Design for Warranty Cost Reduction

advertisement

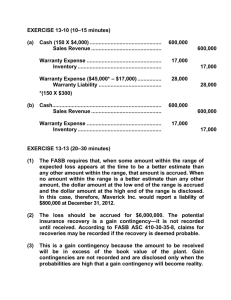

Design for Warranty Cost Reduction Robert H. Mueller, Ops A La Carte & Marisan Group Key Words: warranty, warranty cost model, design for warranty, computer, electronics industry SUMMARY & CONCLUSIONS This paper develops a process based cost model for warranty events and applies it to a number of product instances in the computer and related high tech businesses. It identifies the principle support ‘meta-processes’ that typically contributes >70% to the total cost of warranty. From this model the key warranty cost drivers are identified and the set of strategies are derived that product development teams can use to reduce the cost of warranty for products under development. Proven frameworks for applying the model and warranty cost reduction strategies during the product development cycle are presented. Case study instances are presented that illustrate how product development teams have applied the model, strategies and frameworks that reduced the total warranty costs by 35% are discussed. 1. INTRODUCTION The total cost of warranty for computer and related hightechnology US based companies is now ~$8B per/year [1]. For many companies, their warranty costs approaches what they spend on new product development and often matched their net profit margins; this is particularly true for the ‘commodity’ type businesses such as PCs or personal printers. Many companies are moving toward an extended warranty strategy to manage warranty costs. But, this is no panacea. While extended warranty repairs costs may be considered an operational expense and not a ‘warranty expense” from a SEC [10-K] perspective, the effects of poorer product quality than planned impacts the business’s bottom line with the same force as warranty costs. In the past few years the available choices of service processes used to resolve warranty issues has expanded to include phone support, Web based and customer self-fix schemes. This trend has been driven by need to reduce warranty cost and accelerated by the maturation of the internet. As both consumer and commercial products continue to increase the software/firmware to hardware component mix, these less costly processes need to be utilized more and more Why? The costs per repair of these service processes range over 1½ orders of magnitude; from $30/call for a warrant resolved over the phone to >$700 for on-site repairs. More importantly, the repair process costs are the largest contributor to the total cost of warranty; part cost contribution is typically less than 30% for most products. Because of the business impact of the cost of warranty, product development teams are now being challenged to design products that are both less costly to repair (business metric: warranty $s) and more reliable (business metric: annual failure rates, AFR). To more easily meet this challenge will require warranty costs models that make explicit not only the impact of AFR on cost, but also the effect of the process costs associated with the repair of specific failure modes. Currently used warranty cost models are dominated by traditional Failure Modes and Effects Analysis (FMEA), cost pool based models or models utilizing statistics and simulation forecasting techniques [6]. FMEAs are heavily used by the hardware engineering community in the Aerospace, Military and Auto business segments. Cost pool based models are most frequently used by the financial and supply chain communities. FMEA is a proven methodology for first identifying failure modes or failure mode scenarios [2,3], then developing strategies to mitigate the risk for each failure mode during a product’s development cycle instead of after product launch. The most popular FMEA methodologies use the RPN scheme to prioritize the failure modes, or when cost is used [4], the method is mute on how a product team calculates cost of repair. Cost pool based models aggregate warranty costs into large cost pools such as monthly costs for labor, call centers, material, labor and inventory/logistics. These cost pool based models [5] are a natural fit for warranty cost reduction efforts for the supply chain and procurement areas. Yet, none meets the full needs for modeling of the development team: the model needs to have the following characteristics: • The customer’s problem being resolved is explicit. • The support processes used to diagnose and resolve the warranty event are explicit. • Estimating warranty costs is relatively quick and easy to do, especially when evaluating design alternatives. This paper develops a service process based warranty cost model for warranty events that is grounded in both the customer’s problem and the support process used to resolve it. It will identify the primary ‘meta-processes’ used by most computer and high-tech businesses to service warranty events. Typical standard costs for each of these will be discussed. We will demonstrate that these process based cost models are particularly useful for the computer and other high technology businesses for both the commercial or consumer market spaces. They are less useful for the Automotive, Aerospace or Military business segments because of the support strategies used in those market spaces. From this model, the key cost drivers will be extracted from which we will also develop the primary strategies that product development teams can use to both improve product reliability and deduce its warranty costs. Results from case studies will demonstrate how product development teams have used this model to develop design alternatives and action plans to reduce warranty costs. While presenting the case study a few frameworks will be introduces that the development team used to evaluate what strategies may be affective for reducing costs of specific event types and to identify dependencies deeded to realize the planned cost reductions. Warranty Cost = nHD1 x (process cost + material cost) where: nHD1 = the number of occurrences of the ‘HD1’event type Now the total warranty cost for all event types can easily be calculated. Letting N be the total number of warranty event types for a specific product, the total warranty cost for a specific time interval is simply given by: N Total Cost = ∑ ni × STD Ci (1) i =1 1.1 Nomenclature & Notation AFR = Annualized Failure Rate ASP = Authorized Service Provider PCA = Printed Circuit Assembly TotalCost = the total cost of warranty for the product N = number of occurrences of an event type for a specific time interval ni = number of occurrences for ith warranty event type STDCi = standard service process cost used to resolve the ith warranty event type M = number of warranty event types needed to account for an acceptable fraction of the total warranty expense for a specific time interval Often, dozens or even hundreds of event types may exist for complex products. Yet, it is seldom necessary to sum over all event types to get an excellent estimate of a products warranty costs. Experience has shown that for most products, only a handful of warranty events dominate the total warranty cost; the Pareto principle applies. Hence, it is useful to define M, where M is the number of warranty event types that account for an acceptable percentage, say 90%, of a product’s total warranty costs. Then the cost equation can be re-expresses as: M Total Cost = ∑ ni × STD C i + i =1 N ∑n × i = M +1 i STD Ci (2) 2. PROCESS BASED WARRANTY EVENT COST MODEL At the heart of the cost model is the concept of a warranty event. To illustrate what a warranty event is let’s consider this example. A customer is getting a warning message from the OS that her hard drive is predicted to be failing in her PC. She calls the call center for support. The call center agent, after confirming warranty entitlement, talks the customer through a diagnostic process that confirms a specific hard drive caused failure type known by the support team as ‘HD1’. The prescribed resolution is to replace the hard drive. In this case the customer is directed take the PC to a local Approved Service Provider for ‘bench repair’ service. Notice that this warranty event has a process to diagnose the customer problem (the call center working with customer to diagnose), a specified support process (walk-in service by a local ASP to repair) and a part being consumed (hard drive) to resolve the warranty event. In this model, every warranty event ‘type’ has a unique linking of a diagnosed problem, a specific support process to resolve the event and specific material costs(components), if consumed. The material cost in this case is the cost of the hard drive itself. All costs such as spare-part inventory management or inventory logistics are treated as direct, in-direct or overhead costs to the support process used. The total warranty cost for all of the hard disk failures of event type ‘HD1’ can be simply calculated, for a specific time interval as: As the second term of (2) becomes much smaller than the first term, then we can re-write it as: M Total Cost ≅ ∑ ni × STD Ci (3) i =1 2.1 Empirical Trends Figure 1 shows a Pareto chart of warranty event types for a recently modeled commercial computer/printer product. Each bar represents a specific warranty event type. The YAxis is the total warranty cost for each event type for a oneyear period. The total number of event types having any activity in this time interval was about 300. 90% of the product’s warranty costs were accounted for by only a few event types, in this case M is ~15. Experience has shown that most products have a similar behavior; almost all products modeled had less than 20% of the warranty event types accounting for more than 80% of the costs. The cost of each warranty event type is further broken down into the total labor, travel, material, call center and support overhead costs. The total contribution of material costs to the total warranty cost is less than 35%. This is also a typical distribution of total costs. An important consequence of these cost breakdowns is that, during the design and prototyping phase of product development, the choice of the components based only on its impact on manufacturing cost may have very costly consequences to the product’s overall warranty costs and, therefore on the business’s overall profitability. Finally, the fact that the Pareto principle has held true for all products modeled, this model can be an effective tool in prioritizing that warranty even types should be prioritized by what on value to the business as measured by real costs. Pareto of Warranty Event Costs labor Travel Material Call Center Service OH $1,200,000 $1,000,000 The service engineer, after receiving the parts, goes on-site to perform on-site diagnostics, as necessary, replace failed parts and finish the repair service process for this repair mode. Note that the total cost of this overall process includes: call center costs, part logistics (including all ‘overhead costs’ for spare part management), labor and travel expenses. For the computer business and many similar high-tech industries, the number of frequently used support processes is very small and are listed in table #1. They range from call center phone support only to on-site repair. Also listed in the table for each service process are the nominal costs and their costs. The costs listed in this table have been derived from a dozen different products lines in a number of different companies. Many of the products modeled used different strategies to deploy their product support including a mix of in-house and 3rd party partners implementing their call centers, spare parts management (logistics), on-site service engineering and bench repair. Warranty Event Total Costs [$] $800,000 Process Example – On-site Repair $600,000 A warranty ‘event’ support process $400,000 Step 1: Customer makes call, call center determines entitlement Start Step 2: Call center diagnoses problem; determines on-site repair required and orders needed replacement parts Step 3: Service contractor gets parts, travels to site and replaces parts. $200,000 Step 4: Defective part is discarded or returned. Ev en Ev t 1 en Ev t 2 en Ev t 3 en Ev t 4 en Ev t 5 en Ev t 6 en Ev t 7 en E t8 O ve S nt Pa 9 tc Ev h 1 en t1 3 S Ev N 3 en Ev t 10 en Ev t 18 en Ev t 19 en Ev t 12 en Ev t 11 en Ev t 17 en Ev t 14 en Ev t 15 en Ev t 21 en t2 2 $- ☺ Step 5: Case is closed Warranty Event RAMS 2008 © Figure 1 – Pareto of Warranty Events 2.2 Warranty Service ‘Meta-Processes’ A key step in building an instance of the cost model is sorting out how many support processes are used to resolve warranty events for that product. For efficiency reasons, most support organizations (or, if support has been outsourced, their 3rd party agents) have just a handful of ‘meta-processes’ to resolve the vast majority of warranty or service events. The ‘bench repair’ service process from the hard drive example was one of these ‘meta-processes’. Another is the ‘on-site repair’ process often used for higher end or difficult to move products in the computer, medical and other related high tech businesses. Let’s look at this process in more detail (Figure 2). As with the ‘bench repair’ example, the first steps are focused on confirming warranty entitlement, problem identification, diagnostics and determination of what service process will be used for this event. For this process, the intervention is an on-site service call performed by an authorized service engineer. The call center will also initiate the logistics processes needed to get the parts to the service engineer identified by the diagnostic process for replacement. 1 Figure 2 – On-site Repair process flow Note that the process cost range covers almost 2-orders of magnitude; from as low as $10 for events resolved by phone support resolved events outsourced to off-shore 3rd parties to over $1,000 for a multi-visit ‘on-site repairs’ due to misdiagnosed problems. Web based ‘self-diagnostics and repair’ processes and on-line ‘chat-room’ support schemes are not included because of the inherent difficulty of determining if any specific web site ‘hit’ is a true warranty event or not. This large cost difference is one of the economic drivers pushing the product design teams toward designing for ‘customer self-fix’ or ‘bench repair’ processes for new products. Table 1 – Support ‘Meta-processes’ and their typical costs Service Process Phone Support On-Site Service Customer self-fix Bench Repair Product Exchange Description A warranty event is resolved by Call Center (CC) agent /w no material. Cost=CC(labor rate*call length) A warranty event this is referred by CC agent to service engineer for an onsite service call Cost = CC + labor + travel +logistics + part cost Parts only process where customer replaces parts. Cost = CC + part cost + logistics Customer brings the product to Business/ASP for repair Cost = CC + part costs + logistics + ASP costs Customer exchanges defective product for a ‘new’ / Re-furbished one Cost = CC + cost of product + logistics • Reducing the frequency of the event type by: o Reduce the component’s AFR o ‘Design out’ the event type • Reducing the process cost contribution by: o Switch event type to a cheaper support process (sometimes called changing Support Process Mix) o Develop better diagnostics tools to: a) allow support to switch to cheaper support processes; b) reduce diagnostic errors of currently used support processes. o Improve product serviceability to: a) support customer self-repair for an event type; b) reduce total service call length (time to replace any other service activities required in repair/calibrate process). Process Costs w/o Material Costs [avg./(min/max)] $45 ($10 - $60) $600 ($300 - $1,200) $65 ($40 - $100) $125 ($70 - $200) Design Phase– Warranty Cost Reduction Strategies For each significant event type M Wc ≅ Σ ni * ( Costi + Cmaterial) STD $ 65 ($30 - $100) Having so few standard meta-processes greatly simplifies building a product specific cost model since only a very small number of standard process costs need to be identified and quantified by the support and accounting community when building the model. The other independent variables of the model, event type’s frequency of occurrence and actual material costs are usually readily available to the product development team through the support and procurement team members. Because of its simplicity, the model can readily be built in off-the-shelf data base and analysis tools such as Microsoft Access and Excel. 3 COST DRIVERS AND REDUCTION STRATEGIES By inspection of (3) and from the table of support ‘metaprocesses, two primary warranty cost drivers are apparent (e.g., performing a variance on it): • Number of occurrence for an event type We will use the Annualized Failure Rate (AFR) of the component (or sub-system) associated with that specific event type as its surrogate since we can easily calculate ni from the AFR and the number of units under warranty. • Cost of support process used These cost drivers directly lead to a number of primary strategies that development teams can use to impact warranty costs during product development (depicted in Figure 4). They are: Reduce number of occurrences: Reduce event’s process cost: •Designing new (cheaper) processes Design process around new technology. Design process to meet new market needs •‘Design out’ the event’s occurrence Change product ‘features’ Change how product works Implement ‘feature’ differently •Switching to a cheaper process ID features/capabilities needed to support different process •Reduce the number of occurrences Increase HW reliability (reduce AFR) Improve SW/FW robustness •Reduce standard process costs by: Product changes Process improvements Outsourcing Supply Chain re-engineering RAMS 2008 © 2 Figure 3 – Warranty Cost Reduction Strategies 4. USING COST MODEL IN PRODUCT DEVELOPMENT This model has been used to support the development team’s economic decision-making process for the for various design alternatives that affect warranty costs in the following ways: • To calculate estimates of both the product’s total warranty costs and costs of specific warranty event types. • To prioritize the engineering efforts for product improvements based on warranty costs, not just manufacturing cost reduction • To calculate the difference in warranty costs due to different design alternatives. • To facilitate the identification of necessary product features, capabilities and diagnostic tools needed to realize projected warranty savings of the chosen design alternative. • To facilitate the economic trade-offs between manufacturing costs for specific design alternatives and the warranty costs (and post warranty period support costs). 4.2 Evaluating design alternatives Having the initial model (and its Pareto tables and charts) the design team started the exploration and evaluation of specific event types to determine how they were going to meet their ‘warranty cost budget’. Their Event Pareto was very similar to Figure 1, where the top 20 event types accounted for over 90% of their annualized warranty costs. Their strategy to meet their goal of a 30% reduction in Projecting Warranty Savings Planned engineering actions: Event1: reduce AFR by 50% and reduce time of repair by 50% (labor cost) Event6: re-design for self-fix by qualified customer IT resources Pare to o f Wa rra nty Event Cos ts Travel Material Pareto of Wa rranty Event Cos ts Call Center Service OH labor $500,000 $450,000 $450,000 $400,000 $400,000 $350,000 $350,000 Warran ty Event Total Costs [$] Warranty Event Total Costs [$] labor $500,000 $300,000 $250,000 $200,000 Material Call Center Service OH $250,000 $200,000 $150,000 $100,000 $100,000 $50,000 Travel $300,000 $150,000 $50,000 $- Eve nt 1 Ev en t4 Ev ent 2 Ev en t6 Ev en t1 O 3 S Pa tc h1 Ev en t3 Ev ent Eve 8 nt 18 Eve nt 7 SN Eve 3 nt 19 Ev en t1 Eve 2 nt 1 Eve 4 nt 17 Ev ent 21 t1 4 t1 7 t2 1 en en Ev Ev 7 3 t1 9 t1 2 en Ev en t SN en en Ev Ev 1 Eve nt 3 Eve nt 8 en t1 8 Ev Ev 2 6 13 h ent tc ent Ev Eve nt Pa Ev O S 4 1 $ent [Note: This team did not use the FMEA methodology for product design risk assessment. But, the information from a FMEA would very nicely feed into this cost model. Also, for ‘green field’ products, the initial FMEA’s failure mode scenarios could also very easily be used to seed the cost model. Each failure mode would be paired with its appropriate support process and a relative frequency of occurrence for the failure could be estimated.] The teams used a combination of graphics and tables to specify and document what the reduction in warranty costs would be for the chosen set of action plans and design alternatives. Calculating and visualizing the effects of design alternatives, in both frequency and dollars, is a relatively straightforward task in the Excel based model. For example, Figure 4 depicts the effects alternatives for two specific event types. The first labeled Event1 shows the effect of two changes to the product: reduce AFR of a PCA board by 50% and reduce the total time necessary to complete the on-site repair by 50%. The second event labeled Event2 show the effects of a single change: redesign the product so that ‘qualified’ customer resources can replace the failed component. This example graphically depicts the equality of AFR reductions and support process choice as first order drivers of warranty costs. ent Since the new product would have very similar architecture and function to existing products they choose to build a cost model for a similar product currently in production for which they had easy access to product support information. The first step was to identify the main support processes used by support for the current product. They used all the processes in Table 1 except for the ‘bench repair’ and ‘product exchange’ processes. From accounting, they obtained the current standard process costs. With the standard process costs known, building the initial warranty event cost model was reasonably straightforward. Together with the support team they tabulated the frequency of occurrences for the top 50 warranty event types. Combining each event type’s associated material costs, process costs and its frequency, they then constructed (using Microsoft Excel spreadsheets) the cost model and its corresponding Pareto charts. Finally, they added a number of new event types for the new features and functionality planned for the new product using similar event types from the current product as a ‘guide’ to estimate both support process costs and frequency of occurrence for them. 4.2 Projecting warranty cost saving Ev 4.1 Building cost model and Pareto chart. warranty costs was to develop, design and implement design alternatives for each event type on the Pareto that, when evaluated by the model, predicted a total warranty cost of less than 3.9% of projected product revenue. The framework in Figure 2 was developed to facilitate these discussions. It illustrates the different design options or ‘handles’ that can be turned to reduce warranty costs. Since many of the design alternatives involved either improving the efficiency of the on-site service process or designing the product for customer self-repair, significant involvement by the support and technical marketing groups in the early design phase was critical. Ev How teams have used the model during the product development phase to support the decision making process when choosing between features, functionality and design alternatives can best be exemplified by waking through a case study. Also two frameworks used to develop and choose design alternatives will also be introduced. In this case study, the development team was starting another design cycle for a ‘follow-on’ high volume, moderately priced ($5,000 – $7,000 depending on options) product. They had easy access to most support information. The current product’s annualized cost of warranty was ~5.6 % of total revenue; a competitive position when compared to their competition, but not a competitive advantage. Strategically, management had set a goal of reducing warranty costs by 30% for all products under development to avoid engineering expense reductions in the future. Warranty Event Warranty Event current planned RAMS 2008 © 14 Figure 4 – Projecting warranty savings 4.4 Identifying Dependencies The team then developed the next level of design details that would be needed to realize the warranty savings. Specifically, for each warranty even type targeted for significant reduction they identified the features, functions, capabilities or support diagnostics tools needed to realize the goal of the design change. Figure 5 shows an example of another framework used to evaluate the different design proposals. Because many of the changes required considerable changes to both the product design and in how the product would be supported once released (including the diagnostic tools that would be needed by the support team to correctly diagnose event types that would use a customer self-repair process) this was a cross-functional team including R/D, manufacturing, marketing and support resources. Also note that the table’s ‘Importance’ column included customer satisfaction considerations to help balance the need to reduce warranty costs and customer satisfaction (company brand). In fact marketing frequently calibrated customer satisfaction with both how well specific support processes such as phone support worked and customer satisfaction with the support processes that were used (customer self-repair vs. benchrepair by an ASP). Dependency Planning BIOGRAPHY Warranty events naturally fits to how product teams make decisions throughout the product life cycle. Warranty Event Importance* Planned Actions Required features, functions, capabilities, or diagnostic tools to realize savings Projected Warranty Costs [$] Projected Warranty Savings [$] 1. Design for improved serviceability [1½ hr. total] Reduce AFR by 50% 1. Cabinet re-design ID component with ½ of current AFR $150K/yr. $298K/yr Design for self-fix by customer IT staff 1. Cabinet re-design Write/deploy diagnostic tools $158K/yr. $167/yr … … [1to10] Event 1 8 2. Event6 7 1. … … … 2. J. Bai and H. Pham, Warranty Cost Models of Renewable Risk-Free Policy for Multi-Component Systems. European Journal of the Operational Research, vol. 146, 2004 3. S. Kmenta and K. Ishii, Scenario-Based MFEA: A Life Cycle Cost Perspective. 2000 ASME Design Engineering Technical Conference 4. R. Latino and K. Latino, Root Cause Analysis–Improving Performance For Bottom Line Results, CRC Press, 1999 5. D. Kuettner, Data-Driven Warranty Management, Warranty Chain Management Conference, 2005 6. Kleyner, Sandborn, Boyle, Minimization of Life Cycle Costs Through Optimization of the Validation Program – A Test Sample Size and Warranty Cost Approach, RAMS 2004 2. 2. … e-mail: bobm@opsalacarte.com or robert_mueller@marisan.com Note: Importance ranking includes both customer satisfaction and branding considerations RAMS 2008 © 15 Figure 5 – Dependency Planning After appropriate validation that the designs were viable, the goals, new features and functionality (including diagnostic tools development) where then incorporated into the overall Project, Reliability and Test Plans. Appropriate metrics and other criteria were added to the exit criteria of their development life cycle. 4.5 Case Study Results The warranty costs for the product used in this case study were carefully tracked through the first 18 months after market introduction. The results were: • Actual total warranty costs were 5% less than their targets. • Relative cost contribution by warranty event type of the new product’s event types mostly tracked what the model predicted. • Customers were very satisfied with the customer selfrepair process: good diagnostics (diagnosed problem correctly) and faster time to repair with less hassle. REFERENCES 1. E. Arnum, Warranty Week. May, 2007, www.warrantyweek.com Robert H Mueller, M.S., CQE Ops A La Carte & The Marisan Group 1030 Oakland Ave Menlo Park, CA 94025 USA Robert Mueller has 35 years of experience in product development and management of software intensive products for the computer, analytical and medical industries at Hewlett-Packard and Agilent Companies. Robert Mueller received his B.S. and M.S. degrees in Physics from Northern Illinois University before joining Hewlett-Packard Co. He is currently a senior consultant with both Marisan Group and Ops A La Carte focused on R/D product strategy development, agile development methodologies, Warranty and SW Reliability engineering. He is a Certified Quality Engineer.