1. Shear force and bending moment diagrams

Solid Mechanics

1. Shear force and bending moment diagrams

Internal Forces in solids

Sign conventions

• Shear forces are given a special symbol on given

V y

1

2

and V z

• The couple moment along the axis of the member is

M x

= = Torque

M y

= M z

= bending moment.

Solid Mechanics

We need to follow a systematic sign convention for systematic development of equations and reproducibility of the equations

The sign convention is like this.

If a face (i.e. formed by the cutting plane) is +ve if its outward normal unit vector points towards any of the positive coordinate directions otherwise it is –ve face

• A force component on a +ve face is +ve if it is directed towards any of the +ve coordinate axis direction. A force component on a –ve face is +ve if it is directed towards any of the –ve coordinate axis direction. Otherwise it is –v.

Thus sign conventions depend on the choice of coordinate axes.

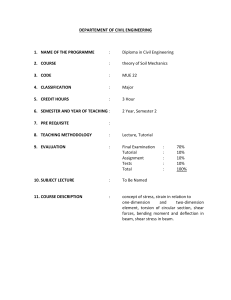

Shear force and bending moment diagrams of beams

Beam is one of the most important structural components.

• Beams are usually long, straight, prismatic members and always subjected forces perpendicular to the axis of the beam

Two observations:

(1) Forces are coplanar

Solid Mechanics

(2) All forces are applied at the axis of the beam.

Application of method of sections

What are the necessary internal forces to keep the segment of the beam in equilibrium?

F x

F y

F z

=

=

0

0

= 0

P

V

M

• The shear for a diagram (SFD) and bending moment diagram(BMD) of a beam shows the variation of shear

Solid Mechanics force and bending moment along the length of the beam.

These diagrams are extremely useful while designing the beams for various applications.

Supports and various types of beams

(a) Roller Support – resists vertical forces only

(b) Hinge support or pin connection – resists horizontal and vertical forces

Hinge and roller supports are called as simple supports

(c) Fixed support or built-in end

Solid Mechanics

The distance between two supports is known as “span”.

Types of beams

Beams are classified based on the type of supports.

(1) Simply supported beam : A beam with two simple supports

(2) Cantilever beam : Beam fixed at one end and free at other

(3) Overhanging beam

(4) Continuous beam : More than two supports

Solid Mechanics

Differential equations of equilibrium

[ Σ F x

= → + ]

Σ F y

= ↑ +

V + ∆ ∆ = 0

∆ V = − ∆

∆ V

∆ x

= − P lim

∆ x → 0

∆

∆

V dV x dx

= − P

[ Σ M

A

= 0

] ∆ + ∆ M −

∆ + ∆ M −

∆ M

∆ x 2

2

2

= 0

= 0

2

2

= 0

lim

∆ x → 0

∆

∆

M x

= dM dx

= − V

From equation dV dx

= − P we can write

V

D

− V

C

= −

X

D

X

C

Pdx

From equation dM dx

= − V

M

D

− M

C

= − Vdx

Special cases:

Solid Mechanics

Solid Mechanics

Solid Mechanics

Solid Mechanics

Solid Mechanics

0

2

6

8 x 2 −

6 ( 2 ( ) x 8 − x 10 − −

0

V

V

V

A

= 5

= 5 ; V

B

= 5

2

V

V

− + −

= − +

V

B

= −

− +

25

(

; V

C

− 2

=

)

5

= 0 x = 5 33

( ) 0

( − 2 )

6

V

V

− + − − =

= + 15

V

C

8

V

= + 15

10

; V

D

4

= +

− 4

15

( ) ( )

− + − − + =

V

V

V

D

= − 5

= − 5 ; V

E

= − 5

Solid Mechanics

2

M

M

M

−

0

M

M

M

A x 2 − ( ) ( )

− 10 5 x = 0

5 x 10

= + 10 ; M

B

= 0 x 6 − ( ) ( )

+ x

= − x + 30 ( x )

=

− 30 ( x

+

)

( − 2 ) 2

2

( − 2 ) 2

2

= 0

M

C x = 6

= 40

6

M x 8 ( ) ( ) [ ]

− + x − 30 ( x ) 30 ( x ) 10 ( x ) =

M

C x = 6

M

D x = 8

= 20 +

= − 10

8

M

M

E x = 8

10

= 0

[ ] ( ) ( )

− + x − 30 ( x ) 30 ( x ) 10 ( x ) − ( x ) 0

Problems to show that jumps because of concentrated force and concentrated moment

Solid Mechanics

We can also demonstrate internal forces at a given section using above examples. This should be carried first before drawing SFD and BMD.

0 2 [ ]

Solid Mechanics

2 6 [ ]

V

V = 5

V

A

V

B

=

= 5

5

M

M

− 10 5 x = 0

M

A

= − x

= 10 ; M

B

= 0

6

V − + −

V = ( )

(

V

B

= − 25

− + (

; V

C

=

)

5

0 x = 5 33

) 0 M − + x − 30 ( x ) .

x = 6

M

C

= 40

M x = .

x

M

= 2

B

= 0

=

( x − 2 ) 2

2

= 0

8 [ ]

V − + −

V

V

C

=

=

15

15 , V

D

=

−

15

=

8 10 [ ]

Solid Mechanics

V

V

V

D

− + − − + =

= − 5

= − 5 , V

E

= − 5

[

[

Solid Mechanics

F x

→ + = 0

]

F y

↑ + = 0

M

∆

= 0 ]

R

Ax

= 0

R

Ay

+ − =

R

Ay

= 30 kN ↑

M

M + 60 90 4 5 0

= 285

30

V =

V − ( x ) 0

30 ( x ) 90

= × −

= −

= 0

M

M

B

B

− M

60

A

= +

( 60 )

M

A

= −

=

225

−

M

M

C

C

− M

B

( )

=

B

+ 90 = − 225 90

= −

M

135

= − − 90

M

D

− M

C

M

D

= M

C

( 135 )

+ 135 = − + =

Solid Mechanics

F y

↑ + = 0

R

Ay

R

Ay

+ R

Cy

+ R

Cy

− − =

= 440

[

M

A

= 0

]

− × − × + R

Cy

R

Cy

= 195 kN ↑

R

Ay

= 245 kN ↑

V

V

V

V

+ 245 200 30 x = 0

= 30 x − 45

= × − = −

= 195

Solid Mechanics

*

[

R

Ay

+

M

A

R

By

= 32

] × + + +

− + + R

By

= 0

R

By

= 12 kN

R

Ay

= 20 kN

M

M

M

− × + ×

= × − ×

= 600

R

By

= 0

Solid Mechanics

Problem :

V

V = 8 x − 20

8 x − = x

+ 20 8 x = 0

= = .

M

C

− M

M

C

= M

A

A

( 50 )

+ 50 = − + =

[

[ F x

R

Ax

=

→ + =

0

F y

M

A

0

]

R

Ay

+ R

Dy

− − =

= 0 ] 60 1 5 50 4 R

Dy

R

Dy

R

Ay

R

Ay

+ R

Dy

=

=

290

5

=

52 kN

58 kN

↑

↑

= 110

Solid Mechanics

F y

V + 52 20 x = 0

V = 20 x − 52 0 x 3 m

[ M = 0 ]

M +

20 x 2

2

M

− 52 x = 0

= 52 x −

20 x

2

2

( 0 x 3 m )

F y

V + − =

V = 8 kN ↑

B

3 ≤ ≤ 4

C x m

[

M

M = 0 ] M − 52 x + 60 ( x − .

) = 0

= x − ( x − .

)

B

52 60 1 5 3 ≤ ≤ 4

C x m

Solid Mechanics

F y

V + − − =

V = 58 kN ( 4 5 )

[ M = 0 ] M − 52 x + 60 ( x − .

) + 50 ( x ) 0

M = 52 x − 60 ( x − .

) − 50 ( x − 4 ) ( 4 5 ) dM dx dV dx

= − V

= − P

20 × − = x = = . m

M

B

− M

E

= −

M

B

= − .

+

Solid Mechanics

M

B

− M

A dM dx dV dx

= −

= − V

= − P

Vdx

20 × − = x = = .

M

B

− M

E

= −

M

B

= − 1 6 + M

E

=

= −

66

.

+

M

C

− M

B

= − 8

M

C

M

B

= − + =

M

D

− M

C

= − 58

M

D

= M

C

+ 58

= − =

Solid Mechanics

2. Concept of stress

Traction vector or Stress vector

Now we define a quantity known as “ stress vector ” or

“ traction ” as

T n

=

∆ lim

A → 0

∆

∆

F

R

A

units P N / m

2 and we assume that the quantity

∆ lim

A → 0

∆

∆

M

A

R → 0

(1) T n

is a vector quantity having direction of ∆ F

R

(2) T n

represent intensity point distributed force at the point

"P" on a plane whose normal is ˆn

(3) T n

acts in the same direction as ∆ F

R

Solid Mechanics

(4) There are two reasons are available for justification of the assumption that

∆ lim

A → 0

∆

∆

M

A

R → 0

(a) experimental

(b) as ∆ A → 0, ∆ F

R

becomes resultant of a parallel force distribution. Therefore ∆ M

R

= 0 for force system.

(5) T n varies from point to point on a given plane

(6) T n

at the same point is different for different planes.

(7) T n ′

= − T n

will act at the point P

(8) In general

Components of T n

∆ F

R

= ∆ ˆ + ∆ v t ˆ + ∆ ˆ

Solid Mechanics

T n

=

∆ lim

A → 0

∆

∆

F

R

A

=

∆ lim

A → 0

∆

∆

F n

A

+

∆ lim

A → 0

∆

∆ v t

A t ˆ + lim

∆ A → 0

∆

∆ v s

A s ˆ

T n

= σ nn

ˆ + τ nt

ˆ t + τ ns

ˆ s where

τ

τ

σ nn nt ns

=

=

=

∆

∆

∆ lim

A → 0 lim

A → 0 lim

A → 0

∆

∆

∆

∆

F n = dF n

A dA v t = dv

A dA t

∆

∆ v s = dv

A dA s

=

=

=

Normal stresscomponent

Shear stresscomponent

Another shear componet

τ

σ

−

− NormalStress

Shear stress dF n

= σ nn dA dV t

= τ nt dA

Notation of stress components

The magnitude and direction of T n

clearly depends on the plane m-m . Therefore, stress components magnitude & direction depends on orientation of cut m-m .

(a) First subscript- plane on which

(b) Second subscript- direction

σ is acting

Solid Mechanics

Rectangular components of stress

Cuts ⊥ to the coordinate planes will give more valuable information than arbitrary cuts.

T x

=

∆ lim

A → 0

∆

∆

F

R

A

=

∆ lim

A → 0

∆

∆

F x

A i

ˆ +

∆ lim

A → 0

∆ v y

∆ A j

ˆ +

∆ lim

A → 0

∆

∆ A k

T x

= σ xx

ˆ i + τ xy

ˆ j + τ xz where

σ xx

τ xy

=

=

∆ lim

A → 0

∆

∆ lim

A → 0

∆

∆

F x

A

∆ v

A y

= Normalstress

= Shear stress; τ xz

=

∆ lim

A → 0

∆

∆ v

A z = Shear stress

dF x

= σ xx dA dv y

= τ xy dA

Solid Mechanics dv z

= τ xz dA

Similarly,

T y

=

∆ lim

A → 0

∆

∆

F

R

A

=

∆ lim

A → 0

∆

∆ v x

A i ˆ +

∆ lim

A → 0

∆ F y

∆ A j ˆ + lim

∆ A → 0

∆

∆ A k

T y

= τ yx

ˆ i + σ yy

ˆ j + τ yz

ˆ k

T z

= τ zx

ˆ i + τ zy

ˆ j + σ zz

ˆ

σ xx

and τ xy

will act only on x -plane. We can see σ x

and τ xy only when we take section ⊥ to x -axis.

The stress tensor

Components directions a point “ P ” on the x-plane in x , y , z

σ jj

=

σ xx

τ xy

τ xz

τ yx

σ yy

τ yz

τ zx

τ zy

σ zz

Rectan gular stresscomponents

• This array of 9 components is called as stress tensor.

• It is a second rank of tensor because of two indices

Solid Mechanics

• These 9 rectangular stress components are obtained by taking 3 mutually ⊥ planes passing through the point

“ P ”

• ∴ Stress tensor is an array consisting of stress components acting on three mutually perpendicular planes.

T n

= τ nx i

ˆ + τ ny j

ˆ + τ nz

ˆ

What is the difference between distributed loading & stress? q =

∆ lim

A → 0

∆

∆

F

R

A q = σ yy

can also be called.

No difference!

Except for their origin!

Solid Mechanics

Sign convention of stress components.

A positive components acts on a +ve face in a +ve coordinate direction or

A positive component acts on a negative face in a negative coordinate direction .

Say σ x means.

= − 20 ;Pa τ xy

= − 10 P a

and τ xz

= 30 Pa at a point P

Solid Mechanics

State of stress at a point

The totality of all the stress vectors acting on every possible plane passing through the point is defined to be state of stress at a point .

• State of stress at a point is important for the designer in determining the critical planes and the respective critical stresses.

• If the stress vectors [and hence the component] acting on any three mutually perpendicular planes passing through the point are known, we can determine the stress vector T n

acting on any plane “ n ” through that point.

The stress tensor will specify the state stress at point.

σ ij ′

=

σ

τ

τ

τ

σ

τ

τ

τ

σ can also represent state of stress at a point.

Solid Mechanics

The stress element

Is there any convenient way to visualize or represent the state of stress at a point or stresses acting three mutually perpendicular planes say x- plane , y-plane and z-plane.

σ ij

P

+ σ xx

= + τ yx

+ τ zx

+ τ xy

+ σ yy

+ τ zy

+ τ xz

+ τ yz

+ σ zz

σ xx

= σ xx

σ yy

= σ yy

(

( x,y,z x,y,z

)

)

Continuous functions of x,y,z

Let us consider a stress tensor or state of stress at a point in a component as

σ ij

=

− 10 5 − 30

5 50 − 60

− 30 − 60 − 100

Solid Mechanics

[

Equilibrium of stress element dy dz y

τ xz

τ xy

σ x x dx z

F x

0

]

σ x dydz + τ yx dxdz + τ zx dydx − σ x dydz − τ yx dxdz − τ zx dxdy = 0

F y

= 0 and F z

= 0 is satisfied. Similarly, we can show that

Solid Mechanics

M z

P

= 0

(

τ xy

) (

τ yx

)

τ xy

− τ yx

= 0

τ xy

= τ yx

= 0

Shearing stresses on any two mutually perpendicular planes are equal.

M x

P

= 0 τ yz

= τ zy

and M y

P

= 0 τ zx

= τ xz

Cross-shears are equal- a very important result

Since τ xy

= τ yx

, if τ xy

= − ve τ yx

is also –ve

Solid Mechanics

∴ The stress tensor

σ ij

=

σ xx

τ yx

= τ xy

τ xy

σ xy

τ xz

τ yz

τ zx

= τ xz

τ zy

= τ yz

σ yz issec ondrank symmetrictensor

Differential equations of equilibrium

[ F x

→ + = ]

σ x

+

∂

∂

σ x x τ yx

+

∂ τ yx

∂ y y x z τ zx

+

∂ τ

∂ zx z

σ

∂

∂

σ x x y z τ xy x z

∂ τ

∂ yx y

τ zx

∆ ∆ + ∆ ∆ ∆ =

2 τ

∂ zx z

0

∆ ∆ + ∆ ∆ ∆ = 0

Canceling x y

and

∆ z

terms and taking limit lim x y

∆ →

0

0

0

∂

∂

σ x x +

∂ τ yx

∂ y

+

∂ τ

∂ z zx + B x

= 0

Similarly we can easily show that

Solid Mechanics

∂

∂

∂

σ x x

τ xy

∂ x

∂ τ

∂ xz x

+

+

+

∂ τ yx

∂

∂

σ y yy

∂ y

∂ τ yz

∂ y

+

+

∂ τ

∂ zx z

∂ τ zy

∂ z

+ B x

=

+ B y

=

0

0

+

∂ σ

∂ z zz + B z

= 0

[

[ F x

=

F y

= 0

F z

=

• If a body is under equilibrium, then the stress components must satisfy the above equations and must vary as above.

For equilibrium, the moments of forces about x, y and z axis at any point must vanish.

τ

M z p

= 0 xy

+

∂ τ xy

∂ x x y z

2 x

+ τ xy y z

∆

2 x

−

− τ yx x z

∆

2 y

= 0

τ yx

+

∂ τ

∂ y yx y x z

∆ y

2

2 τ xy

Solid Mechanics

2 y x z

+

∂ τ xy

∂ x

τ xy

2

+

2

∂ τ xy

∂ x

∆ x

2

−

2 τ yx

− τ yx

−

2 x y z

−

∂ τ yx

∂ y

∂ τ yx

∂ y

∆ y

2

= 0

2

2

= 0

Taking limit lim x y z

0

0

0

τ xy

+

∂ τ xy

∂ x

τ xy

− τ yx

= 0 τ xy

= τ yx

∆ x

2

− τ yx

−

∂ τ yx

∆ y

∂ y 2

= 0

Relations between stress components and internal force resultants

Solid Mechanics

F x

=

A

σ xx dA ; V y

τ

=

− τ xy

A

τ xy dA ; V z x

M x

=

A

( y τ xz

− τ xy

=

A

τ xz dA

M y

=

A

σ xz dA ; M z

= −

A

σ xy dA

Solid Mechanics

3. Plane stress and Plane strain

Plane stress- 2D State of stress

3

σ ij

=

σ x

τ xy

τ xz

τ yx

σ yy

τ yz

τ zx

τ zy

σ zz

− 6 components

σ ij

=

2

σ x

τ xy

τ xy

σ y

0

0

0 0 0

=

τ

σ x yx = τ xy

Stresscomponentsin plane xy

τ xy

σ y

If

σ ij

=

τ

σ x xy

( )

( )

τ

σ xy yy

( )

( )

− plane stress-is a --- state of stress

All stress components are in the plane x y i.e all stress components can be viewed in x y plane.

Solid Mechanics

This type of stress-state (i.e plane stress) exists in bodies whose z - direction dimension is very small w.r.t other dimensions.

Stress transformation laws for plane stress

The state of stress at a point P in 2 D -plane stress problems are represented by

σ ij

=

σ x

τ xy

τ xy

σ y

=

σ nn

τ nt

τ nt

σ tt

Solid Mechanics

* We can determine the stress components on any plane “ n ” by knowing the stress components on any two mutually

⊥ planes.

Stress transformation laws for plane stress

In order to get useful information we take different cutting planes passing through a point. In contrast to 3 D problem, all cutting planes in plane stress problems are parallel to x -

Solid Mechanics axis. i.e we take different cutting plane by rotating about z - axis.

As in case of 3D, the state of stress at a point in a plane stress domain is the totality of all the stress. If we know the stress components on any two mutually

⊥ planes then stress components on any arbitrary plane m-m can be determined.

Thus the stress tensor

σ ij

=

σ x

τ xy

τ xy

σ y

is sufficient to tell about the state of stress at a point in the plane stress problems. dACs θ = Areaof BC dASin θ = Area of AC

F n

+ = 0

σ nn dA − σ x

θ θ τ xy

σ yy

= 0

σ nn

− σ x

Cos 2 θ − 2 τ xy

θ θ σ

− xy yy

Sin 2 θ

θ θ −

= 0

Solid Mechanics

σ

σ nn nn

=

=

σ x

Cos

2 y

Sin

2 θ + 2 τ xy

σ x

+

2

σ y

+

σ x

−

2

σ y

Cos 2 θ τ

θ θ xy

Sin 2 θ

F n

+ = 0

σ nt dA − σ x

θ θ τ xy

σ y

θ θ = 0

θ θ τ xy

θ θ −

τ nt

= − σ x

θ θ σ y

θ θ τ xy

τ nt

τ nt

(

Cos

2 θ − Sin

2 θ

= −

= −

(

θ

σ x

− σ

2 y

θ σ

) x

Sin

− σ y

2 θ τ

)

+ τ xy

(

Cos

2 θ − Sin

2 θ xy

Cos 2 θ

)

)

We shall now show that if you know the stress components on two mutually

⊥

planes then we can compute stresses on any inclined plane. Let us assume that we know that state of stress at a point P is given

σ ij

=

σ x

τ xy

τ xy

σ y

This also means that

Solid Mechanics

Solid Mechanics

If θ θ we can compute on AB

If θ θ

π

2

we can compute on BC

If θ θ π we can compute on CD

If θ θ

3 π

2

we can compute on DA

• σ nn

and τ nt

equations are known as transformation laws for plane stress.

• They are not only useful in determination of stresses on any plane but also useful in transforming stresses from one coordinate system to another

• Transformation laws do not require an equilibrium state and thus are also valid at all points of the body under accelerations.

• These laws are true for any point P of a body.

Invariants of stress tensor

• Any quantity for which its 2D scalar components transform from one coordinate system to another according to σ nn

and τ nt

is called a two dimensional

Solid Mechanics symmetric tensor of rank 2. Here in particular the tensor is a stress tensor.

• Moment of inertia if σ x

= I , σ y

= I ; τ xy

= − I xy

• By definition a tensor is a mathematical quantity that transforms according to certain laws, such that certain invariant properties are maintained for all coordinate systems.

• Tensors, as governed by their transformation laws, possess several properties. We now develop those properties for 2D second vent symmetric tensor.

σ nn

=

σ x

+

2

σ y

+

σ x

−

2

σ y

Cos 2 θ τ xy

Sin 2 θ

σ t

=

σ x

+

2

σ y

+

σ x

−

2

σ y

Cos 2 θ τ xy

Sin 2 θ

τ nt

= −

σ x

− σ

2 y

Sin 2 xy

Cos 2 θ

σ n

+ σ σ x

+ σ y

= σ x ′

+ σ y ′

= I

1

Solid Mechanics

I

1

= First invariant of stress in 2 D

σ σ τ 2 nt

= σ σ − τ 2 xy

= σ σ

′

− τ = I

2

I

2

= Second invariant of stress in 2 D

• I ,I are invariants of 2 D symmetric stress tensor at a point.

• Invariants are extremely useful in checking the correctness of transformation

• Of I

1

and I

2

, I

1

is the most important property : the sum of normal stresses on any two mutually

⊥ directions) is a constant at a given point.

⊥ planes

(

• In 2 D we have two stress invariants; in 3 D we have three invariants of stresses.

Solid Mechanics

Solid Mechanics

Problem :

A plane-stress condition exists at a point on the surface of a loaded structure, where the stresses have the magnitudes and directions shown on the stress element. (a) Determine the stresses acting on a plane that is oriented at a − 15 w.r.t. the x-axis (b) Determine the stresses acting on an element that is oriented at a clockwise angle of 15 w.r.t the original element.

Solution :

σ x

σ y

τ xy

= − 46

= 12

= − 19

Q = − 15

it is in C.W.

Sin 2 θ

σ x

+ σ y

2

σ x

− σ y

2

=

− +

2

=

− 34

2

= − 17 MPas

=

− −

2

=

− 58

2

= − 29 MPa

= Sin ( − ) = − . ; Cos 2 θ

σ n

= − −

σ n

1

= −

×

= Cos

+ × .

( −

Substituting θ = − 15 in τ nt

equation

τ nt

= −

σ x

− σ

2 y

Sin 2 θ τ xy

Cos 2 θ

τ = − × − × .

τ = − 31 MPa

Solid Mechanics

)

σ n

=

σ x

+

2

σ y

+

σ x

−

2

σ y

Cos 2 θ τ xy

Sin 2 θ

= .

Solid Mechanics

σ σ n

2

= τ nt θ = 75

∴ σ t

= − − cos − sin 150

σ t

= − 1 4

τ tn

= τ n t

= τ nt θ = 75

τ tn

=

= + ×

31

Sin − ×

MPa

Cos 150

Now θ = 145

σ n

= − −

= − 32 MPa

Cos × − Sin ×

τ nt

τ nt

= . Sin

= − 31 MPa

− Cos 330

0

As a check

σ n

+ σ σ x

+ σ y

= − .

− .

= − 34 MPa s

Solid Mechanics

4. Principal Stresses

Principal Stresses

Now we are in position to compute the direction and magnitude of the stress components on any inclined plane at any point, provided if we know the state of stress (Plane stress) at that point. We also know that any engineering component fails when the internal forces or stresses reach a particular value of all the stress components on all of the infinite number of planes only stress components on some particular planes are important for solving our basic question i.e under the action of given loading whether the component will ail or not? Therefore our objective of this class is to determine these plane and their corresponding stresses.

(1) σ n

= ( ) =

σ n

+

2

σ y

+

σ n

−

2

σ y

Cos 2 θ τ xy

Sin 2 θ

(2) Of all the infinite number of normal stresses at a point, what is the maximum normal stress value, what is the minimum normal stress value and what are their

Solid Mechanics corresponding planes i.e how the planes are oriented ? Thus mathematically we are looking for maxima and minima of

σ n function..

(3) σ n

=

σ n

+

2

σ y

+

σ n

−

2

σ y

Cos 2 θ τ xy

Sin 2 θ

For maxima or minima, we know that d d

σ

θ n 0

(

σ x

− σ y

)

Sin 2 θ + 2 τ xy

Cos tan 2 θ =

2 τ xy

σ x

− σ y

(4) The above equations has two roots, because itself after π . Let us call the first root as θ

P

1 tan repeats tan 2 θ

P

1

=

2 τ xy

σ x

− σ y tan 2 θ

P

2

= tan

(

2 θ

P

1

+ π

)

=

2 τ xy

σ x

− σ y

Solid Mechanics

θ

P

2

= θ

P

1

+

π

2 s

(5) Let us verify now whether we have minima or minima at

θ

P

1

and θ

P

2

∴ d d

2 σ

θ 2 n d d

2 σ

θ 2 n

= − 2

(

σ x

− σ y

)

Cos 2 θ − 4 τ xy

Sin 2 θ

= − 2

(

σ x

− σ y

)

Cos 2 θ

P

1

− 4 τ xy

Sin 2 θ

P

1

P

1

We can find Cos 2 θ

P

1 s and Sin 2 θ

P

1 s as

Cos 2 θ

P

1

=

2

σ x

− σ y

2 σ x

− σ y

2

+ τ 2 xy

Sin 2 θ

P

1

=

2

2 τ xy

σ x

− σ

2 y

2

+ τ 2 xy

=

Substituting Cos 2 θ

P

1

and Sin 2 θ

P

1

τ xy

σ x

− σ

2 y

2

+ τ 2 xy

d d

2 σ

θ 2 n

=

=

P 1

Solid Mechanics

=

− 2

(

σ x

− σ y

)(

σ x

− σ y

)

2

2

σ x

− σ y

2

+ τ 2 xy

−

−

(

σ x

− σ y

) 2

σ x

− σ y

2

2

+ τ 2 xy

−

4 τ 2 xy

σ x

− σ

2 y

4

σ x

− σ

2 y

2

+ τ 2 xy

2

+ τ 2 xy

− 4

σ x

− σ y

2

2

+ τ 2 xy

σ x

− σ y

2

2

+ τ 2 xy

∴ d d

2 σ

θ 2 n = − 4

σ x

− σ y

2

2

+ τ 2 xy

(-ve) d 2 d θ

σ

2 n

θ θ θ

π

2

= 2

(

σ σ y

)

Cos

(

2 θ

P

1

π

)

4 τ xy

Sin

(

2 θ

P

1

+ π

)

= 2

(

σ σ y

)

Cos 2 θ

P

1

+ 4 τ xy

Sin 2 θ

P

1

Substituting Cos 2 θ

P

1

&Sin 2 θ

P

1 m we can show that

∴ d d

2 σ

θ 2 n

P 2

= − 4

σ x

− σ

2 y

2

+ τ 2 xy s (+ve)

Solid Mechanics

Thus the angles θ

P

1 s and θ

P

2 s define planes of either maximum normal stress or minimum normal stress.

(6) Now, we need to compute magnitudes of these stresses

We know that,

σ n

=

σ x

+

2

σ y

+

σ x

−

2

σ y

Cos 2 xy

Sin 2 θ

σ n

P 1

= σ

1

=

σ x

+

2

σ y

+

σ x

−

2

σ y

Cos 2 θ

P

1

+ τ xy

Sin 2 θ

P

1

Substituting Cos 2 θ

P

1 s and Sin 2 θ

P

1

σ

1

=

σ x

+ σ

2 y

+

σ x

− σ

2 y

2

+ τ 2 xy

Similarly,

τ

σ n xy

θ θ

P 2

= θ

P 1

=

π

2

Sin

(

2 θ

P

1

+ π

)

= σ

2

=

σ x

+

2

σ y

+

σ x

−

2

σ y

Cos

(

2 θ

P

1

+ π

)

+

=

σ x

+

2

σ y

−

σ x

−

2

σ y

Cos 2 θ

P

1

− τ xy

Sin 2 θ

P

1

Substituting Cos 2 θ

P

1

and Sin 2 θ

P

1

σ =

σ x

+ σ

2 y

−

Solid Mechanics

σ x

− σ

2 y

2

+ τ 2 xy

We can write

σ

1 or σ

2

=

σ x

+ σ y

2

±

σ x

− σ

2 y

2

+ τ 2 xy

(7) Let us se the properties of above stress.

(1) θ

P

2

= θ

P

1

+

π

2 s - planes on which maximum normal stress and minimum normal stress act are ⊥ to each other.

(2) Generally maximum normal stress is designated by and minimum stress by σ

2

. Also θ

P

1

→

P

2

→ σ

2

σ

1

σ

1

> σ

0 −

2

− 1000 − alg ebraically i.e.,

σ

σ

1

2

Solid Mechanics

(4) maximum and minimum normal stresses are collectively called as principal stresses.

(5) Planes on which maximum and minimum normal stress act are known as principal planes.

(6) θ

P

1

and θ

P

2

that define the principal planes are known as principal directions.

(8) Let us find the planes on which shearing stresses are zero.

τ nt

0

(

σ x

− σ y

)

Sin 2 xy

Cos θ tan 2 θ =

2 τ xy

σ x

= σ y

= directionsof principal plans

Thus on the principal planes no shearing stresses act.

Conversely, the planes on which no shearing stress acts are known as principal planes and the corresponding normal stresses are principal stresses. For example the state of stress at a point is as shown.

Then σ x

and σ y

are principal stresses because no shearing stresses are acting on these planes.

Solid Mechanics

(9) Since, principal planes are

⊥

to each other at a point P , this also means that if an element whose sides are parallel to the principal planes is taken out at that point P , then it will be subjected to principal stresses. Observe that no shearing stresses are acting on the four faces, because shearing stresses must be zero on principal planes.

(10) Since σ

1

and say that

σ

2

are in two

⊥

directions, we can easily

σ x

+ σ y

= σ

1

+ σ

2

= σ x ′

+ σ y ′

= I

1

Solid Mechanics

5. Maximum shear stress

Maximum and minimum shearing stresses

So far we have seen some specials planes on which the shearing stresses are always zero and the corresponding normal stresses are principal stresses. Now we wish to find what are maximum shearing stress plane and minimum shearing stress plane. We approach in the similar way of maximum and minimum normal stresses

(1) τ nt

= −

σ x

− σ

2 y

Sin 2 xy

Cos 2 θ d τ d θ nt = −

(

σ x

− σ y

)

Cos 2 θ τ xy

Cos

For maximum or minimum d τ d θ nt 0

(

σ x

− σ y

)

Cos 2 θ − 2 τ xy

Sin tan 2 θ =

−

(

σ x

2 τ

− xy

σ y

)

This has two roots tan 2 θ

S

1

= −

(

σ x

− σ

2 τ xy y

)

tan 2 θ

S

2

= tan

(

2 θ

S

1

+ π

)

=

Solid Mechanics

−

(

σ x

2 τ

− xy

σ y

)

∴ θ

S

2

= θ

S

1

+

π

2

Now we have to show that at these two angles we will have maximum and minimum shear stresses at that point.

Similar to the principal stresses we must calculate d d

2 τ

θ nt

2

= 2

(

σ x

− σ y

)

Sin 2 θ − 4 τ xy

Cos 2 θ

Cos 2 θ

S

1 d d

2 τ

θ nt

2

=

2

= 2

(

σ x

− σ y

)

Sin 2 θ

S

1

S

1

2 τ xy

σ x

− σ

2 y

2

+ τ 2 xy

− 4 τ xy

Cos 2 θ

S

1

Sin 2 θ

S

1

=

2

−

(

σ x

− σ y

)

σ x

− σ y

2

2

+ τ 2 xy

Substituting above values in the above equation we can show that

Solid Mechanics d

2 τ d θ nt

2

= - ve

S 1

Similarly we can show that d d

2 τ

θ nt

2

θ θ

S 2

= θ

S 1

+

π

2

= + ve

Thus the angles θ

S

1 and θ

S

2 define planes of either maximum shear stress or minimum shear stress. Planes that define maximum shear stress & minimum shear stress are again

⊥ to each other.. Now we wish to find out these values.

τ nt

τ nt

= −

θ θ

S

1

(

σ x

− σ y

)

2

= −

Sin 2

(

σ x

− σ y

)

2 xy

Cos 2 θ

Sin 2 θ

S

1

+ τ xy

Cos 2 θ

S

1

Substituting Cos 2 θ

S

1

and Sin 2 θ

S

1 s , we can show that

τ nt θ θ

S 2

= θ

S 1

+

π

2

τ max

= +

= −

(

σ x

− σ y

)

2

σ x

− σ y

2

Sin

(

Substituting Cos 2 θ

S

1

and Sin 2 θ

S

1

2

+ τ 2 xy

2 θ

S

1

+

) xy

Cos

(

2 θ

S

1

+ π

)

τ min

= −

σ x

− σ

2 y

2

+ τ 2 xy

Solid Mechanics

τ max

is algebraically > τ min

, however their absolute magnitude is same. Thus we can write

τ max or τ min

= ±

σ x

− σ y

2

2

+ τ 2 xy

Generally

τ

τ max

− θ

θ

S min

−

S

2

1

Q. Why τ max

and τ min

are numerically same. Because

θ

S

2

are ⊥ planes.

θ

S

1

&

(2) Unlike the principal stresses, the planes on which maximum and minimum shear stress act are not free from normal stresses.

Solid Mechanics

σ n

=

σ x

+

2

σ y

+

σ x

−

2

σ y

Cos 2 θ τ xy

θ

σ n θ θ

S

1

=

σ x

+

2

σ y

+

σ x

−

2

σ y

Cos 2 θ

S

1

+ τ xy

Sin 2 θ

S

1

Substituting Cos 2 θ

S

1

and Sin 2 θ

S

1 n

S 1

=

σ x

+ σ y

2

σ

+ τ n θ θ

S

2

= θ

S

1

+

π

2 xy

Sin

(

=

2 θ

S

1

+ π

)

σ x

+

2

σ y

+

σ x

−

2

σ y

Cos

(

2 θ

S

1

+ π

)

Simplifying this equation gives n

S

2

=

σ x

+ σ

2 y

Therefore the normal stress on maximum and minimum shear stress planes is same.

(3) Both the principal planes are planes of τ max

and min

⊥ to each other and also the

τ are also ⊥ to each other. Now let us see there exist any relation between them.

Solid Mechanics

6. Mohr’s circle

Mohr’s circle for plane stress

So far we have seen two methods to find stresses acting on an inclined plane

(a) Wedge method

(b) Use of transformation laws.

Another method which is purely graphical approaches is known as the Mohr’s circle for plane stress.

A major advantage of Mohr’s circle is that, the state of the stress at a point, i.e the stress components acting on all infinite number of planes can be viewed graphically.

Equations of Mohr’s circle

We know that, σ n

=

σ x

+

2

σ y

+

σ x

−

2

σ y

Cos 2 θ τ xy

Sin 2 θ

This equation can also be written as

σ n

τ

−

σ x

+

2

σ y

=

σ x

−

2

σ y nt

= −

σ x

− σ

2 y

Cos 2

Sin 2 xy xy

Cos

Sin 2 θ

2 θ

σ n

−

( x

σ x

+ σ y

2

↓

− a ) 2

+

2

+ τ 2 nt

=

↓ y 2 =

σ x

+ σ y

2

↓

R 2

2

+ τ 2 xy

The above equation is clearly an equation of circle with center at a on τ σ plane it represents a circle with center at

σ x

+

2

σ y

, 0 and having radius

R =

σ x

− σ

2 y

+ τ 2 xy

This circle on

Mohr’s circle.

σ τ plane-

From the above deviation it can be seen that any point P on the Mohr’s circle represents stress which are acting on a plane passing through the point.

In this way we can completely visualize the stresses acting on all infinite planes.

Solid Mechanics

Solid Mechanics

(3 ) Construction of Mohr’s circle

Let us assume that the state of stress at a point is given

A typical problem using Mohr’s circle i.e given σ σ y ′

and

τ on an inclined element. For the sake of clarity we assume that, σ σ y ′ s and τ all are positive and σ x

> σ y

Solid Mechanics

• Since any point on the circle represents the stress components on a plane passing through the point.

Therefore we can locate the point A on the circle.

• The coordinates of the plane A

(

σ x

, + τ xy

)

Therefore we can locate the point A on the circle with coordinates

(

+ σ x

, + τ xy

) s

• Therefore the line AC represents the x-axis. Moreover, the normal of the A -plane makes 0 w.r.t the x -axis.

• In a similar way we can locate the point B corresponding to the plane B .

Solid Mechanics

The coordinates of B

(

σ y

, − τ xy

) s

Since we assumed that for the sake of similarity σ y

< σ x s .

Therefore the point B diametrically opposite to point A .

• The line BC represents y - axis. The point A corresponds to Q = 0 , and pt. B corresponds to Q = 90 (+ve) of the stress element.

At this point of time we should be able to observe two important points.

• The end points of a diameter represents stress components on two ⊥ planes of the stress element.

• The angle between x - axis and the plane B is 90 ° (c.c.w) in the stress element. The line CA in Mohr’s circle represents x - axis and line CB represents y -axis or plane

B . It can be seen that, the angle between x -axis and y axis in the Mohr’s circle is 180 ° (c.c.w). Thus 2 Q in

Mohr’s circle corresponds to Q in the stress element diagram.

Stresses on an inclined element

• Point A corresponds to

Q = 0

on the stress element.

Therefore the line CA i.e x -axis becomes reference line from which we measure angles.

• Now we locate the point “ D ” on the Mohr’s circle such that the line CD makes an angle of 2 Q c.c.w from the x axis or line CA . we choose c.c.w because in the stress element also Q is in c.c.w direction.

Solid Mechanics

• The coordinates or stresses corresponding to point D on the Mohr’s circle represents the stresses on the x ′

- face or

D on the stress element.

σ x ′

= σ avg

τ =

+

RSin β

RCos β

σ y ′

= σ avg

− RCos β stress element,thenthey become diametrically opposite point son thecircle, just likethe planes A& Bdid

Calculation of principal stress

The most important application of the Mohr’s circle is determination of principal stresses.

The intersection of the Mohr’s circle --- with normal stress axis gives two points P

1

and P

2

. Thus P

1

and P

2

represents points corresponding to principal stresses. In the current diagram the coordinates the of

P

1

P

2

=

=

σ

σ

1

2

σ

1

= σ avg

, 0

+ R

σ

2

= σ avg

− R

The principal direction corresponding to σ

2 θ p

1

, in c.c.w direction from the x-axis.

1

is now equal to

Solid Mechanics

θ p

2

= θ p

1

±

π

2

We can see that the points P

1

and P

2

are diametrically opposite, this indicate that principal planes are ⊥ to each other in the stress element. This fact can also be verified from the Mohr’s circle.

In- plane maximum shear stress

What are points on the circle at which the shearing stress are reaching maximum values numerically? Points the top and bottom of the Mohr’s circle.

S

1

and S

2

at

• The points S

1 points P

1

P

2

and S

2

are at angles 2 θ = 90 from

and, i.e the planes of maximum shear stress are oriented at ± 45 to the principal planes.

• Unlike the principal stresses, the planes of maximum shear stress are not free from the normal stresses. For example the coordinates of

S

1

S

2

= + τ max

, σ avg s

= − τ max

, σ avg

τ max

= ± R avg

Mohr’s circle can be plotted in two different ways. Both the methods are mathematically correct.

Solid Mechanics

Finally

• Intersection of Mohr’s circle with the principal stresses.

σ -axis gives

• The top and bottom points of Mohr’s circle gives maximum –ve shear stress and maximum +ve shear stress.

• Do not forget that all these inclined planes are obtained by rotation about z -axis.

Mohr’ circle problem

Solution:

σ x

+

2

σ y

=

2

A - (15000,4000)

B - (5000,-4000)

R =

σ x

− σ y

2

2

+ τ 2 xy

=

(a)

= 5000

2 + 4000

2

R

σ x

= 6403

− σ y

2

MPa

= 5000

= 10000 MPa

2

Solid Mechanics

2

+ 4000

2

Point D : σ x ′

τ

= + Cos .

= − 6403 Sin .

Solid Mechanics

= MPa

= − 4229 MPa

Point D ′ : σ n

= σ y ′

=

τ nt

= τ

− Cos .

= 6403 Sin .

=

= 4229

MPa b) σ

1

= 16403 ; θ

P

1

=

σ

2

= 3597 MPa

2

= c) τ max

= 6403 MPa − θ

S

1

= .

= − .

Solid Mechanics

(2) θ = 45

Principal stresses and principal shear stresses.

Solution :

σ x

+

2

σ y

=

R =

σ x

− σ y

2

2

= − 20

2

+ τ 2 xy

=

A

B → (

( 50 40

)

)

2 p

1 p

2

= σ

1

=

σ x

+ σ y

= σ

2

=

σ x

2

+ σ y

2

2

( 40 ) 2 = 50 MPa

R = s

R 20 50 = − 70

Solid Mechanics

2 Q p

1

Q p

1

=

=

Q p

2

=

2 Q

Q s

1 s

1

=

=

Q s

2

=

Solid Mechanics

Q. σ x

= 31 MPa, σ y

= − 5 MPa and τ xy

= 33 MPa

Stresses on inclined element θ = 45

Principal stresses and maximum shear stress.

Solution :

σ avg

=

σ x

+ σ y

2

=

2

= 13 MPa

R =

σ x

− σ

2 y

2

+ τ 2 xy

=

A ( 31 33 )

B ( 5 33 )

τ

σ x ′

=

= RCos β σ avg s

+ = MPa

= − RSin β = − .

.

= − .

σ y ′

= RCos β σ avg

= − 20 MPa

∴ σ

1

=

σ

2

= −

θ p

1

=

τ max

=

τ min

σ σ

= − avg

= 13

−

MPa

θ s

1

= −

Solid Mechanics

Solid Mechanics

7. 3D-Stress Transformation

3D-stress components on an arbitrary plane

Basically we have done so far for this type of coordinate system

ˆ i n

′ = n n

ˆ i + n n ˆ

− j

D i r . c o s i n e s o f x ′

+ n

ˆ k n y x n

′ n

′

ˆ ˆ ˆ n z x n

′ n

′

ˆ ˆ ˆ

T n

= ˆ + ˆ + ˆ

T n

= σ i

ˆ ′ + τ ˆ j ′ + τ ˆ k ′

Solid Mechanics

[

F x

→ + = ]

T da = σ x dAn x x

+ τ yx dAn x y

+ τ zx dAn

T

T

T

= σ

= τ

= τ n + τ n

′

+ τ n

′ n + σ n + τ n

′ n + τ n

′

+ σ n

τ

σ x ′

τ τ

σ y ′

τ

τ τ σ z ′

σ τ x y

, τ x z

τ

τ

σ x ′

= T i

ˆ ′ =

(

ˆ + ˆ + ˆ

) (

=

=

ˆ ′ =

(

ˆ + ˆ + ˆ

ˆ ′ =

(

ˆ + ˆ + ˆ

) (

) (

σ y ′

σ z ′

=

(

=

(

ˆ

ˆ

ˆ

ˆ

T

T

T

ˆ +

ˆ +

ˆ +

ˆ +

ˆ +

ˆ +

ˆ

)

(1)

ˆ

ˆ

)

(2)

)

(3)

= σ

= τ

= τ

)(

)( n + τ n

′

+ τ n

′ n + σ n + τ n

′ n + τ n

′

+ σ n

ˆ

ˆ

ˆ

ˆ ˆ

)

(4)

ˆ

)

(5)

τ =

(

ˆ n = Cos θ n = Sin θ n n n = 0 n

ˆ

)(

ˆ

= − Sin θ

= Cos θ n n

= 0 n

ˆ

= 0

= 0

= 1

ˆ

Solid Mechanics

)

(6)

σ z ′

= 0

= σ z

: τ = 0 : τ = 0

σ x ′

= σ x

Cos

2 y

Sin

2 θ + 2 τ xy

θ θ

τ

σ y ′

= σ

= − x

(

Sin

σ x

2

− σ y

) y

Cos

2 θ − 2 τ

θ θ τ xy xy

θ θ

(

Cos

2 θ − Sin

2 θ

)

Principal stresses n ,n ,n z

T n

= σ = σ

( x

ˆ + ˆ +

T n

= nx

ˆ + ˆ + ˆ z

ˆ

)

σ x

τ xy

τ xy

σ y

0

0

0 0 0

Where

T nx

T ny

T nz

=

=

= τ

τ

σ n + τ n + τ n

+ σ n + τ n n + τ n + σ

Tn x

= σ n Tn y

= σ n Tn z

= σ n z

Solid Mechanics

τ

τ

( σ x

− σ )

( n x

+ τ

+ σ y

− σ

) n + τ n n + τ n n y

+ τ

+ ( σ z

− σ ) n z

= 0

= 0

= 0

Syst.of linear homog.eqns.

n x

= n y

= n z

= 0 : n

2 x

+ n

2 y

+ n

2 z

= 1

σ x

− σ τ xy

τ xy

σ y

− σ τ

τ zx zy

τ zx

τ yz n x n y n z

=

For non trivial solution must be zero.

−

σ 3 −

(

σ x

+ σ y

+

)

2 +

(

σ σ + σ σ + σ σ − τ 2 xy

− τ 2 yz

−

)

(

σ σ σ + 2 τ τ τ − σ τ 2 − σ τ 2 − σ τ 2 z xy

)

= 0

This has 3- real roots σ σ σ

3

τ

( σ x

− σ

+

1

(

σ

) n x

+ τ n + τ n y

− σ

1

) n y

+ τ n

= 0

= 0 and n + n + n = 1 n ,n ,n z

→

σ

1

> σ

2

> σ

3

σ

1

Stress invariants

σ 3 − I

1

σ 2 + I

2

σ I

3

0 (1)

Solid Mechanics

I

1

= σ x

+ σ y

+ σ z

I

2

= σ σ + σ σ + σ σ τ 2 − τ 2 − τ 2 x z xy yz zx

I

3

= σ σ σ + 2 τ τ τ − σ τ 2 − σ τ 2 − σ τ 2 z xy

σ 3 − I ′

1

σ 2 ′

3

0 stress inv ar iants

I ′

1

= σ x ′

+ σ y ′

+ σ z ′

I ′

2

= σ σ

′

+ σ σ + σ − τ 2

′ ′

− τ 2 − τ 2

I

1

I

2

I

3

=

=

=

σ

1

σ σ

σ σ

+ σ

σ

+

3

3D

2

+ σ

σ σ

3

I

1

=

1 2

= ′

2 3

= I ′

3

+ σ σ

Principal planes are orthogonal

2D

I

1

I

2

I

3

= σ

1

+ σ

=

2

= 0

ˆ ˆ

= ˆ + y

ˆ + z

ˆ

′ =

′

ˆ + y ′

ˆ + z ′

ˆ

T n

= ˆ + ˆ + ˆ

T n ′

= ˆ + ˆ + ˆ

Solid Mechanics

τ xy

ˆ

= n ′

ˆ

τ yx

ˆ n n ′ n ′

ˆ

( σ

1

) = ( σ

2

′ )

σ

1

( n n

′

+ n n

′

+ n n

′ n n

′

+ n n

′

+ n n

′

)

σ

1

≠ σ

2 n n

′

+ n n

′

+ n n

′

= 0

′ must be ⊥ to each other.

The state of stress in principal axis

σ

0

1

0 0

σ

0 0

2

σ

0

3

T n x

T n y

T n z

= σ

1 n x

= σ

2 n y

= σ

3 n z

σ n

= σ

1 n 2 x

+ σ

2 n 2 y

+ σ

3 n 2 z

T n

2

= T

2 n x

+ T

2 n y

+ T s

= σ 2 2

1 x

+ σ 2 2

2 y

+ σ 2 2

3 n z

τ 2 = T n

2

− σ 2 n

Solid Mechanics

8. 3D Mohr’s circle and Octahedral stress

3-D Mohr’s circle & principal shear stresses

σ ij

=

σ x

τ xy

τ xy

σ y

0 0

0

0

σ z

Once if you know σ

1 and σ

2

τ

τ

τ

1

σ

τ

2

σ

τ

3

σ

τ

2

1

=

σ

σ

2

−

2

σ

=

=

σ

1

1

+

−

2

2

σ

σ

3

=

σ

1

+ σ

2

3

3

2

3

=

=

σ

1

− σ

2

σ

1

− σ

2

2

2

σ

1

> σ

2

> σ

3

τ max

= max

σ σ σ

2

2

−

2

σ σ

3

−

2

σ

1

Solid Mechanics

• The maximum normal stress stress

σ

1

and maximum shear

τ max

and their corresponding planes govern the failure of the engineering materials.

• It is evident now that in many two-dimensional cases the maximum shear stress value will be missed by not considering σ

3

= 0 and constructing the principal circle.

Solid Mechanics

Problem:

The state of stress at a point is given by

τ

σ x xy

=

=

100

τ yz

MPa,

= τ zx

=

σ

0 y

= − 40 MPa, σ z

= 80 MPa and

Determine in plane max shear stresses and maximum shear stress at that point.

Solution:

σ

1

= 100 MPa, σ

2

= 80 MPa

τ

τ

12

13

=

σ

1

− σ

2

2

=

σ

1

− σ

2

3

=

=

τ

σ

23

12

σ

σ

13

23

=

=

σ

2

− σ

2

3

=

=

σ

30

1

+ σ

2

2

MPa

20 MPa

=

= 90

2

2

2

σ

3

= − 40 MPas

= 10 MPa

= 70 MPa

= 60 MPa

τ max

= max τ τ τ

τ max

= 70 MPa This occurs in the plane of 1-3

τ τ τ → Principal shear stress in 3 D

τ max

= max

( τ τ τ )

Solid Mechanics

Solid Mechanics

Plane stress

σ

σ

1

3

>

=

σ

σ z

= 0

τ = ±

σ x

− σ

2 y

2

+ τ 2 xy

---- in plane principal shear stresses.

τ max

=

σ σ

2

3 =

σ

2

1

Solid Mechanics

Problem

At appoint in a component, the state of stress is as shown.

Determine maximum shear stress.

Solution:

σ ij

=

100 0

0 50

- plane stress problem

We can also write the matrix as a ij

=

100 0 0

0 50 0

0 0 0

σ

σ

1

2

=

=

100

50

σ

1

− σ

2

2 =

2

τ max

= 25 MPa

= 25

Now with σ

1

= 100 , σ

2

= 50 , σ

3

= 0

τ max

=

2

3 = 50 MPa

Occurs in the plane 1-3 instead of 1-2

Solid Mechanics

Solid Mechanics

Some important states of stresses

(1) Uniaxial state of stress : Only one non-zero principal stress.

σ

1

0 0

0 0 0

0 0 0

=

σ

1

0

0 0

- plane stress.

(2) Biaxial state of stress : two non-zero principal stresses.

σ

0

1

0 0

σ

1

0

0 0 0

=

σ

0

1

0

σ

1

- plane stress

(3) Triaxial state of stress : All three principal stresses are non zero.

σ

0

1

0 0

σ

0 0

2

σ

0

3

− 3 D stress

(4) Spherical state of stress : σ

1

= σ

2

= σ

3

(either +ve or – ve)

σ

0

0 0

σ

0 0

0 − 3 D stress-special case of triaxial stress.

σ

Solid Mechanics

(5) Hydrostatic state of stress

+

0

0

P 0 0

+ P 0

0 + P

hydrostatic tension

−

0

0

P 0 0

− P 0

0 − P

hydrostatic compression.

(6) The state of pure shear

σ ij

=

σ x

τ xy

τ xz

τ xy

σ y

τ yz

τ zx

τ zy

σ z

σ ij

=

0 τ

τ

τ τ

0 τ

τ

0

Then we say that the point P is in state of pure shear .

I

1

= 0 shear

is necessary and sufficient condition for state of pure

Solid Mechanics

Octahedral planes and stresses

If n x

= n y

= n z

w.r.t to the principal planes , then these planes are known as octahedral planes. The corresponding stresses are known as octahedral stresses.

Eight number of such planes can be identified at a given point ---

Octahedron

T n

2

=

1 n

2 x

σ

+

2 2

1 n x

σ

2 n

2 y

+ σ

+

2 2

2 n y

σ

3 n

2 z

+ σ 2 2

3 n z n

2 x

+ n

2 y

+ n

2 z

= 1 n x

= n y

= n z

= ±

1

3

=

σ oct

=

=

σ

σ

1

1

+ σ

1

3

2

3

+

2

σ

+

3

σ

1

1

3

2

+ σ

1

0

1

3

2

Solid Mechanics

σ

1

+ σ

3

2

+ σ

3 =

3

1

σ oct

= canbeint erpreted − − meannormalstress at a pt.

τ oct

= T n

2

− σ 2 oct

τ oct

=

1

3

(

2

) 2 + ( σ

2

− σ

3

+ σ

3

− σ

1

) 2

Therefore, the state of stress at a point can be represented with reference to

(i) stress components of x,y,z coordinate system

(ii) stress components of x’,y’z’ coordinate system

(iii) using principal stresses

(iv) using octahedral shear and normal stresses

We can prove that:

τ oct is smaller than planes at a point.

τ max

(exist only on 4 planes) but can exist on 8

Solid Mechanics

Decomposition into hydrostatic and pure shear stress

σ ij

=

σ x

τ xy

τ xz

τ yx

σ z

τ yz

τ zx

τ zy

σ z

Mean stress P =

σ x

+ σ y

+ σ z

3

=

I

3

1

σ x

τ xy

τ xz

τ yx

τ y

τ yz

τ zx

τ zy

σ z

=

P 0 0

0 P

0 0

0

P

+

Hydrostatic stat of stress

Dilitationalstress

σ x

−

τ yx

τ zx

P τ xy

σ y

−

τ zy

P

σ z

τ xz

τ yz

− P

State of pureshear

Deviatoric state of stress

Stress deviator

Thus the state of the stress at a point can alos be represented by sum of dilational stress and stress deviator

σ

0

1

0 0

σ

0 0

2

σ

0

3

=

Solid Mechanics

P =

σ

1

+ σ

3

2

+ σ

3 =

I

3

1

P

0

0 0

P 0

0 0 P

+

σ

1

0

− P

0

0

σ

2

0

− P

0

σ

3

0

− P

σ

1

= mean stress + deviation from the mean

The deviatoric and octahedral shear stresses are the answer for the yielding behavior of materials – which is a type of failure of materials .

Solid Mechanics

9. Deformation and strain analysis

( ) ˆ + ( ) ˆ + ( ) ˆ

(

( )

)

( )

(x,y,z) is the point in the undeformed geometry

Two types of deformation have been observed for an infinitesimal element.

Deformation of the whole body = Sum of deformations of

Deformation is described by measuring two quantities .

(1)Elongation or contraction of a line segment

(2)Rotation of any two ⊥ lines .

Measure of deformations of an infinitesimal element is known as strain .

• The strain component that measures elongation or construction – normal strain -

ε

• The strain component that measures rotation of any two

⊥ lines is – shearing strain-

γ

Solid Mechanics

Normal strain points.

ε - Account for changes in length between two

∈ n

( ) = lim

∆ → 0

P Q − PQ

PQ

= lim

0

∆ − ∆ s

∆ s

We can also define the same point x

, , z

(1) By definition ∈ x

is + if

∈ x

is - if s

* s

* s s s lim as

* ( 1

∆ → n

)

0 s

∆ s

* ( 1 ) s if s s s s

0

(2) It is immaterial how P Q is oriented finally. However for

∈ n

we must consider PQ in the direction of ˆn in the undeformed geometry

(3) In general ∈ =∈ n

( )

(4) No units.

Mm/mm,0.5%=0.005;

µ = 10

− 6 , µ

(5) Meaning of ∈ nn

Shearing strain -

= × − 6 = .

mm / mm

Accounts the change in angle

Y n +

( ) Change in angle between

⊥ lines in ˆn& t ˆ direction.

( ) x y

0

0

π φ nt

= lim x y

0

0

Solid Mechanics

(1)We must select two ⊥ lines in the undeformed geometry.

(2)Units of Y nt

→ radius.

(3)By deflection Y nt

= Y tn

(4)Two subscripts are required for

Y - to show directions of initial infinitesimal line segments.

(5) Y nt

is +ve if angle is decreased

Y nt

is -ve if angle is more.

By taking two ⊥ lines

We can define ∈ ∈ nt

Rectangular strain components

∈ ∈ y andY xy

− PQRS

∈ ∈ y andY yz

− QABS

∈ ∈ xz

− RSCD

E ij

=

∈

Y

Y x xy xz

Y xy

Y xz

∈ y

Y yz

Y yz

∈ z

Rectangular strain components .

We then say that we have strain computer associated with x,y,z coordinate system.

They represent the state of strain at a point , since we can determine strain along any direction ˆn

lim x

*

∆ → 0 x

Solid Mechanics

Strain displacement relations : Strains are due to deformation as displacement so there must be some relation between deformational displacements and strains. So let us consider the side of the element PQRS . We shall demonstrate that ‘ w ’ has no impact. So it can be neglected.

P → u,v

Q u

∂

∂ u x

∆ x ; v +

∂

∂ v x

∆ x

PQ = ∆ x

= ∆ x

*

∆ x * ( 1 ) x

( ) x

=

1

∂ u

∂ x

2 ∂ v

∂ x

2

+ ∆ x + ∆ x +

+

∂

∂ u x

+

∂

∂ u x

2

+

∂

∂ v x

2

+

∂ w

∂ x

∆ x

2 ∂ w

∂ x

2

∆ x

Solid Mechanics lim

∆ → 0

∆ − ∆ x

∆ x

= lim

0

∈ = 1 2

∂

∂ u x

+

∂

∂ u x

+

∂

∂ u x

∂

∂ u x

2

+

∈ = 1 2

∂

∂ v y

+

∂

∂ u y

2

+

2

+

∂

∂ v x

∂ v

∂ x

2

+

∂

∂ v y

2

+

2

+

∂

∂ w x

∂ w

∂ x

2

− 1

2

− 1

∂

∂ w y

2

− 1

∈ = 1 2

∂

∂ w z

+

∂

∂ u z

2

+

∂ v

∂ z

2

+

∂

∂ w z

2

− 1

So far no assumption has been made except for size of x, y& z

Cos φ * xy

= 1 +

∂

∂ u x

∆

∆ x x

*

∂

∂ u y

∆

∆ y y

*

+

∂ ∆

∂ x ∆ x *

1 +

∂ v

∂ y ∆

∆ y y

*

+

∂ ∆

∂ x ∆ x *

∂

∂ w y ∆

∆ y y

*

Y xy

= lim x y

∆ →

0

0

0

π φ

* xy

Solid Mechanics

SinY xy

= lim Cos x y

∆ →

0

0

0

φ * xy

SinY xy x * y *

= lim x y

∆ →

0

0

0

( 1 )

(

1

) x y

1 + + 1 + v v

∂ ∂

+ w w

∂ ∂

∆ ∆

∆ ∆ *

SinY xy

= lim x y

∆ →

0

0

0

∂

∂ u y

+

∂

∂ v x

+ u u x y

+ v v x y

+ w w x y

( 1 + ∈ x

) (

1 + ∈ y

)

Y xy

=

Sin

− 1

Y yz

= sin

− 1

∂

∂ u y

+

∂

∂ v x

+ u u x y

+ v v x y

+ w w x y

( 1 +∈ x

) (

1 +∈ y

)

∂

∂ u y

+

∂

∂ v x

+ u u x y

+ v v x y

+ w w x y

( 1 + ∈ x

) (

1 + ∈ y

)

Y xz

= sin

− 1

∂

∂ w x

+

∂

∂ u w

(

+

1 w w

∂ ∂

+∈ x

)(

+

1 u u

∂ ∂

+∈ z

)

+ v v

∂ ∂

All bodies after the application of loads under go “small deformations”

Solid Mechanics

Small deformations :

(1) The deformational displacements infinitesimally small .

= ˆ + + are

(2) The strains are small

(a) Changes in length of a infinitesimal line segment are infinitesimal.

(b) Rotations of line segment are also infinitesimal.

∂ ∂ ∂ ∂

∂ ∂ ∂ ∂

1 ∈ x

1 ; 1 ; z

1 ;

∂

∂ u x

2

; are negligible compare to quantities.

∈ = 1 2

2 ∂ u

∂

∂ u x

∂ x

2

− 1

− 1

∂ u

∂

∂ x v

∂ y

∂ w

∂ z

SinY xy

≈ Y xy

Solid Mechanics

Y xy

=

∂

∂ u y

+

∂

∂ v x

(

1 + ∈ +∈ y

) =

∂

∂ v x

+

∂

∂ u y

Y xz

Y yz

=

=

∂

∂

∂

∂ w v z x

+

+

∂

∂

∂

∂ u w y z

Another derivation : Let us take plane PQRS in xy plane.

Also assume that

( ) ( )

only.

Small deformation

Displacements are small

Strains are small lim

∆ → 0

P Q −

PQ

PQ

= x

∆ x x

∆ x

*

P Q

′ lim

∆ → 0

1

= 1 +

∂

∂ y x

∆ x

+

∂ y

∂ x

∆ x x x

=

∂ u

∂ x lim

0

1 +

∂

∂ v y y y

∆ y

=

∂ v

∂ y

Strains<0.001

Y < .

∆ = 0 2002 s

− 4 mm

Solid Mechanics

Y xy

= x y lim

0

0

− * xy

= x y lim

0

0 tan α =

1

∂

∂ x

+ v

∂ y

∂

∆ x x

∆ x

=

1

∂ v

∂ x

+

∂ y

∂ x

α

β

=

=

∂ v

∂

∂ x u

∂ y

Y xy tan α α

=

∂

∂ u y

+

∂

∂ v x

∂ ∂ ∂ ∂

∂ ∂ ∂ ∂

2

2

∂ u

∂ x

,

∂ u

∂ y

,

1

∂ v

∂ yx

2

We can define the state of strain at point by six components of strains

∈ ∈ ∈ Y , Y , Y yz

↓ ↓ ↓

Y yx

Y zx

Y zy

State of strain

∈ x

Y xy

E ij

= Y xy

∈ y

Y xz

Y yz

Y

Y

∈ xz yz z

-

-

Engineering strain matrix

We can find ∈ n

in any direction we can find Y nt for any two arbitrary directions.

∈ =

Y yz

=

0

0

Y zx

= 0

2D- strain transformation

Plain strain : In which

∈ x

Y xy

Y xy

∈ y

∈ =∈ x

∈ =∈ y

( )

( )

Y xy

= Y xy

( ) implication of these equation is that a point in a given plane does not leave that plane all deformations are in to plane of the body.

Solid Mechanics

Solid Mechanics

Given ∈ ∈ xy what are ∈ ∈ nt

.

We can always draw PQRS for given ˆn

If ∈ ∈ xy

As in case of stress we call these formulae as transformations laws.

α

1

=

∈ x

=∈ x

=∈ x dxSin θ ds sin θ dx ds

θ θ

α

2

=∈ y cos θ

α

3

=

= dy ds

=∈ y

θ dy ds

θ θ

θ θ

dL =∈

x

dL dS dxcos

=∈ =∈

=∈

x x

θ

+∈

y

θ

θ θ

dy sin

θ

+

Solid Mechanics

Y dycos

θ

+∈

y

+ ∈

y

dy ds sin

θ

+ Y

xy

dy ds cos

θ

sin

2 θ

+

θ θ

∈ +∈

2 y

+

∈ −∈

2 y cos 2 θ +

Y xy

2 sin 2 θ

α = −∈ x

θ θ + ∈ y

θ θ − Y sin

2 θ

β = −∈ x cos θ ( − sin θ ) + ∈ y

=∈ x

θ θ −∈ y cos θ ( − sin θ ) − Y cos

2 θ

θ θ − Y cos 2 θ

Y nt

2

= −

(

∈ −∈

2 y

) sin 2 θ +

Y xy

2 cos 2 θ

∈ x

Y xy

Y xy

∈

Y

2 x

∈ y

Y

∈ xy

2 y

- state of strain at a point

∈ =

Y

2

- strain tensor

∈

∈ x xy

∈

∈ xy y xy xy

τ

σ x xy

τ

σ

Replace

τ

σ

σ x y xy

→∈ x

→∈ y xy y

Y xy

2

- stress tensor

Principal shears and maximum shear

In plane- principal strains

2 p

=

2 y

ϒ xy

/ 2

θ p

1

− θ p

2

− ⊥ to each other

1

,

2

∈ >∈

2 tan 2 θ s

= −

θ θ p

1

± π

( y

)

2 ∈ xy

/ 4

θ s

1

− θ s

2

− ⊥ to each other

σ x

+ σ y

= y

J

I

I

1

σ σ − τ 2 xy

= I

2

∈∈ −∈ = J

2

2

Y xy

2

= J

2

∈ max or ∈ min

R

Y max

2

Y min

2

=∈ max

− θ s

=∈ min

− θ s

2

1

Solid Mechanics

2 y

2

+ ∈ 2 xy

Mohr’s Circle for strain

∈ x ′

,Y , ∈ y ′

3D -strain transformation

σ x

→∈ x

; σ y

→∈ y

; σ z

→∈ τ

(

∈ xy

∈ xz

) ∈ xy

( )

∈ yz

(

∈ xz

∈ yz

)

= 0

Y xy

2

1

, ,

3

- ∈ >∈ >∈

3

2 x 2 y 2

∆ s *

2

= P Q

′ 2

+ P R

′ 2

= 1

∂ u

∂ x

2

1

∂ v

∂ x

2

+ ∆ x + + ∆ y x 2

Solid Mechanics y 2

Solid Mechanics

∈ = 1 +

= 1 +

∂ u

∂ x

∆ y

∆ x

2

2

+ 1 +

∂ v ∆ y x x

2

2 x 2 y 2

=

=

1 +

∂ u

∂ x

2

+ 2

∂ u

∂ x

∂

∂ u x

2

1

∂

∂ v y

2

+ 2

∂ v

∂ y

1 +

∆ y

∆ x x

2

1 2

∂ v

∂ y

1 +

∆

∆ y x

2

∆ x

2

2

∆ x x

2 y

2

Transformation

σ x ′

= σ

+ τ n

2 + σ n

2 + σ n

2 n n + τ n n

′

+ τ n n

′

σ x

σ y

σ z

→∈ x

→∈ y

→∈ zx

2 x

2

τ xy

τ yz

τ zx

→∈ xy

→∈ yz

→∈ zx y

2

τ

′

+ ∈ n 2 + ∈ n 2

′

+∈ n 2 n n +∈ n n

′

+∈ n n

′

→∈ →

Y

2

Solid Mechanics

Principal strains:

( ∈ −∈ ) n x

+ ∈ n +∈ n

∈

∈

( ) n y

+ ∈ n n +∈ n

=

( ) n z

=

=

0

0

0

( )

∈ xy

∈ xz

∈ xy

( )

∈ yz

J

2

System of linear homogeneous equations

(

∈ xz

∈ yz

)

= 0 x z y z

2

1 1

J

2

J

J

1

=∈ +∈ +∈ z

0

2 xy

2 yz

2 zx

∈ x

∈ xy

∈ xy

∈ y

+

∈

∈ y yz

∈

∈ yz z

+

∈

∈ x xz

∈

∈ xz z

J

3

=∈ ∈ ∈ + ∈ ∈ ∈ −∈ ∈ −∈ ∈

∈ x

∈ xy

∈ xz

−∈ ∈ ∈ ∈ y

∈ yz

∈ zx

∈ zy

∈ z

∈ >∈ >∈

3

∈

( ∈ −∈

1

) n x

+∈ n + ∈

(

1

) n y

+ ∈ n

2 x

+ n

2 y

+ n

2 z

= 1

= 0

Solid Mechanics

= 0 n ,n & n z unique

J

J

2

3

=∈ + ∈ + ∈

1 2

=∈ ∈ ∈

3

=∈ ∈ +∈ ∈ +∈ ∈

Decomposition of a strain matrix into state of pure shear + hydrostatic strain

∈ x

∈ xy

∈ xz xy

∈ xz

∈ 0 0

∈ = ∈ yx

∈ y

∈

∈ zx

∈ zy

∈ yz z

= ∈

∈ yx zx

∈ −∈ ∈ yz

+ 0 ∈

∈ zy

0 0

0

∈

State of pureshear Hydrostatic where ∈=

3 y z

Solid Mechanics

Plane strain as a special case of 3 D

∈ = 0 is also a principal strain z → is a principal direction

if

1 2

;

1 2

+ve if ∈

1

+ve, ∈

2

-ve. if ∈

1

+ve, ∈

2

-ve

P & z ′ will come closer to the maximum extent,

so that the included angle is

π

2

−∈ max

Solid Mechanics

Transformation equations for plane-strain

Given state of strain at a point P.

E ij

=

∈ xx

Y xy

Y

∈ xy yy

This also means that deformation

Now what are the strains associated with x ,y i.e

E =

∈

Y

Y

∈

This also means that

Solid Mechanics

Assume that xx

, yy

and Y are +ve

Applying the law of cosines to triangular P* Q* R*

( P* R* cos

π

2

2

+ Y xy

P* R*

2

Q* R* ) 2 − 2 ( )

∆ x ′ ( 1 +∈ x ′

)

∆ y

(

1 +∈ y

)

2

= ∆ x ( 1 + ∈ x

) 2

+ ∆ y

(

1 +∈ y

) 2

2 x ( 1 + ∈ x

) cos

π

2

+ Y xy

∆ = ∆ x cos θ and ∆ = ∆ x sin θ cos

(

π

2

+ Y xy

)

= − sinY xy

≈ − Y xy

∆ x ′ 2 ( 1 + ∈ x ′

) 2

= ∆ 2 2 θ ( 1 +∈ x

) 2

+ ∆

2 θ θ ( 1 + ∈ x