Chapter9 dp&c - Springer Static Content Server

advertisement

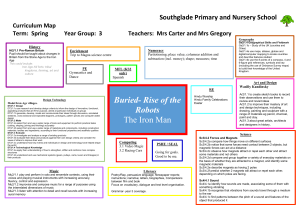

“Education in Pursuit of Supply Chain Leadership” dp&c Chapter9 Chapter 9 Replenishment in a Distribution Environment 9-1 dp&c Chapter9 Learning Objectives • • • • • • • • Describe distribution channel dependencies Detail “push” system functions Detail “pull” system functions Define distribution requirements planning (DRP) Decide what to choose: reorder points or DRP? Explore DRP in a multiechelon environment Understand the DRP planning grid Calculate the projected available balance (PAB) and the DRP grid 9-2 dp&c Chapter9 Learning Objectives (cont.) • Calculate net requirements and the DRP grid • Review the DRP planned order generation • Perform PAB and net requirements recalculation • Outline the DRP planning process • Perform a full DRP calculation • Review supply chain capacity planning 9-3 dp&c Chapter9 Chapter 9 Replenishment in a Distribution Environment Inventory Distribution Management Basics Channel Basics 9-4 dp&c Chapter9 Distribution Channel Dependencies Product Flow Plant Decoupling Point Information Flow Replenishment Point Central Warehouse Replenishment Point Decoupling Point Local Warehouse Replenishment Point Decoupling Point Customer 9-5 dp&c Chapter9 “Push” or “Pull”? Push Channel Allocation Plant Central Warehouse Local Warehouse Pull Demand Requirement Customer 9-6 dp&c Chapter9 “Push” System Functions Aggregate Channel Demand History Central Inventory Planning Yes Stock OK? No Review Branch Order Points Inventory Allocation “Fair-Share” Allocation Echelon Shipment 9-7 Resupply Order Supplier Shipment Order Receipt dp&c Chapter9 “Push” System Functions (cont.) Warehouses DCs 55% Manufacturing Plant 45% 60% Forecasting – Aggregate Requirements 40% 65% Production Lot Size Allocation 35% Allocation 9-8 dp&c Chapter9 Advantages of a Push System Performance Measurement Enables performance management of the entire supply channel Central Planning Enables channel inventory planning to be centralized in a single plan Cost Reductions By centralizing inventory planning and deployment, planners can remove planning redundancies Safety Stock Control Push systems cut safety stocks by centralizing them at supply DCs 9-9 dp&c Chapter9 “Push” System Allocation – Example Forecast Periods National forecast Regional forecast Region 1 Region 2 Region 3 Region 4 1 2 3 4 5 6 7 8 Percent 100% 15,000 15,000 18,000 18,000 19,000 19,000 20,000 21,000 12% 1,800 1,80015,000 2,160 x 2,160 12% =2,280 1,8002,280 units 2,400 2,520 28% 4,200 4,200 5,040 5,040 5,320 5,320 5,600 5,880 38% 5,700 5,700 6,840 6,840 7,220 7,220 7,600 7,980 22% 3,300 3,300 3,960 3,960 4,180 4,180 4,400 4,620 100% Region 1 Area forecast Area 1 Area 2 Area 3 Area 4 40% 25% 15% 20% 100% 720 450 270 360 720 1,800 x864 40% 864 = 720 912 units 912 570 342 456 960 600 360 480 1,008 630 378 504 Region 1, Area 1, Store forecast Store 1 Store 2 Store 3 Store 4 30% 15% 50% 5% 100% 216 108 360 36 216 720 108 360 36 288 144 480 48 302 151 504 50 Region 1, Area 2, Store forecast Store 1 Store 2 20% 15% 43 32 43 32 58 43 60 45 450 270 360 540 324 432 540 324 432 570 342 456 274 x 259 30% =259 216 units 9-10 130 432 43 130 432 43 137 456 46 274 137 456 46 52 39 52 39 55 41 55 41 dp&c Chapter9 “Pull” System Functions Local Facility Stock Status Customer requirements Stock OK? Order point/ DRP Shipment Resupply Order Interbranch shipments DRP Interbranch resupply order Distribution Center Plant Plant Stock No No Plant Resupply Order 9-11 Order Point Purchase Receipt dp&c Chapter9 “Pull” System Functions (cont.) Warehouses DCs Manufacturing Plant Master Schedule OP DRP Plant MRP Order Shipment Planned Orders Order Shipment 9-12 Planned Orders dp&c Chapter9 Advantages of a Pull System Planning Simplicity Planning is simplified because there is no centralized planning functions. Each facility does it own planning Turnover Because facilities calculate their exact requirements, push system stock excess is removed Overhead Cost Reduction By decentralizing planning, centralized planning overheads can be reduced Use of ROP and DRP techniques Pull system enable the effective use of ROP and DRP planning methods 9-13 dp&c Chapter9 BOMs and BODs Bill of Material Product A Component A Component B Component C Warehouse 1 Warehouse 2 Warehouse 3 Bill of Distribution Supply DC 9-14 dp&c Chapter9 Purchased Finished Product Flow Lead Time (LT) = days Central DC LT=4 Regional DC2 LT=3 Warehouse 1 Outside Supply Source LT=4 Regional DC1 LT=3 LT=5 Warehouse 2 LT=3 Warehouse 3 LT=3 Warehouse 4 LT=3 Warehouse 3 LT=2 Customer 9-15 dp&c Chapter9 Reorder Point Channel Management Warehouse 1 Warehouse 2 OP SS OP SS OP SS Resupply order LT=3 Resupply order LT=3 Warehouse 3 Resupply order LT=3 Quantity Central DC Regional DC1 Inventory LT=4 Resupply order X OP Available Inventory OP SS OP= order point SS=safety stock Time 9-16 dp&c Chapter9 Defining Distribution Requirements Planning (DRP) The function of determining the need to replenish inventory at branch warehouses. A time-phased order point approach is used where the planned orders at the branch warehouse level are “exploded” via MRP logic to become gross is requirements the supplyingplanning source. In(DRP)? the case of What distributionon requirements multilevel distribution networks, this explosion process can continue down through the various levels of regional warehouses (master warehouse, factory warehouse, etc.) and become input to the master production schedule. Demand on the supplying sources is recognized as dependent, and standard MRP logic applies. 9-17 dp&c Chapter9 Manufactured Finished Product Flow Lead Time (LT) = days Central DC LT=4 Regional DC2 LT=3 Warehouse 1 Manufacturing Plant LT=4 Regional DC1 LT=3 LT=25 Warehouse 2 LT=3 Warehouse 3 LT=3 Warehouse 4 LT=3 Warehouse 3 LT=2 Customer 9-18 dp&c Chapter9 Time Phasing – The Heart of DRP Solving the question of when in the inventory replenishment equation!! Product Lead Time/days Order Quantity On Hand Inventory/units KL-2000-10 2 50 55 1 2 DAILY PERIODS 3 4 5 6 Gross Requirements 20 35 25 25 45 65 Projected Available Balance 35 0 25 0 5 40 50 100 DRP Planned Order Receipt DRP Planned Order Release 50 50 50 9-19 100 dp&c Chapter9 Chapter 9 Replenishment in a Distribution Environment Inventory Basics of DRP Management Basics 9-20 dp&c Chapter9 DRP Grid Rows DAILY PERIODS Gross Requirements 1 2 3 115 115 125 DRP In Transit Receipts 200 Projected Available Balance 0 85 0 Net Requirements 115 0 40 DRP Planned Order Receipt 115 0 40 DRP Planned Order Release 40 0 0 9-21 dp&c Chapter9 DRP Period Variations Day Requirement Week Month 1 2 3 4 5 2 3 4 5 10 10 10 10 10 50 50 50 50 9-22 2 3 4 5 200 200 200 200 dp&c Chapter9 Projected Available Balance Calculation Product Safety Stock/units Min Order Qty/units Lead Time/months Lot size/units KL-2000-10 0 0 2 75 On Hand/units 200 Gross Requirements 1 2 3 4 100 110 125 130 120 -60 -190 -310 7 8 9 10 110 150 135 165 145 -420 -570 -705 -870 -1,015 75 DRP Intransit Receipts Projected Available Balance DAILY PERIODS 5 6 100 65 9-23 dp&c Chapter9 Net Requirements Calculation Product Safety Stock/units Min Order Qty/units Lead Time/months Lot size/units KL-2000-10 0 0 2 75 On Hand/units 200 Gross Requirements 1 2 3 4 100 110 125 130 120 Net Requirements 7 8 9 10 110 150 135 165 145 75 DRP Intransit Receipts Projected Available Balance DAILY PERIODS 5 6 100 65 -60 -190 -310 -420 -570 -705 -870 -1,015 0 0 60 190 310 420 570 705 870 1,015 9-24 dp&c Chapter9 DRP Planned Order Receipt Product Safety Stock/units Min Order Qty/units Lead Time/days Lot size/units KL-2000-10 0 0 2 75 On Hand/units 200 Gross Requirements DAILY PERIODS 6 5 1 2 3 4 100 110 125 130 120 7 8 9 10 110 150 135 165 145 75 DRP Intransit Receipts 100 65 15 35 65 30 30 45 30 35 Net Requirements 0 0 60 115 85 45 120 105 120 115 DRP Planned Order Receipt 0 0 75 150 150 75 150 150 150 150 Projected Available Balance 9-25 dp&c Chapter9 DRP Planned Order Release Product Safety Stock/units Min Order Qty/units Lead Time/days Lot size/units KL-2000-10 0 0 2 75 On Hand/units 200 Gross Requirements DAILY PERIODS 5 6 1 2 3 4 100 110 125 130 120 7 8 9 10 110 150 135 165 145 75 DRP Intransit Receipts 100 65 15 35 65 30 30 45 30 35 Net Requirements 0 0 60 115 85 45 120 105 120 115 DRP Planned Order Receipt 0 0 75 150 150 75 150 150 150 150 DRP Planned Order Release 75 150 150 75 150 150 150 150 0 0 Projected Available Balance Two day lead-time offset 9-26 dp&c Chapter9 DRP Recalculation Product Safety Stock/units Min Order Qty/units Lead Time/days Lot size/units KL-2000-10 0 0 2 75 On Hand/units 200 Gross Requirements 1 2 3 4 100 110 125 130 120 7 8 9 10 110 150 135 165 145 75 DRP Intransit Receipts Projected Available Balance DAILY PERIODS 5 6 100 65 15 35 65 30 30 45 30 35 Net Requirements 0 0 60 115 85 45 120 105 120 115 DRP Planned Order Receipt 0 0 75 150 150 75 150 150 150 150 DRP Planned Order Release 75 150 150 75 150 150 150 150 0 0 9-27 dp&c Chapter9 Order Policies Discrete (lot-for-lot) Fixed period requirements Discrete above the standard lot size Incremental above the standard lot size Multiples of a standard lot size EOQ models Min/max order quantity Lot costing models 9-28 dp&c Chapter9 DRP Safety Stock Safety Stock = 75 units Product Safety Stock/units Min Order Qty/units Lead Time/days Lot size/units KL-2000-10 0 0 3 200 On Hand/units 275 Gross Requirements Safety stock violations DAILY PERIODS 5 6 1 2 3 4 200 200 230 230 250 7 8 9 10 250 275 275 280 280 200 DRP Intransit Receipts 75 75 45 15 165 115 40 165 85 5 Net Requirements 0 0 155 185 235 85 160 235 115 195 DRP Planned Order Receipt 0 0 200 200 400 200 200 400 200 200 DRP Planned Order Release 200 400 200 200 400 200 200 0 0 0 Projected Available Balance 9-29 dp&c Chapter9 DRP Safety Stock Recalculation Product Safety Stock/units Min Order Qty/units Lead Time/days Lot size/units KL-2000-10 75 0 3 200 On Hand/units 275 Gross Requirements DAILY PERIODS 5 6 1 2 3 4 200 200 230 230 250 7 8 9 10 250 275 275 280 280 200 DRP Intransit Receipts 75 75 245 215 165 115 240 165 85 205 Net Requirements 0 0 230 60 110 160 235 110 190 270 DRP Planned Order Receipt 0 0 400 200 200 200 400 200 200 400 DRP Planned Order Release 200 200 200 400 200 200 400 0 0 0 Projected Available Balance Covering planned order 9-30 dp&c Chapter9 Chapter 9 Replenishment in a Distribution Environment Inventory The DRP Management Basics Calculation 9-31 dp&c Chapter9 Basic DRP Calculation Data Elements Length of the planning horizon Size of the planning buckets Item forecasts by due date Open customer orders by item by due date Beginning on-hand quantities by item Purchase, interbranch, and postponement orders by item by due date Replenishment lead times by item Safety stock by item Order policy code by item Supply sources based on the bill of distribution 9-32 dp&c Chapter9 DRP System Outputs Exception Reporting Availability of online displays and dashboards as a result of the DRP generation Planned Orders The DRP generation provides the planner with a window into the schedule of planned order release Action Messages Pegged Requirements Generation of action messages to inform the planner of required planning and scheduling problems Pegging enables planners to trace item resupply orders back to their sources 9-33 dp&c Chapter9 Bucketless DRP Display Item # KL-2000-10 Safety Stock Lead time 3 days OHB 75 275 Gross Reqs Scheduled Receipts Date Type Ref # OHB 01/01/XX FORECAST 01/08/XX PUR Ord 01/08/XX FORECAST 175 01/09/XX CUST Ord 25 01/15/XX PLN Ord 01/15/XX FORECAST 175 01/15/XX CUST Ord 10 CO#8754457 290 01/15/XX CUST Ord 15 CO#8754458 275 01/15/XX CUST Ord 30 CO#8754459 245 200 75 200 PO#789654 275 100 400 CO#8754456 75 PL#76543 475 300 9-34 dp&c Chapter9 Chapter 9 Replenishment in a Distribution Environment Inventory DRP in a MultiManagement Basics Echelon Environment 9-35 dp&c Chapter9 DRP Multiechelon Channel Implosion Lead Time/weeks Min Order Qty/units Order Quantity On Hand/units DISTRIBUTION CENTER 1 1 0 600 240 1 PRODUCT KL-2000-10 Gross Requirements 210 DRP In Transit Receipts Projected Available Balance Net Requirements DRP Planned Order Receipt DRP Planned Order Release Lead Time/weeks 30 0 0 0 Min Order Qty/units Order Quantity On Hand/units 6 210 7 210 8 210 210 0 0 0 180 0 0 600 570 30 600 0 360 0 0 0 0 0 0 600 390 210 600 0 SUMMARY PRODUCT KL-2000-10 1 Distribution Center 1 0 Distribution Center 2 0 Distribution Center 3 250 TOTAL 250 2 0 225 0 225 WEEKLY PERIODS 3 4 5 0 600 0 0 225 0 250 250 250 250 1,075 250 6 600 0 250 850 7 0 225 0 225 8 0 0 0 0 WEEKLY PERIODS 1 2 3 4 5 6 7 8 100 225 150 0 0 0 100 100 100 100 100 100 100 50 0 0 225 175 50 225 0 75 0 0 225 200 25 225 0 100 0 0 0 0 0 0 225 125 100 225 0 DISTRIBUTION CENTER 3 1 0 250 350 PRODUCT KL-2000-10 Gross Requirements DRP In Transit Receipts Projected Available Balance Net Requirements DRP Planned Order Receipt DRP Planned Order Release WEEKLY PERIODS 3 4 5 210 210 210 DISTRIBUTION CENTER 2 1 Min Order Qty/units 0 Order Quantity 225 On Hand/units 25 PRODUCT KL-2000-10 Gross Requirements DRP In Transit Receipts Projected Available Balance Net Requirements DRP Planned Order Receipt DRP Planned Order Release Lead Time/weeks 2 210 600 420 0 0 0 1 200 2 200 WEEKLY PERIODS 3 4 5 200 200 200 150 0 0 250 200 50 250 0 0 0 0 250 50 200 250 250 100 150 250 250 6 200 7 200 8 200 150 100 250 250 200 50 250 0 0 0 0 0 Lead Time/weeks 9-36 MANUFACTURING PLANT 2 Min Order Qty/units 550 Order Quantity 1 On Hand/units 25 PRODUCT KL-2000-10 Gross Requirements MRP Scheduled Receipts Projected Available Balance Net Requirements MRP Planned Order Receipt MRP Planned Order Release WEEKLY PERIODS 1 2 3 4 5 6 7 8 250 550 325 0 0 550 225 250 1,075 250 850 225 0 100 0 0 675 400 150 550 550 0 675 675 550 300 250 550 550 0 550 550 0 325 225 550 0 325 0 0 0 dp&c Chapter9 DRP Planning Process DRP Generation Determine Gross Requirements Review Inventory Balances Net Requirements Calculation Total Demand OK? Quantities OK? Shortages OK? Orders OK? Plan New Orders DRP Order Release 9-37 dp&c Chapter9 DRP Order Action Report Item # Order # Order Quantity Release Due 1425 Plan 5,000 01/01/XX 01/14/XX Release 1551 Plan 5,000 01/07/XX 01/14/XX No Action 2300 1234 345 4110 Plan 4,500 3320 1267 3345 1275 01/24/XX 07/07/XX Revised Due 01/07/XX Action Message Expedite 01/14/XX Release 1,234 01/23/XX De-Expedite 4,567 01/25/XX Cancel 9-38 dp&c Chapter9 Chapter 9 Replenishment in a Distribution Environment Inventory Stocking MultiManagement Basics Echelon Supply Channels 9-39 dp&c Chapter9 Selective Stocking A method of maximizing available warehouse space in the channel by determining which items are to be stocked at what channel echelon level based on item ABC classification 9-40 dp&c Chapter9 Square-Root Rule Calculating the advantage gained through a channel inventory consolidation strategy CI SI n where: CI is the inventory value if the entire network stock were to be centralized at n number of stocking locations SI is the amount of inventory stocked at n distribution locations n is the number of stocking points in the channel. 9-41 dp&c Chapter9 Square-Root Rule – Exercise Objective: Cost benefit of consolidating an item stocked in 10 warehouses to 3 warehouses Data: Stocking cost of item in 10 warehouses = US$20,554.80 Formula: CIn3 X 1 n2 / n1 where: CIn3 = total cost for three facilities n2 = 3 facilities n1 = number of existing facilities (10) X1 = total unit cost for 10 facilities Solution: CIn3 US$20,554.80 3 / 10 US$11,258.33 9-42 dp&c Chapter9 Push System With Stocking Constraint – Steps 1. Determine the quantity of the production run or supplier purchase. 2. Determine the forecast requirements of each of the channel locations between the current time and the next expected production run or supplier purchase. 3. Calculate the adjusted requirements forecast by using the predetermined stocking target and the forecast error (standard deviation). 4. Tally the existing on-hand balances at each channel location. 5. Subtract the adjusted requirements forecast from the current onhand balances at each warehouse to arrive at the warehouse’s net allocation. 6. Sum the net allocations and then subtract it from the total push quantity determined in step 1. 9-43 dp&c Chapter9 Push System With Stocking Constraint – Steps 7. Apportion the inventory excess over the adjusted requirements forecast to arrive at the proration of excess. 8. Add each warehouse’s net allocation and the proration of excess to arrive at the new push allocation for each warehouse. 9. Establish the normal capacity target for storing inventories at each channel location and the max stock quantity target. 10. Divide the max stock quantity target by the prorated allocation to arrive at the percent utilization of capacity for each warehouse. 9-44 dp&c Chapter9 Push System Stocking Constraint – Exercise Objective: Reviewing the impact of an opportunity supply order Data: Supplier discount if 55,000 units purchased Inventory Quantities Product # KL-1000-20 Inventory Qty 55,000 Warehouses 1 2 3 4 Total Forecasted Forecast Percent Requirements 5,000 7,000 9,000 12,000 33,000 Forecast Error (s ) 15.15% 21.21% 27.27% 36.36% 9-45 500 1,000 1,500 2,000 Total Current Inventory Balance 2,500 3,000 5,000 6,000 16,500 Service Percent Target 90.0% 90.0% 95.0% 95.0% dp&c Chapter9 Push System Stocking Constraint – Exercise Objective: Determine forecast allocation Formula: Forecast + (NORMSINV [Service target]) * Standard Deviation (s) Allocation Warehouses 1 2 3 4 Total Adjusted Current Inventory Requirements Balance Forecast 5,640.78 2,500 8,281.55 3,000 11,467.28 5,000 15,289.71 6,000 Totals 40,679.32 Net Allocation 9-46 3,140.78 5,281.55 6,467.28 9,289.71 24,179.32 Proration Allocation 4,669.80 6,537.72 8,405.64 11,207.52 30,820.68 Adjusted Allocation 7,810.58 11,819.00 14,872.92 20,497.00 54,999.50 dp&c Chapter9 Push System Stocking Constraint – Exercise Objective: Determine allocation capacity Formula: Prorated allocation / max quantity target Capacity Stocking Capacity Target Warehouses 1 2 3 4 90.00% 90.00% 95.00% 95.00% Totals Max Quantity Target 8,500 12,000 15,500 20,000 56,000 9-47 Prorated Allocation 7,810.58 11,819.00 14,872.92 20,497.00 54,999.50 Capacity Percent of Prorated Allocation 91.89% 98.49% 95.95% 102.49% 97.21% dp&c Chapter9 Least-Cost Redistribution Objective: Restore channel warehouse inventory imbalances at the least cost Data: Transportation cost matrix On-hand Balance Warehouse 75 60 -50 50 -60 Chicago New York Dallas Denver Los Angles Chicago $ $ $ $ $ 1.45 1.65 1.75 2.05 New York $ $ $ $ $ 1.35 1.85 1.95 2.25 Dallas $ $ $ $ $ Denver 1.63 1.82 1.65 2.03 $ $ $ $ $ 1.70 1.80 1.70 1.25 Los Angles $ $ $ $ - 2.10 2.40 2.00 1.10 Solution: On-hand Balance Warehouse 75 60 -50 50 -60 Chicago New York Dallas $ Denver Los Angles $ Chicago New York Dallas Denver Los Angles 81.50 $ 91.00 $ - $ 82.50 $ 126.00 $ 144.00 $ - $ 66.00 - 9-48 - dp&c Chapter9 “Fair Share” Technique Objective: Provide branch locations with equal run out resupply sufficient enough to prevent stock out Formula 1: Days of total inventory at all facilities 𝐷𝑆 = 𝐴𝑄 + 𝑛 𝑏=1 𝐼𝑏 𝑛 𝑏=1 𝐷𝑏 where DS = Common days supply for branch inventories AQ = Inventory units to be allocated from the DC Ib = Inventory in units for branch b Db = Daily demand for branch b 9-49 dp&c Chapter9 “Fair Share” Technique (cont.) Objective: Determine fair share allocation Formula 2: Calculate fair share allocation Ab = (DS – Ib/Db)Db, where Ab = Amount allocated to branch b DS = days supply provided for each branch Ib = Inventory in units for branch b Db = Daily demand for branch b 9-50 dp&c Chapter9 “Fair Share” Technique – Exercise Objective: Allocating 200 units across three branches Data: Weekly Requirements Location DC Branch A Branch B Branch C Totals On-Hand 200 30 37 33 300 Week 1 40 50 60 150 Week 2 Week 3 40 50 60 150 9-51 40 50 60 150 Week 4 40 50 60 150 Week 5 40 50 60 150 Daily Usage 8 10 12 30 dp&c Chapter9 “Fair Share” Technique – Exercise (cont.) Formula 1: Days of total inventory at all facilities 𝐷𝑆 = 𝐴𝑄 + 𝑛 𝑏=1 𝐼𝑏 𝑛 𝑏=1 𝐷𝑏 200 + (30 + 37 + 33) = = 10 𝑑𝑎𝑦𝑠 (8 + 10 + 12) Formula 2: Branch A fair share allocation Ab = (DS – Ib/Db)Db = ((10 – (30/8)) * 8) = 50 units Formula 2: Branches B and C fair share allocation Ab = (DS – Ib/Db)Db = ((10 – (37/10)) * 10) = 63 units Ab = (DS – Ib/Db)Db = ((10 – (33/12)) * 12) = 87 units 9-52 dp&c Chapter9 Chapter 9 Replenishment in a Distribution Environment Inventory Supply Chain Management CapacityBasics Planning 9-53 dp&c Chapter9 Supply Chain Capacity Planning Financial Estimating Labor and Equipment Capacity DRP Transportatio n Planning Warehouse Space Planning 9-54 dp&c Chapter9 Costed DRP Inventory Report Warehouse: Chicago Date From: 01/01/20XX Date To: 12/31/20XX Product Family On Hand Planned Order Qty Cost Projected Value 1425 2,550 15,300 $ 16.50 $ 294,525.00 1551 2,250 18,000 $ 9.50 $ 192,375.00 2300 1,250 14,000 $ 4.50 $ 68,625.00 4100 900 11,500 $ 42.50 $ 527,000.00 3320 250 7,500 $ 35.80 $ 277,450.00 5673 11,000 55,500 $ 3.65 $ 242,725.00 7836 15,000 45,500 $ 2.40 $ 145,200.00 9835 20,000 100,000 $ 12.50 $ 1,500,000.00 3478 8,000 54,000 $ 26.50 $ 1,643,000.00 5903 2,000 1,000 $ 13.75 $ 41,250.00 2237 3,250 21,000 $ 27.50 $ 666,875.00 3410 670 8,500 $ 22.75 $ 208,617.50 Totals 67,120 351,800 Totals $ 5,807,642.50 9-55 dp&c Chapter9 Transportation Report Warehouse: Chicago Date From: 01/01/20XX Date To: 01/31/20XX Standard Pallet Cube (inches) 64 Product Family Forecasted Shipments Total Weight (lbs.) Number of Pallets Cube (pallet) 1425 1,488 11,345 149 9,536 1551 1,688 12,356 169 10,816 2300 1,271 8,525 128 8,192 4100 1,033 8,400 104 6,656 3320 645 4,278 65 4,160 5673 5,542 48,500 278 17,792 7836 5,042 51,000 252 16,128 9835 10,000 1,670 500 32,000 3478 5,167 62,000 259 16,576 5903 250 1,125 25 1,600 2237 2,020 19,357 10 640 3410 765 6,350 77 4,928 Totals 34,910 234,906 2,016 129,024 9-56 dp&c Chapter9 Detailed Shipping Report Warehouse: Chicago Standard Pallet Cube (inches) Week Item # 1425-01 1 1425-03 1425-04 2300-01 2300-04 5673-01 5673-02 5673-04 9835-02 9835-04 9835-06 9835-07 3410-01 Totals Date From: 01/01/20XX 64 Quantity 70 35 21 36 43 76 25 48 125 257 310 223 10 1,279 Order Type Weight (lbs.) CO 280 CO 145 CO 125 CO 148 PLN ORD 153 CO 175 PLN ORD 125 CO 165 CO 245 PLN ORD 450 CO 625 PLN ORD 460 PLN ORD 45 3,141 9-57 Date To: 01/31/20XX Pallets 7 4 2 4 5 4 2 5 7 13 16 23 2 94 Cube (pallet) 448 256 128 256 320 256 128 320 448 832 1,024 1,472 128 6,016 dp&c Chapter9 Warehouse Space Report Warehouse: Chicago Storage Type Location Shelf Rack 7010101 Shelf Rack 7010102 Shelf Rack 7010103 Shelf Rack 7010104 Shelf Rack 7010201 Shelf Rack 7010202 Storage Type Bin Bin Bin Bin Bin Bin Location 6010101 6010102 6010103 6010104 6010105 6010106 Date From: 01/01/20XX Code Weight SR4 1,500 SR4 1,500 SR4 1,500 SR2 750 SR4 1,500 SR4 1,500 Code B6 B6 B12 B12 B6 B6 Weight 450 450 450 450 450 450 9-58 Date To: 01/31/20XX Dimensions (ft) Volume (ft3) 4x8x4 128 4x8x4 128 4x8x4 128 2x8x4 64 4x8x4 128 2x8x4 64 Totals 25,000 Dimensions (in) 6x36x24 6x36x24 12x36x24 12x36x24 6x36x24 6x36x24 Totals Volume (in3) 5,184 5,184 10,368 10,368 5,184 5,184 1,550,000 dp&c Chapter9 “Education in Pursuit of Supply Chain Leadership” dp&c Chapter9 Chapter 9 End of Session 9-59 dp&c Chapter9