11-1

Inventory Management

11-2

Inventory Management

CHAPTER

Operations Management

11

Inventory

Management

William J. Stevenson

8th edition

Operations Management, Eighth Edition, by William J. Stevenson

Copyright © 2005 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

11-3

Inventory Management

11-4

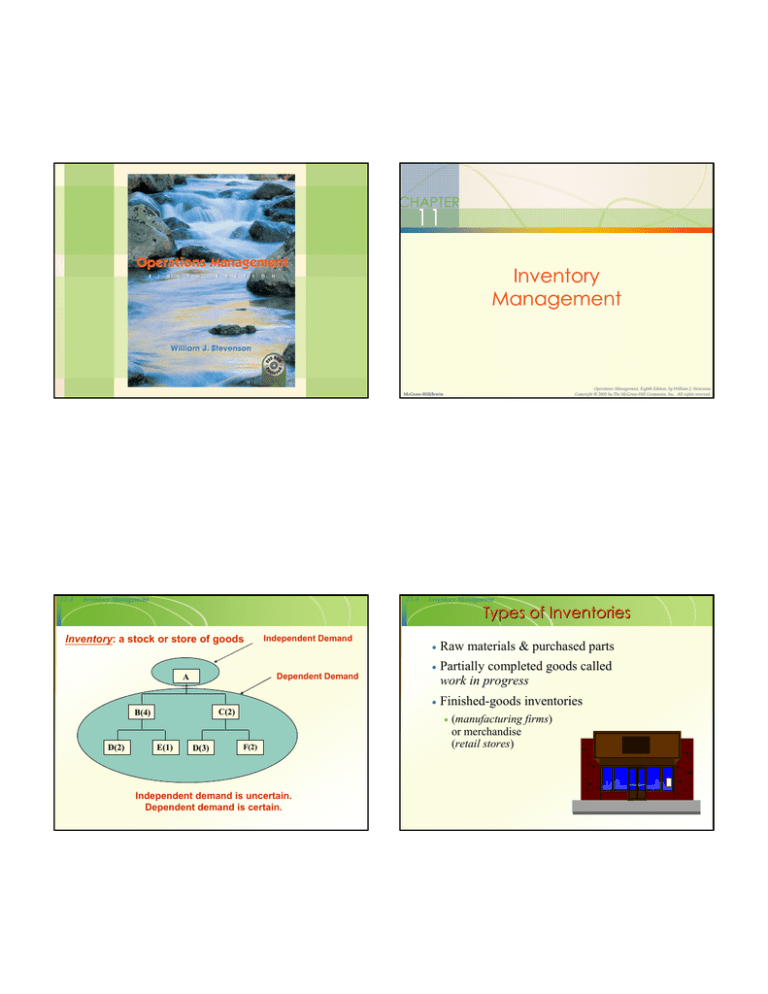

Inventory: a stock or store of goods

Independent Demand

Dependent Demand

A

Inventory Management

Types of Inventories

Raw materials & purchased parts

• Partially completed goods called

work in progress

•

•

C(2)

B(4)

D(2)

E(1)

D(3)

Finished-goods inventories

•

F(2)

Independent demand is uncertain.

Dependent demand is certain.

(manufacturing firms)

or merchandise

(retail stores)

11-5

11-7

Inventory Management

Types of Inventories (Cont’

(Cont’d)

11-6

Inventory Management

Functions of Inventory

•

Replacement parts, tools, & supplies

•

To meet anticipated demand

•

Goods-in-transit to warehouses or customers

•

To smooth production requirements

•

To decouple operations

•

To protect against stock-outs

Inventory Management

Functions of Inventory (Cont’

(Cont’d)

•

To take advantage of order cycles

•

To help hedge against price increases

•

To permit operations

•

To take advantage of quantity discounts

11-8

Inventory Management

Objective of Inventory Control

•

To achieve satisfactory levels of customer

service while keeping inventory costs within

reasonable bounds

•

Level of customer service

•

Costs of ordering and carrying inventory

11-9

Inventory Management

Effective Inventory Management

•

A system to keep track of inventory

•

A reliable forecast of demand

•

Knowledge of lead times

•

Reasonable estimates of

•

•

Holding costs

•

Ordering costs

•

Shortage costs

11-10 Inventory Management

Inventory Counting Systems

•

Periodic System

Physical count of items made at periodic

intervals

•

Perpetual Inventory System

System that keeps track

of removals from inventory

continuously, thus

monitoring

current levels of

each item

A classification system

11-11 Inventory Management

Inventory Counting Systems (Cont’

(Cont’d)

Two-Bin System - Two containers of

inventory; reorder when the first is empty

• Universal Bar Code - Bar code

printed on a label that has

information about the item

to which it is attached

•

0

214800 232087768

11-12 Inventory Management

Key Inventory Terms

Lead time: time interval between ordering

and receiving the order

• Holding (carrying) costs: cost to carry an

item in inventory for a length of time,

usually a year

• Ordering costs: costs of ordering and

receiving inventory

• Shortage costs: costs when demand exceeds

supply

•

11-13 Inventory Management

11-14 Inventory Management

ABC Classification System

Cycle Counting

Figure 11.1

Classifying inventory according to some

measure of importance and allocating control

efforts accordingly.

A - very important

B - mod. important

C - least important

High

•

A physical count of items in inventory

•

Cycle counting management

A

Annual

$ value

of items

•

How much accuracy is needed?

•

When should cycle counting be performed?

•

Who should do it?

B

C

Low

Few

Many

Number of Items

11-15 Inventory Management

Economic Order Quantity Models

11-16 Inventory Management

Assumptions of EOQ Model

•

Economic order quantity model

•

Only one product is involved

•

Economic production model

•

Annual demand requirements known

•

Quantity discount model

•

Demand is even throughout the year

•

Lead time does not vary

•

Each order is received in a single delivery

•

There are no quantity discounts

11-17 Inventory Management

11-18 Inventory Management

The Inventory Cycle

Total Cost

Figure 11.2

Profile of Inventory Level Over Time

Q

Usage

rate

Quantity

on hand

Annual

Annual

Total cost = carrying + ordering

cost

cost

TC =

Reorder

point

Receive

order

Place Receive

order order

Q

H

2

+

DS

Q

Time

Place Receive

order order

Lead time

11-19 Inventory Management

Cost Minimization Goal

11-20 Inventory Management

Deriving the EOQ

Figure 11.4C

Annual Cost

The Total-Cost Curve is U-Shaped

TC =

D

Q

H+ S

2

Q

Using calculus, we take the derivative of the

total cost function and set the derivative

(slope) equal to zero and solve for Q.

Q OPT =

Ordering Costs

QO (optimal order quantity)

Order Quantity

(Q)

2DS

=

H

2( Annual Demand )(Order or Setup Cost )

Annual Holding Cost

11-21 Inventory Management

Minimum Total Cost

The total cost curve reaches its minimum

where the carrying and ordering costs are

equal.

Q OPT =

2DS

=

H

2( Annual Demand )(Order or Setup Cost )

Annual Holding Cost

11-23 Inventory Management

Economic Production Quantity Assumptions

Only one item is involved

• Annual demand is known

• Usage rate is constant

• Usage occurs continually

• Production rate is constant

• Lead time does not vary

• No quantity discounts

11-22 Inventory Management

Economic Production Quantity (EPQ)

Production done in batches or lots

• Capacity to produce a part exceeds the part’s

usage or demand rate

• Assumptions of EPQ are similar to EOQ

except orders are received incrementally

during production

•

11-24 Inventory Management

Economic Run Size

•

Q0 =

p

2DS

H p− u

11-25 Inventory Management

Total Costs with Purchasing Cost

11-26 Inventory Management

Total Costs with PD

Cost

Figure 11.7

Annual

Annual

TC = carrying + ordering + Purchasing

cost

cost

cost

TC =

Q

H

2

+

DS

Q

+

Adding Purchasing cost

doesn’t change EOQ

TC with PD

TC without PD

PD

PD

0

11-27 Inventory Management

Total Cost with Constant Carrying Costs

EOQ

Quantity

11-28 Inventory Management

When to Reorder with EOQ Ordering

Figure 11.9

•

Reorder Point - When the quantity on hand

of an item drops to this amount, the item is

reordered

•

Safety Stock - Stock that is held in excess of

expected demand due to variable demand

rate and/or lead time.

•

Service Level - Probability that demand will

not exceed supply during lead time.

Total Cost

TCa

TCb

Decreasing

Price

TCc

CC a,b,c

OC

EOQ

Quantity

11-29 Inventory Management

Determinants of the Reorder Point

11-30 Inventory Management

Safety Stock

Figure 11.12

The rate of demand

• The lead time

• Demand and/or lead time variability

• Stockout risk (safety stock)

Quantity

•

Maximum probable demand

during lead time

Expected demand

during lead time

ROP

Safety stock reduces risk of

stockout during lead time

11-31 Inventory Management

Safety stock

LT

Time

11-32 Inventory Management

Reorder Point

FixedFixed-OrderOrder-Interval Model

Figure 11.13

The ROP based on a normal

Distribution of lead time demand

Service level

Risk of

a stockout

Probability of

no stockout

Expected

demand

0

ROP

Quantity

Safety

stock

z

z-scale

Orders are placed at fixed time intervals

• Order quantity for next interval?

• Suppliers might encourage fixed intervals

• May require only periodic checks of

inventory levels

• Risk of stockout

•

11-33 Inventory Management

FixedFixed-Interval Benefits

Tight control of inventory items

• Items from same supplier may yield savings

in:

•

Ordering

Packing

• Shipping costs

•

11-34 Inventory Management

FixedFixed-Interval Disadvantages

Requires a larger safety stock

• Increases carrying cost

• Costs of periodic reviews

•

•

•

May be practical when inventories cannot be

closely monitored

11-35 Inventory Management

Single Period Model

•

Single period model: model for ordering of

perishables and other items with limited

useful lives

•

Shortage cost: generally the unrealized

profits per unit

•

Excess cost: difference between purchase

cost and salvage value of items left over at

the end of a period

11-36 Inventory Management

Single Period Model

•

•

Continuous stocking levels

•

Identifies optimal stocking levels

•

Optimal stocking level balances unit shortage

and excess cost

Discrete stocking levels

•

Service levels are discrete rather than

continuous

•

Desired service level is equaled or exceeded

11-37 Inventory Management

11-38 Inventory Management

Operations Strategy

•

CHAPTER

Too much inventory

Tends to hide problems

• Easier to live with problems than to eliminate

them

• Costly to maintain

•

•

Wise strategy

•

•

11

Additional PowerPoint slides

contributed by

Geoff Willis,

University of Central Oklahoma.

Reduce lot sizes

Reduce safety stock

11-39 Inventory Management

Usage

Production

& Usage

Production

& Usage

Economic Production Quantity

11-40 Inventory Management

Gortrac Manufacturing

Usage

In

v

en

t

or

yL

ev

el

GTS3

Inventory/Assessment/Reduction

11-41 Inventory Management

Materials

PS7

Washburn Guitars