Pulse-Width Modulated Rectifiers Chapter 18

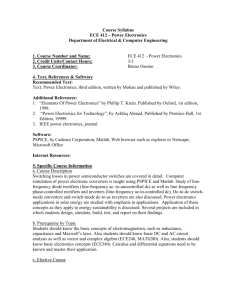

advertisement

Chapter 18 Pulse-Width Modulated Rectifiers 18.1 Properties of the ideal rectifier 18.2 Realization of a near-ideal rectifier 18.3 Control of the current waveform 18.4 Single-phase converter systems employing ideal rectifiers 18.5 RMS values of rectifier waveforms 18.6 Modeling losses and efficiency in CCM high-quality rectifiers 18.7 Ideal three-phase rectifiers Fundamentals of Power Electronics 1 Chapter 18: PWM Rectifiers 18.1 Properties of the ideal rectifier It is desired that the rectifier present a resistive load to the ac power system. This leads to • unity power factor • ac line current has same waveshape as voltage vac(t) i ac(t) = Re Re is called the emulated resistance iac(t) + vac(t) Re – Fundamentals of Power Electronics 2 Chapter 18: PWM Rectifiers Control of power throughput V 2ac,rms Pav = Re(vcontrol) iac(t) + vac(t) Power apparently “consumed” by Re is actually transferred to rectifier dc output port. To control the amount of output power, it must be possible to adjust the value of Re. Fundamentals of Power Electronics 3 Re(vcontrol) – vcontrol Chapter 18: PWM Rectifiers Output port model The ideal rectifier is lossless and contains no internal energy storage. Hence, the instantaneous input power equals the instantaneous output power. Since the instantaneous power is independent of the dc load characteristics, the output port obeys a power source characteristic. Fundamentals of Power Electronics Ideal rectifier (LFR) iac(t) + 2 p(t) = vac /Re vac(t) Re(vcontrol) i(t) + v(t) – – ac input dc output vcontrol v 2ac(t) p(t) = Re(vcontrol(t)) 4 v 2ac(t) v(t)i(t) = p(t) = Re Chapter 18: PWM Rectifiers The dependent power source i(t) i(t) p(t) v(t)i(t) = p(t) i(t) + + v(t) v(t) – – power source p(t) v(t) power sink i-v characteristic Fundamentals of Power Electronics 5 Chapter 18: PWM Rectifiers Equations of the ideal rectifier / LFR When connected to a resistive load of value R, the input and output rms voltages and currents are related as follows: Defining equations of the ideal rectifier: i ac(t) = vac(t) Re(vcontrol) v(t)i(t) = p(t) v 2ac(t) p(t) = Re(vcontrol(t)) Fundamentals of Power Electronics 6 Vrms = Vac,rms R Re I ac,rms = I rms R Re Chapter 18: PWM Rectifiers 18.2 Realization of a near-ideal rectifier Control the duty cycle of a dc-dc converter, such that the input current is proportional to the input voltage: dc–dc converter ig(t) 1 : M(d(t)) + iac(t) vac(t) i(t) + vg(t) v(t) – – C R d(t) ig Controller vg Fundamentals of Power Electronics 7 Chapter 18: PWM Rectifiers Waveforms vac(t) ig(t) VM t v(t) iac(t) V VM /Re M(t) t Mmin vg(t) VM Fundamentals of Power Electronics vac(t) = VM sin (ωt) M(d(t)) = vg(t) = VM sin (ωt) M min = V VM 8 v(t) V = vg(t) VM sin (ωt) Chapter 18: PWM Rectifiers Output-side current Averaged vg(t)i g(t) v 2g(t) i(t) = = over V VRe switching V 2M i(t) = sin 2 (ωt) period VRe V 2M 1 – cos (2ωt) = 2VRe Averaged over ac line I = i(t) period V 2M P= 1 : M(d(t)) + vac(t) 2Re dc–dc converter ig(t) iac(t) V 2M = TL 2VRe i(t) + vg(t) v(t) – – C R d(t) ig Controller vg Fundamentals of Power Electronics 9 Chapter 18: PWM Rectifiers Choice of converter M(d(t)) = v(t) V = vg(t) VM sin (ωt) M(t) Mmin • To avoid distortion near line voltage zero crossings, converter should be capable of producing M(d(t)) approaching infinity • Above expression neglects converter dynamics • Boost, buck-boost, Cuk, SEPIC, and other converters with similar conversion ratios are suitable • We will see that the boost converter exhibits lowest transistor stresses. For this reason, it is most often chosen Fundamentals of Power Electronics 10 Chapter 18: PWM Rectifiers 18.2.1 CCM Boost converter with controller to cause input current to follow input voltage Boost converter i(t) ig(t) + iac(t) vac(t) + L D1 vg(t) Q1 v(t) R – – vg(t) C ig(t) d(t) Controller • DC output voltage ≥ peak AC input voltage • Controller varies duty cycle as necessary to make ig(t) proportional to vg(t) Fundamentals of Power Electronics 11 Chapter 18: PWM Rectifiers Variation of duty cycle in boost rectifier M(d(t)) = v(t) V = vg(t) VM sin (ωt) Since M ≥ 1 in the boost converter, it is required that V ≥ VM If the converter operates in CCM, then M(d(t)) = 1 1 – d(t) The duty ratio should therefore follow vg(t) d(t) = 1 – V Fundamentals of Power Electronics 12 in CCM Chapter 18: PWM Rectifiers CCM/DCM boundary, boost rectifier Inductor current ripple is vg(t)d(t)Ts ∆i g(t) = 2L Low-frequency (average) component of inductor current waveform is i g(t) Ts = vg(t) Re The converter operates in CCM when i g(t) 2L > ∆i (t) ⇒ d(t) < g Ts ReTs Substitute CCM expression for d(t): Re < 2L vg(t) Ts 1 – V Fundamentals of Power Electronics for CCM 13 Chapter 18: PWM Rectifiers CCM/DCM boundary Re < 2L vg(t) Ts 1 – V for CCM Note that vg(t) varies with time, between 0 and VM. Hence, this equation may be satisfied at some points on the ac line cycle, and not at others. The converter always operates in CCM provided that Re < 2L Ts The converter always operates in DCM provided that Re > 2L VM Ts 1 – V For Re between these limits, the converter operates in DCM when vg(t) is near zero, and in CCM when vg(t) approaches VM. Fundamentals of Power Electronics 14 Chapter 18: PWM Rectifiers Static input characteristics of the boost converter A plot of input current ig(t) vs input voltage vg(t), for various duty cycles d(t). In CCM, the boost converter equilibrium equation is vg(t) = 1 – d(t) V The input characteristic in DCM is found by solution of the averaged DCM model (Fig. 11.12(b)): p(t) V – vg(t) ig(t) Solve for input current: + vg(t) + – 2L d 2T s p(t) + – i g(t) = V – Beware! This DCM Re(d) from Chapter 11 is not the same as the rectifier emulated resistance Re = vg/ig Fundamentals of Power Electronics 15 with vg(t) 2L d 2T s + p(t) V – vg(t) p(t) = v 2g(t) 2L d 2T s Chapter 18: PWM Rectifiers Static input characteristics of the boost converter Now simplify DCM current expression, to obtain 2L i (t) 1 – vg(t) = d 2(t) vg(t) VTs g V V CCM/DCM mode boundary, in terms of vg(t) and ig(t): 2L i (t) > vg(t) V VTs g Fundamentals of Power Electronics 1– vg(t) V 16 Chapter 18: PWM Rectifiers Boost input characteristics d=0 d = 0.2 d = 0.4 d = 0.6 d=1 1 d = 0.8 with superimposed resistive characteristic jg(t) = 2L i g(t) VT s 0.75 CCM: vg(t) = 1 – d(t) V DCM: 0.5 ) i g(t = t) v g( 2L i (t) 1 – vg(t) = d 2(t) vg(t) VTs g V V /R e CCM when CCM 0.25 2L i (t) > vg(t) VTs g V DCM 1– vg(t) V 0 0 0.25 0.5 m g(t) = Fundamentals of Power Electronics 0.75 1 vg(t) V 17 Chapter 18: PWM Rectifiers Open-loop DCM approach We found in Chapter 11 that the buck-boost, SEPIC, and Cuk converters, when operated open-loop in DCM, inherently behave as loss-free resistors. This suggests that they could also be used as near-ideal rectifiers, without need for a multiplying controller. Advantage: simple control Disadvantages: higher peak currents, larger input current EMI Like other DCM applications, this approach is usually restricted to low power (< 200W). The boost converter can also be operated in DCM as a low harmonic rectifier. Input characteristic is vg(t) v 2g(t) i g(t) T = + Re s R v(t) – v (t) e g Input current contains harmonics. If v is sufficiently greater than vg, then harmonics are small. Fundamentals of Power Electronics 18 Chapter 18: PWM Rectifiers Other similar approaches • Use of other converters (in CCM) that are capable of increasing the voltage: SEPIC, Cuk, buck-boost Flyback, isolated versions of boost, SEPIC, Cuk, etc. • Boundary or critical conduction mode: operation of boost or other converter at the boundary between CCM and DCM • Buck converter: distortion occurs but stresses are low • Resonant converter such as parallel resonant converter or some quasi-resonant converters • Converters that combine the functions of rectification, energy storage, and dc-dc conversion Fundamentals of Power Electronics 19 Chapter 18: PWM Rectifiers 18.2.2 DCM flyback converter Flyback converter EMI filter ig(t) iac(t) n:1 D1 + L vac(t) i(t) + v(t) C R vg(t) Q1 – – D Operation in DCM: we found in Chapter 11 that the converter input port obeys Ohm’s law with effective resistance Re = 2n2L/D2Ts. Hence, simply connect input port to AC line. Fundamentals of Power Electronics 20 Chapter 18: PWM Rectifiers Averaged large-signal model EMI filter ⟨ ig(t) ⟩T Averaged model ⟨ i(t) ⟩T + iac(t) vac(t) vg(t) + 2n 2L D 2T s ⟨ p(t) ⟩T – ⟨v(t)⟩T C R – D • Under steady-state conditions, operate with constant D • Adjust D to control average power drawn from AC line Fundamentals of Power Electronics 21 Chapter 18: PWM Rectifiers Converter design Select L small enough that DCM operation occurs throughout AC line cycle. DCM occurs provided that d3 > 0, or d 2(t) < 1 – D But vg(t) d 2(t) = D nV Substitute and solve for D: D< 1 vg(t) 1+ nV Area q1 ipk i 1(t) d1Ts Ts d2Ts d3Ts t Ts To obtain DCM at all points on input AC sinusoid: worst case is at maximum vg(t) = VM : Converter operates in DCM in every switching period where above inequality is satisfied. Fundamentals of Power Electronics i1(t) D< 22 1 V 1+ M nV Chapter 18: PWM Rectifiers Choice of L to obtain DCM everywhere along AC sinusoid We have: D< 1 V 1+ M nV with Substitute expression for Re to obtain D = 2nV VM L RT s Solve for L: L < L crit = RT s 4 1 + nV VM 2 Vrms = Vac,rms R Re Worst-case design For variations in load resistance and ac input voltage, the worst case occurs at maximum load power and minimum ac input voltage. The inductance should be chosen as follows: L < L crit-min = Fundamentals of Power Electronics 23 Rmin T s 4 1 + nV V M-min 2 Chapter 18: PWM Rectifiers 18.3 Control of the Current Waveform 18.3.1 Average current control Feedforward 18.3.2 Current programmed control 18.3.3 Critical conduction mode and hysteretic control 18.3.4 Nonlinear carrier control Fundamentals of Power Electronics 24 Chapter 18: PWM Rectifiers 18.3.1 Average current control ig(t) Boost example vg(t) + – v(t) – + – Low frequency (average) component of input current is controlled to follow input voltage + L Gate driver Pulse width modulator va(t) ≈ Rs ⟨ ig(t)⟩T Gc(s) Compensator s – Current v (t) reference r Fundamentals of Power Electronics 25 + Chapter 18: PWM Rectifiers Block diagram Boost converter • Current reference derived from input voltage waveform i(t) ig(t) + iac(t) vac(t) vg(t) vg(t) Multiplier Q1 X C v(t) – ig(t) Rs PWM va(t) v (t) +– err Gc(s) vr (t) = kx vg(t) vcontrol (t) • Compensation of current loop Fundamentals of Power Electronics + D1 – vcontrol (t) • Multiplier allows control of emulated resistance value L Compensator Controller 26 Chapter 18: PWM Rectifiers R The emulated resistance • Current sensor has gain Rs : va(t) = Rs i g(t) Ts Boost converter i(t) ig(t) + iac(t) vg(t) vac(t) • If loop is well designed, then: L + D1 C Q1 – vcontrol (t) va(t) ≈ vr (t) vg(t) Multiplier X v(t) – ig(t) Rs PWM va(t) v (t) +– err Gc(s) • Multiplier: vr(t) = k x vg(t) vcontrol(t) vr (t) = kx vg(t) vcontrol (t) Compensator Controller • Hence the emulated resistance is: Re = vg(t) = i g(t) vr (t) k xvcontrol (t) which can be simplified to Re vcontrol(t) = va(t) Rs Fundamentals of Power Electronics 27 Rs k xvcontrol(t) Chapter 18: PWM Rectifiers R System model using LFR Average current control Ideal rectifier (LFR) ⟨ig(t)⟩Ts iac(t) vac(t) + ⟨vg(t)⟩T ⟨i(t)⟩T + ⟨ p(t)⟩Ts s Re C – ⟨v(t)⟩T s – Re(t) Re(t) = Fundamentals of Power Electronics s 28 Rs vcontrol (t) k x vcontrol(t) Chapter 18: PWM Rectifiers R Use of multiplier to control average power An analog multiplier introduces the dependence of Re on v(t). ig(t) + vg(t) + – C Gate driver Pulse width modulator va(t) Gc(s) Compensator Multiplier x y v(t) – + – As discussed in Chapter 17, an output voltage feedback loop adjusts the emulated resistance Re such that the rectifier power equals the dc load power: V 2g,rms Pav = = Pload vg(t) Re kx xy vref1(t) – + verr(t) v(t) vcontrol(t) Gcv(s) – + vref2(t) Voltage reference Fundamentals of Power Electronics 29 Chapter 18: PWM Rectifiers Feedforward Feedforward is sometimes used to cancel out disturbances in the input voltage vg(t). ig(t) + vg(t) + – v(t) To maintain a given power throughput Pav, the reference voltage vref1(t) should be + – Pavvg(t)Rs vref 1(t) = V 2g,rms – Pulse width modulator vg(t) multiplier Peak detector V M x z y Gate driver kv xy z2 va(t) vref1(t) vcontrol(t) Gc(s) Compensator – + – Gcv(s) + vref2(t) Voltage reference Fundamentals of Power Electronics 30 Chapter 18: PWM Rectifiers Feedforward, continued ig(t) Controller with feedforward produces the following reference: + k vvcontrol(t)vg(t) vref 1(t) = V 2M vg(t) + – v(t) – Pav = k vvcontrol(t) 2Rs + – The average power is then given by Pulse width modulator vg(t) multiplier Peak detector V M x z y Gate driver kv xy z2 va(t) vref1(t) vcontrol(t) Gc(s) Compensator – + – Gcv(s) + vref2(t) Voltage reference Fundamentals of Power Electronics 31 Chapter 18: PWM Rectifiers Modeling the inner wide-bandwidth average current controller Averaged (but not linearized) boost converter model: L ⟨i1(t)⟩T ⟨i(t)⟩T ⟨vg(t)⟩Ts + + s s + – ⟨v1(t)⟩Ts + – ⟨i2(t)⟩Ts ⟨v2(t)⟩Ts – C R ⟨v(t)⟩T s – Averaged switch network In Chapter 7, we perturbed and linearized using the assumptions vg(t) Ts = Vg + vg(t) d(t) = D + d(t) ⇒ d'(t) = D' – d(t) i(t) T = i 1(t) T = I + i(t) s v(t) v1(t) i 2(t) Fundamentals of Power Electronics Ts Ts Ts s = v2(t) Ts = V + v(t) = V1 + v1(t) = I 2 + i 2(t) 32 Problem: variations in vg, i1 , and d are not small. So we are faced with the design of a control system that exhibits significant nonlinear time-varying behavior. Chapter 18: PWM Rectifiers Linearizing the equations of the boost rectifier When the rectifier operates near steady-state, it is true that v(t) Ts = V + v(t) with v(t) << V In the special case of the boost rectifier, this is sufficient to linearize the equations of the average current controller. The boost converter average inductor voltage is d i g(t) L Ts dt = vg(t) Ts – d'(t)V – d'(t)v(t) substitute: d i g(t) L dt Fundamentals of Power Electronics Ts = vg(t) Ts 33 – d'(t)V – d'(t)v(t) Chapter 18: PWM Rectifiers Linearized boost rectifier model d i g(t) L Ts dt = vg(t) Ts – d'(t)V – d'(t)v(t) The nonlinear term is much smaller than the linear ac term. Hence, it can be discarded to obtain d i g(t) L dt Ts = vg(t) Ts – d'(t)V L Equivalent circuit: i g(t) i g(s) V = d(s) sL Fundamentals of Power Electronics vg(t) Ts + – 34 Ts + – d'(t)V Chapter 18: PWM Rectifiers The quasi-static approximation The above approach is not sufficient to linearize the equations needed to design the rectifier averaged current controllers of buck-boost, Cuk, SEPIC, and other converter topologies. These are truly nonlinear timevarying systems. An approximate approach that is sometimes used in these cases: the quasi-static approximation Assume that the ac line variations are much slower than the converter dynamics, so that the rectifier always operates near equilibrium. The quiescent operating point changes slowly along the input sinusoid, and we can find the slowly-varying “equilibrium” duty ratio as in Section 18.2.1. The converter small-signal transfer functions derived in Chapters 7 and 8 are evaluated, using the time-varying operating point. The poles, zeroes, and gains vary slowly as the operating point varies. An average current controller is designed, that has a positive phase margin at each operating point. Fundamentals of Power Electronics 35 Chapter 18: PWM Rectifiers Quasi-static approximation: discussion • In the literature, several authors have reported success using this method • Should be valid provided that the converter dynamics are suffieiently fast, such that the converter always operates near the assumed operating points • No good condition on system parameters, which can justify the approximation, is presently known for the basic converter topologies • It is well-understood in the field of control systems that, when the converter dynamics are not sufficiently fast, then the quasi-static approximation yields neither necessary nor sufficient conditions for stability. Such behavior can be observed in rectifier systems. Worstcase analysis to prove stability should employ simulations. Fundamentals of Power Electronics 36 Chapter 18: PWM Rectifiers 18.3.2 Current programmed control Current programmed control is a natural approach to obtain input resistor emulation: Boost converter vg(t) + – + C Q1 v(t) – vg(t) is(t) ma Clock ++ Fundamentals of Power Electronics i2(t) D1 Peak transistor current is programmed to follow input voltage. Peak transistor current differs from average inductor current, because of inductor current ripple and artificial ramp. This leads to significant input current waveform distortion. L ig(t) ia(t) 0 vcontrol(t) Ts S Q Multiplier X + – R ic(t) Comparator = kx vg(t) vcontrol(t) Latch Current-programmed controller 37 Chapter 18: PWM Rectifiers R CPM boost converter: Static input characteristics vg(t) T s in CCM L 1 Fundamentals of Power Electronics e e =2 R bas e bas e R bas Re = 0 .2R Re = 0.1R CCM b as e e DCM 10 R 0.2 vg(t) i c(t) = Re Minimum slope compensation: 0.4 R It is desired that vg(t) 1– V 0.6 =4 TsV m a L vg(t) i c(t) > + L V V Ts vg(t) TsV vg(t) 1– V 2L V R or, Ts > jg(t) = i g(t) i g(t) 0.8 Rbase V Mode boundary: CCM occurs when ma = V 2L Rbase = 2L Ts R = e R ma + ase vg(t) V base i c(t) – 1 – Re = 0.5R b V – vg(t) vg(t) + m a L ase Ts = in DCM Re = 0.33R b i g(t) Static input characteristics of CPM boost, with minimum slope compensation: base vg(t) Li 2c (t) fs Re = 0 0.0 ma = V 2L 38 0.2 0.4 0.6 0.8 vg(t) V Chapter 18: PWM Rectifiers 1.0 Input current waveforms with current mode control i g(t) Peak i g • Substantial distortion can occur 1.0 ma = V 2L Rbase = 2L Ts 0.2 ase Re = 0.33 Rb R = e 0.1R bas e 0.4 Re = 2R b id uso Sin 0.6 • Can meet harmonic limits if the range of operating points is not too large ase 0.8 0.0 Fundamentals of Power Electronics ωt 39 • Difficult to meet harmonic limits in a universal input supply Chapter 18: PWM Rectifiers 18.3.3 Critical conduction mode and hysteretic control Variable switching frequency schemes ig(t) Hysteretic control • Hysteretic control • Critical conduction mode (boundary between CCM and DCM) ωt ig(t) Critical conduction mode ton Fundamentals of Power Electronics 40 ωt Chapter 18: PWM Rectifiers An implementation of critical conduction control Boost converter EMI filter ig(t) i(t) + iac(t) vac(t) L + D1 vg(t) C Q1 – vcontrol (t) v(t) – vg(t) Multiplier X Zero current ig detector Rs va(t) vr (t) = kx vg(t) vcontrol (t) + – Comparator S Q R Latch Controller Fundamentals of Power Electronics 41 Chapter 18: PWM Rectifiers R Pros and cons of critical conduction control • Simple, low-cost controller ICs • Low-frequency harmonics are very small, with constant transistor on-time (for boost converter) • Small inductor • Increased peak current • Increased conduction loss, reduced switching loss • Requires larger input filter • Variable switching frequency smears out the current EMI spectrum • Cannot synchronize converter switching frequencies Fundamentals of Power Electronics 42 Chapter 18: PWM Rectifiers Analysis ig(t) Transistor is on for fixed time ton Transistor off-time ends when inductor current reaches zero Ratio of vg(t) to ⟨ig(t)⟩ is Re = 2L t on Inductor volt-second balance: On time, as a function of load power and line voltage: vg t on + vg – V t off = 0 t on = 4LP V 2M Solve for toff: t off = t on Fundamentals of Power Electronics ωt ton 43 vg V – vg Chapter 18: PWM Rectifiers Switching frequency variations Solve for how the controller varies the switching frequency over the ac line period: 1 T s = t off + t on T s = 4LP V 2M vg(t) 1– V For sinusoidal line voltage variations, the switching frequency will therefore vary as follows: V 2M V 1 fs = = 1 – M sin (ωt) V T s 4LP Minimum and maximum limits on switching frequency: V 2M V min fs = 1– M V 4LP V 2M max fs = 4LP These equations can be used to select the value of the inductance L. Fundamentals of Power Electronics 44 Chapter 18: PWM Rectifiers 18.3.4 Nonlinear carrier control • Can attain simple control of input current waveform without sensing the ac input voltage, and with operation in continuous conduction mode • The integral of the sensed switch current (charge) is compared to a nonlinear carrier waveform (i.e., a nonlinear ramp), on a cycle-bycycle basis • Carrier waveform depends on converter topology • Very low harmonics in CCM. Waveform distortion occurs in DCM. • Peak current mode control is also possible, with a different carrier Fundamentals of Power Electronics 45 Chapter 18: PWM Rectifiers Controller block diagram Nonlinear carrier charge control of boost converter Boost converter D1 L ig(t) is(t) + is(t) v(t) C :1 vg(t) + – R n Q1 – is /n vi (t) Comparator Ci – vi (t) + R Q vc(t) Nonlinear carrier generator vcontrol (t) vc(t) Latch + – vi (t) S Q 0 0 Ts dTs Ts Clock Nonlinear-carrier charge controller Fundamentals of Power Electronics 46 Chapter 18: PWM Rectifiers Derivation of NLC approach The average switch current is t + Ts 1 i s(t) T = i s(τ)dτ Ts t s We could make the controller regulate the average switch current by • Integrating the monitored switch current • Resetting the integrator to zero at the beginning of each switching period • Turning off the transistor when the integrator reaches a reference value In the controller diagram, the integrator follows this equation: vi(t) = 1 Ci i.e., vi(dT s) = Fundamentals of Power Electronics dT s 0 is i s(τ) n dτ Ts nC i fs for 0 < t < dT s for interval 0 < t < T s 47 Chapter 18: PWM Rectifiers How to control the average switch current Input resistor emulation: vg(t) i g(t) = Ts Ts Re(vcontrol) Relate average switch current to input current (assuming CCM): i s(t) Ts = d(t) i g(t) Ts Relate input voltage to output voltage (assuming CCM): vg(t) Ts = d′(t) v(t) Ts Substitute above equations to find how average switch current should be controlled: v(t) i s(t) Ts = d(t) 1 – d(t) Fundamentals of Power Electronics Ts Re(vcontrol) 48 Chapter 18: PWM Rectifiers Implementation using nonlinear carrier v(t) Desired control, from previous slide: i s(t) Ts = d(t) 1 – d(t) Ts Re(vcontrol) Generate carrier waveform as follows (replace d by t/Ts ): vc(t) = vcontrol t 1 – t for 0 ≤ t ≤ T s Ts Ts vc(t + T s) = vc(t) The controller switches the transistor off when the integrator voltage equals the carrier waveform. This leads to: vi(dT s) = vc(dT s) = vcontrol(t) d(t) 1 – d(t) i s(t) Ts nC i f s = vcontrol(t) d(t) 1 – d(t) v(t) Re(vcontrol) = d(t) 1 – d(t) Fundamentals of Power Electronics 49 i s(t) Ts Ts v(t) = Ts nC i fsvcontrol(t) Chapter 18: PWM Rectifiers Generating the parabolic carrier Removal of dc component vcontrol (t) vc(t) +– Integrator with reset Integrator with reset Clock (one approach, suitable for discrete circuitry) Note that no separate multiplier circuit is needed Fundamentals of Power Electronics 50 Chapter 18: PWM Rectifiers 18.4 Single-phase converter systems containing ideal rectifiers • It is usually desired that the output voltage v(t) be regulated with high accuracy, using a wide-bandwidth feedback loop • For a given constant load characteristic, the instantaneous load current and power are then also constant: pload (t) = v(t)i(t) = VI • The instantaneous input power of a single-phase ideal rectifier is not constant: pac(t) = vg(t)i g(t) with so vg(t) = VM sin (ωt) vg(t) i g(t) = Re V 2M V 2M 2 pac(t) = sin ωt = 1 – cos 2ωt Re 2Re Fundamentals of Power Electronics 51 Chapter 18: PWM Rectifiers Power flow in single-phase ideal rectifier system • Ideal rectifier is lossless, and contains no internal energy storage. • Hence instantaneous input and output powers must be equal • An energy storage element must be added • Capacitor energy storage: instantaneous power flowing into capacitor is equal to difference between input and output powers: pC(t) = d EC(t) = dt d 1 2 Cv 2C(t) dt = pac(t) – pload(t) Energy storage capacitor voltage must be allowed to vary, in accordance with this equation Fundamentals of Power Electronics 52 Chapter 18: PWM Rectifiers Capacitor energy storage in 1¿ system pac(t) Pload vc(t) d = 1 2 Cv 2C(t) dt = pac(t) – pload(t) t Fundamentals of Power Electronics 53 Chapter 18: PWM Rectifiers Single-phase system with internal energy storage ⟨ pac(t)⟩T + iac(t) vac(t) pload(t) = VI = Pload Ideal rectifier (LFR) i (t) 2 ig(t) vg(t) + + s Re C – vC(t) Dc–dc converter i(t) v(t) load – – Energy storage capacitor Energy storage capacitor voltage vC(t) must be independent of input and output voltage waveforms, so that it can vary according to d = 1 2 Cv 2C(t) dt This system is capable of = pac(t) – pload(t) Fundamentals of Power Electronics 54 • Wide-bandwidth control of output voltage • Wide-bandwidth control of input current waveform • Internal independent energy storage Chapter 18: PWM Rectifiers Hold up time Internal energy storage allows the system to function in other situations where the instantaneous input and output powers differ. A common example: continue to supply load power in spite of failure of ac line for short periods of time. Hold up time: the duration which the dc output voltage v(t) remains regulated after vac(t) has become zero A typical hold-up time requirement: supply load for one complete missing ac line cycle, or 20 msec in a 50 Hz system During the hold-up time, the load power is supplied entirely by the energy storage capacitor Fundamentals of Power Electronics 55 Chapter 18: PWM Rectifiers Energy storage element Instead of a capacitor, and inductor or higher-order LC network could store the necessary energy. But, inductors are not good energy-storage elements Example 100 V 100 µF capacitor 100 A 100 µH inductor each store 1 Joule of energy But the capacitor is considerably smaller, lighter, and less expensive So a single big capacitor is the best solution Fundamentals of Power Electronics 56 Chapter 18: PWM Rectifiers Inrush current A problem caused by the large energy storage capacitor: the large inrush current observed during system startup, necessary to charge the capacitor to its equilibrium value. Boost converter is not capable of controlling this inrush current. Even with d = 0, a large current flows through the boost converter diode to the capacitor, as long as v(t) < vg(t). Additional circuitry is needed to limit the magnitude of this inrush current. Converters having buck-boost characteristics are capable of controlling the inrush current. Unfortunately, these converters exhibit higher transistor stresses. Fundamentals of Power Electronics 57 Chapter 18: PWM Rectifiers Universal input The capability to operate from the ac line voltages and frequencies found everywhere in the world: 50Hz and 60Hz Nominal rms line voltages of 100V to 260V: 100V, 110V, 115V, 120V, 132V, 200V, 220V, 230V, 240V, 260V Regardless of the input voltage and frequency, the near-ideal rectifier produces a constant nominal dc output voltage. With a boost converter, this voltage is 380 or 400V. Fundamentals of Power Electronics 58 Chapter 18: PWM Rectifiers Low-frequency model of dc-dc converter Dc-dc converter produces well-regulated dc load voltage V. Load therefore draws constant current I. Load power is therefore the constant value Pload = VI. To the extent that dc-dc converter losses can be neglected, then dc-dc converter input power is Pload , regardless of capacitor voltage vc(t). Dc-dc converter input port behaves as a power sink. A low frequency converter model is p (t) = VI = P i (t) load 2 + C vC(t) + Pload V + – – Energy storage capacitor Fundamentals of Power Electronics 59 load i(t) v(t) load – Dc-dc converter Chapter 18: PWM Rectifiers Low-frequency energy storage process, 1¿ system A complete low-frequency system model: iac(t) vac(t) pload(t) = VI = Pload i2(t) ig(t) ⟨ pac(t)⟩Ts + vg(t) Re + C vC(t) + Pload V + – – – Ideal rectifier (LFR) Energy storage capacitor i(t) v(t) load – Dc-dc converter • Difference between rectifier output power and dc-dc converter input power flows into capacitor • In equilibrium, average rectifier and load powers must be equal • But the system contains no mechanism to accomplish this • An additional feeback loop is necessary, to adjust Re such that the rectifier average power is equal to the load power Fundamentals of Power Electronics 60 Chapter 18: PWM Rectifiers Obtaining average power balance iac(t) vac(t) pload(t) = VI = Pload i2(t) ig(t) ⟨ pac(t)⟩Ts + vg(t) Re + C vC(t) + Pload V + – v(t) load – – Ideal rectifier (LFR) Energy storage capacitor i(t) – Dc-dc converter If the load power exceeds the average rectifier power, then there is a net discharge in capacitor energy and voltage over one ac line cycle. There is a net increase in capacitor charge when the reverse is true. This suggests that rectifier and load powers can be balanced by regulating the energy storage capacitor voltage. Fundamentals of Power Electronics 61 Chapter 18: PWM Rectifiers A complete 1¿ system containing three feedback loops Boost converter i2(t) + ig(t) + iac(t) vac(t) L vg(t) Q1 vC(t) – vcontrol(t) vg(t) Multiplier X i(t) D1 DC–DC Converter C Load v(t) – – ig(t) Rs d(t) PWM v(t) va(t) vref1(t) = kxvg(t)vcontrol(t) + v (t) +– err Gc(s) Compensator and modulator –+ vref3 Compensator Wide-bandwidth output voltage controller Wide-bandwidth input current controller vC(t) Compensator –+ vref2 Low-bandwidth energy-storage capacitor voltage controller Fundamentals of Power Electronics 62 Chapter 18: PWM Rectifiers Bandwidth of capacitor voltage loop • The energy-storage-capacitor voltage feedback loop causes the dc component of vc(t) to be equal to some reference value • Average rectifier power is controlled by variation of Re. • Re must not vary too quickly; otherwise, ac line current harmonics are generated • Extreme limit: loop has infinite bandwidth, and vc(t) is perfectly regulated to be equal to a constant reference value • Energy storage capacitor voltage then does not change, and this capacitor does not store or release energy • Instantaneous load and ac line powers are then equal • Input current becomes i ac(t) = Fundamentals of Power Electronics pac(t) p (t) Pload = load = vac(t) vac(t) VM sin ωt 63 Chapter 18: PWM Rectifiers Input current waveform, extreme limit i ac(t) = pac(t) p (t) Pload = load = vac(t) vac(t) VM sin ωt THD → ∞ Power factor → 0 vac(t) iac(t) t Fundamentals of Power Electronics 64 So bandwidth of capacitor voltage loop must be limited, and THD increases rapidly with increasing bandwidth Chapter 18: PWM Rectifiers 18.4.2 Modeling the outer low-bandwidth control system This loop maintains power balance, stabilizing the rectifier output voltage against variations in load power, ac line voltage, and component values The loop must be slow, to avoid introducing variations in Re at the harmonics of the ac line frequency Objective of our modeling efforts: low-frequency small-signal model that predicts transfer functions at frequencies below the ac line frequency Fundamentals of Power Electronics 65 Chapter 18: PWM Rectifiers Large signal model averaged over switching period Ts Ideal rectifier (LFR) ⟨ ig(t)⟩Ts s ⟨ p(t)⟩T ⟨ vg(t)⟩T s + – ⟨ i2(t)⟩T + s ⟨ v(t)⟩T C Re (vcontrol ) s Load – ac input dc output vcontrol Ideal rectifier model, assuming that inner wide-bandwidth loop operates ideally High-frequency switching harmonics are removed via averaging Ac line-frequency harmonics are included in model Nonlinear and time-varying Fundamentals of Power Electronics 66 Chapter 18: PWM Rectifiers Predictions of large-signal model Ideal rectifier (LFR) ⟨ ig(t)⟩Ts If the input voltage is vg(t) = 2 vg,rms sin ωt ⟨ p(t)⟩T ⟨ vg(t)⟩T s + – Re (vcontrol ) ⟨ i2(t)⟩T s + s C ⟨ v(t)⟩T s – Then the instantaneous power is: vg(t) ac input dc output vcontrol 2 v 2g,rms p(t) T = = 1 – cos 2ωt s Re(vcontrol(t)) Re(vcontrol(t)) Ts which contains a constant term plus a secondharmonic term Fundamentals of Power Electronics 67 Chapter 18: PWM Rectifiers Load Separation of power source into its constant and time-varying components ⟨ i2(t)⟩T s + V 2g,rms – cos 2 2ωt Re V 2g,rms Re C ⟨ v(t)⟩Ts Load – Rectifier output port The second-harmonic variation in power leads to second-harmonic variations in the output voltage and current Fundamentals of Power Electronics 68 Chapter 18: PWM Rectifiers Removal of even harmonics via averaging v(t) ⟨ v(t)⟩Ts ⟨ v(t)⟩T 2L t T2L = Fundamentals of Power Electronics 1 2 69 2π = π ω ω Chapter 18: PWM Rectifiers Resulting averaged model ⟨ i2(t)⟩T2L + V 2g,rms Re C ⟨ v(t)⟩T2L Load – Rectifier output port Time invariant model Power source is nonlinear Fundamentals of Power Electronics 70 Chapter 18: PWM Rectifiers Perturbation and linearization The averaged model predicts that the rectifier output current is p(t) i 2(t) T 2L = v(t) T 2L T 2L = v 2g,rms(t) Re(vcontrol(t)) v(t) = f vg,rms(t), v(t) Let T 2L , vcontrol(t)) T 2L with v(t) i 2(t) T 2L T 2L = V + v(t) V >> v(t) = I 2 + i 2(t) I 2 >> i 2(t) vg,rms = Vg,rms + vg,rms(t) vcontrol(t) = Vcontrol + vcontrol(t) Fundamentals of Power Electronics Vg,rms >> vg,rms(t) Vcontrol >> vcontrol(t) 71 Chapter 18: PWM Rectifiers Linearized result vcontrol(t) I 2 + i 2(t) = g 2vg,rms(t) + j2v(t) – r2 where df vg,rms, V, Vcontrol) g2 = = dvg,rms – 1 = r2 v g,rms = V g,rms df Vg,rms, v d v , Vcontrol) T 2L =– T 2L dvcontrol Fundamentals of Power Electronics I2 V v T =V 2L df Vg,rms, V, vcontrol) j2 = Vg,rms 2 Re(Vcontrol) V v control = V control 72 V 2g,rms dRe(vcontrol) =– VR 2e (Vcontrol) dvcontrol v control = V control Chapter 18: PWM Rectifiers Small-signal equivalent circuit i2 + r2 j2 vcontrol g 2 vg,rms C v R – Rectifier output port Predicted transfer functions Control-to-output v(s) 1 = j2 R||r 2 vcontrol(s) 1 + sC R||r 2 Line-to-output v(s) 1 = g 2 R||r 2 vg,rms(s) 1 + sC R||r 2 Fundamentals of Power Electronics 73 Chapter 18: PWM Rectifiers Model parameters Table 18.1 Small-signal model parameters for several types of rectifier control schemes Controller type g2 j2 r2 Average current control with feedforward, Fig. 18.14 0 Pav VVcontrol V2 Pav Current-programmed control, Fig. 18.16 2Pav VVg,rms Pav VVcontrol V2 Pav Nonlinear-carrier charge control of boost rectifier, Fig. 18.21 2Pav VVg,rms Pav VVcontrol V2 2Pav Boost with critical conduction mode control, Fig. 18.20 2Pav VVg,rms Pav VVcontrol V2 Pav DCM buck-boost, flyback, SEPIC, or Cuk converters 2Pav VVg,rms 2Pav VD V2 Pav Fundamentals of Power Electronics 74 Chapter 18: PWM Rectifiers Constant power load ig(t) ⟨ pac(t)⟩Ts + iac(t) vg(t) vac(t) pload(t) = VI = Pload i2(t) Re C – + + vC(t) Pload V + – v(t) load – – Ideal rectifier (LFR) Energy storage capacitor i(t) Dc-dc converter Rectifier and dc-dc converter operate with same average power Incremental resistance R of constant power load is negative, and is 2 V R=– Pav which is equal in magnitude and opposite in polarity to rectifier incremental output resistance r2 for all controllers except NLC Fundamentals of Power Electronics 75 Chapter 18: PWM Rectifiers Transfer functions with constant power load When r2 = – R, the parallel combination r2 || R becomes equal to zero. The small-signal transfer functions then reduce to j v(s) = 2 vcontrol(s) sC g v(s) = 2 vg,rms(s) sC Fundamentals of Power Electronics 76 Chapter 18: PWM Rectifiers 18.5 RMS values of rectifier waveforms Doubly-modulated transistor current waveform, boost rectifier: iQ(t) t Computation of rms value of this waveform is complex and tedious Approximate here using double integral Generate tables of component rms and average currents for various rectifier converter topologies, and compare Fundamentals of Power Electronics 77 Chapter 18: PWM Rectifiers RMS transistor current RMS transistor current is I Qrms = 1 Tac T ac iQ(t) i 2Q(t)dt 0 Express as sum of integrals over all switching periods contained in one ac line period: I Qrms = 1 T Tac s T ac/T s ∑ n=1 1 Ts t nT s i 2Q(t)dt (n-1)T s Quantity in parentheses is the value of iQ2, averaged over the nth switching period. Fundamentals of Power Electronics 78 Chapter 18: PWM Rectifiers Approximation of RMS expression I Qrms = T ac/T s ∑ 1 T Tac s 1 Ts n=1 nT s i 2Q(t)dt (n-1)T s When Ts << Tac, then the summation can be approximated by an integral, which leads to the double-average: I Qrms ≈ = = Fundamentals of Power Electronics 1 lim T Tac T s→0 s 1 Tac T ac 0 i 2Q(t) 79 Ts 1 Ts T ac/T s ∑ n=1 t+T s 1 Ts nT s i 2Q(τ)dτ (n-1)T s i 2Q(τ)dτ dt t T ac Chapter 18: PWM Rectifiers 18.5.1 Boost rectifier example For the boost converter, the transistor current iQ(t) is equal to the input current when the transistor conducts, and is zero when the transistor is off. The average over one switching period of iQ2(t) is therefore t+T i 2 Q T s s 1 = i 2Q(t)dt Ts t = d(t)i 2ac(t) If the input voltage is vac(t) = VM sin ωt then the input current will be given by VM i ac(t) = sin ωt Re and the duty cycle will ideally be V = 1 vac(t) 1 – d(t) Fundamentals of Power Electronics 80 (this neglects converter dynamics) Chapter 18: PWM Rectifiers Boost rectifier example Duty cycle is therefore d(t) = 1 – VM sin ωt V Evaluate the first integral: i 2 Q T s V 2M V = 2 1 – M sin ωt V Re sin 2 ωt Now plug this into the RMS formula: I Qrms = = I Qrms = Fundamentals of Power Electronics 1 Tac T ac i 2Q 0 T ac 1 Tac 0 2 M 2 e 2 V Tac R 81 Ts dt V 2M VM 1 – sin ωt V R 2e T ac/2 sin 2 ωt – sin 2 ωt dt VM sin 3 ωt dt V 0 Chapter 18: PWM Rectifiers Integration of powers of sin θ over complete half-cycle n 1 π π n sin (θ)dθ = 0 2 2⋅4⋅6 (n – 1) if n is odd π 1⋅3⋅5 n 1⋅3⋅5 (n – 1) if n is even 2⋅4⋅6 n Fundamentals of Power Electronics 82 1 π π sin n (θ)dθ 0 1 2 π 2 1 2 3 4 3π 4 3 8 5 16 15π 6 15 48 Chapter 18: PWM Rectifiers Boost example: transistor RMS current I Qrms = VM 2 Re V 1– 8 M 3π V = I ac rms V 1– 8 M 3π V Transistor RMS current is minimized by choosing V as small as possible: V = VM. This leads to I Qrms = 0.39I ac rms When the dc output voltage is not too much greater than the peak ac input voltage, the boost rectifier exhibits very low transistor current. Efficiency of the boost rectifier is then quite high, and 95% is typical in a 1kW application. Fundamentals of Power Electronics 83 Chapter 18: PWM Rectifiers Table of rectifier current stresses for various topologies Tabl e 18. 3 Summary of rectifier current stresses for several converter topologies rms Average Peak CCM boost Transistor I ac rms Diode I dc VM 1 – 8 3π V V I ac rms 2 π2 1 – π M 8 V 16 V 3π V M I dc I ac rms 2 π2 I ac rms Inductor I ac rms 2 2 I dc V VM I ac rms 2 CCM flyback, with n:1 isolation transformer and input filter Transistor, xfmr primary I ac rms L1 C1 Diode, xfmr secondary Fundamentals of Power Electronics I ac rms I dc V 1+ 8 M 3π nV I ac rms 2 π2 I ac rms I ac rms 2 π2 8 VM 3π nV 0 3 + 16 nV 2 3π V M I dc 84 I ac rms 2 1 + V n I ac rms 2 I ac rms 2 max 1, VM nV 2I dc 1 + nV VM Chapter 18: PWM Rectifiers Table of rectifier current stresses continued CCM SEPIC, nonisolated Transistor V 1+ 8 M 3π V I ac rms I ac rms L1 C1 8 VM 3π V I ac rms L2 I dc I ac rms 2 1 + I ac rms 2 π2 I ac rms 2 0 VM 3 V 2 I ac rms V M 2 V 3 + 16 V 2 3π V M I dc I ac rms Diode I ac rms 2 π2 I ac rms max 1, I ac rms VM V VM V VM 2 V 2I dc 1 + V VM CCM SEPIC, with n:1 isolation transformer transistor I ac rms V 1+ 8 M 3π nV I ac rms L1 C1, xfmr primary Diode, xfmr secondary I ac rms I dc 8 VM 3π nV 3 + 16 nV 2 3π V M I ac rms 2 π2 I ac rms 2 1 + I ac rms 2 π2 I ac rms 2 0 I dc VM nV I ac rms 2 max 1, n 2I dc 1 + nV VM I ac rms = 2 V , ac input voltage = V M sin(ω t) VM I dc dc output voltage = V with, in all cases, Fundamentals of Power Electronics 85 Chapter 18: PWM Rectifiers Comparison of rectifier topologies Boost converter • Lowest transistor rms current, highest efficiency • Isolated topologies are possible, with higher transistor stress • No limiting of inrush current • Output voltage must be greater than peak input voltage Buck-boost, SEPIC, and Cuk converters • Higher transistor rms current, lower efficiency • Isolated topologies are possible, without increased transistor stress • Inrush current limiting is possible • Output voltage can be greater than or less than peak input voltage Fundamentals of Power Electronics 86 Chapter 18: PWM Rectifiers Comparison of rectifier topologies 1kW, 240Vrms example. Output voltage: 380Vdc. Input current: 4.2Arms Converter Transistor rms current Transistor voltage Diode rms current Transistor rms current, 120V Diode rms current, 120V Boost 2A 380 V 3.6 A 6.6 A 5.1 A Nonisolated SEPIC 5.5 A 719 V 4.85 A 9.8 A 6.1 A Isolated SEPIC 5.5 A 719 V 36.4 A 11.4 A 42.5 A Isolated SEPIC example has 4:1 turns ratio, with 42V 23.8A dc load Fundamentals of Power Electronics 87 Chapter 18: PWM Rectifiers 18.6 Modeling losses and efficiency in CCM high-quality rectifiers Objective: extend procedure of Chapter 3, to predict the output voltage, duty cycle variations, and efficiency, of PWM CCM low harmonic rectifiers. Approach: Use the models developed in Chapter 3. Integrate over one ac line cycle to determine steady-state waveforms and average power. Boost example RL L D1 ig(t) i(t) RL DRon D' : 1 VF i(t) + – ig(t) + + vg(t) + – Q1 C R v(t) vg(t) + – R – – Dc-dc boost converter circuit Fundamentals of Power Electronics Averaged dc model 88 v(t) Chapter 18: PWM Rectifiers Modeling the ac-dc boost rectifier Boost rectifier circuit ig(t) + iac(t) id(t) RL + L D1 vg(t) vac(t) i(t) Q1 C v(t) R – – controller RL d(t) Ron Averaged model vg(t) + – d'(t) : 1 VF + – ig(t) id(t) i(t) = I + C (large) R v(t) = V – Fundamentals of Power Electronics 89 Chapter 18: PWM Rectifiers Boost rectifier waveforms vg(t) ig(t) 300 10 vg(t) Typical waveforms 8 200 ig(t) (low frequency components) 6 4 100 ig(t) = 2 0 0 0° d(t) vg(t) Re 30° 60° 90° 120° 150° 180° 1 6 0.8 5 id(t) 4 0.6 i(t) = I 3 0.4 2 0.2 1 0 0 0° 30° 60° 90° Fundamentals of Power Electronics 120° 150° 180° 90 0° 30° 60° 90° 120° 150° 180° ωt Chapter 18: PWM Rectifiers Example: boost rectifier with MOSFET on-resistance ig(t) + id(t) d(t) Ron vg(t) i(t) = I d'(t) : 1 + – C (large) R v(t) = V – Averaged model Inductor dynamics are neglected, a good approximation when the ac line variations are slow compared to the converter natural frequencies Fundamentals of Power Electronics 91 Chapter 18: PWM Rectifiers 18.6.1 Expression for controller duty cycle d(t) ig(t) Solve input side of model: d(t) Ron i g(t)d(t)Ron = vg(t) – d'(t)v with ig(t) = vg(t) Re vg(t) i(t) = I d'(t) : 1 + – + id(t) C (large) R v(t) = V – vg(t) = VM sin ωt eliminate ig(t): solve for d(t): v – vg(t) d(t) = R v – vg(t) on Re vg(t) d(t)Ron = vg(t) – d'(t)v Re Again, these expressions neglect converter dynamics, and assume that the converter always operates in CCM. Fundamentals of Power Electronics 92 Chapter 18: PWM Rectifiers 18.6.2 Expression for the dc load current Solve output side of model, using charge balance on capacitor C: I = id T ac ig(t) d(t) Ron vg(t) + – i(t) = I d'(t) : 1 + id(t) C (large) R vg(t) i d (t) = d'(t)i g(t) = d'(t) Re v(t) = V – Butd’(t) is: hence id(t) can be expressed as R vg(t) 1 – on Re d'(t) = R v – vg(t) on Re Ron Re v 2g(t) i d (t) = Re Ron v – vg(t) Re 1– Next, average id(t) over an ac line period, to find the dc load current I. Fundamentals of Power Electronics 93 Chapter 18: PWM Rectifiers Dc load current I Now substitute vg (t) = VM sin ωt, and integrate to find ⟨id(t)⟩Tac: T ac/2 V 2M Re I = id T = 2 ac Tac 1– v– 0 Ron sin 2 ωt Re VM Ron sin ωt Re dt This can be written in the normalized form T ac/2 2 M R V I= 2 1 – on Tac VRe Re with a= Fundamentals of Power Electronics VM V sin 2 ωt 1 – a sin ωt 0 dt Ron Re 94 Chapter 18: PWM Rectifiers Integration By waveform symmetry, we need only integrate from 0 to Tac/4. Also, make the substitution θ = ωt: π/2 2 M V R 2 I= 1 – on π VRe Re 0 sin 2 θ 1 – a sin θ dθ This integral is obtained not only in the boost rectifier, but also in the buck-boost and other rectifier topologies. The solution is π/2 4 π 0 sin 2 θ dθ = F(a) = 22 aπ 1 – a sin θ 1 – a2 • a is typically much smaller than unity • Result is in closed form • a is a measure of the loss resistance relative to Re Fundamentals of Power Electronics – 2a – π + 4 sin – 1 a + 2 cos – 1 a 95 Chapter 18: PWM Rectifiers The integral F(a) π/2 4 π 0 sin 2 θ dθ = F(a) = 22 aπ 1 – a sin θ Approximation via polynomial: Fundamentals of Power Electronics 1 – a2 1.15 1.1 F(a) ≈ 1 + 0.862a + 0.78a 2 For | a | ≤ 0.15, this approximate expression is within 0.1% of the exact value. If the a2 term is omitted, then the accuracy drops to ±2% for | a | ≤ 0.15. The accuracy of F(a) coincides with the accuracy of the rectifier efficiency η. – 2a – π + 4 sin – 1 a + 2 cos – 1 a 1.05 F(a) 1 0.95 0.9 0.85 –0.15 –0.10 –0.05 0.00 0.05 0.10 0.15 a 96 Chapter 18: PWM Rectifiers 18.6.3 Solution for converter efficiency η Converter average input power is V 2M Pin = pin(t) T = ac 2Re Average load power is Pout = VI = V V 2M R F(a) 1 – on VRe Re 2 VM a= V with Ron Re So the efficiency is η= Pout R = 1 – on F(a) Pin Re Polynomial approximation: R η ≈ 1 – on Re Fundamentals of Power Electronics V R V R 1 + 0.862 M on + 0.78 M on V Re V Re 97 2 Chapter 18: PWM Rectifiers Boost rectifier efficiency η 1 η= .05 R on /R e = 0 0.95 R on/R e 0.9 = 0.1 • To obtain high efficiency, choose V slightly larger than VM 15 0. /R e = R on 0.85 = /R e 0.2 • Efficiencies in the range 90% to 95% can then be obtained, even with Ron as high as 0.2Re R on 0.8 0.75 0.0 0.2 0.4 0.6 0.8 VM /V Fundamentals of Power Electronics Pout R = 1 – on F(a) Pin Re 98 1.0 • Losses other than MOSFET on-resistance are not included here Chapter 18: PWM Rectifiers 18.6.4 Design example Let us design for a given efficiency. Consider the following specifications: Output voltage 390 V Output power 500 W rms input voltage 120 V Efficiency 95% Assume that losses other than the MOSFET conduction loss are negligible. Average input power is P Pin = ηout = 500 W = 526 W 0.95 Then the emulated resistance is V 2g, rms (120 V) 2 Re = = = 27.4 Ω Pin 526 W Fundamentals of Power Electronics 99 Chapter 18: PWM Rectifiers Design example Also, η VM 120 2 V = = 0.435 V 390 V 95% efficiency with VM/V = 0.435 occurs with Ron/Re ≈ 0.075. 1 .05 R on /R e = 0 0.95 R on/R e 0.9 So we require a MOSFET with on resistance of = 0.1 Ron ≤ (0.075) Re 15 0. /R e = R on 0.85 = /R e = (0.075) (27.4 Ω) = 2 Ω 0.2 R on 0.8 0.75 0.0 0.2 0.4 0.6 0.8 1.0 VM /V Fundamentals of Power Electronics 100 Chapter 18: PWM Rectifiers