An efficient synthesis of substituted benzene-1,2-dicarboxaldehydes ZHU Peter C

advertisement

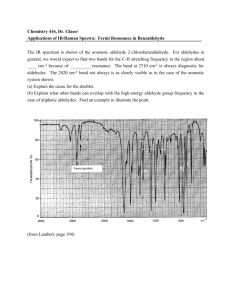

Science in China Series B: Chemistry © 2007 Science in China Press Springer-Verlag An efficient synthesis of substituted benzene-1,2-dicarboxaldehydes ZHU Peter C1†, WANG Der-Haw1, LU Kaitao1 & MANI Neelakandha2 1 2 Advanced Sterilization Products, Johnson & Johnson, 33 Technology Drive, Irvine, CA 92618, USA; Pharmaceutical Research and Development La Jolla, Johnson & Johnson, 3210 Merryfield Row, San Diego, CA 92121, USA Substituted-benzene-1,2-dicarbaldehydes were synthesized by the reaction of substituted-1,2-bis (dibromomethyl) benzenes with fuming sulfuric acid, followed by hydrolysis. The yields were significantly improved by introducing solid sodium bicarbonate into the reaction mixture before hydrolysis and workup. aromatic aldehyde, 1,2-bis(dibromomethyl)arene, hydrolysis, oxidation, sodium bicarbonate, fuming sulfuric acid 1 Introduction Aromatic dicarboxaldehydes are an important class of compounds used for synthetic intermediates, polymer synthesis, analytical reagents, and disinfectants[1,2]. For example, o-phthalaldehyde (OPA) is widely used as an analytical reagent for proteins analysis and also as a disinfectant for medical devices in hospitals. OPA-like compounds are a fairly new class of compounds being developed as new germicidal compounds for disinfec- tion or sterilization[3 6]. Although relatively stable, these compounds are nevertheless susceptible to oxidation[7], - reduction [8 10] and strongly basic [11] conditions, as shown in Figure 1[12]. Thus, despite the numerous synthetic methods reported for the preparation of aromatic - aldehydes[13 15], only a few can be used for the synthesis of OPA-like compounds. One of the most widely-used synthetic methods to this class of compounds involved the hydrolysis of gem-dihalides to aldehydes[16,17]. From a practical standpoint, this method is especially useful since the requisite tetrahalo-1,2-xylenes can be easily obtained by radical halogenation. A major drawback to this approach, however, has been the lack of an efficient and general method for the hydrolysis of the gem dihalides due to the sensitivity of the dialdehyde product to the hydrolytic conditions, resulting in poor yields and 0H 1H 2H 3H 4H 5H 6H 7H www.scichina.com www.springerlink.com side products in many instances. We wish to report here an improved procedure for this reaction in which solid bicarbonate was used to initially neutralize excess acid in the reaction mixture, which was then subjected to hydrolysis leading to cleaner products in higher yields. 2 Experimental The following chemicals were purchased from Aldrich Fine Chemicals and were used without purification: bromine, carbon tetrachloride, 4-chloro-o-xylene, 4-bromo-o-xylene, 4-nitro-o-xylene, sodium bicarbonate, sodium hydroxide, potassium bicarbonate, calcium hydroxide, calcium carbonate and triethylamine. Fuming sulfuric acid (Oleum) with 20% free SO3 and 4-fluoro-oxylene was purchased from Fisher Scientific. 2.1 4-Chloro-OPA 2.1.1 Bromination of 4-chloro-o-xylene. In a typical example, the following modified bromination procedures were employed[18]. 4-chloro-o-xylene (5.0 g) and about 200 mL of CCl4 were added into a 250 mL three-neck round-bottom flask equipped with a magnetic stirring bar, a 200 mL addition funnel, a condenser, and a stopper. The outlet of the condenser was connected via 8H Received April 11, 2006; accepted May 16, 2006 doi: 10.1007/s11426-007-0031-y † Corresponding author (email: pzhu1@alzus.jnj.com) 9H Sci China Ser B-Chem | April 2007 | vol. 50 | no. 2 | 249-252 Figure 1 Possible OPA byproducts via redox or disproportionation reactions. Tygon tubing and a funnel to a beaker filled with a Na2CO3 solution to trap HBr generated during bromination. The solution in the flask was first heated to reflux (oil bath). Liquid bromine was then added dropwise from the addition funnel. The bromine addition rate was controlled in order to control the concentration of the bromine in the solution in the flask. Additional bromine was added if the color of the solution became lighter, or colorless. Two 250 W tungsten lamps were used to irradiate the mixture to enhance the bromination. If desired, the progression of the reaction was monitored for the reaction progress. The reaction was allowed to proceed for about 6 h. CCl4 was removed at normal pressure by distillation at 130℃ until about 180 mL of the CCl4 was removed. Then, a series of five additions of methanol, of about 20 mL each, were added to the residual in the flask to azeotropically remove residual CCl4 by distillation at 130℃. On the final distillation, when about 20 mL of solution remained in the flask, the solution was cooled to room temperature. The remaining solvent was removed at 40℃ with a rotary evaporator at about 10 mmHg to produce a solid. The solid was recrystallized in about 150 mL of hexane to yield 4-chloro-1,2-bis-dibromomethyl-benzene as white needle crystals (12.0 g, yield ~72%, GC indicated a purity of 99%). 2.1.2 Hydrolysis of substituted-1,2-bis-dibromomethyl-benzene. (i) Procedure 1 (Modified for 4-chloro-1,2-bis-dibromomethyl-benzene). About 6.4 g of 4-chloro-1,2-bis-dibromomethyl-ben250 zene were ground into a powder and added to a dry 100 mL round-bottom flask equipped with a magnetic stirring bar. About 20 mL of fuming sulfuric acid was poured into the flask while stirring. The mixture was stirred at room temperature for about 1 h. During the hour, the powder was dissolved, and the solution gradually became dark brownish. The solution was poured into a 100 mL beaker immersed in a dry ice/acetone bath. The brownish solution was gradually added to about 25 g of crushed ice with stirring so that the temperature of the solution was controlled. Then the solution was allowed to gradually warm to room temperature, and extracted with ethyl acetate (2×100 mL). The organic phase was washed with 5% Na2CO3 (3×50 mL). The resultant organic phase was dried with Na2SO4 overnight. After drying, the remaining solvent was removed at 40℃ by rotary evaporator at about 10 mmHg to obtain a yellow solid. The yellow solid was recrystallized in about 30 mL of hexane to yield 4-chloro-OPA as white crystals (1.7 g, GC purity 99%, yield = 72%). (ii) Procedure 2 (Optimized using NaHCO3 for 4-substituted-1,2-bis-dibromomethyl-benzene). To a round bottom flask, 1 equivalent of the brominated compound, or product of the bromination reaction, and 12 mole equivalents of fuming sulfuric acid were added. The flask was equipped with a rubber stopper and a CaCl2 drying tube. The mixture was stirred until all bromides were dissolved. Eight mole equivalents of solid sodium bicarbonate powder were added while the mixture was being stirred in an ice bath. After the mixture stopped bubbling, ice was slowly added for the hydrolysis. The remaining processes were the same as ZHU Peter C et al. Sci China Ser B-Chem | April 2007 | vol. 50 | no. 2 | 249-252 Procedure 1, giving the desired dialdehyde. 2.2 4-Bromo-OPA and 4-fluoro-OPA method involves treatment with fuming sulfuric acid or sulfur trioxide followed by quenching with water. Li et al. [18] reported the preparation of several aromatic polyaldehydes, including OPA, by the hydrolysis of gem-dibromides using this procedure. Even though the exact mechanism of this reaction remains unclear, pioneering studies by Hart and Freedman indicate that in strongly ionic media, halomethyl groups attached to an aromatic nuclei, undergo ionization to form multica- tionic species[20 22]. These dicationic species, thus formed on hydrolysis with water, yield the dicarboxaldehyde (Scheme 2, Eq. (1)). Mark et al. described[23] the suggested formation of polyhaloaralkyl (halosulfonyl) sulfoxonium inner salts compounds by the reaction of benzal halides with sulfur trioxide (Scheme 2, Eq. (2)). The hydrolysis was carried by following Li’s procedure, using fuming sulfuric acid at room temperature followed by quenching with water. Even though this procedure worked reasonably well with unsubstituted OPA, less than satisfactory yields and purity were obtained with many substituted derivatives. To improve the 11H The synthesis of other 4-halo-OPA’s, 4-bromo-OPA and 4-fluoro-OPA followed similar procedures as described for 4-chloro-OPA. The oil 4-fluoro-OPA was purified by silica column chromatograph (hexane︰ethyl acetate = 2︰1). Others were purified by recrystallization. Key reaction and workup conditions are summarized Table 1. 12H 3 Results and discussion Our general synthetic route to substituted ortho-phthalaldehydes is outlined in Scheme 1. Radical bromination of xylenes was carried out by a reported procedure. Thus, bromine was added to a refluxing solution of the substituted xylene in carbon tetrachloride while the reaction was irradiated, using two 250 W tungsten lamps. The desired tetrabromoderivatives were obtained in very good yields and in excellent purity. Several methods have been reported for the hydrolysis of gem-dihalides [19]. The most widely reported 10H 13H Table 1 Summary and comparison of key reaction and workup conditions for the two-step synthesis of 4-halo-OPA’s Condition variables 4-chloro-OPA 4-bromo-OPA 4-fluoro-OPA bromination time ~6h ~2h ~6h Bromination crystallization workup crystallization solventa) fuming H2SO4 24 equivalents 12 equivalents 12 equivalents Hydrolysis workup recrystallization recrystallization silica column a) Hot hexane was used to isolate 4-bromo-1,2-bis(dibromomethyl)benzene from 3-bromo-1-bromomethyl-2-dibromomethylbenzene (from an isomeric impurity came with starting material). Scheme 1 General two-step synthesis of 4-substituted o-phthalaldehydes. (1) (2) Scheme 2 Possible mechanisms for the hydrolysis. ZHU Peter C et al. Sci China Ser B-Chem | April 2007 | vol. 50 | no. 2 | 249-252 251 Table 2 Yield comparison of three reaction/work up conditions Product Process Equivalents of H2SO4 reference method 28.4 OPA with controlled acid 12 12 with added NaHCO3 reference method 28.4 4-chloro-OPA with controlled acid 12 with added NaHCO3 12 reference method 28.4 4-bromo-OPA with controlled acid 12 with added NaHCO3 12 reference method 28.4 4-nitro-OPA with controlled acid 12 with added NaHCO3 12 yield and purity of the aldehyde, we decided to improve the Li’s hydrolysis protocol by reducing the amount of sulfuric acid used and changing the work-up procedure. Thus, the amount of acid was reduced from 28.4 equivalents to 12 equivalents, and instead of directly adding the reaction mixture to ice, the excess acid was neutralized prior to quenching with water. Several inorganic bases such as Na2CO3, NaOH, K2CO3, KOH, and CaCO3 were screened for neutralizing the reaction. Adding 8 equivalents of solid NaHCO3 gave the best results. This modification significantly improved the yield of the product in the case of all four products: OPA, 4-chloro-OPA, 4-bromo-OPA, and 4-nitro-OPA. The yields of products obtained using Li’s procedure, and our improved synthesis processes are outlined in Table 2. 1 2 3 Russell A D. Introduction of biocides into clinical practice and the impact on antibiotic-resistant bacteria. Society for Applied Microbiology Symposium Series 31. In Antibiotic and Biocide Resistance in Bacteria. Boston: Blackwell Science, 2002. 31: 121S-135S Boucher R M G. Biocidal mechanisms in the aldehyde series. Can J Pharm Sci, 1975, 10(1): 1-7 Walsh S E, Maillard J-Y, Russell A D. Ortho-phthalaldehyde: a possible alternative to glutaraldehyde for high level disinfection. J Appl Microbiol, 1999, 86(6): 1039-1046[DOI] Zhu P C, Roberts C G, Favero M S. Ortho-phthalaldehyde: a possible alternative to glutaraldehyde for high level disinfection. Curr Org Chem, 2005, 9(12): 1155-1166[DOI] Brewer B N, Mead K T, Pittman C U Jr, Lu K, Zhu P C. Smart solution chemistry: Prolonging the lifetime of ortho-phthalaldehyde disinfection solutions. Heterocycl Chem, 2006, 43(12): 361-363 Zhu P C, Wang D-H. Improved process for the preparation of 4-substituted phthalaldehydes. U.S. Patent 6,891,069, 2005 Zhu P. Non-hazardous oxidative neutralization of aldehydes. U.S. Patent 6,531,634, 2003 Armstrong A. Synthetic methods Part (ii) Oxidation and reduction methods. Annu Rep Prog Chem B, 2003, 99: 21-48[DOI] Gomez S, Peters J A, Maschmeyer T. The reductive amination of aldehydes and ketones and the hydrogenation of nitriles: Mechanistic aspects and selectivity control. Adv Synth Catal, 2002, 344(10): 1037-1057[DOI] Murray B A. Reactions of Aldehydes and Ketones and Their Derivatives in Organic Reaction Mechanisms. New Jersey: John Wiley & Sons Ltd, 2001. 1-35 Zhu P, Roberts C G, Chan-Myers H. Non-hazardous basic neutralization of aldehydes. U.S. Patent Appl Publ, 2003, 065,239, 2003 4 Conclusions Significant improvement to the hydrolysis of gem-dibromomethylarenes to the corresponding dialdehydes has been achieved. Our improvements (1) adding solid NaHCO3 before workup under cooling or (2) minimizing the amount of sulfuric acid in the reaction appear to be suitable for preparing a variety of substituted OPAs ——an important class of compounds used as synthetic intermediates, polymer starting compounds and important antimicrobial agents. 12 13 14 15 15H 5 6 7 8 16H 9 16 17 18 19 20 21 17H 10 11 252 Yield (%) 79 86 91 66 88 88 17 88 92 2 28 48 It is important to note that adding excess of base should be avoided to prevent Cannizaro type reactions, which will reduce the yield and purity of the product. 14H 4 Equivalents of NaHCO3 0 0 8 0 0 8 0 0 8 0 0 8 22 23 Zhu P C, Roberts C G, Wu J. Chemical detoxifying neutralization of o-phthalaldehyde: Seeking the “greenest”. In: Gan J, Zhu P C, Aust S D, Lemley A T eds, Pesticide Decontamination and Detoxification. ACS Symposium Series 863. Washington DC: American Chemical Society, 2004. 85-97 Lawrence N J. Aldehydes and ketones. J Chem Soc Perk T 1, 1998, (10): 1739-1749 Hollingworth G J. Aldehydes: Aryl and heteroaryl aldehydes. In: Katrizky A R, Meth-Cohn O, Rees C W, eds, Comprehensive Organic Functional Group Transformations 3. Oxford: Elsevier, 1995. 81-109, 733-856 Roberts S M. Aldehydes and ketones [general and synthetic methods]. Gen Synth Methods, 1978, 1: 76-110 Bill J C, Tarbell D S. o-Phthalaldehyde. Org Synth, 1954, 34: 82-85 Thiele J, Guenther O. Preparation of three phthalaldehydes. Liebigs Ann Chem, 1906, 347: 106-111 Li M, Fan N. Preparation of aromatic polyaldehydes by hydrolysis of gem-dibromides. Chem World (in Chinese), 1985, 26(5): 168-70 Liu H, Liu X, Song C. Side-chain chlorination of o-xylene and the synthesis of phthalaldehyde. J Jiangxi Normal U (Nat Sci Ed) (in Chinese), 2001, 25(3): 227-230 Hart H, Fish R. Multicharged carbonium ions. III. Long-lived ions from trichloromethylpolymethylhenzenes. J Am Chem Soc, 1961, 83(21): 4460-4466 Hart H, Fleming J S. Multicharged carbonium ions. IV. Stable crystalline salts. Tetrahedron Lett, 1962, 3(22): 983-986 Freedman H H, Frantz Jr A M. Tetraphenylcyclobutadiene derivatives. V. The tetraphenylcyclobutenium dication. J Am Chem Soc, 1962, 84(21): 4165-4167 Mark V, Mark C A. Halosulfonyl sulfooxonium compounds, U.S. Patent 3,869,491, 1975 ZHU Peter C et al. Sci China Ser B-Chem | April 2007 | vol. 50 | no. 2 | 249-252