Capacity and Aggregate Planning Chapter 9

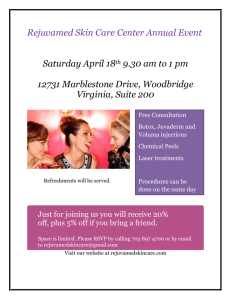

advertisement

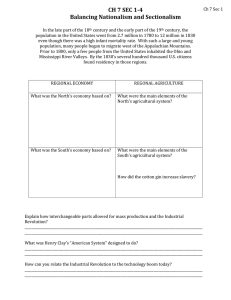

MGT 4700 - Operations Management Georgia State University - Spring, 2004 Capacity and Aggregate Planning Chapter 9 1 Objectives Capacity Planning n Aggregate Production Planning n Adjusting Capacity n Demand Management n Yield Management n Linear Programming n 2 Capacity Planning n n n Long-term strategic decision on overall resources of the firm Inadequate vs. excess capacity How much to increase capacity and when? n How much n n n When (timing) n Sec# 12213 Demand volume and uncertainty Incremental vs. one-step expansion Lead, lag, & average capacity strategies 3 1 MGT 4700 - Operations Management Georgia State University - Spring, 2004 Capacity Expansion (a) Capacity lead strategy (b) Capacity lag strategy Capacity Demand Units Units Demand Capacity Time (c) Average capacity strategy Time (d) Incremental vs. one-step expansion One -step expansion Capacity Units Units Demand Incremental expansion Demand Time Time 4 Aggregate Production Planning (APP) n n n Determine resources required to meet annual demand in general terms Establish company -wide game plan for allocating resources Develop economic strategy for meeting demand 5 Inputs and Outputs to APP Capacity Constraints Aggregate Production Planning Demand Forecasts Size of Workforce Strategic Objectives Production per month (in units or $) Inventory Levels Company Policies Financial Constraints Units or dollars subcontracted, backordered, or lost 6 Sec# 12213 2 MGT 4700 - Operations Management Georgia State University - Spring, 2004 Adjusting Capacity n n Demand Units Level production Chase demand Maintaining resources for high demand Production Time Demand Production Units n Time 7 Adjusting Capacity n n n n n Overtime and undertime Subcontracting Part-time workers Backordering Mixed strategies 8 Demand Management n Shift demand into other periods n n n Incentives, promotions, advertising campaigns Offer products or service with counter-cyclical demand patterns Partnering with suppliers to reduce information distortion along the supply chain 9 Sec# 12213 3 MGT 4700 - Operations Management Georgia State University - Spring, 2004 Hierarchical Planning Production Planning Capacity Planning Resource Level Product lines or families Aggregate production plan Resource requirements plan Plants Individual products Master production schedule Rough-cut capacity plan Critical work centers Components Material requirements plan Capacity requirements plan Manufacturing operations Shop floor schedule Input/ output control Items All work centers Individual machines 10 Aggregate Planning for Services n n n n n Services can’t be inventoried Demand for services difficult to predict Capacity also difficult to predict Service capacity must be provided at the appropriate place and time Labor is usually the most constraining resource for services 11 Yield Management n n n n Attempts to find the optimal number of rooms or seats overbooked Based on the probability of noshows Matches overbooking policy to the number of no-shows Also used to partition demand into different fare classes 12 Sec# 12213 4 MGT 4700 - Operations Management Georgia State University - Spring, 2004 Linear Programming n n Quantitative modeling technique Helps make operational decisions n Production level, worker requirements, shipment amounts, inventory levels, … n Subject to limited resources n Driven by a common objective n n n Time, labor, materials, budgets, … Minimizing cost Maximizing profit 13 LP Model n Decision variables n Production levels for different products n Objective function n Constraints n n n Profit function Labor and material restrictions on each of the products Solution n Excel’s Solver tool 14 Sec# 12213 5