Viking CPR Close Proximity Safe Radiography

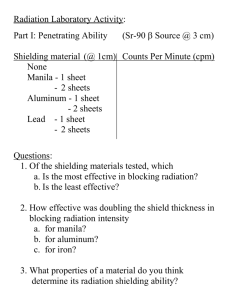

advertisement

Viking Designing a Gamma Radiography System Who we are. • Gilligan Engineering Services est. 1988. • Whole market experience - not tied to any manufacturers equipment • Very few new pieces of equipment launched onto the market. • Close Proximity Radiography (CPR) is becoming more widely used. • In 2008 we decided to design and supply our own brand of equipment. Design Influences 1. Radiation Shielding Material: An alternative to Depleted Uranium 2. Safer: Historical Incidents to avoid in the design 3. New equipment for a new era: Close Proximity Radiography while keeping flexibility 1. Radiation Shielding Material Advantages of tungsten over DU • • • • • No health issues or risk of contamination spread No end of life disposal issues Easy to machine No IAEA Safeguards reporting No sheathing around the material required 1. Radiation Shielding Material Challenges of using tungsten • • • • Rumours of brittleness? Can’t be cast in elaborate shapes. Not as efficient for shielding compared to DU. Relatively expensive 1. Radiation Shielding Material • No signs of brittleness in the material testing • Cooled to -40°C • Impact mark from the drop. • The impact had an energy of 3.5kJ • Resulted in a conventional deforming of the impact edge • No signs of brittleness. 1. Radiation Shielding Material • The design of the radiation shield would have to be a simple shape. • The shield should be as small as possible. • This would give the optimum shielding to mass ratio 1. Radiation Shielding Material • The design resulted in a camera that is physically small and compact. • We have 6 different units based on the same layout and components • Allows the size and weight of the camera to reflect the source strength installed within. 1. Radiation Shielding Material Challenges of using tungsten • • • • Rumours of brittleness? Can’t be cast in elaborate shapes. Not as efficient for shielding compared to DU. Relatively expensive Design Influences 1. Radiation Shielding Material: An alternative to Depleted Uranium 2. Safer: Historical Incidents to avoid in the design 3. New equipment for a new era: Close Proximity Radiography while keeping flexibility 2. Incident Avoidance • Some of the typical incidents we have observed with all brands of equipment over time are: A. Butt connection B. Source holder connection C. Registering the source is home - how the source operates the Autolock. 2.A. Butt Connection • A butt connection is a term for the equipment allowing the source to be released from the camera and projected from the shielded position without the source being attached to the windout inner cable. • It is easy to design a radiography system to resist a butt connection and all equipment manufacturers do • Butt Connections still occur in industry as a result of: 1. The equipment not been maintained correctly. 2. The equipment not been maintained within the time laid down by the manufacturer. 2.A. Butt Connection • In this state it is not possible to screw the nut onto the equipment meaning the source can not be released • The Viking system source holder has been designed to allow 8mm of wear of components before a Butt Connection can occur. 2.B. Source holder connection Incomplete Connection • It should not be possible to operate the equipment with the windout connector and source holder in a partially connected state. 2.B. Source holder connection • The windout ball is depressing the plunger and the two components are practically in line. • This allows the windout to be connected to the projector while the source holder is in this partially connected state which will probably later lead to a disconnect. 2.B. Source Holder Connection • Viking 3 point connection 1. 2. 3. 90° Insertion Sliding backwards 1mm Laying flat 2.B. Source Holder Connection • This combination ensures the source can not become detached in the guide tube CAD image 2.C. Source home on retraction • Ensuring the source has returned home following the exposure is of the upmost importance. • ISO 3999 requires that the equipment gives an indicator when the source has returned home. 2.C. Source home on retraction • The end cap is the widest link on the source holder • The end cap houses the source capsule • The end cap is responsible for operating the AutoLock • If the AutoLock has operated the source is home and shielded End Cap 2.C. Source home on retraction • It is always best practice to use a radiation monitor to verify the source is home. • Usually this is only ensuring there is low radiation levels in the work area • A further benefit of tungsten shielding however... • A radiation monitor can detect the radiation emitted by even a low energy isotope therefore allowing direct monitoring of camera to confirm the source is inside. 2. Incident Avoidance A. B. C. • Butt connection Source holder connection Registering the source is home - how the source operates the Autolock. The three addressed are a sample of many we considered while designing the equipment: Crushed control housing Crushed guide tube Run off Premature AutoLock operation Windout connector failure Outer housing swage failure Securing the source in the source holder Source tube damage from small drop Spread of contamination from worn S-tube Design Influences 1. Radiation Shielding Material: An alternative to Depleted Uranium 2. Safer: Historical Incidents to avoid in the design 3. New equipment for a new era: Close Proximity Radiography while keeping flexibility 3. Conventional CPR Advantages • Lowers dose rates to non-radiation workers • Results in less dose for radiographers and others. • Speeds up a radiography production line by lowering delays between processes • Lower probability of incident occurrence and severity 3. Conventional CPR Challenges • Slows down radiography due to prolonged setup. • Limited selection of isotopes. • Radiography jobs can not be conducted solely as CPR as access for the equipment is limited • A choice of mobilising two kits or carrying out the whole job as projection 3. Viking Solutions • Is very well suited but not limited to the use of Selenium-75 however it can also be used with Ir-192 and Yb-169. • Equipment eliminates the hot pass between source container and collimator with out unique and patented tungsten chamfered face. • Accessories designed in consultation with the end users – radiographers. • This makes the equipment easy to use , flexible and encourages radiographers to use CPR where they are able. • It also allows more CPR in industry by lowering the cost of entry to companies – they just need a single system and have CPR capability. 3. CPR Equipment • Each Viking camera can be used as a projector or as a close proximity container with the attachment of a large collimator. • This is possible as the Tungsten shield does not need to be encased in a secondary material. 3. CPR Equipment • The accessories provided with the CPR system were designed in consultation with radiographers to ensure efficient working. 3. Accessories - Positioning • The CPR container is suspended from an supporting strap • Standoff is achieved using a flexible 3D arm or a lightweight bracket • A fast setup ensures CPR is cost effective as well as safe. 3. Accessories - GammaShield • GammaShield is a flexible and pliable radiation blanket. • Can be used to form a movable wall of radiation shielding. • Flexible to bend around complex shapes such as radiography projectors and pipe work. • GammaShield is pliable allowing easy shaping and the gives the ability of sheet to support itself. 3. Target Pad • The Target Pad is an encased plate of lead for attenuating the direct radiation. • The component contains flanges to allow it to be easily mounted. • This is positioned behind the film and attenuates a high degree of the primary radiation. • Using the target pad takes the place of three sheets of GammaShield which saves the radiographer time. Working with the System Establishing and Monitoring an Area Stand alone radiation detectors • Ensuring proper signals are given to the radiographer and other workers is vital • We have developed an area monitoring system • The PWS is a system of indicating the radiation safety status of a work area. • The system should ensure all points of access have appropriate and correct signals shown and these should be controlled from one centrally controlled master unit. Warning System – Radiation Detection • The system features a radiation detector to be positioned next to the container. • When the detector picks up a high level of radiation all the system lamps show a red light. • Using the system like this ensures the barrier signals are correct and they are always consistent with the radiation level within the high radiation area. Warning System - Lights and Sounders • The warning system balances automatic control and manual control. – Amber (imminent) condition manually operated – High radiation at particular points gives automatic red signal Viking A complete radiography system