mod 3 Sept 09 v2

advertisement

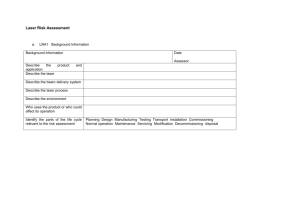

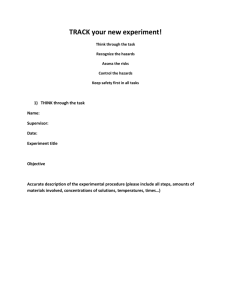

Foundation Training in Laboratory Safety Faculty Safety Managers Stefan Hoyle, Jan de Abela-Borg 1 Module 3 Gases and cryogenics sdfgafgafga 2 Objectives Reinforce basics of risk assessment Explain how gases and cryogenics can cause harm Identify and understand control measures to minimise exposure Identify other potential hazards within the laboratory setting Common gases - physical properties and hazards CARBON DIOXIDE (GASEOUS) Description: Colourless, odourless gas. Pungent odour at high concs. Relative density (Air = 1): 1.52 Flammable? No Workplace Exposure Limits: 1.5% (short term), 0.5% (long term) Hazards: Intoxicating at high concentrations (5%+) sdfgafgafga 4 Common gases - physical properties and hazards CARBON DIOXIDE (SOLID) Description: Translucent white solid Pellets or flakes. Relative density (Air = 1): 1.52 Flammable? No Workplace Exposure Limits: 1.5% (short term), 0.5% (long term) Hazards: Cold burns / frostbite Sublimes to form gaseous CO2 – asphyxiation risk sdfgafgafga 5 Common gases - physical properties and hazards Don’t play games with dry ice! 6 Common gases - physical properties and hazards NITROGEN (GASEOUS) Description: Colourless, odourless gas. Present in air ~ 78% Relative density (Air = 1): 0.97 Flammable? No Workplace Exposure Limits: None Hazards: Asphyxiation by reduction in O2 content of air sdfgafgafga 7 Common gases - physical properties and hazards NITROGEN (LIQUID) Description: Colourless, odourless liquid (-196oC) Relative density (Air = 1): Cold gas / vapour heavier than air Expansion factor of x700 Flammable? No Workplace Exposure Limits: None Hazards: Asphyxiation – evolved gas will displace air Cryogenic burns Frostbite and hypothermia in certain circumstances 8 Common gases - physical properties and hazards HYDROGEN Description: Colourless, odourless gas Relative density (Air = 1): 0.07 Flammable? Extremely Workplace Exposure Limits: None Hazards: Fire and explosion sdfgafgafga 9 Hazard information MSDS and Hazard Labels 10 Foreseeable risks Uncontrolled release of gas due to: Regulator failure Failure of pipe work or tubing connecting cylinder to other equipment Over pressurisation Damage caused by impact e.g. falling cylinder or vessel Damage caused by fire 11 The control hierarchy 1 Prevent or minimise the risk of release at source 2 Disperse the gas before it reaches a critical level 3 Warning systems should the gas reach a critical level 12 Control measures Ensure that regulators, pressure vessels etc. are subject to maintenance and inspection regimes Ensure cylinders are secure and away from sources of heat Training – ensure that users are familiar with the equipment and the properties of the substances they are handling 13 Control measures Wear appropriate Personal Protective Equipment (PPE) Ventilation – ensure that it is adequate Ensure the physical environment is suitable for liquid nitrogen dispensing e.g. floor surfaces, adequate space for manoeuvre Consider fixed point gas detection monitors / alarms Ensure emergency procedures have been considered 14 Some Do’s……… Always: Store bulk quantities of cylinders upright in purpose-designed storage areas Segregate full and empty cylinders Segregate flammable and non-flammable gases Keep cylinder valves clean Ensure the correct regulators are fitted Ensure the regulator is designed to take the cylinder pressure Observe for faults and leaks at each time of use 15 ……… and some Don’ts Never: Tamper with cylinders in any way Dispose of cylinders in any way other than returning them to the suppliers Oil or grease cylinder fittings Use PTFE tape to achieve a seal Use non-standard cylinder keys ‘Snift’ hydrogen or toxic gases 16 Manual handling cylinders and vessels Make use of the BOC ‘point-to-point’ service on sites where this is in force Plan your route in advance Avoid moving cylinders through populated work areas Report problems with paths and roadways to Estates Be aware of your physical capabilities – some jobs need to be carried out by two people Use purpose designed trolleys Never roll a cylinder Don’t attempt to catch a cylinder if it falls Never transport a cylinder off site without consulting BOC / College Safety Department Never travel in a lift with liquid nitrogen vessels 17 Removing specimens from liquid nitrogen vessels There is a risk that vials may explode as liquid nitrogen warms and converts from liquid form to gaseous PRECAUTIONS: Store the samples in the vapour phase Place the vial into secondary containment immediately after removal Wear appropriate PPE e.g. full face visor 18 Carrying out and recording the risk assessment STEP 1: Identify the hazards STEP 2: Identify who may be at risk STEP 3: Establish control measures STEP 4: Record the assessment STEP 5: Review the assessment 19 Accidents do happen…… CO2 cylinder safety valve vented Cylinders left unsupported Cylinders obstructing fire escape route Leaks from reducing valve Cylinders dropped / fell in transit Liquid nitrogen vessel toppled in transit Burst silicone tubing carrying gas Connector tubing became detached Failure of trolley wheels on liquid nitrogen vessel Structural failure in neck of liquid nitrogen vessel 20 Lasers, radiation, and an assortment of other potential hazards in the laboratory 21 Radiation • All persons working with ionising radiations must be registered. • All work with ionising radiations must be registered. • Before starting work with ionising radiation you must: • 1. Register as a Radiation Worker with the Safety Dept. • 2. Attend Safety Department ‘Principles of Radiation Protection’ Course. • 3. Attend Local Induction Training Course (RPS will arrange). • 4. Ensure your work is registered with the Safety Dept. • http://www3.imperial.ac.uk/safety/guidanceandadvice Lasers •All work with lasers in college must be registered •All people working with lasers must be registered •All college Departments where lasers are used must have a Departmental Laser Safety Officer (DLSO) •Anyone wishing to work with lasers must see the DLSO before they start work • they will then be informed of the Departmental procedure for registering and risk assessing the work. •All work with class 3B & class 4 lasers must be registered with the Safety Department. •Before starting work you must attend the College Laser Course. •You will receive further training locally as required. 95% of laser accidents are caused by: •Unanticipated eye exposure during alignment •Misaligned optics and upwardly directed beams •Available laser eye protection not used Suitable and sufficient training is vital to ensure competency! Magnetic fields Safety issues: •Nitrogen and Helium •Risk assessment / code of practice •Training •Limited access •No metal tools, swipe cards, mobile phones •Gauss lines 24 High / low pressure / vacuum Safety issues •Implosion / Explosion •Risk assessment •Training 25 High Voltage / Electricity Safety issues: •Risk of electrocution / burns / death •Overload of systems •Fire •‘Competent ‘design •PAT and electrical testing •Segregation from liquids •Risk assessment •Training •Lone working issues •Interlocks Centrifuges Main causes of rotor failure: Incorrect Loading Overloading Corrosion/Stress Corrosion Fatigue / Old Age Rotor Care – What it means in practice: Before each run: After every run: Is my rotor corrosion-free? Is the anodising intact? Is the rotor within its service life? Are the ‘O’ rings in place and not degraded? Are samples balanced and loaded? Is the rotor secure? Is the lid in place? Keep it clean Keep it dry Remove rubber cushions Store upside down in a warm place Polish regularly Machine tools Safety issues Machines: •Risk of injury •Guarding •Emergency stops •Training / competency •Lock off key Soldering: •Respiratory problems e.g. due to colophony •Burns / fire •COSHH •LEV (dispersal or extraction) 28 What next for you ? Local lab inductions including emergency procedures and waste routes Training needs analysis Speak to supervisor and discuss training needs for now and future using Dept training needs analysis form (book and attend identified courses) Risk Assessments Go through risk assessments associated with your work with your supervisor and review as required, write new where necessary. Local training Will be ongoing as you progress. Further information available on Dept and Safety Dept websites. Training – what next? Fieldwork safety Gases and Cryogenics training Fire safety and fire prevention CBS training RAFT Laser safety training Principles of Radiation Safety Local lab training Centrifuge safety Training needs analysis Basic Laboratory Safety (inc Bio-safety) training INDUCTION Your Department – Physics http://www3.imperial.ac.uk/physics/about/safety Your Deptartment Chemistry Safety web site: http://www3.imperial.ac.uk/chemistry/about/safety Chemistry Safety Handbook – YOU MUST READ THIS http://www3.imperial.ac.uk/pls/portallive/docs/1/7289602.PDF Chemistry Department People with Safety responsibilities: Head of Dept: Tom Welton Faculty Safety Manager: Jan de Abela-Borg Department Laser Safety Officer: Saif Haque X-Ray Radiation Protection Supervisor: Oscar Ces 3H Radiation Protection Supervisor (C1/C2): William Heal Biological Safety Officer: Jan de Abela-Borg First Aid Coordinator: Simon Mann Chemical Safety Officer C1/C2: Chris Braddock Chemical Safety Officer RCS1: Joachim Steinke Display Screen Equipment (DSE) Assessor: Sara Jagambrun Chief Services Technician: Pete Sulsh Safety info and contacts in Dept of Life Sciences Life Sciences Safety web site: http://www3.imperial.ac.uk/naturalsciences/staff/healthandsafety/ls Building or campus handbooks (via web page above) – Refer to the relevant document Head of Dept: Prof Ian Owens Chair of Life Sciences H&S committee: Dr. Pietro Spanu Chair of Silwood H&S committee: Prof Susan Parry PG safety representative : Ms Catherine Reynolds Faculty Safety Manager: Mr Stefan Hoyle Flowers building: Ms. Marian Blokpoel / Dr Francis Girard Biochemistry building: Mr. Samuel Bamigbade / Mr. Barry Crook (Senior Services Technician) SAF building: Ms. Fiona May / Mr Ian Morris (Chief Services Technician) RCS1 (and Biochemistry): Mr. Dave Featherbe Bioreactor and X-ray Facility: Dr. Jeremy Moore Cross Faculty NMR suite: Dr. Pete Simpson Electron Microscopy centre: Dr. Raffa Carzaniga Biophysics (Huxley Building): Mr John Akins Silwood Campus: Ms Ros Jones Objectives MCQs Short MCQ test to help us ensure that the learning objectives for the course have been met....... What is the correct definition of a hazard? A. Something with the potential to cause harm B. A physical object that can cause significant injury C. A process which always results in harm D. Something that will cause significant injury What is the correct definition of risk? A. The likelihood that harm will occur to one or more people B. A description of the severity of harm from anything C. How harm occurs to the environment, people or equipment D. The likelihood and severity of harm occurring A biological agent in hazard group 2 cannot be used at containment level: A. 2 B. 1 C. 2, 3 or 4 D. 2 or 4 E. 3 A Class I microbiological safety cabinet provides: A. Protection to the user and others in the lab only B. 100% Protection to the user and samples in the cabinet C. A negative pressure to protect the samples D. Airflows that ensure a sterile environment is maintained in the cabinet E. Protection to the user and a sterile environment for any samples A Class II Microbiological safety cabinet cannot be used when: A. Changing the media on cells infected with a airborne human pathogen B. Creating aerosols when homogenizing human tissues C. Performing reactions using chemicals with a inhalation risk Which of the following is unlikely to affect the air flow in a fume hood? A. A person rushing passed the front of the hood B. Positioning a double fridge beside the fume hood C. Positioning a storage cupboard at right angles to the fume hood D. Slowly lowering the sash while an experiment is in progress E. Opening a window in the lab The 5 steps of Risk Assessment are? A) Identify the hazards /establish control measures / test control measures / inform and instruct staff / record the assessment B) Identify the hazards / identify who may be harmed and how / establish control measures / record the assessment / review the assessment C) Identify the hazards /establish control measures / test control measures / record the assessment / inform and instruct staff Which of the following would you not do if your fume hood breaks down during a hazardous procedure? A) Make the experiment safe B) Turn off ignition sources C) Cool the equipment by spraying with tap water D) Close reagent containers E) Inform your demonstrator/supervisor immediately Working in a fume hood would mitigate against which of these routes of exposure to chemicals? A) Ingestion B) Inhalation C) Skin contact Which of the following is not a correct statement? A. When liquid nitrogen becomes gaseous it expands approximately 700 times B. Nitrogen replaces the oxygen in the air and can lead to asphyxiation C. Gas cylinders should always be stored flat on the floor or on a bench D. Changing gas regulators requires specific training E. Manual handling training is advisable for anyone moving gas cylinders To use a high power Class 4 laser which of these action chains should you follow? A.Turn laser on / Look for the beam to check if it is working / Avoid looking directly down the beam / Wear a pair of safety goggles B.Register with the Departmental Laser Safety Officer / Attend laser user Training / Wear a pair of Laser safety goggles / Turn laser on C.Register with the Departmental Laser Safety Officer / Attend laser user Training / Await supervision and training for use of the specific laser / Wear appropriate Laser Safety Goggles if required. You are untrained in the use of mechanical workshop equipment and you need a hole drilled in a piece of metal as part of your research, which of these action chains should you follow? A. Ask a mate to instruct you how to drill a hole / Find the nearest power drill / Find some Safety Glasses / Then drill the hole B. Buy a power drill / Buy some Safety Glasses / Ask a mate to instruct you how to use the drill / Then drill hole C. Find some Safety Glasses / Find the nearest Lab Technician / Ask if you can borrow their power drill / Then drill the hole D. Go to the nearest mechanical workshop / Ask for a Mechanical Technician / Ask them to drill the hole for you E. Go into the nearest mechanical workshop / Find some Safety Glasses / Find the nearest Mechanical Technician / Ask to use their pedestal drill Did you benefit from the course? A. Yes B. No C. Indifferent Do you think the course will prove to be useful to you in your work? A.Yes B.No C.Don’t know Did the course meet it’s learning objectives? A. Yes B. No C. Partially Was the quality of the talks good? A. Yes B. No C. Sometimes