MAE 343_Class 7

advertisement

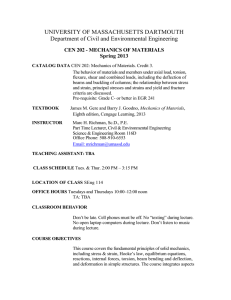

MAE 343 - Intermediate Mechanics of Materials Tuesday, Sep. 14, 2004 Textbook Section 4.4 Overview of Structural Analysis for Beams and Shafts Overview of Loads ON and IN Structures / Machines Structural Analysis Applied LoadsForces &Moments Body forces &couples Reaction Forces & Moments (at supports) From FBD of entire structure Surface forces&couples Flow Lines from Applied to Reaction Forces Resultants on Cutting Surface From FBD of Part of Structure Equilibrium Eqs. (3 in 2D, 6 in 3D) Concentrated FBD of Each Component from Forces through Contact Surfaces Distributed / Pressures Internal Forces & Moments Depend on Location& Orientation of Cutting Plane Equilibrium Eqs. (3 in 2D, 6 in 3D) Shear Force & Bending Moment Diagrams Overview of Various Stress Patterns Stresses- from Distribution of Internal Forces over Given Cross-Section Uniaxial Tension or Compression of Straight Bars or Lap Joints Pure Bending of Long Beams Beams Subjected to Transverse Forces Torsion of Round or Prismatic Shafts Uniform Distributions of Stresses Neutral Axis at Centroid of Cross-section Transverse Shear Stresses Result (Add-up) in Shear Force in the Cross-Section Moment of differential torsional stress about centroid results in the internal torque in cross-section Normal Stress-Straight Bars Sigma=F/A Linear Distribution over from Neutral Axis Sigma=(My)/I (Normal Axial Stresses) Distribution from Neutral Axis Depends on Shape of Cross-section Tau(y)=(V*MomentArea)/(I*Z(y)) Circular Cross-section: Linear distribution, with Max. at the outer edge: Tau=(Tr)/J Maximum may not be at neutral axis Tau_max=(coef.)Tau_average Prismatic Shafts -Torsion Leads to Warping Membrane Analogy: Tau_max=T/Q, Theta=(TL)/KG Direct Shear in Lap Joints Tau =P/A The Resultant of Bending Stresses is the Bending Moment in the Cross-section Maximum at top or bottom, and zero at neutral axis Zero at top and bottom edges Bending of Asymmetric Beams: IF Plane of Transverse Forces passes through the SHEAR CENTER, NO Torsion occurs Power-Torque-RPM Relations: hp=(Tn)/63,025 kw=(Tn)/9549 Solution of Example Problem 4.3 • Step 1 –Construct shear&moment diagrams • Step 2 –Find dmin=0.90in to resist allowable=35,000psi at section where Mmax=2500in-lb • Step 3 –Find dmin=0.56in to resist allowable=20,200psi for maximum direct average shear stress • Step 4 –Find dmin=0.65in to resist allowable=20,000psi for maximum transverse shear stress Example 4.2- Calculation of Transverse Shear Stresses • Hollow rectangular cross-section (Channel) – Moment of Inertia about neutral axis, Izz=8.42 in4 • Max. transverse shear stress at neutral axis – Direct application of “area moment” method • xy(max)=0.34V, xy(ave)=0.2V, so that • xy(max) =1.7 xy(ave)=1.7(F/A)….Table 4.3 – Divide irregular section into several regular parts • Transverse shearing stress distribution, xy(y) Summary of Solutions to Textbook Problems – Problem 4.10 • Module support D6AC steel beam with two small hole and cracks – Ignore for now stress concentrations&fracture mechanics – Beam subjected to four-point bending • Uniform bending moment at mid-span, M=PL/3 =281.25 kN-m • No transverse shear stress in central span, V =0 • Check for possible failure by yielding – Max. bending stress at: • The tip of bottom crack, yct =10.3cm, x(ct)=(M*yct)/Izz=556 MPa • At the outer fibers: x(max)=(281.25x103)(12.5x10-2)/5.21x10-5=675 Mpa – From Table 2.1, Syp=1570MPa, so that the “safety factor” is equal to 1570/675=2.3 NO yielding Summary of Solutions to Textbook Problems – Problem 4.15 • Short tubular cantilever bracket, AISI 1020 steel (CD) – Critical points at the wall: • Top and bottom fibers for bending • At neutral axis for transverse shearing stress • Calculate maximum stresses – Axial bending stress: x=48,735 psi – Transverse shear: use Table 4.3 to obtain yz(ts)=2(F/A)=48,890psi • Yielding failure mode for uniaxial tensile stress – No failure since Table 3.3 shows Sy=51,000psi>48,735 psi • Multiaxial failure theory is necessary for yz(ts) Example 4.5- Calculation of Stresses in Channel-Section Cantilever Beam • Determine maximum bending stress – z(max)=48000(2.0)/4.74 =20,250 psi, Ixx=4.74in4 • Max. transverse shear at neutral axis – Area moment methods yields: zy(max)= 7720 psi • Flow of torsional shearing stresses – Locate SHEAR CENTER by using Table 4.5: e=0.56 in – Find torsional moment since the plane of “P” is located at a distance a=1.26 in. from the shear center: T=Pa =10,080 in-lb – Find horizontal shear forces that form resisting couple, T = Rd – Maximum torsional shearing stresses in the flanges: • zx(max)= R/Af= 2739/((1.72)(0.32)) = 4976 psi • Could be eliminated by translating the plane of “P” by 1.26in to the left

![Applied Strength of Materials [Opens in New Window]](http://s3.studylib.net/store/data/009007576_1-1087675879e3bc9d4b7f82c1627d321d-300x300.png)

![Strength of Materials [Opens in New Window]](http://s2.studylib.net/store/data/009980952_1-af573ee3f319ca71dbd5b53d99fdf436-300x300.png)