NANOPARTICLES ENGINEERED TO BIND SERUM ALBUMIN: MICROWAVE

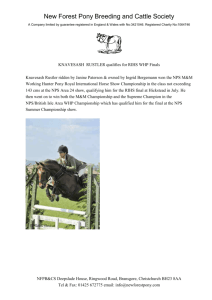

advertisement