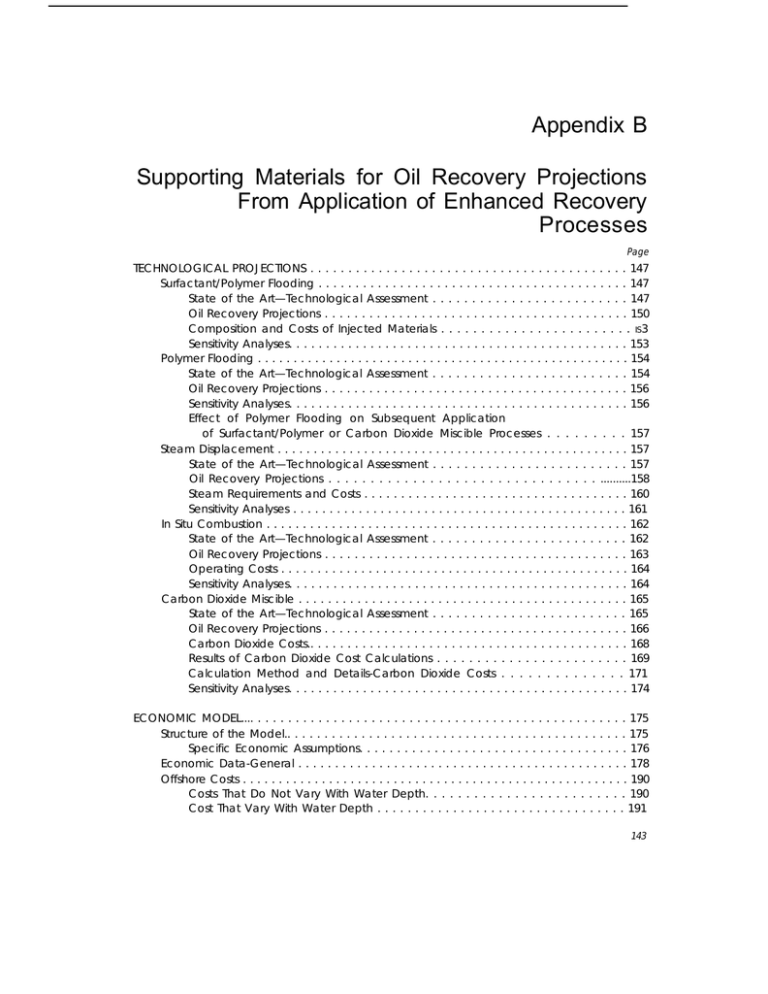

Appendix B Supporting Materials for Oil Recovery Projections Processes

advertisement