceptable on account of the diverse project constraints, risks and requirements. Although creative techniques such as brainstorming are now commonplace it has been noticed in VMD workshops for projects that straight brainstorming does not oblige engineers in particular to think creatively. Rather what is often seen is a regurgitation of ‘ideas’ pre-formulated but maybe modified to suit the revealed project information. More creative techniques that contain no space for the formal mind to wriggle free are suggested as being more productive with engineers engaged in complex projects so as to break through any prearranged formalistic response to a facilitator imposed demand to come up with new ideas. The success of such techniques as Forced Relationships in workshops has been noted as confronting teams with an impasse that does not yield to left brain assault and so obliges a different response. This technique works well when used in conjunction with a slightly more formal brainstorming technique such as Philips Buzz 66 where the workshop team having been softened up with forced relationships, is divided into competitive teams to come up with the most number of ideas within a limited time frame. The productivity and quality of ideas from this latter session always appears enhanced by the initial forced relationships session. 5.3 Post-Workshop 5.3.1 The importance of getting feedback Especially when trying out new approaches and techniques and building on the established canon of VMD practice, the effectiveness of an approach must be vindicated by obtaining good quality feedback from workshop participants and no facilitator should shirk from this essential. Such feedback has supported the contentions and propositions contained in this paper and continue to inform the development of the ideas described. It is contended that the application of VMD is largely empirical and not an exact science. It is also immensely practical and its strength and principal selling point is the demonstrable achievement of results. 6 SUMMARY The relatively short history of VMD has seen it develop from a technique designed to improve the value of products to an all-embracing methodology able to be applied to a great range of subjects, which within them include construction projects. Although the subjects have changed and grown, VMD techniques when applied to modern projects exhibiting complexity, high technology and with large teams coupled with a pressure to minimise VMD workshop time, require modifications in order SAVE paper rev G.doc This paper is © J Downer 2005 Page 21 of 22 to maximise the delivered value to the project. It is suggested that by re-considering the components of value for a project, better ways of improving those components may be proposed during the creative phase. By preparing the workshop team with imported information further ideas may emerge. If the facilitator obliges the team to confront a range of open questions about the project then a new shared view of the project will come about and this has a particular shape for each project that can be the foundation on which value adding ideas of significance can be proposed. 7 REFERENCES Lawrence D. Miles. ‘Techniques of Value Analysis and Engineering’, McGraw-Hill Book Company, 1st Edition, 1961, Library of Congress Catalog No. 61-7844. Theodore C. Fowler. ‘Value Analysis in Design’, Van Nostrand Rheinhold, 1990, ISBN – 0-44223710-3. Alphonse J Dell’Isola. ‘Value Engineering for the Process Industry’, SAVE Proceedings, 1993. S.Male, J.Kelly, S.Fernie, M.Gronqvist, G Bowles. ‘Value Management – The Value Management Benchmark’, CD Thomas Telford Publishing 1998 SAVE paper rev G.doc This paper is © J Downer 2005 Page 22 of 22