Practical Temperature Measurements

advertisement

Agilent Technologies Classroom Series

Practical

Temperature

Measurements

001

Agenda

Background, history

Mechanical sensors

Electrical sensors

Optical

Pyrometer

RTD

Thermistor, IC

Thermocouple

Summary & Examples

A1

What is Temperature?

A scalar quantity that determines the

direction of heat flow between two bodies

A statistical measurement

A difficult measurement

A mostly empirical measurement

002

How is heat transferred?

Conduction

Metal coffee cup

Convection

Radiation

003

The Dewar

Glass is a poor conductor

Gap reduces conduction

Metallization reflects radiation

Vacuum reduces convection

004

Thermal Mass

Don't let the measuring

Sensor

device change the

temperature of what you're

measuring.

Response time =

f{Thermal mass}

f{Measuring device}

Sensor

005

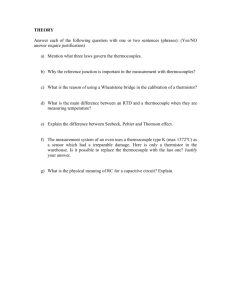

Temperature errors

What is YOUR normal temperature?

Thermometer accuracy, resolution

Contact time

Thermal mass of thermometer, tongue

Human error in reading

97.6 98.6 99.6

36.5 37 37.5

006

History of temperature sensors

1600

ad

1700

12

ad

96

Fahrenheit

1

Instrument

0

Galileo: First

temp. sensor

pressure-

sensitive

not repeatable

Early

thermometers

Not

repeatable

No good way

to calibrate

Maker

12*8=96

points

Hg:

Repeatable

One

standard

scale

007

The 1700's: Standardization

1700 ad

1800 ad

0

100

Thomson effect

Absolute zero

100

Celsius:

Common,

repeatable

calibration

reference points

0

"Centigrade"

scale

008

1821: It was a very good year

1800 ad

1900 ad

The Seebeck

effect

Davy: The RTD

Pt 100

d @ O deg.C

009

The 1900's: Electronic sensors

1900 ad

Thermistor

2000 ad

1 uA/K

IC sensor

IPTS 1968 IPTS

1990

"Degree Kelvin">> "kelvins"

"Centigrade">> " Celsius"

010

Temperature scales

Freezing

point H2O

Absolute

zero

Celsius

0

100

Kelvin

273.15

373.15

32

212

-273.15

0

Fahrenheit

-459.67

0

Boiling point

H O2

Rankine

427.67

671.67

"Standard" is "better":

Reliable reference

points

Easy to understand

011

IPTS '90: More calibration points

–

–

273.16: TP

H2O

234.3156: TP

Hg

Large gap

–

–

–

–

–

–

–

–

–

–

–

–

83.8058: TP

Ar

54.3584: TP

O2

24.5561: TP

20.3:

BP

Ne

17 Liq/vapor

H2

13.81

TP

H2

3 to 5: Vapor

H2

He

–

–

1357.77: FP

Cu

1337.33: FP

Au

1234.93: FP

Ag

933.473: FP

Al

692.677: FP

Zn

505.078: FP

Sn

429.7485: FP

In

–

302.9146: MP

Ga

012

Agenda

Background, history

Mechanical sensors

Electrical sensors

Optical

Pyrometer

RTD

Thermistor, IC

Thermocouple

Summary & Examples

A2

Bimetal thermometer

Two dissimilar Forces due to

thermal

expansion

metals, tightly

bonded

0

Result

100 200 300 Bimetallic thermometer

400

Poor accuracy

Hysteresis

Thermal expansion causes big

problems in other designs:

IC bonds

Mechanical interference

013

Liquid thermometer; Paints

100

0

Thermally-sensitive paints

Liquid-filled thermometer

Irreversible change

Low resolution

Useful in hard-to-measure area

Accurate over a small range

Accuracy & resolution= f(length)

Range limited by liquid

Fragile

Large thermal mass

Slow

014

Agenda

Background, history

Mechanical sensors

Electrical sensors

Optical

Pyrometer

RTD

Thermistor, IC

Thermocouple

Summary & Examples

A3

Optical Pyrometer

Infrared Radiation-sensitive

Photodiode or photoresistor

Accuracy= f{emissivity}

Useful @ very high temperatures

Non-contacting

Very expensive

Not very accurate

015

Agenda

Background, history

Mechanical sensors

Electrical sensors

Optical

Pyrometer

RTD

Thermistor, IC

Thermocouple

Summary & Examples

A4

Resistance Temperature Detector

Most accurate & stable

Good to 800 degrees Celsius

Resistance= f{Absolute T}

Self-heating a problem

Low resistance

Nonlinear

016

RTD Equation

R= 100 Ohms @ O C

Callendar-Van Deusen Equation:

For T>OC:

R=Ro(1+aT) - Ro(ad(.01T)(.01T-1))

R

Ro=100 @ O C

a= 0.00385

/ - C for Pt

d= 1.49

300

200

100

0

Nonlinearity

200

400

600

800

T

017

Measuring an RTD: 2-wire method

Rx

100d

Pt

Rlead

+

Rlead

-

V

I ref= 5 mA

R= Iref*(Rx + 2* Rlead)

Error= 2d /.385= more than 5 degrees C for 1 ohm

Rlead!

Self-heating:

For 0.5 V signal, I= 5mA;

P=.5*.005=2.5 mwatts

@ 1 mW/deg C,

Error = 2.5 deg C!

Moral: Minimize Iref; Use 4-wire method

If you must use 2-wire, NULL out the lead resistance

018

The 4-Wire technique

Rx

100d

+

Rlead=1d

-

V

I ref= 5 mA

R= Iref * Rx

Error not a function of R in source or sense

leads

No error due to changes in lead R

Twice as much wire

Twice as many scanner channels

Usually slower than 2-wire

019

Offset compensation

Voffset

+

100d

-

V

I ref (switched)

Eliminates thermal voltages

Measure V without I applied

Measure V With I applied

R=

V

I

020

Bridge method

100 d

d

1000

V

d

1000

100d

High resolution (DMM

stays on most sensitive

range)

Nonlinear output

Bridge resistors too

close to heat source

021

3-Wire bridge

100d

1000d

Rlead 1

V

1000d

Sense wire

3-Wire

PRTD

Rlead 2

Keeps bridge away from heat source

Break DMM lead (dashed line); connect to

100d

RTD through 3rd "sense" wire

If Rlead 1= Rlead 2, sense wire makes

error small

Series resistance of sense wire causes no

error

022

Agenda

Background, history

Mechanical sensors

Electrical sensors

Optical

Pyrometer

RTD

Thermistor, IC

Thermocouple

Summary & Examples

A5

Electrical sensors: Thermistor

Rlead=1

5k d

d

Rlead=1d

+

-

Hi-Z; Sensitive: 5 k

V

d

I= 0.1 mA

@ 25C;

R = 4%/deg C

Limited range

2-Wire method: R= I * (Rthmr + 2*Rlead)

Lead R Error= 2

d /400= 0.005 degrees C

Low thermal mass: High self-heating

Very nonlinear

023

I.C. Sensor

I= 1 uA/K

+

5V -

100 d

V = 1mV/K

960d

High output

Very linear

Accurate @

room ambient

Limited range

Cheap

024

Summary: Absolute T devices

RTD

Thermistor

I.C.

Most accurate

Most stable

Fairly linear

High output

Fast

2-wire meas.

High output

Most linear

Inexpensive

Expensive

Slow

Needs I source

Self-heating

4-wire meas.

Very nonlinear

Limited range

Needs I source

Self-heating

Fragile

Limited variety

Limited range

Needs V source

Self-heating

025

Agenda

Background, history

Mechanical sensors

Electrical sensors

Optical

Pyrometer

RTD

Thermistor, IC

Thermocouple

Summary & Examples

A6

Thermocouples

The Gradient Theory

Ta

Tx

The WIRE is the

V=

V

sensor, not the

junction

Tx

The Seebeck

e(T) dT

Ta

coefficient (e) is a

function of

temperature

026

Making a thermocouple

Ta

Tx

B

V

Two wires make a

A

Ta

thermocouple

V=

e

Ta

A

Voltage output is

Ta

Tx

dT +

e

B

dT

nonzero if metals are

not the same

Tx

027

Gradient theory also says...

Ta

Tx

A

V

If wires are the

A

Ta

Ta

Tx

e dT +

A

V=

Ta

e

A

dT = 0

same type, or if there

is one wire, and

both ends are at the

same temperature,

output= Zero.

Tx

028

Now try to measure it:

a

Fe

b

Tx Theoretically,

Vab= f{Tx-Tab}

Con

But, try to measure it with a DMM:

Cu

Tx

V

Cu

Cu

Fe

Con

=

Fe

V

Tx

Con

Cu

Result: 3 unequal junctions, all at unknown

temperatures

029

Solution: Reference Thermocouple

Problems: a) 3 different thermocouples,

b) 3 unknown temperatures

Solutions: a) Add an opposing thermocouple

b) Use a known reference temp. Isothermal

block

Fe

Cu

Cu Fe

Tx

Add

Tx

Con

V

V Con

Tref

Tref

= 0 oC

Cu

Fe

Cu Fe

030

The Classical Method

Cu Fe

Tx

V

Con

Tref

o

=0C

Cu Fe

If both Cu junctions are at

same T, the two "batteries"

cancel

Tref is an ice bath

(sometimes an electronic ice

bath)

All T/C tables are

referenced to an ice bath

V= f{Tx-Tref}

Question: How can we eliminate the ice bath?

031

Eliminating the ice bath

Don't force Tref to icepoint, just

Cu

V

Fe

Con

Cu

Fe

measure it

Compensate for Tref

Tx

mathematically:

V=f{ Tx

- Tref

}

Tice

Tref

Tice

If we know Tref

, we can

Tice

compute Tx.

032

Eliminating the second T/C

Cu

Fe

Tx

V

Extend the isothermal block

If isothermal, V1-V2=0

2

Con

Cu

Fe

Tref

Cu

Fe

1

Tx

V

Tref

2

Con

Cu

1

033

The Algorithm for one T/C

Cu

V

Tref

Cu

Fe

IC or thermistor

Tx Measure Tref: RTD,

o

Tref ==> Vref @ O C for Type J(FeCon C)

Know V, Know Vref: Compute Vx

Solve for Tx using Vx

Compute

Vx=V+Vref

Vx

Vref

0 o Tref

V

Tx

034

V

Linearization

Small sectors

0 o Tref

Tx

T

2

3 V +.... a9 V

Polynomial: T=a

+a

V

+a

V

+a

0 1

2

3

9

Nested (faster): T=a

0 +V(a

1 +V(a

2 +V(a

3

2

+.......)))))))))

0

Small sectors (faster): T=T +bV+cV

Lookup table: Fastest, most memory

035

Common Thermocouples

mV

E

60

Platinum T/Cs

Base Metal T/Cs

K

J N

40

20

T

0

500

RS

1000

2000

deg C

All have Seebeck coefficients in MICROvolts/deg.C

036

Common Thermocouples

Type

J

K

T

S

E

N

Metals

Seebeck

Coeff: uV/C

Fe-Con

Ni-Cr

Cu-Con

Pt/Rh-Pt

Ni/Cr-Con

Ni/Cr/Si-Ni/Si

50

40

38

10

59

39

Microvolt output is a

tough measurement

Type "N" is fairly new..

more rugged and

higher temp. than type

K, but still cheap

037

Extension Wires

Possible problem

here

Large extension wires

Small diameter

measurement

wires

Extension wires are cheaper, more rugged, but not

exactly the same characteristic curve as the T/C.

Keep extension/TC junction near room temperature

Where is most of the signal generated in this circuit?

038

Noise: DMM Glossary

Normal Mode

ac NOISE

DMM

Input

Resistance

HI

LO

Normal Mode

dc SIGNAL

Normal Mode: In series with input

Common Mode: Both HI and LO

HI

DMM

Input

Resistance

terminals driven equally

LO

Common Mode

ac NOISE

039

Generating noise

Electrostatic

Noise

DMM

Input

Resistance

Magnetic

Noise

HI

Normal Mode

LO

dc SIGNAL

Large surface area, high Rlead: Max. static

DMM

Input

Resistance

R leak

coupling

HILarge loop area: Max. magnetic coupling

Large R lead, small R leak:

R lead

Max.

LO

common mode noise

Common Mode Current

Common Mode

ac source

040

Eliminating noise

Electrostati

c

Noise

DM

M

Inpu

tR

Magneti

c

Noise

HI

Normal Mode

dc SIGNAL

L

O

Filter, shielding, small loop area

(Caution: filter slows down the

measurement)

HI

DM

M

Input

R

R

leak

Make R leak close to

L

O

-

+

Common Mode

Current

Common

Mode

ac source

041

Magnetic Noise

Magnetic coupling

DMM

Input

Resistance

Induced I

Minimize area

Twist leads

Move away from strong fields

042

Reducing Magnetic Noise

Equal and opposite induced currents

DMM

Input

Resistance

Even with twisted pair:

Minimize area

Move away from strong fields

043

Electrostatic noise

AC Noise

source

Stray capacitances

DMM

Input

Resistance

Inoise

Stray resistances

Stray capacitance causes I noise

DMM resistance to ground is important

044

Reducing Electrostatic

AC Noise source

Coupling

DMM

Input

Resistance

HI

LO

Rleak

Shield shunts stray current

For noise coupled to the tip,

Rleak is still important

045

A scanning system for T/Cs

One thermistor,

multiple T/C channels

Noise reduction

CPU linearizes T/C

DMM must be

very high quality

OHMs

Conv.

Isolators

HI

uP

LO

Integrating

A/D

Floating Circuitry

ROM

Lookup

uP

I/O

(HP-IB,

RS-232)

To

Computer

Grounded Circuitry

046

Errors in the system

Ref. Block Thermal gradient

T/C Calibration

& Wire errors

Thermal emf

Ref. Thermistor cal, linearity

OHMs

Conv.

Reference

Thermistor

Ohms

measurement

Linearization

algorithm

Isolators

HI

uP

LO

Integrating

A/D

Floating Circuitry

ROM

Lookup

DMM offset, linearity, thermal emf, noise

uP

Extension wire

junction error

I/O

(HP-IB,

RS-232)

Grounded Circuitry

047

Physical errors

Shorts, shunt impedance

Galvanic action

Decalibration

Sensor accuracy

Thermal contact

Thermal shunting

048

Physical Errors

Water droplets

cause galvanic

action; huge offsets

Hot spot causes shunt Z, mete

shows the WRONG temperatur

Exceeding the T/C's range can cause permanent

offset

Real T/C's have absolute accuracy of 1 deg C @

25C: Calibrate often and take care

049

Physical error: Thermal contact

Surface probe

Make sure thermal mass is much smaller

than that of object being measured

050

Physical errors: Decalibration

350 C

300 C

200 C

100 C

975 C

1000 C

This section

Don't exceed Tmax of T/C

produces the Temp. cycling causes work-hardening,

ENTIRE signal decalibration

Replace the GRADIENT section

051

Agenda

Background, history

Mechanical sensors

Electrical sensors

Optical

Pyrometer

RTD

Thermistor, IC

Thermocouple

Summary & Examples

A7

The basic 4 temperature sensors

RTD Thermistor

Most accurate High output

Fast

Most stable

2-wire meas.

Fairly linear

Expensive

Very nonlinear

Slow

Limited range

Needs I source Needs I source

Self-heating

Self-heating

4-wire meas. Fragile

I.C.

Thermocouple

High output

Most linear

Cheap

Limited variety

Limited range

Needs V

source

Self-heating

Wide variety

Cheap

Wide T. range

No self-heating

Hard to measure

Relative T. only

Nonlinear

Special

connectors

Absolute temperature sensors

052

Summary

Innovation by itself is not enough...

you must develop standards

Temperature is a very difficult,

mostly empirical measurement

Careful attention to detail is required

053

Examples

Measurement

Photochemical process

Sensor

RTD (most accurate)

control:

Thermistor

Flower petal:

Molten glass:

Induction furnace:

100 degree Heat aging oven:

(lowest thermal mass)

Optical pyrometer

(hi temp, no contact)

RTD (if <800C); or T/C

(Beware magnetic I

noise)

Any of the 4 sensors

054