Short Version

advertisement

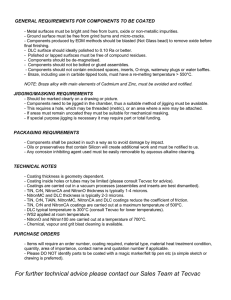

MINIATURE ENGINEERING SYSTEMS GROUP (http://www.mmae.ucf.edu/~kmkv/mini) Two-Stage CryoCooler Development for Liquid Hydrogen Systems Miniature Engineering Systems Group Core Group of Faculty Dr. Louis Chow Director System design, spray cooling, thermal management, thermalfluids design/ experiment, thermodynamics Dr. Jay Kapat Co-Director System design, design of turbo machinery, heat transfer and fluidic components, component and system testing Dr. Quinn Chen Associate Director for Educational Programs Micro-fabrication and tribology, actuators Dr. Linan An Polymer-derived ceramic micro-fabrication Dr. Joe Cho Bio-MEMS, Magnetic MEMS, MOEMS, micro/nano fabrication, micro fluidics Dr. Neelkanth Dhere Tribological coatings, multilayer thin films, sensors Dr. Chan Ham Control, micro-satellites Dr. K.B. Sundaram Micro-fabrication, thin film, sensors, micro- and meso-scale motors and generators Dr. Abraham Wang Vibration and control, health monitoring, piezoelectric materials, shape memory alloy Dr. Tom Wu RF MEMS, miniature electromagnetic devices Motivation and Objective Storage of cryogenic propellants (LH2 and LOX) for extended periods have become increasingly important within NASA. There would be loss of propellants in storage tanks as well as in transfer lines both in space and ground applications due to heat leak. The objective of this project is to design and build a cryocooler, which is capable of removing 50W of heat at liquid hydrogen temperature and thus contribute to NASA efforts on ZBO storage of cryogenic propellants and to attain extremely high hardness, extremely low coefficient of friction, and high durability at temperatures lower than 60 K for the tribological coatings to be used for this cryocooler. Approach and Innovation Two Stage Reverse Turbo Brayton Cycle (RTBC) CryoCooler reliable, efficient, compact and light weight RTBC bottom stage with He as the working fluid (immediate goal) RTBC top stage with Ne as the working fluid Key Enabling / Innovative Features for the bottom stage: Compressor – Four stage centrifugal compressor with very high efficiency in its class. Design incorporates intercooling, inlet guide vanes, deswirler vanes, endwall contouring, axial diffuser at the exit integrated with after- or inter-cooler. Motor – The motor would be a high speed three phase PMSM with a magnet integrated rotor and high frequency soft switching control system. Recuperative heat exchanger for regeneration –Non-conventional design for reduction of axial or parasitic heat conduction, massively parallel design with micro-channels and special manifolds for ultra-high effectiveness, low pressure drop and uniform flow distribution. Gas foil bearings – Completely hydrodynamic gas foil bearings for both radial and axial support - key in minimizing losses associated with the compressor and the motor. Tribological coatings – Extremely hard coatings of titanium nitride (TiN), bilayer coatings of TiN and molybdenum disulphide (MoS2), diamond-like-carbon (DLC) coatings, bilayer coatings of DLC/MoS2 for low values of coefficient of friction at cryogenic temperatures. Efforts in Alternative Funding Sources NASA KSC – Miniature Joule Thomson (JT) CryoCoolers for Propellant Management (funded). KSC Partners: Bill Notardonato and George Haddad. Defense Advance Research Projects Agency (DARPA) – We have been invited to the presolicitation workshop on micro cryocoolers. Communicating with potential team members and planning a proposal. Also, inviting Dr. Ray Radebaugh and Dr. Marty Nisenoff (leading, world-renowned experts in cryocoolers) to UCF campus for this DARPA proposal and ongoing projects. Harris Corporation – We have reciprocal visits for possible joint proposals to DoD. Technology Associates, Inc. (based in Boulder, CO) – They have recently opened a branch in UCF research park in order to collaborate with us, and have provided UCF subcontracts on multiple of their DoD/NASA contracts on MEMS cryocoolers. Rini Technologies, Inc. – partner on this project and several DoD SBIR projects on miniature cryocoolers. Lockheed Martin Missiles and Fire Control (LMMFC) – They have provided initial funding for miniature coolers. We are currently exploring opportunities of mutual interests. Their engineers are on this project time as part-time graduate students. Proposal for collaboration in materials research in the areas of ultra-low friction (COF<0.01) of MoS2 and carbon-based coatings with European Research Institutes from National Science Foundation is being solicited. Preparing to submit. Proposal on Threat Control submitted to DTRA in January 2003, which included miniature cryocoolers for sensors for nuclear treaty verification. Communicating with DTRA. Important Parameters to Measure Performance Performance of the two stage cryocooler (with emphasis on performance of the bottom stage) – COP, weight and size. Compressor performance – weight, size, efficiency. Heat exchanger performance – effectiveness, size, pressure drop, and weight. Motor performance – speed, weight, size, efficiency. Motor control system performance – switching frequency, efficiency. Gas foil bearings – load bearing capacity, wear during start and stop, dynamic stability. Performance of tribological coatings – coefficient of friction, hardness, wear resistance and durability at cryogenic temperatures. Performance Comparison – Quantifiable Research Results Component Performance Commercially Short term Long term characteristic available goal goal Compressor (mesoscale) Efficiency 35% (Creare) 45% 75% Motor Speed 150,000 200,000 200,000 (rpm) (Koford Motors) Efficiency 30% 60% 96% Performance Comparison – Quantifiable Research Results Component Performance characteristic Commercially available Short term goal Long term goal Controller Efficiency 80% 60% 95 % Effectiveness 98% 95% 99% Size (Length) 67 cm (Creare Inc,.) 8 cm < 8 cm Heat Exchanger Performance Comparison – Quantifiable Research Results Component Performance characteristics Commercially Available Short Term goal Hardness DLC (40 GPa) TiN (25 GPa) Long Term Goal TiN (20-25 GPa) Tribological Coatings Coefficient of Friction (COF) DLC COF At Room Temp 0.1-0.15 At 770K LN2 0.24-0.48 TiN=0.143 TiN/MoS2 on Glass = 0.05-0.1 TiN/ MoS2 on Al = 0.12-0.18 TiN/ MoS2 on Si wafer = 0.045 Nitrides At Room Temp TiN (< 0.1) At 770K LN2 ZrN (0.4-0.8) COF < 0.15 at 770K LN2 and finally satisfactory operation in the Cryocooler Overall System Thermodynamic Schematic Compressor Future Work To continue with the single stage compressor simulation and testing and to verify its design. To integrate the single stage compressor into a four stage centrifugal helium compressor for the bottom cycle. To design and check the fabrication feasibility of the four stage compressor. Permanent Magnet Synchronous Motor Ongoing Research & Future Work Performing dynamic simulation of the shaft. Fabricating and testing of a test-motor with ball bearings. Designing of a controller for the new motor. Enhancing the efficiency by improving the PWM and the LPF designs. Realizing the ‘Close loop control’. Tribological Coatings Future Research Cryogenic temperatures degrade tribological properties. However, hydrogen improves lubrication. TiN and DLC provides good hardness and low friction. Improved tribological properties expected for TiN/MoS2 and DLC/MoS2 bilayers at cryogenic temperatures. Basic understanding of the role of hydrogen and effect of cryogenic temperatures on tribological properties. Ultra-low COF (< 0.01 at RT) MoS2 coating study in collaboration with Dr. Martin, France. Next Year Work for the Project To continue with the single stage compressor simulation and testing and to verify its design. To design and check the fabrication feasibility of the four stage compressor. To fabricate and test the permanent magnet synchronous motor. To design and check the fabrication feasibility of high effectiveness micro channel heat exchanger. To design and develop gas foil bearings for the overall system. To achieve values of COF for the tribological coatings comparable to RT at cryogenic temperatures and finally satisfactory operation in the cryocooler.