PowerPoint-Präsentation

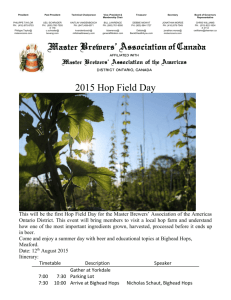

advertisement

Short tour around Hops with HVG & AGRARIA Carlos Ruiz Wolnzach, June 2015 Content • Hops in Beer and as a result Motto and Vision of HVG • Main Hop Varieties in Germany • Hop Products of HVG and Quality Chain from Hops to Hop Products 2 Hops in Beer • 3 important groups of substances – Bitter substances – Aroma compounds – Polyphenols 3 Quotations from the Hop Book – „At one extreme, hops are simply employed to add bitterness, but at the other, hop varieties are utilized in a number of ways to impart mouthfeel and aroma to beer.“ – „Even using the same technology, the sensory results obtained by different research groups will by no means be identical.“ – „The authors realized that there are no clear and simple rules pertaining to the process of hopping beer. Depending on the hopping technique, the amount of hops remaining in beer ranges from only few mg of iso-alpha-acids per liter to circa 100 mg per liter of various bitter substances and polyphenols along with more than 100 µg per liter of aroma compounds.“ 4 Two commercial Beers (aprox. 20 Bitter Units) 90 (mg/l) iso-extract 300g/hl aroma hops 80 70 60 50 IAS nIAS AS PP Others = Iso- α-Acids = non-iso-α-acids bitter substances = Aroma Substances = Polyphenols = Glycosides, Proteins, … 40 30 20 10 0 IAS nIAS AS PP Others 5 Our Motto „There are thus far no known hop compounds with a negative influence on beer quality if one excludes environmental contaminants like pesticides, nitrates and metals. Consequently it would not be necessary to eleminate any hop compounds with respect to the quality of the beer from a sensory standpoint.“ 6 Hops in Beer Hops can…. generate bitterness through iso-α-acids (IAA) define quality of bitterness through non-iso-α-acid-bittersubstances (nIAA) create a diversity of hop aromatic impressions through aroma components create taste: palatefullness, mouthfeel, drinkability and harmony through water-soluble substances like polyphenols, glycosides improve foam improve flavour stability 7 Overview of sensoric Effects of Bitter Compounds • Accompanying (NIAA) bitter substances show a pleasant bitterness; β:α is an interesting indicator • Polyphenolic bitter substances (Hard Resins, others) show a very pleasant bitterness • Low cohumulon ratio is positive for quality of bitterness, foam and flavour stability • α-acids are positive for foam and flavour stability These effects become more evident by dosing of aroma hops in later hop additions 8 Hop Aroma in Beer Estimation of the world beer market – Not desired: more than 60% – Indirectly desired: 20-30% (this ratio increases; search for innovative flavour impressions from hops) – Directly desired: less than 10% (this ratio increases; scene of craft brewers) 9 Differentiation of Hop Aroma in Beer „Kettle hop flavour“: beginning of boil (BB), seldom perceptible „Late hop aroma“: end of boil (EB) or whirpool (WP); goal is a perceptible hopnote („Hopfenblume“) „Dry hop aroma“: Dry-hopping into the cold beer, hop aroma is linked to a specific variety 10 Descriptors of Hop Aroma There exist different proposals, f.i. • Beer aroma wheel, many examples • Descriptors according properties like flowery, fruity, citrussy, hoppy, herbal, woody… • Descriptors according comparison like: Apple, Orange, Grapefruit, Vanilla, Melon, Lemon, Mandarin, Ananas, Passion Fruit,… No uniform understanding of different panels 11 What are Polyphenols (PP)? • Secondary Metabolites like bitter and aroma components • ~ 5000 known in the world of plants, many of them have a positive reputation (health benefits) as e.g. antioxidants and radical scavengers… 12 Hop Polyphenols and Beer Taste Prejudice: - „PP are responsible for a tannic bitterness“ >50 years ago: - Hops stored in air resulted in oxidized and polymerized PP - Longer boiling time (>120 min.) with contact to oxygen Today: - Hops are stored in cold warehouses - Hops and pellets are packed inert - Boiling time < 60 min without air/oxygen - Hop PP are dosed in „fresh“ form to the beer Positive influence on beer flavour 13 Palatefullness 14 Main variable Parameters for Hopping • Hop varieties (n > 100) • Growing conditions – Country, region – Harvest time (colour, max α, max oil?) • Handling of cone hops (temperature, density, oxygen?) • Hop product • Whole hops (inert packaging!) • Pellets / Extract • „Advanced“ Products (Iso, Aroma) • Criteria and quantity of dosage (weight, α, oil, Linalool, PP, others) • Time of addition (BB, MB, EB, WP, Dry Hopping…) 15 Thoughts on Hop Varieties • The later the hop dosage, the less alternatives concerning the selection of possible hop varieties number Begin of boil Middle of boil End of boil /WP Dry hopping time • Think of alternatives or use a blend of 2 or even more varieties. The ratio may vary according to crop results. 16 Our Vision „Make use of hops in its natural form!“ 17 Hop Varieties Official groups: aroma & bitter Defining aroma and bitter varieties No clear differentiation possible according chemical composition More oriented on application; bitter hops provide beer bitterness; aroma hops fulfill additionally other purposes Expectations: bitter hops > 10% α, strong aroma; aroma hops < 10% α, mild aroma, high polyphenol content 18 Additional (inofficial) groups • Dual-purpose hops (f.i. Chinook, Centennial) • Noble (aroma) hops = land races (f.i. Tettnang, Spalt, Hersbruck, Hallertau Mittelfrueh, Saaz) • Hops with special flavor = special flavor hops = flavor hops = hops with unique flavor mainly used for dry hopping 19 Characterisation of hop varieties • Agronomic characteristics: yield, resitance to deseases… • Chemical compounds (examples): α-acids, β:α, cohumulone-ratio, polyphenols, polyphenols:α, total oil, total oil:α, linalool, linalool:α 20 German Noble Aroma Hops α-acids Dimension Spalt Tettnang Hall. Mfr. Hersbruck Average %w/w 4.1 4.1 4.1 3.1 3.9 1.3 1.3 1.3 2.4 1.6 β:α Cohumulone %rel. 24 24 21 20 22 Polyphenols %w/w 5.3 5.3 4.6 4.4 4.9 1.3 1.3 1.1 1.4 1.3 ml/100g 0.60 0.60 0.85 0.75 0.70 ml/g 0.15 0.15 0.21 0.24 0.19 mg/100g 4 4 6 5 4.8 mg/g 1.0 1.0 1.5 1.6 1.3 Polyphenols:α Total oil Total oil:α Linalool Linalool:α 21 German Aroma Hops bred in Huell Dim. α-acids %w/w β:α Perle Tradition Select Saphir Opal Smaragd Averg. 7.4 6.2 5.1 4.1 7.9 5.9 6.1 0.7 0.8 1.0 1.9 0.8 0.9 1.0 Cohumulone %rel. 30 26 23 15 15 15 21 Polyphenols %w/w 4.1 4.3 4.9 4.5 3.7 4.5 4.3 0.6 0.7 1.0 1.1 0.5 0.8 0.8 ml/100g 1.30 0.70 0.70 1.10 0.95 0.90 0.94 ml/g 0.18 0.11 0.14 0.27 0.12 0.16 0.16 mg/100g 4 7 8 10 11 10 8.3 mg/g 0.5 1.1 1.6 2.4 1.4 1.7 1.3 Polyphenols:α Total oil Total oil:α Linalool Linalool:α 22 German Bitter Hops α-acids Dimension North. Brew. Magnum Taurus Herkules Average %w/w 9.2 13.9 15.9 15.9 13.7 0.6 0.5 0.3 0.3 0.43 β:α Cohumulone %rel. 27 27 23 36 28 Polyphenols %w/w 3.9 2.6 3.1 3.5 3.3 0.4 0.2 0.2 0.2 0.25 ml/100g 1.5 2.4 2.0 1.8 1.9 ml/g 0.16 0.17 0.13 0.11 0.14 mg/100g 4 8 19 8 10 mg/g 0.4 0.6 1.2 0.5 0.7 Polyphenols:α Total oil Total oil:α Linalool Linalool:α 23 Averages α-acids Dimension Noble Aroma Aroma Bitter %w/w 3.9 6.1 13.7 1.6 1.0 0.43 β:α Cohumulone %rel. 22 21 28 Polyphenols %w/w 4.9 4.3 3.3 1.3 0.8 0.25 ml/100g 0.70 0.94 1.9 ml/g 0.19 0.16 0.14 mg/100g 4.8 8.3 10 mg/g 1.3 1.3 0.7 Polyphenols:α Total oil Total oil:α Linalool Linalool:α 24 German Special Flavor Hops α-acids Dimension H. Cascade Blanc Melon Mandarina Polaris %w/w 5.9 9.7 7.2 8.4 19.7 1.0 0.5 1.2 0.6 0.3 β:α Cohumulone %rel. 31 24 29 33 24 Polyphenols %w/w 3.2 5.7 4.5 4.1 3.5 0.6 0.6 0.6 0.5 0.2 ml/100g 1.2 1.3 1.6 1.2 3.9 ml/g 0.20 0.13 0.22 0.14 0.20 mg/100g 6 6 5 7 9 mg/g 1.1 0.6 0.7 0.8 0.5 Polyphenols:α Total oil Total oil:α Linalool Linalool:α 25 Selected Aroma Substances mg/100g Hall. Mfr. Saphir H. Cascade Melon Mandarin a Blanc Polaris Myrcene 173 428 720 771 833 914 2,248 βCaryophyllene 76 48 48 25 46 52 278 Humulene 273 113 134 25 143 145 739 α- + β-Selinene 10 25 14 193 113 218 27 Linalool 6 9 6 5 7 6 9 Geraniol 1 1 7 8 14 2 4 Geranylacetate 0 0 15 1 1 8 17 Sum of 9 Esters 11 13 36 106 87 89 359 26 Hop Dosing Regime (yield in %rel.) α-acids Polyphenols Esters/Alc. Terpenes Begin of boil 40-50 50-60 0 0 Middle of boil 15-25 50 5 0 10 50 30-50 <2 5-10 40-50 40-60 <2 5 up to 50 up to 100 up to 5 End of boil Whirpool Dry hopping • • • • BB MB EB/WP Dry Bitter hops Aroma hops Aroma hops Aroma/flavor hops Bitterness Palatefullness Palatefullness + flavor individual flavor 27 28 Conventional Hop Products Problems with whole hops – – – – – – Logistic Heterogenity Stability Automatic dosing Yields Wort clarification Conventional hop products should overcome the disadvantages of whole hops without chemical changes of substances by gentle processes. 29 Whole Hops • In bales: oxygen is present! • In gas-tight foil bags: inert like pellets • HVG produces Vakupacks= whole hops pressed (500kg/m3): packed in foils under vacuum; lupulin glands are crushed (better extraction of hop oil) 30 Pellets • Regular pellets= Type 90; yield approx. 9096kg pellets from 100 kg hops; identical with hops • Enriched pellets= type 45; yield approx. 4590kg pellets from 100 kg hops; alpha and oil enriched up to a double of hops 31 Flow Chart of normal Hop Pellets 32 Background of enriched Pellets • Seperation of lupulin glands from leafs (waste) • Grinding and seaving are only possible with hard lupulin glands • The liquid phase of resin and oil in the lupulin must be hard, which needs temperatures below -20°C 33 Lupulin Glands 34 Flow Chart of enriched Pellets 35 Comparison of normal and enriched Pellets (values in %rel. to amounts of whole hops) 36 Sensitive Steps during the Pellet Production Product Temperature Exposure Time Kilning < 60 °C < 30 min Grinding < 20 °C few seconds Sieving for Type 45 < -30 °C - Mixing powder < 20 °C < 120 min Pelletiziation < 55 °C few seconds Pellet cooling < 18 °C < 20 min Packing in Foils • Oxygen-diffusion of the foil material: < 0.5 ml/m² * 24h * 1bar • More than 95% of all packed foils less than 1% v/v Oxygen 38 Carbon Dioxide Extraction 39 Flow Chart of a supercritical CO2-Extraction 40 Hop Oil Production 41 42 The Quality Chain from Hops to Hop Products Definition of “Quality Chain“: • All processes from hops untill dosage in the brew house are parts of the quality chain • Goal of an optimal quality chain is the best possible identity of all components between the harvest at hop and ist dosage in form of a hop product Can Hops be a Risk for Health? Components Deterioration Contamination with - Plant protection substances - Heavy metals - Mycotoxines - Microbiology? Definition of "Quality" Definition is being done normally according to Variety and Growing area Definition in this case: "Quality defines the degree of deterioration of the hop components from the harvest until the dosing into the wort." Quality = Freshness Analytical indices such as alpha degradation or Hop Storage Index (HSI) describe only partial aspects. All important hop components suffer through deterioration Bitter substances Aroma substances Polyphenols Hop Quality according to the Deterioration vs. freshly harvested Hops Category of Freshness / Ageing Fresh Slightly deteriorated Deteriorated Strongly deteriorated Overaged Loss of Alpha-acids in % rel. 0 to 10 11 to 20 21 to 30 31 to 40 > 40 Hop Storage Index < 0.32 0.33 to 0.40 0.41 to 0.50 0.51 to 0.60 > 0.61 Steps of a "Quality Chain" with conventional Hop Products Hop harvest with picking, drying, conditioning, baling Storage in form of cone hops Processing to hop products Storage of hop products Transport to the brewery Storage and dosing in the brewery Drying of Hops • What is the "right drying temperature"? • Common understanding today: Tmax = 63 °C • Enzymatic reactions of polyphenols are unclear • new findings may result in new rules Conditioning of Hops Goal is the homogenisation of the moisture within the cones. 2 - 3 hours conditioning with circulating air Afterwards blending of outside and inside air according to desired water content • Air temperature of approx. 18 °C Correlation of Humidity in the Air and the Moisture of Hops Desired Moisture Weight - % Air Humidity % relative 12 10 9 8 65 60 55 50 Packing of Hops Goal: Optimal logistics with minimal damaging of the lupulin membrane Better storage stability through limited oxidation protection of the lupulin membrane Requirement for lupulin enriched pellets (Type 45) are intact lupulin glands Lupulin Glands from Bales 139 kg/m3 185 kg/m3 Hop Storage Trials 12 varieties were stored in 3 types of storage: - Moderate storage ( 5 to 30 °C) - Good storage ( 5 to 20 °C) - Cold storage ( 1 to 5 °C) Summary of Storage Tests Average changes after three month in % relative Moderate Storage Good Storage Cold Storage Decrease of alpha EBC 7.7 22 18 5 Increase of HSI ASBC 53 43 13 Consequences Cold storage of hops soonest possible after the crop Optimal systems for an economical storage Improvement of Hop Products Logistic Homogeneity Stability Dosing in the brew house Hop production means to overcome the disadvantages of cone hops without damaging components. Sensitive Steps during the Pellet Production Product Temperature Exposure Time Kilning < 60 °C < 30 min Grinding < 20 °C few seconds Sieving for Type 45 < -30 °C - Mixing powder < 20 °C < 120 min Pelletiziation < 55 °C few seconds Pellet cooling < 18 °C < 20 min Physical Characteristics of Pellet Foils Quality criterion Method Example for Limits Diffusion of oxygen DIN 53 380 Stability of weld seam DIN 53 455 > 20 Newton Penetration resistance DIN 53 373 > 300 Newton O2 in foils several <0.5 ml/m2/24 h/1 bar < 0.5 vol-% O2 Physical Characteristics of Cartons Quality criterion Method Example for Limits Stackability test EN-DIN 3037 > 17 kN/m Penetration test DIN 53 142 > 18 Joule Proposed Storage Temperature for Hops and Hop Products Intended storage time Whole hops Pellets Extracts 1 year 3 years 5 years 0 °C - 20 °C not practicable 10 to 15 °C < 20 °C 5 °C 0 °C 10 °C 5 °C Temperature in a Container "winter normal" • Temperature in a Container "on deck" °C 50 45 40 35 30 25 20 15 10 5 date 0 23.2. 2.3. 10.3. 18.3. 26.3. 3.4. Temperature in a Container "harbour" 50 °C 45 40 35 30 25 20 15 10 5 date 0 15.7. 6:07 23.7. 6:07 31.7. 6:07 8.8. 6:07 16.8. 6:07 24.8. 6:07 1.9. 6:07 Temperature in a Container "disastrous" °C 50 45 40 35 30 25 20 15 10 5 date 0 18.9. 26.9. 4.10. 12.10. 20.10. 28.10. 05.11. Consequences during Pellet Transport With an intact foil only inert reactions occur; Alpha-losses 2 - 15 % relative; unpleasant aroma substances will be formed Formation of gas pressure increases foil gets a hole Gas escapes and air penetrates Oxidation up to total loss Timing of shipment (winter months) or preferably the use of reefer containers CONCLUSIONS Damaging potential of alpha-acids (% rel.) Pellets conditions Good Extracts conditions Moderate Good Moderate Kilning + conditioning 3 to 5 10 3 to 5 10 Storage of whole Hops 3 to 8 30 3 to 8 30 Production* 0 to 2 5 0 to 2 5 Storage for 1 year 3 to 6 12 1 to 2 3 2 15 0 2 7 to 17 50 Overseas shipment Total 11 to 23 62 * Alpha-losses in form of yield not taken into consideration Think of strategic Stocks You as a brewer have developed a beer with a special recipe and defined hops. In a short crop, these hops are very expensive or not even available. Properly packed hops or pellets (O2-free) stored at approx. 0°C keep quality for several years. Be more independent of bad (and expensive) crops, especially in the case of aroma hops with special character. A product, some years old, produced from a good crop is better than a product of a current bad crop. A simple rule: good crops in quantity are normally combined with high quality and often with low spot prices for some varieties. 68 Summary (1) "Quality" is the degree of freshness independent of the growing area and the hop variety. A degradation of bitter acids, aroma components and polyphenols from the time of harvest to the point of hop addition to the kettle is defined as ageing. There are analytical methods (ageing indicators like HSI), but further research is necessary. Summary (2) "Quality chain" comprises all processes from harvest to the dosage into the wort. Farmer, Processor and Brewer are partners in the quality chain. They are responsible to prevent damages of hop components. Thank you for your attention! 71