FME 212: Screw Thread Problems W λ φ

advertisement

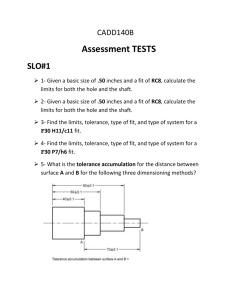

FME 212: Screw Thread Problems 1. A square-threaded screw jack with a single start is operated to lift a vertical load of W newtons. If the helix angle is λ and the friction angle is φ , show, with the use of usual notations, that the maximum mechanical efficiency is attained when: ⎡π φ⎤ λ = ⎢ − ⎥ radians ⎣ 4 2⎦ and that this maximum mechanical efficiency may be expressed as follows: ηmax ⎡1 − tan (φ 2 )⎤ =⎢ ⎥ ⎣1 + tan (φ 2 )⎦ 2 Alternatively, show that the maximum mechanical efficiency may be expressed as follows: ηmax = 2. 1 − sin φ 1 + sin φ Name two major categories of applications of screw threads in mechanical engineering and explain how the square thread and the triangular thread are suited to each of these categories of applications. In a screw jack, the square threaded single-start screw has a mean diameter that is six times the pitch of the screw. What is the mechanical efficiency of the jack while it is being used to raise a load, if the coefficient of friction is 0.15? Suppose that the pitch of the screw thread is 12 mm. What is the force, applied through a lever of 500 mm effective length, that will be required in order to raise a mass of 500 kg? Neglect any collar friction that may arise in the device. 3. Define the terms lead and pitch, as applied to screw threads. relationship between the lead and the pitch of a screw thread? What is the A screw jack has a single start square thread, the mean diameter of which is five times its pitch. A lever, the effective length of which is ten times the mean diameter of the screw, is used to turn the jack. The coefficient of friction between the threads is 0.12. The load can rotate freely relative to the screw. Determine the mechanical advantage and the efficiency of the jack, when raising the load. Friction and Screw Threads 1 4. With reference to a square threaded screw, define the terms pitch, lead, major diameter, minor diameter and mean diameter. A power screw has a double start square thread with a pitch diameter of 30 mm and a pitch of 3 mm. The coefficient of friction between the threads is 0.14. If the screw has a power input of 3 kW at 60 rpm, determine the maximum axial load against which the screw may be safely driven, and the mechanical efficiency of the screw. Neglect any collar friction that may occur in the device. 5. Comment on the theoretical basis of the “block on an inclined plane” mechanical model of the square threaded screw jack. A double start square threaded power screw is to be applied in a jacking device. The root diameter of the thread is 28 mm, while the major diameter is 32 mm. The limiting coefficient of friction is 0.15, and the load to be lifted is 6.5 kN. Assuming there is no collar friction in the device, determine: 6. • The helix angle of the screw • The torque required to raise the load • The mechanical efficiency of the device • The torque required to lower the load • Whether the device is self-locking or not. Explain your answer. Discuss the suitability of the square thread and the triangular thread for power transmission and fastening applications. A single start square threaded jackscrew turns in a stationary nut. The jackscrew, which has a nominal diameter of 50 mm and a pitch of 25 mm, is turned using a straight lever lying in the plane perpendicular to the axis of the jackscrew. The effective length of the lever, measured from the axis of the jackscrew, is 500 mm. The coefficient of friction between the jackscrew and the nut is 0.2. If the jackscrew is to be used to lift a 5 kN load, neglecting any collar friction that may occur in the device, determine: 7. • The mechanical advantage of the device • The mechanical efficiency of the device • Whether the device is self-locking or not. A jackscrew consists of a single-start triangular-threaded screw with a lead angle of 90, turning in a stationary nut. The pitch diameter of the screw thread is 50 mm, and the angle of friction is 110. A lever lying in a plane perpendicular to the axis of the screw turns the device. If the device is to have a mechanical advantage of 50, then Friction and Screw Threads 2 8. • What should be the effective length of the turning lever? Take the apex angle of the thread to be 400. • What will be the mechanical efficiency of the drive? • What will be the load that can be lifted by the device if the maximum available effort is 90 N? • Will the device be able to sustain this load without unwinding when there is no effort applied to the lever? Explain. Two railway coaches are coupled with the help of two tie rods of a turnbuckle mechanism such as the one illustrated in Fig. Q8. The tie rods have single-start square threads with a pitch of 8 mm and a mean diameter of 30 mm. The coefficient of friction between the threads on the rods and those on the coupler is 0.12. If the turnbuckle is used to draw the two coaches closer to each other through a distance of 200 mm, against a steady load of 2 kN then; • Determine the work output of the turnbuckle mechanism, • The efficiency of the turnbuckle mechanism. • The work input into the turnbuckle mechanism, and Coupler W W Rod with left-handed thread Rod with right-handed thread Fig. Q8 – Turnbuckle Mechanism Resources • SHIGLEY, J. E., C. R. MISCHKE and R. G. BUDYNAS. Mechanical Engineering Design, Seventh Edition, Chapter 8 – Screws, Fasteners and the Design of Nonpermanent Joints. McGraw-Hill Higher Education, 2004. • DIMAROGONAS, A. D. Machine Design. A CAD Approach, Chapter 8 – Design for Shear Strength: Fastening and Joining. Wiley Interscience, 2001. Friction and Screw Threads 3 • WILSON, C. E. Computer Integrated Machine Design – Chapters 14 (Power Screws and Linear Actuators) and 15 (Fasteners). Prentice-Hall International, 1997. • SPOTTS, M. F. Design of Machine Elements, Chapter 5 – Screws. PrenticeHall, 1991. • JUVINALL, ROBERT C. Fundamentals of Machine Component Design, Chapter 10 – Threaded Fasteners and Power Screws. John Wiley and Sons, 1983. • BLACK, PAUL H. and O. EUGENE ADAMS Jr. Machine Design, Chapter 12 – Translation Screws. McGraw-Hill International, 1981. • DEUTSCHMAN, A. D., W. J. MICHELS and C. E. WILSON. Machine Design: Theory and Practice, Chapter 15 – Power Screws and Chapter 16 - Fasteners. Collier Macmillan, 1975. • WRIGHT, DOUGLAS. Threaded Fasteners. http://school.mech.uwa.edu.au/~dwright/DANotes/threads/intro/intro.html#top • WRIGHT, DOUGLAS. Screw Thread Mechanics. http://school.mech.uwa.edu.au/~dwright/DANotes/threads/mechanics/mechanics.ht ml#top • Most standard engineering mechanics texts have chapters on friction, which often deal with screw thread mechanics. • The internet has numerous pages and websites that deal with screw thread mechanics and design. Friction and Screw Threads 4