Process Consulting Services

advertisement

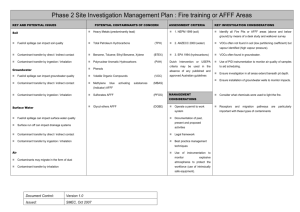

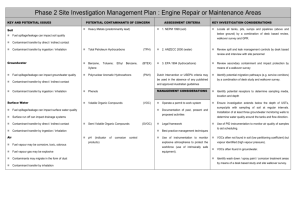

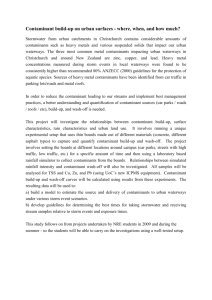

Contaminant Control: a New Approach David Burns davbur@sps2test.com Scientific Process Solutions a division of Perry Equipment Corporation Introduction Scientific Process Solutions (SPS) is a division of Perry Equipment Corporation (PECO) that offers field contaminant measurement and consulting services. SPS serves the natural gas transmission and processing, chemical processing, refining, and power generation industries. Contaminants and Contaminant Mixtures Contaminant –Solids –Liquids –Semi-solids –Foams –Emulsions Types Solids Common solid contaminants – – – Formation solids (reservoir and frac sand) Corrosion solids (iron sulfide, iron oxide) Precipitating solids (elemental sulfur, salt compounds) Formation Solids Corrosion Solids (Iron Sulfide) Precipitating Solids Sulfur Compounds Precipitating Solids Siloxane Compounds Liquids lube oil salt water or brine water condensate hydrocarbon condensate crude oil glycol (TEG) gas processing amines corrosion inhibitors biocides foaming agents defoaming agents mecury Semi-solids Semi-solids are usually mixtures of solid and liquid contaminants Foams Foams are mixtures of gases and liquids Emulsions Emulsions are mixtures of different liquids and gas Contaminants and Contaminant Mixtures Each of these different types of contaminants and contaminant mixtures can cause serious process problems if the filtration separation system is not properly designed to handle them. Hard to remove contaminant mixtures are more common than ever due to increased use of well head and pipeline injection chemicals. Greater contaminant removal performance is required today, due to the increased use of industry technology like formulated processing solvents, membrane separators, gas fired turbines, LoNox nozzles and burner tips. Filtration & Separation Devices Filtration technology has greatly advanced over the last few years to meet industry’s need for improved performance. This advancement in new filtration technologies makes the equipment selection process even more difficult. Filtration & Separation Devices Gas Filters Technology Typical Application Dry Gas Filters Solids removal. Knock Out Drums Removal of bulk pipeline liquids. Vane Separators Cyclones Removal of continuous pipeline liquids. Used usually upstream of other more efficient filtration equipment. Removal of continuous pipeline liquids. Usually used on the suction and discharge of compressors. Removal of low surface tension pipeline liquids and semi-solids. Removal of bulk pipe solids. Scrubbers Removal of small liquid slugs. Slug Catchers Removal of large liquid slugs. Filter Separators Removal of pipeline liquids and solids. Coalescers Removal of low surface tension liquids and aerosols. Gemini Purasep Coalescer Removal of low surface tension liquids, solids, and aerosols. Wire Mesh Separators Centrifugal Separators Performance Characteristics Uses replaceable filter elements and has a limited dirt holding capacity. Large liquid handling capacity and low removal efficiency. Low cost with moderate removal efficiency. Low cost and low removal efficiency. Low cost, high pressure drop and improved removal efficiency. Low cost, no replacement parts and improved removal efficiency. Low cost and moderate removal efficiency Large vessels or piping systems with very low removal efficiency. Uses replacement elements and has a good removal efficiency. Low element replacement cost. Excellent removal efficiency. Low contaminant handling ability. High element replacement cost. Excellent removal efficiency. Moderate contaminant handling ability. Moderate element replacement cost. Filtration & Separation Devices Liquid Filters Technology Typical Application Cartridge Filters Solid and semi-solid removal. Hydrocyclones Removal of bulk pipeline solids. Basket Strainers Bag Filters Removal of bulk pipeline solids. Used usually upstream of other more efficient filtration equipment. Removal of pipeline solids. Liquid Phase Separators or Coalescers Separation of two immisible liquids. Removal of free moisture from fuels. . Performance Characteristics Uses replaceable filter elements and has a limited dirt holding capacity. Removal efficiency depends on element technology used. Usually used where excellent removal efficiency is needed. Large solids handling capacity with moderate removal efficiency. Low cost with moderate to low removal efficiency. Low cost. Removal efficiency depends on contaminant and bag technology used. Low bag replacement cost. Short life when semi-solids are present. Excellent separation efficiency. High element cost. Low solids handling ability. The Contaminant Dictates the Method A system’s contaminant content and properties dictate the separation technology used. It is important to provide detailed scientific data on a system’s contaminant species on RFQ process data sheets. Detailed scientific data on a system’s contaminant species will help insure that filtration separation technologies are selected that will provide the required removal efficiency at an optimum operational cost. Optimally designed filtration and separation equipment will save money. Field Experiences Example 1 Field Experiences Example 1 This processing facility had 4 coalescers experience a decrease in removal performance. The additional vane mist extractor had been selected for use on the coalescers to handle high liquid loads. However, over 4 years time the extreme solids loading eventually plugged off the drainage ports of the vane mist extractors, sending more liquid to the coalescer elements than they could handle. Had up front contaminant testing been done on this system, the large solids load would have lead filtration designers to use a different technology to protect the coalescer elements for the system’s high liquid and solids contaminant content. Field Experiences Example 1 The Solution – – – – Solvent and steam cleaning failed. Coalescers had to be cut open to be cleaned. Coalescers were put back into service. Bulk solids loading removal technologies are being reviewed for installation upstream of the coalescers. Field Experiences Example 2 A custody transfer station was having problems with liquid contamination fouling pressure control and measurement equipment. A surplus filter separator was sized for the gas flow rate and installed to eliminate the contamination causing the problems. Field Experiences Example 2 The problems continued. SPS was hired to test the contaminant loading entering and exiting the filter separator. Field Experiences Example 2 The inlet gas stream was measured to contain 98 liters per day of free liquid contaminant entering the filter separator. The filter separator outlet gas stream was measured to contain 98 liters per day of free liquid contaminant entering the filter separator. The liquid was identified to be lube oil with a surface tension of 28 dynes/cm. Field Experiences Example 2 Conclusion – The liquid contaminant’s surface tension was too low for a filter separator to work properly. The Solution – A slug catcher and high liquid loading horizontal coalescer were installed in place of the filter separator. The Result – Test results of the new system measured an outlet contaminant content of 0.43 PPB(wt) or about 0.007 liters of carryover per day. – Pressure control and measurement equipment are now working properly. Field Experiences Example 3 This gas element came under attack from a contaminant that was not chemically compatible with it’s media material. It is important to study the chemical compatibility of all of a system’s contaminant species with any filter materials that might be used. This is a case where a filter element problem can go undetected contaminating downstream processes. Field Experiences Example 3 The Solution – A chemically compatible element material was selected and installed in service. – No other process problems have been reported. Field Experiences Example 4 A natural gas fired turbine failed it’s NOx emissions requirement. The turbine’s LONOx fuel gas nozzles were found to be damaged and partially plugged off with contaminant. The LONOx nozzles were protected by a 1 micron filtration separation system. Field Experiences Example 4 Conclusion – The standard 1 micron filtration vessel was not efficient enough for the system’s contaminant size. The Solution – A 0.3 micron high dirt loading coalescer vessel was installed. The Result – The turbine passed it’s next NOx emissions test. – No additional nozzle damage has occurred. Field Experiences Example 5 A gas processing facility was experiencing plant iron sulfide contamination resulting in excessive TEG and amine filter element changes. The system’s inlet gas 0.3 micron coalescer was tested and found to be allowing iron sulfide contamination to pass downstream. Field Experiences Example 5 Conclusion – The standard 0.3 micron element technology was not sufficient to remove the system’s iron sulfide contaminant. – Dry pipeline conditions and high velocities worked to shear the iron sulfide contaminant size distribution to be partially under 0.3 microns in size. The Solution – An iron sulfide removing element technology was installed in the existing coalescer. – An upstream water wash system was also installed. Field Experiences Example 5 The result – Down stream element life was extended by 7 times. – The water wash system worked with the iron sulfide element technology to wash the contaminant off of the coalescer elements extending their life to over a year and counting. A New Approach Gather information on your system’s contaminant species before entering the bidding process. Have liquid samples from the system or at least a nearby system analyzed for identification, surface tension, viscosity, pH, density, total suspended solids loading, and solid particle size. If possible, have the system on-line tested for contaminant loading and size. Testing done on-site will provide important contaminant content data that is not available from laboratory tests. A New Approach Field Testing Protocols DCM (Direct Contaminant Measurement Laser Testing) CCM (Coalescer Contaminant Measurement Testing) SCM(Solids Contaminant Measurement Filter Disk Testing) A New Approach DCM Direct Contaminant Measurement A New Approach DCM Direct Contaminant Measurement DCM Specifications The DCM protocol utilizes a high pressure laser particle counter to measure and quantify aerosol contaminant in a gas stream. The protocol is used for testing down stream of coalescers, Gemini Purasep units, and filter separators. Measurement range 0.3 - 8 micron Operating pressure range 2 - 2000 psi Operating temperature range 40 - 180 deg. F Maximum aerosol content 30 ppm Maximum gas velocity 30 ft/sec Scientific Process Solutions Direct Measurement Contaminant Analysis High Pressure Laser Field Test Report Test Summary No. 1 Date: Tested By: Vessel Type: Element Type: Client: Testing Location: Vessel Model No: PGCPH-18-382-34-750 Input Values Vessel Flow Rate: (MMSCFD) Operating Pressure: (PSIG) Operating Temperature: (F) Specific Gravity: Vessel ID: (inches) Liquid Density: (lbs/ft3) Number of Samples: Ave. Particle Size (micron) 0.300 0.350 0.400 0.450 0.500 0.550 0.600 0.650 0.700 0.750 0.800 1.000 3.000 5.000 8.000 Particle Wt (lbs) 2.49E-17 3.96E-17 5.91E-17 8.42E-17 1.15E-16 1.54E-16 2.00E-16 2.54E-16 3.17E-16 3.90E-16 4.73E-16 9.24E-16 2.49E-14 1.15E-13 4.73E-13 147 586 81 0.6 34 50 360 Sample Average 34022.43 15257.16 6926.63 1405.64 25.15 22.25 2.14 0.09 0.01 0.00 0.01 0.01 0.00 0.00 0.00 Average Sample wt 8.4863E-13 6.0432E-13 4.0954E-13 1.1833E-13 2.9042E-15 3.4202E-15 4.2784E-16 2.2489E-17 1.7555E-18 1.0796E-18 6.5512E-18 5.1182E-18 0 0 0 Calculations Compressibility: Flow Rate: (acfh) Gas Density: (lbs/ft3) X-Sec Area: (ft2) Sample Velocity: (ft/hr) Flow Meter Setting: (ml/sec) 0.925 144316 1.946 6.305 22889 16.0 Sample Sequence: 10 Sec 22-Jan-04 T. Borjon, D. Burns Gemini PGC-382 Testing Notes Liquid Surface Tension: (dyn/cm) Sample Collection Time: (sec.) Sample Connection: Atm Press. Sampling Duration 11:03-12:03 (min) 10 Pipeline 14.7 60 Total Accumulated Sample Wt: (lbs/10sec) Total Accumulated Sample Wt: (lbs/sec) 1.99E-12 1.99E-13 Carryover PPM (wt) 0.007368 Carryover Gal/Day 0.00595 Notes: Ave Total Counts 57662 Average Particle Counts Versus Micron Size 50000 45000 40000 35000 30000 25000 20000 15000 10000 5000 0 0.300 0.350 0.400 0.450 0.500 0.550 0.600 0.650 0.700 0.750 0.800 1.000 3.000 5.000 A New Approach CCM Coalescer Contaminant Measurement A New Approach CCM Coalescer Contaminant Measurement CCM Specifications The CCM test coalescer system is designed to measure free liquids and aerosols in almost any application. The CCM unit is commonly used for testing gas separators and scrubbers. The unit can also be used to quantify the inlet gas streams to coalescers, Gemini Purasep units, and filter separators. Liquid collection range 0.3 micron - free liquid Operating pressure range 2 - 1480 psi Operating temperature range - 40 - 250 deg F Testing sample line size 1/2” - 1” Scientific Process Solutions Coalescer Contaminant Measurement Analysis Test Summary No. 6 Date: File Name: Tested By: Test Vessel Type: Element Type: Client: Testing Location: Compressor Station Vessel Name/No: Sample Point: Upstream Pipeline High Point Vent Input Pipeline Values Pipeline Flow Rate: (MMSCFD) Operating Pressure: (PSIG) Operating Temperature: (F) Specific Gravity: Pipeline ID: (inches) Liquid Density: (lbs/ft3) Test Start Time: Test Finish Time: 81.3 319 81 0.75 19.25 50 12:15:00 4:15:00 Calculations Compressibility: Flow Rate: (acfm) Gas Density: (lbs/ft3) Pipeline X-Sec Area: (ft2) Gas Velocity: (ft/min) 4:15:00 Totals 20 Special Testing Notes: Input Test Vessel Values Operating Pressure: (PSIG) 341 Operating Temperature: (F) 60 Sampling Line Diameter ID:(inch) 1 Sampling pipe X-sec Area: (ft2) 0.0055 Sample Line Velocity: (ft/min) 1100.08 0 1440 Test Vessel Flow Rate: (acfm) Total Testing Period: (minutes) Total Testing Period: (hours) 240 4.00 Test Start DP: (in of WC) Test Finish DP: (in of WC) 6.00 0 0 Liquid Collection Summarys Upper Sum p Low er Sum p (milliliters) 20 Tomas Borjon, David Burns 77V-1-312-8-1480 NGGC312 Initial Totalizer Reading: (cuft) Final Totalizer Reading: (cuft) Liquid Collection Log Time 0.912 2360 1.371 2.021 1167.54 Nov. 5, 2003 (milliliters) 0 0 Total Liq (milliliters) 20 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 20 Total Total Total Total Total Total Amount of Liquid Collected: (milliliters) Amount of Liquid Collected in Upper Sump (aerosols): (milliliters) Amount of Liquid Collected in Lower Sump (free liq): (milliliters) Liquid Mass Collected: (lbs) Liquid Mass Collected in Upper Sump (aerosols): (lbs) Liquid Mass Collected in Lower Sump (free liq): (lbs) 20 20 0 0.0353 0.0353 0.0000 Total Mass of Gas Tested Total Gas Tested During Testing Period: (cuft) Total Gas Tested During Testing Period: (lbs) 1440 1974.89 Liquid Contaminant Content Level Liquid Aerosol Content in the gas: (PPM wt) Free Liquid Content in the gas: (PPM wt) 17.9 0.0 Total Liquid Content in the Gas Stream: (PPM wt) 17.9 Pig entered plant receiver at 2:50 p.m. A New Approach SCM Solids Contaminant Measurement A New Approach SCM Particle Sizing Laboratory Equipment A New Approach SCM Solids Contaminant Measurement SCM Specifications The SCM testing protocol is used to quantify solid or semi-solid contaminant content in a gas stream. Microscopic analysis can be added to provide a particle size distribution. Operating pressure range 2 - 2000 psi Operating temperature range - 40 - 250 deg f A New Approach Provide the contaminant data on filtration separation specification data sheets for E&C’s to include during the bidding process. Performance verify new and existing filtration and separation equipment. Include performance verification in initial equipment scope of supply. Have process optimization studies done for your plant or facility’s contaminant control equipment. A New Approach The Result – Scientific contaminant data provided on RFQ data sheets will result in the purchase of filtration separation systems that will provide optimum operational performance at an optimum capital and operational cost. – Performance verification of new and existing equipment will identify problems before additional damage to expensive downstream equipment occurs. – Process optimization studies of contaminant control systems will lower overall plant operational cost. Thank you for your kind attention. Questions???