Dynamic Cone Penetrometer - Ethiopian Roads Authority

advertisement

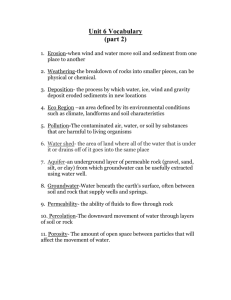

Material Testing and Field Compliance Test Ethiopian Roads Authority Universal Rural Roads Access Program Training of Trainers for Contractors 02 – 07 August 2013, Chancho Presentation Outline Background Need for Testing and Specification Material Field Test Laboratory Testing Compliance Test data management & QC Background Road formation ◦ ◦ ◦ ◦ ◦ Site clearance Earth work/ embankment construction Subgrade construction Subbase and Surfacing Engineered natural surfaces Typical gravel road cross section Embankment/Subgrade Material quality Requirements for borrow material, Earth work for embankment and subgrade construction The material used in embankment, subgrade, shoulders, etc. shall be soil, gravel, a mixture of these or other material approved by an Engineer. It shall be free from logs, stumps, roots, rubbish, etc. Cut and Fill (Embankment) Sections Granular Subbase Gravel material to be used for sub-base shall be obtained from approved sources in borrow areas, cuts or existing pavement layers. The complete sub-base shall contain no material having a maximum dimension exceeding two-thirds of the completed layer thickness. Gravel Sub-base material shall, unless otherwise stated, conform to specification requirements in terms of: Need for Testing and Specification Material testing is essential to verify material characteristics for application trials, detect defects, analyze failures, improve new materials or conduct basic research. The materials used in construction projects must meet strict quality regulations, standards, and service life requirements. The materials will affect the quality, costs, sustainability and environmental impact of the construction project. …. cont • The technical staff involved in testing areas should have educational certificate and work experience. • The Engineer shall verify that the laboratory has the appropriate equipment, calibration and verification records, test procedures, and trained personnel to perform every procedure in the proposed scope. • Test procedures shall be performed with applicable materials Contractor’s Responsibilities from the view of the provision of the Contract General Responsibilities The Contractor has obligation with respect to the supply of materials and workmanship. Do the work with care and skill in a proper and workmanlike manner; Use materials of good and viable quality; Ensure that both the work and the materials should reasonably fit for the purpose they are wished-for. …cont Clause 8.1 The Contractor shall, with due care and diligence, execute and maintain the works and provide all labour, including the supervision thereof, materials. Construction plant and all other things, whether of a temporary or permanent nature, required. Clause 36.1 All materials and workmanship shall be of the respective kinds described in the Contract and in accordance with the Engineer’s instructions, and shall be subjected from time to time to such tests as the Engineer may direct at the place of manufacture of fabrication, or on the site or at such other places as may be specified in the contract. …cont Clause 36.2. All samples shall be supplied by the Contractor at his own cost if the supply thereof is clearly intended by or provided for in the contract. Clause 36.3. The Cost of making any test shall be borne by the Contractor if such test is clearly intended by or provided for in the contract. Material Standards to be Met on Completion of Construction The Specification sets out materials standards to be met by each major construction material tested in the Site laboratory. 1209 Specifications American, British and Ethiopian standards are used in this Technical Specification. In the absence of any definite provisions in the Specification on any particular issue, reference may be made to the latest codes of AASHTO, ASTM, BS or Ethiopian standards in this order of precedence. …cont 3202 MATERIALS FOR EMBANKMENTS a) Fill The following soils are unsuitable for construction of embankments: •Materials with more than 5% by weight of organic materials •Materials with a swell of more than 3% •Clays with plasticity index over 45 or a liquid limit over 90. b) Improved Subgrade The following are minimum requirements for fill materials to be used in area of weak sub-grade: •Minimum 25% passing 2.36 mm sieve. •Ip less than 30. •Reject index less than 10% •Soils shall be non-expansive, non-dispersive and free from any deleterious matter. …cont SERIES 4000: CULVERT AND DRAINAGE WORKS Concrete cube strength aggregate water 5102 Gravel Wearing Course The minimum requirements for gravel wearing course material Maximum size (mm) Oversize Index (Io) Shrinkage product (Sp) Grading coefficient (Gc) Soaked CBR (at 95% Mod AASHTO) Treton Impact Value (%) Laboratory Testing Basic testing requirements – Soils ◦ ◦ ◦ ◦ ◦ Atterberg limits (LL, PL) Linear shrinkage Particle size distribution – grading Moisture content and compaction California Bearing Ratio (CBR) Unsuitable soil materials for subgrade Clay soil which contains the value of Liquid Limit more than 80% and/or Plasticity Index more than 55%, It is flammable materials (oily), and organically clay soil, Contain lots of rotten roots, grass and other vegetation, Soil which is soft and unstable because it is too wet or dry which makes it difficult to compact properly. Desirable Properties of Soil as Subgrade Material Stability. Incompressibility. Minimum changes in volume and stability under adverse condition of weather and ground water. Permanency of strength. Good drainage. Ease of compaction. Granular Subbase Grading limits Grading Modulus Plastic Index, PI Compaction requirements CBR Gravel wearing surface Based on ◦ Shrinkage product (linear shrinkage) ◦ Grading Coefficient Atterberg Limit Casagrande LL Device Plastic index PI = LL - PL PL Device Soil phases and Atterberg limits Phase Solid state Semi-solid state Plastic state Liquid state Suspension Water content increasing Water Limits Dry soil Shrinkage limit Plastic Sticky limit limit Liquid limit Plastic index Shrinkage Constant volume Condition Hard to soft Shear strength [kN/m2] Moisture content Volume increasing Sticky Workable Slurry Shear strength decreasing 0 (~170) (~1.7) SL PL Water-held suspension Negligible to Nil PI LL Particle Size Distribution Particle Size Distribution Gradation ◦ Poor/ Uniform ◦ Well/ continuous ◦ Gap graded If there are a lot of different fractions between the largest and the smallest, the sample is well graded. If only a few sizes can be seen, the sample is single sized or poorly graded. Single-sized materials do not compact well, because there are no suitably small-sized particles to fill the empty voids between the bigger particles a good mechanical interlock States of soil aggregate mixtures a) no fines b) enough fines c) excess fines High stability when confined High stability when confined High stability when confined AND dry No cohesion High cohesion when dry High cohesion when dry, low when wet High angle of internal friction High angle of internal friction No angle of internal friction when wet Not affected by moisture conditions Moderately affected by moisture conditions Greatly affected by moisture conditions Very difficult to compact Moderately dificult to Not difficult to compact at Alemgenaright Alene,moisture PhD compact level CENG6305 – Ch2 Purpose of soil classification Development of soil classification Basis of soil classification systems Key soil components in soil classification systems Extension of USCS for LVR Comparison AASHTO and USCS (Lia 1970) Comparison of soil classification systems Material Classes for Pavement formation ERA Testing Standards Differences in Test Methods Differences in Test Methods Differences in Test Procedure - CBR Rationale for Specification Specs and Use of Local Materials Appropriateness of current specs Use of local materials ERA Low Volume Roads Material requirements for roadbase ◦ A wide range of materials including lateritic, calcareous and quartzitic gravels, river gravels and other transported and residual gravels, or granular materials resulting from weathering of rocks can be used successfully as road base materials Particle size distribution for natural gravel base Concrete Test Concrete grade shall be confirmed at least through strength test Field Compliance Tests Field density – Sand cone replacement Strength – Dynamic cone penetrometer Dynamic Cone Penetrometer (DCP) • How to do test • How to analyse data • How to calculate Structural Number 1 K e y : 1 H a n d l e 2 H a m m e r ( 8 k g ) 3 H a m m e r s h a f t 4 C o u p l i n g 5 H a n d g u a r d 6 C l a m p r i n g 7 S t a n d a r d s h a f t 8 1 m e t r e r u l e 9 6 0 ° c o n e 2 Dynamic Cone Penetrometer 3 4 5 6 Ø 2 0 m m 7 9 8 9 · 6 0 ° I N C 1. Kleyn and Van Heerden, 1983 (60° cone) 2. Smith and Pratt, 1983 (30° cone) 3. Van Vuuren, 1969 (30° cone) 4. TRRL, 1990 (60° cone) CBR (per cent) 100 50 10 5 3 4 1 2 1 1 5 10 50 DCP (mm/blow) 1. Log10 (CBR) = 2.632 - 1.28 Log10 (mm/blow) 2. Log10 (CBR) = 2.555 - 1.145 Log10 (mm/blow) 3. Log10 (CBR) = 2.503 - 1.15 Log10 (mm/blow) 4. Log10 (CBR) = 2.48 - 1.057 Log10 (mm/blow) DCP - CBR RELATIONSHIP 100 DCP TEST Site/road: Test No: Section No/Chainage: Direction: Wheel path: No. Blows Blows mm Date: Zero reading of DCP: Started test at: No. Blows Blows mm No. Blows Blows mm DCP Test Date:_______________ ________ Site/Road Addis Ababa Gohatsion Test No._______________________ Section No.Chainage 115+000 RHS Zero reading of DCP: 100 Started test at: Subgrade Direction:________________________ Wheel Path: ______________________ No. ∑ Blows Blows mm 1 150 1 180 1 210 1 230 1 250 1 265 1 1 1 1 1 3 5 5 10 10 10 280 295 315 330 340 345 350 355 360 362 362 No. ∑ Blows Blows mm Alemgena Alene, PhD CENG6302 - Ch6 No. ∑ Blows Blows mm Number of blows 0 40 80 120 160 0 100 200 Roadbase Thickness 266 mm CBR 41 per cent 300 Depth (mm) 400 500 Sub-base Thickness 380 mm CBR 20 per cent 600 Gravel surfacing Thickness 220 mm CBR >100 per cent 700 800 900 1000 Subgrade CBR 13 per cent 1100 1200 Typical DCP result