Bulk Nanostructured thermoelectrics: Is ZT ready?

advertisement

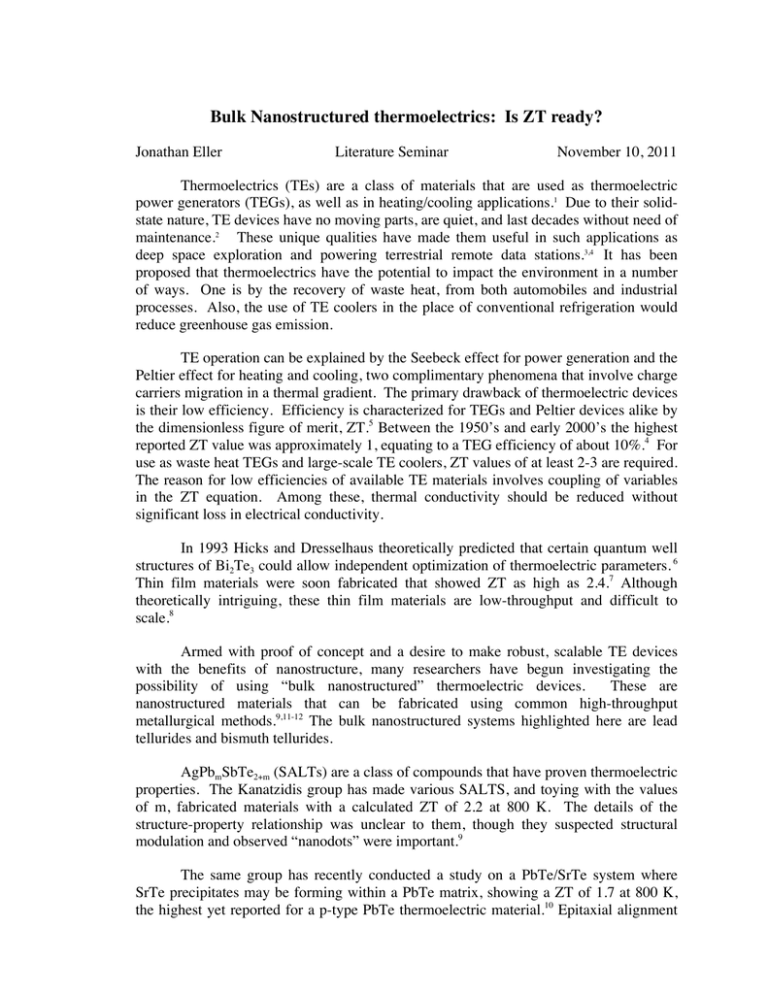

Bulk Nanostructured thermoelectrics: Is ZT ready? Jonathan Eller Literature Seminar November 10, 2011 Thermoelectrics (TEs) are a class of materials that are used as thermoelectric power generators (TEGs), as well as in heating/cooling applications.1 Due to their solidstate nature, TE devices have no moving parts, are quiet, and last decades without need of maintenance.2 These unique qualities have made them useful in such applications as deep space exploration and powering terrestrial remote data stations.3,4 It has been proposed that thermoelectrics have the potential to impact the environment in a number of ways. One is by the recovery of waste heat, from both automobiles and industrial processes. Also, the use of TE coolers in the place of conventional refrigeration would reduce greenhouse gas emission. TE operation can be explained by the Seebeck effect for power generation and the Peltier effect for heating and cooling, two complimentary phenomena that involve charge carriers migration in a thermal gradient. The primary drawback of thermoelectric devices is their low efficiency. Efficiency is characterized for TEGs and Peltier devices alike by the dimensionless figure of merit, ZT.5 Between the 1950’s and early 2000’s the highest reported ZT value was approximately 1, equating to a TEG efficiency of about 10%.4 For use as waste heat TEGs and large-scale TE coolers, ZT values of at least 2-3 are required. The reason for low efficiencies of available TE materials involves coupling of variables in the ZT equation. Among these, thermal conductivity should be reduced without significant loss in electrical conductivity. In 1993 Hicks and Dresselhaus theoretically predicted that certain quantum well structures of Bi2Te3 could allow independent optimization of thermoelectric parameters. 6 Thin film materials were soon fabricated that showed ZT as high as 2.4.7 Although theoretically intriguing, these thin film materials are low-throughput and difficult to scale.8 Armed with proof of concept and a desire to make robust, scalable TE devices with the benefits of nanostructure, many researchers have begun investigating the possibility of using “bulk nanostructured” thermoelectric devices. These are nanostructured materials that can be fabricated using common high-throughput metallurgical methods.9,11-12 The bulk nanostructured systems highlighted here are lead tellurides and bismuth tellurides. AgPbmSbTe2+m (SALTs) are a class of compounds that have proven thermoelectric properties. The Kanatzidis group has made various SALTS, and toying with the values of m, fabricated materials with a calculated ZT of 2.2 at 800 K. The details of the structure-property relationship was unclear to them, though they suspected structural modulation and observed “nanodots” were important.9 The same group has recently conducted a study on a PbTe/SrTe system where SrTe precipitates may be forming within a PbTe matrix, showing a ZT of 1.7 at 800 K, the highest yet reported for a p-type PbTe thermoelectric material.10 Epitaxial alignment is thought to reduce charge scattering, while phonon scattering can occur over a wide range due to various mechanisms. Figure 1: Boundaries enriched in Bi are thought to lower thermal conductivity and raise electrical conductivity in BixSb2-xTe3 compounds Improved thermoelectric performance has also been demonstrated by bulk nanostructured BixSb2-xTe3.11. Structural analysis12 revealed that the material contained a hierarchy of grains and nano-precipitates ranging from 5 nm to 10μm, which allow phonon scattering over a wide range of frequencies. Additionally, Bismuth-rich boundary regions (see Figure 1) are thought to increase overall hole concentration, lower thermal conductivity with little concomitant scattering of charge carriers. As a result, ZT reaches 1.2 at room temperature and 1.4 at 100 oC and is as high as 0.8 at 250 oC, showing a 40-200% improvement over the bulk. The interdependence of parameters determining TE efficiency presents a significant challenge in improving their performance. Researchers have discovered that nanoscale features, such as epitaxially embedded nanodots and other structural modulations allow selective scattering of phonons and one type of charge carrier over another. Future investigations should include using cheaper, more abundant, less toxic material as potential TE devices. References 1. DiSalvo, F. J. Thermoelectric Cooling and Power Generation. Science 1999, 285, 703–706. 2. Shakouri, A. Recent Developments in Semiconductor Thermoelectric Physics and Materials. Annu. Rev. Mater. Res. 2011, 41, 399–431. 3. Bell, L. E. Cooling, Heating, Generating Power, and Recovering Waste Heat with Thermoelectric Systems. Science 2008, 321, 1457–1461. 4. Kraemer, D. High-performance flat-panel solar thermoelectric generators with high thermal concentration. Nature materials 2011, 10, 532–538. 5. Snyder, G.; Toberer, E. Complex thermoelectric materials. Nature materials 2008, 7, 105–114. 6. Hicks, L.; Dresselhaus, M. Effect of quantum-well structures on the thermoelectric figure of merit. Phys. Rev. B 1993, 47, 12727. 7. Venkatasubramanian, R.; Siivola, E.; Colpitts, T.; O'Quinn, B. Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 2001, 413, 597–602. 8. Szczech, J. R.; Higgins, J. M.; Jin, S. Enhancement of the thermoelectric properties in nanoscale and nanostructured materials. J. Mater. Chem. 2011, 21, 4037. 9. Hsu, K. F.; Loo, S.; Guo, F.; Chen, W.; Dyck, J. S.; Uher, C.; Hogan, T.; Polychroniadis, E. K.; Kanatzidis, M. G. Cubic AgPb(m)SbTe(2+m): bulk thermoelectric materials with high figure of merit. Science (New York, N.Y.) 2004, 303, 818–821. 10. Biswas, K.; He, J.; Zhang, Q.; Wang, G.; Uher, C.; Dravid, V. P.; Kanatzidis, M. G. Strained endotaxial nanostructures with high thermoelectric figure of merit. Nature Chem 2104, 3, 160–166. 11. Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; Chen, X.; Liu, J.; Dresselhaus, M. S.; Chen, G.; Ren, Z. High-Thermoelectric Performance of Nanostructured Bismuth Antimony Telluride Bulk Alloys. Science 2008, 320, 634–638. 12. Lan, Y.; Poudel, B.; Ma, Y.; Wang, D.; Dresselhaus, M.; Chen, G.; Ren, Z. Structure study of bulk nanograined thermoelectric bismuth antimony telluride. Nano Lett. 2009, 9, 1419–1422.