Influences of pyrolysis condition and acid treatment on properties of... peel-based activated carbon

advertisement

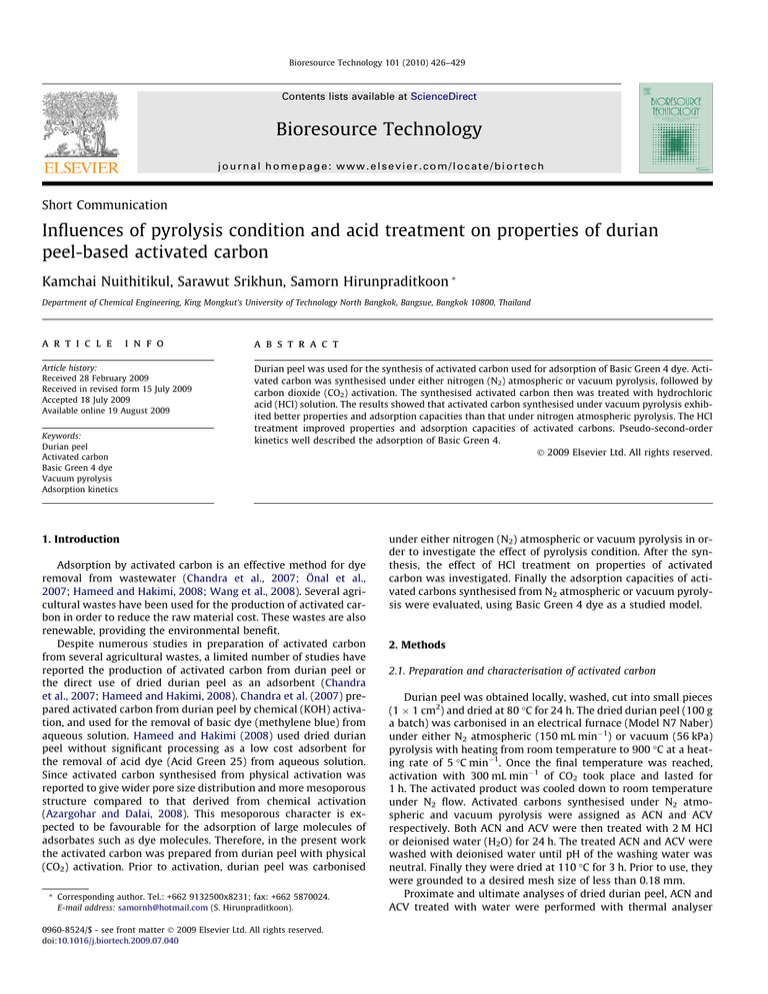

Bioresource Technology 101 (2010) 426–429 Contents lists available at ScienceDirect Bioresource Technology journal homepage: www.elsevier.com/locate/biortech Short Communication Influences of pyrolysis condition and acid treatment on properties of durian peel-based activated carbon Kamchai Nuithitikul, Sarawut Srikhun, Samorn Hirunpraditkoon * Department of Chemical Engineering, King Mongkut’s University of Technology North Bangkok, Bangsue, Bangkok 10800, Thailand a r t i c l e i n f o Article history: Received 28 February 2009 Received in revised form 15 July 2009 Accepted 18 July 2009 Available online 19 August 2009 Keywords: Durian peel Activated carbon Basic Green 4 dye Vacuum pyrolysis Adsorption kinetics a b s t r a c t Durian peel was used for the synthesis of activated carbon used for adsorption of Basic Green 4 dye. Activated carbon was synthesised under either nitrogen (N2) atmospheric or vacuum pyrolysis, followed by carbon dioxide (CO2) activation. The synthesised activated carbon then was treated with hydrochloric acid (HCl) solution. The results showed that activated carbon synthesised under vacuum pyrolysis exhibited better properties and adsorption capacities than that under nitrogen atmospheric pyrolysis. The HCl treatment improved properties and adsorption capacities of activated carbons. Pseudo-second-order kinetics well described the adsorption of Basic Green 4. Ó 2009 Elsevier Ltd. All rights reserved. 1. Introduction Adsorption by activated carbon is an effective method for dye removal from wastewater (Chandra et al., 2007; Önal et al., 2007; Hameed and Hakimi, 2008; Wang et al., 2008). Several agricultural wastes have been used for the production of activated carbon in order to reduce the raw material cost. These wastes are also renewable, providing the environmental benefit. Despite numerous studies in preparation of activated carbon from several agricultural wastes, a limited number of studies have reported the production of activated carbon from durian peel or the direct use of dried durian peel as an adsorbent (Chandra et al., 2007; Hameed and Hakimi, 2008). Chandra et al. (2007) prepared activated carbon from durian peel by chemical (KOH) activation, and used for the removal of basic dye (methylene blue) from aqueous solution. Hameed and Hakimi (2008) used dried durian peel without significant processing as a low cost adsorbent for the removal of acid dye (Acid Green 25) from aqueous solution. Since activated carbon synthesised from physical activation was reported to give wider pore size distribution and more mesoporous structure compared to that derived from chemical activation (Azargohar and Dalai, 2008). This mesoporous character is expected to be favourable for the adsorption of large molecules of adsorbates such as dye molecules. Therefore, in the present work the activated carbon was prepared from durian peel with physical (CO2) activation. Prior to activation, durian peel was carbonised * Corresponding author. Tel.: +662 9132500x8231; fax: +662 5870024. E-mail address: samornh@hotmail.com (S. Hirunpraditkoon). 0960-8524/$ - see front matter Ó 2009 Elsevier Ltd. All rights reserved. doi:10.1016/j.biortech.2009.07.040 under either nitrogen (N2) atmospheric or vacuum pyrolysis in order to investigate the effect of pyrolysis condition. After the synthesis, the effect of HCl treatment on properties of activated carbon was investigated. Finally the adsorption capacities of activated carbons synthesised from N2 atmospheric or vacuum pyrolysis were evaluated, using Basic Green 4 dye as a studied model. 2. Methods 2.1. Preparation and characterisation of activated carbon Durian peel was obtained locally, washed, cut into small pieces (1 1 cm2) and dried at 80 °C for 24 h. The dried durian peel (100 g a batch) was carbonised in an electrical furnace (Model N7 Naber) under either N2 atmospheric (150 mL min1) or vacuum (56 kPa) pyrolysis with heating from room temperature to 900 °C at a heating rate of 5 °C min1. Once the final temperature was reached, activation with 300 mL min1 of CO2 took place and lasted for 1 h. The activated product was cooled down to room temperature under N2 flow. Activated carbons synthesised under N2 atmospheric and vacuum pyrolysis were assigned as ACN and ACV respectively. Both ACN and ACV were then treated with 2 M HCl or deionised water (H2O) for 24 h. The treated ACN and ACV were washed with deionised water until pH of the washing water was neutral. Finally they were dried at 110 °C for 3 h. Prior to use, they were grounded to a desired mesh size of less than 0.18 mm. Proximate and ultimate analyses of dried durian peel, ACN and ACV treated with water were performed with thermal analyser 427 K. Nuithitikul et al. / Bioresource Technology 101 (2010) 426–429 (NETZSCH STA 409C) and elemental analyser (CHN analyser) respectively. Yields of both ACN and ACV treated with water were calculated based on the weight of dried durian peel initially put into the furnace. The treated ACN and ACV were characterised with N2 adsorption at 196 °C using Autosorb I (Quantachrome Corporation) and the Brunauer–Emmett–Teller (BET) model. 2.2. Adsorption study Basic Green 4 dye, C50H52N4O8, at pH of 5 was used for adsorption study. A set of volumetric flasks containing 25 mL of Basic Green 4 solutions with different initial concentrations (337, 562, 784 and 1000 mg L1) was prepared. HCl-treated ACN or HCl-treated ACV (0.05 g) was added into each flask. The flasks were placed in an isothermal shaker in which the temperature was maintained at 30 ± 1 °C with the stirring speed of 150 rpm. The flasks were taken out from the shaker at various time intervals and samples were taken for analysis. The amount of dye adsorbed onto activated carbon per unit mass of activated carbon at any time t, qt (mg g1), was calculated by: qt ¼ ðC 0 C t ÞV m ð1Þ where C 0 and C t (mg L1) are the liquid–phase concentrations of dye at initial and time t, respectively. V is the volume of solution (L), and m is the amount of activated carbon used (g). To determine dye concentrations, samples after adsorption were taken and centrifuged at 2500 rpm. The clarified supernatant solutions were carefully decanted to be analysed with a double beam UV/VIS spectrophotometer (UV500 model, UNICAM). The optimum wavelength for Basic Green 4 was 617 nm. The final concentrations of the solutions were calculated from the calibration curve. 3. Results and discussion 3.1. Characterisation of activated carbon and durian peel precursor Proximate and ultimate analyses of dried durian peel and ACN and ACV treated with H2O are shown in Table 1. Yield of ACN treated with H2O is higher than that of ACV treated with H2O. This is due to vacuum pyrolysis gives higher volatilisation and CO2–carbon reaction. Typically the yield loss of activated carbon is due to two main causes: volatilisation and reaction. It is likely that char obtained from vacuum pyrolysis has a lower yield than that obtained from N2 atmospheric pyrolysis because substances are more volatilised under reduced pressure compared to atmospheric pressure. As a result, the structure of char from vacuum pyrolysis is less occupied by deposits (Cao et al., 2002). When this char is further activated, it can react faster with CO2. As can be seen from Table 1, the carbon content of ACV is lower than ACN, suggesting higher CO2–carbon reaction. BET surface areas and pore volumes of ACN and ACV treated with HCl and H2O solutions are reported in Table 1. The results show that activated carbons synthesised under vacuum pyrolysis have greater BET surface areas and pore volumes than those synthesised under N2 atmospheric pyrolysis. This is owing to the char obtained from vacuum pyrolysis being more reactive to CO2 oxidation than that obtained from N2 atmospheric pyrolysis (Cao et al., 2002). Moreover, char produced from N2 atmospheric pyrolysis has higher concentration of carbonaceous deposits on the surface and/or in the pores than that from vacuum pyrolysis (Cao et al., 2002). These deposits inhibit the access of the oxidising gas (CO2). For activated carbons synthesised under the same carbonisation condition (either N2 atmospheric or vacuum pyrolysis), those treated with HCl solution had greater BET surface areas and pore volumes than those treated with H2O. An increase in these properties of activated carbons treated with HCl solution is likely to be due to the removal of impurities on the surface and/or in the pores. Acid solution is generally used to purify activated carbon after the synthesis (Berman, 2003). Activated carbon can contain up to 20 wt.% of mineral matter occluded in the pores (PastorVillegas et al., 1999). These inorganic constituents could be removed from both activated carbon and its precursor with HCl, H2SO4 or HF treatment reducing, consequently ash content (Davini, 2001; Kopac and Toprak, 2007; Wang and Zhu, 2007). The highest BET surface area (1015 m2 g1) and pore volume (0.66 cm3 g1) of durian-based activated carbon prepared by physical activation in this work were higher than that prepared by chemical KOH activation in the study of Chandra et al. (2007). Their activated carbon had BET surface area of 991.82 m2 g1 and pore volume of 0.471 cm3 g1. Nitrogen adsorption isotherms of ACN and ACV treated with HCl solution and H2O are similar and shown in Fig. 1. Activated carbons synthesised under vacuum pyrolysis give higher adsorption capacities than those synthesised under N2 atmospheric pyrolysis. This attributes to the higher BET surface area and pore volume of the former. For activated carbons synthesised under the same Table 1 Properties of activated carbons synthesised under nitrogen atmospheric and vacuum pyrolysis and treated with various solutions. Properties ACN treated with ACV treated with Durian peel HCl H2O HCl H2O precursor BET surface area (m2 g1) Pore volume (cm3 g1) Average pore diameter (nm) Yield (wt.%) 748 0.46 2.488 – 659 0.40 2.411 21.32 1015 0.66 2.602 – 951 0.61 2.570 18.74 – – – – Proximate analysis (%) Moisture content Volatile matter Ash Fixed carbonb – – – – – 23.05a 16.19a 60.76a – – – – – 25.35a 19.91a 54.74a 4.54 69.82 4.22 21.42 Ultimate analysis (%) Carbon Hydrogen Nitrogen Oxygen, sulfur and othersb – – – – 64.36 1.25 0.00 34.39 – – – – 55.77 0.96 0.06 43.21 42.86 5.71 0.18 51.25 Note: ACN, ACV mean activated carbon synthesised under nitrogen atmospheric and vacuum pyrolysis respectively. a Dry basis. b By difference. 428 K. Nuithitikul et al. / Bioresource Technology 101 (2010) 426–429 300 ACN - HCl ACV - HCl ACN - H 2O ACV - H 2O Commercial AC (Coconut shell based) 450 400 250 200 -1 qt (mg g ) 3 -1 Volume adsorbed (cm g STP) 500 350 300 150 100 200 250 -1 150 100 50 50 200 a 0 0 15 30 45 60 337 mg L -1 562 mg L -1 784 mg L -1 1000 mg L 0 150 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0 1.0 1000 2000 3000 4000 5000 t (min) Relative pressure, p/p o 300 Fig. 1. Nitrogen adsorption isotherms of ACN and ACV treated with H2O and HCl solution. 250 3.2. Adsorption kinetics The influences of initial dye concentration and contact time on adsorption capacities of HCl-treated ACN and HCl-treated ACV are shown in Fig. 2. The adsorption can be described by two-stage kinetic behaviour for all the initial concentrations of Basic Green 4. During the first 1 min, the rapid initial adsorption rates are observed. After that the adsorption capacities begin to level off indicating much slower rates. The plateaus are finally obtained implying no more dye is removed from the solution. At this state, equilibrium is reached. The amount of dye adsorbed at the equilibrium time indicates the maximum adsorption capacity of the activated carbon under that condition. When the initial dye concentrations are increased, the maximum adsorption capacities 200 -1 qt (mg g ) carbonisation condition, those treated with HCl solution have better nitrogen adsorption capacities than those treated with H2O solution. Activated carbons synthesised under vacuum pyrolysis and treated with HCl solution or H2O give higher adsorption capacities than a commercial activated carbon (C. Gigantic Carbon derived from coconut shell), suggesting a potential use of the durian peel-based activated carbon as a commercial grade. According to the IUPAC classification for adsorption isotherm, the isotherms in this study showed characteristics between those of Type I and II. Volume of adsorbed nitrogen considerably increased with the relative pressure from 0 to 0.05. Moreover microporous solids are typically associated with Type-1 adsorption isotherm. However, nitrogen could be adsorbed, but to a lesser degree, with the relative pressure higher than 0.05, particularly for activated carbons synthesised under vacuum pyrolysis. This indicated a presence of mesopores. The average pore diameters between 2.411 and 2.602 nm principally denoted mesoporous characteristics. Within the relative pressures range of 0.2–1.0, isotherms of activated carbons synthesised under vacuum pyrolysis were steeper than those synthesised under N2 atmospheric pyrolysis. In other words, the former deviated more from Type-1 isotherm. This suggests that mesopores are more generated with activated carbons synthesised under vacuum pyrolysis. Therefore it can be concluded that the nature of the activated carbon derived from durian peel is a combination of microporous and mesoporous. This is in agreement with the study of Chandra et al. (2007). The presence of mesopores in combination with micropores is expected to play a significant role in the adsorption of large molecules of adsorbates including dye molecules. 150 250 200 150 100 50 0 100 50 b 0 0 -1 0 1000 2000 15 30 45 60 3000 337 mg L -1 562 mg L -1 784 mg L -1 1000 mg L 4000 5000 t (min) Fig. 2. Influences of initial dye concentration and contact time on adsorption capacities of: (a) HCl-treated ACN; (b) HCl-treated ACV. of both HCl-treated ACN and HCl-treated ACV increase due to the increase in the driving force (concentration gradient). The equilibrium time for adsorption of Basic Green 4 with initial concentrations of 337 and 562 mg L1 was 24 h. However for dye with higher initial concentrations of 784 and 1000 mg L1, longer equilibrium time of 48 h was noticed. The long equilibrium time indicates that adsorption of Basic Green 4 from aqueous solution onto durian peel-based activated carbon is a gradual process. This corresponds to the fact that activated carbon typically consists of a porous structure with large internal surface area, and the adsorption process consists of three consecutive steps. First molecules of dye diffuse through the film surrounding the surface of the activated carbon (film diffusion). Next the molecules move from the external surface into the pores of the activated carbon (pore diffusion). Finally the molecules are adsorbed onto the active sites at the internal surface within the pores of the activated carbon. Long contact time is required for this phenomenon. Moreover, HCl-treated ACV had higher maximum adsorption capacities than those HCl-treated ACN. With an increase in the initial dye concentrations from 337 to 1000 mg L1, the maximum adsorption capacities for HCl-treated ACN and HCl-treated ACV increased from 122.4 to 243.8 mg g1 (Fig. 2a) and 147.6 to 284.0 mg g1 for (Fig. 2b), respectively. To determine adsorption kinetics, pseudo-first-order and pseudo-second-order kinetic models (Lagergren, 1898; Ho and McKay, 1999) were used and compared with the adsorption data. The results indicated that pseudo-second-order kinetics better represented the adsorption of Basic Green 4 on activated carbons both synthesised under N2 atmospheric and vacuum pyrolysis. As 429 K. Nuithitikul et al. / Bioresource Technology 101 (2010) 426–429 Table 2 Rate constants, correlation coefficients and parameters of pseudo-first-order and pseudo-second-order kinetics models. C0 (mg L qe;exp 1 ) HCl-treated ACN 337 562 784 1000 HCl-treated ACV 337 562 784 1000 (mg g Pseudo-first-order 1 ) 3 1 k1 10 (min ) Pseudo-second-order qe;cal (mg g 1 ) 2 R k2 104 (g mg1 min1) qe;cal (mg g1) R2 122.4 155.5 226.8 243.8 6.45 3.22 2.30 3.46 54.8 74.6 129.5 119.9 0.948 0.906 0.963 0.893 9.05 8.82 5.76 5.74 113.6 125.0 186.3 226.1 0.996 0.995 0.990 0.996 147.6 217.8 259.6 284.0 5.53 5.07 5.52 4.14 42.4 74.2 88.1 91.1 0.938 0.935 0.907 0.828 14.48 7.65 6.97 8.12 137.0 200.0 238.1 250.0 0.998 0.998 0.998 0.998 shown in Table 2, pseudo-second-order model gives very high values of correlation coefficients (R2) of more than 0.99 for both HCl-treated ACN and HCl-treated ACV. Moreover the calculated qe values from the pseudo-second-order kinetic model are better closed to the experimental data than those from the pseudofirst-order kinetic model. Similar finding was reported by Wang et al. (2008) who found the pseudo-second-order equation better predicted the adsorption of Basic Green 4 on wheat bran-based activated carbon. However Chandra et al. (2007) who produced activated carbon from durian peel with chemical activation found that pseudo-first-order kinetics model was better described the adsorption kinetics of methylene blue than pseudo-second-order kinetics model. This difference is attributed to a difference in the adsorption system (e.g. adsorbate). 4. Conclusions BET surface area and pore volume of durian peel-based activated carbon synthesised from vacuum pyrolysis and CO2 activation at 900 °C in this study were comparable to those synthesised from chemical activation using KOH (Chandra et al., 2007). Vacuum pyrolysis provided activated carbon with superior properties (higher BET surface area, pore volume and adsorption capacities for Basic Green 4 dye) than N2 atmospheric pyrolysis. Post-treatment of activated carbon with HCl solution improved BET surface area and pore volume in comparison to H2O treatment. Acknowledgements This research was financially supported by Faculty of Engineering, King Mongkut’s University of Technology North Bangkok, Thai- land. The authors would like to thank C. Gigantic Carbon Co., Ltd. for the provision of the commercial activated carbon. References Azargohar, R., Dalai, A.K., 2008. Steam and KOH activation of biochar: experimental and modeling studies. Microporous and Mesoporous Materials 110, 413–421. Berman, Y., 2003. Process for preparing activated carbon from urban waste. United States Patent 6558644. Cao, N., Darmstadt, H., Soutric, F., Roy, C., 2002. Thermogravimetric study on the steam activation of charcoals obtained by vacuum and atmospheric pyrolysis of softwood bark residues. Carbon 40, 471–479. Chandra, T.C., Mirna, M.M., Sudaryanto, Y., Ismadji, S., 2007. Adsorption of basic dye onto activated carbon prepared from durian shell: studies of adsorption equilibrium and kinetics. Chemical Engineering Journal 127, 121–129. Davini, P., 2001. SO2 adsorption by activated carbons with various burnoffs obtained from a bituminous coal. Carbon 39, 1387–1393. Hameed, B.H., Hakimi, H., 2008. Utilization of durian (Durio zibethinus Murray) peel as low cost sorbent for the removal of acid dye from aqueous solutions. Biochemical Engineering Journal 39, 338–343. Ho, Y.S., McKay, G., 1999. Pseudo-second order model for sorption processes. Process Biochemistry 34, 451–465. Kopac, T., Toprak, A., 2007. Preparation of activated carbon from Zonguldak region coals by physical and chemical activations for hydrogen sorption. International Journal of Hydrogen Energy 32, 5005–5014. Lagergren, S., 1898. Zur theorie der sogenannten adsorption gelöster stoffe. Kungliga Svenska Vetenskapsakademiens. Handlingar 24 (4), 1–39. Önal, Y., Akmil-Basßar, C., Sarıcı-Özdemir, Ç., 2007. Investigation kinetics mechanisms of adsorption malachite green onto activated carbon. Journal of Hazardous Materials 146 (1–2), 194–203. Pastor-Villegas, J., Gómez-Serrano, V., Durán-Valle, C.J., Higes-Rolando, F.J., 1999. Chemical study of extracted rockrose and of chars and activated carbons prepared at different temperatures. Journal of Analytical and Applied Pyrolysis 50, 1–16. Wang, S., Zhu, Z.H., 2007. Effects of acidic treatment of activated carbons on dye adsorption. Dyes and Pigments 75, 306–314. Wang, X.S., Zhou, Y., Jiang, Y., Sun, C., 2008. The removal of basic dyes from aqueous solutions using agricultural by-products. Journal of Hazardous Materials 157, 374–385.