HOPI FAA PDR - Lowell Observatory

advertisement

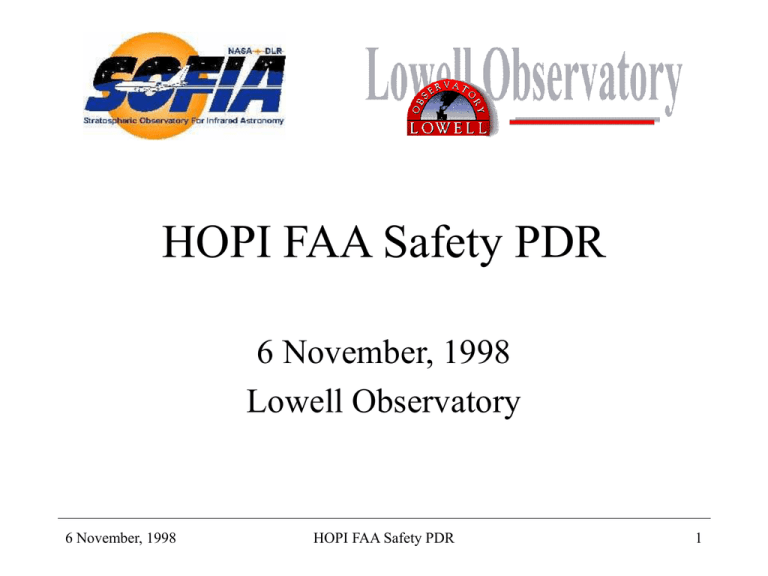

HOPI FAA Safety PDR 6 November, 1998 Lowell Observatory 6 November, 1998 HOPI FAA Safety PDR 1 Overview • Staff Introductions – – – – – – Ted Dunham - PI, Overall responsibility Jim Elliot - Co-I Brian Taylor - Software Ralph Nye - Mechanical Design Jim Darwin - Machinist Rich Oliver - Electronics Technician 6 November, 1998 HOPI FAA Safety PDR 2 Overview • Character of the Instrument – Special Purpose Science Instrument for SOFIA – Occultation Observing • What are occultations? • Deployment operation will be common – Guest Investigator use – SOFIA Testing - most stringent requirements – OPERATIONAL FLEXIBILITY IS CRITICAL 6 November, 1998 HOPI FAA Safety PDR 3 Overview – HOPI is a high-speed imaging system – Two CCD detectors capable of fast readout – Reimaging optics, one set optimized for 0.3-0.6 microns, the other for 0.4-1.0 microns – Unbinned image scale 0.33 arcsec/pixel – Selectable filters, Hartmann and Focault tests. – Goal - Allow simultaneous mount on SOFIA with FLITECAM to extend coverage to 5 mm. 6 November, 1998 HOPI FAA Safety PDR 4 Overview Stellar Occultation Geometry Toward Occulted Star Motion of Occulting object Occulting object Shadow of Occulting object Earth 6 November, 1998 HOPI FAA Safety PDR 5 Overview An occultation occurs when an object in the solar system passes between an observer and a star. The figure above shows how the object's shadow is cast on the Earth by the starlight. The object's motion causes the shadow to move across the Earth. The path of the shadow across the Earth's surface is called the occultation track. The cartoon on the left shows how the occultation appears as seen by an observer. The occulting object moves across the sky, approaching a star. If the observer is in the correct position on the Earth, the star disappears behind the object. 6 November, 1998 HOPI FAA Safety PDR 6 Overview • Operation with FLITECAM is important – Simultaneous IR imaging capability needed for: • Certain occultation opportunities • SOFIA testing • FLITECAM is just beginning to be defined – This is the biggest certification issue we face – We are trying to allow for FLITECAM mount 6 November, 1998 HOPI FAA Safety PDR 7 Overview View of HOPI with red and blue channels in place. Electronics are located under the instrument. The figures on the next sheet show views from the left and top. Note the small dewar sizes. 6 November, 1998 HOPI FAA Safety PDR 8 Overview 6 November, 1998 HOPI FAA Safety PDR 9 Overview • This view shows HOPI as seen looking toward the telescope. The large circular plate is the 41” mounting flange. The red optics are on the left, the blue on the right. The mounting location for the bare CCD or FLITECAM is at top center. 6 November, 1998 HOPI FAA Safety PDR 10 Overview The Hartmann test mode requires a modification to the red side of HOPI. Some additional optics are installed and the camera lens is removed. These are small and fully contained inside the instrument case. 6 November, 1998 HOPI FAA Safety PDR 11 Overview A high-throughput mode is possible by moving either dewar (the red one is shown here) to the top center location. No reimaging optics are in the path. The other CCD can image the outer part of the field for what it’s worth. 6 November, 1998 HOPI FAA Safety PDR 12 Overview The preferred location for FLITECAM is at top center. Here its dewar is assumed to be 12 inches in diameter and 24 inches long. 6 November, 1998 HOPI FAA Safety PDR 13 Overview • Instrument Envelope – A cone with 41” base at the flange and 12 3/8” radius 2 meters from the flange represents the instrument envelope. Two electronics boxes protrude. – Could rotate about the optical axis to fix this. 6 November, 1998 HOPI FAA Safety PDR 14 Overview • The HOPI dewars will be made by Precision Cryogenics Inc. (PCI) like the EXES and FORCAST dewars. • This drawing is for a similar PCI dewar for another Lowell project. • The fused silica windows will have a safety factor > 10. Dewar for Lowell Observatory Teflon washer Half Scale Sketch Ted Dunham 520-774-3358 1.50 OD 1/2-20 thread for inverted operation Slot in top of fitting for insertion & extraction 3.00 .71 ID Same as other end of dewar 6061-T6 extruded pipe 0.125 wall, 6.25" OD Need about an inch of clear space here for a mounting bracket 0.065 wall G10 Supports evenly spaced, 4 places. 1" wide x 1/16 thick x 8" long ND-16 vacuum fitting .25 ID min stainless thinwall tube 2.0 liters LN Knob pointing away from fill tube ~ 7" deep 13.63 6.00 Evacuation valve is rotated 90° into view. 5.00 4 holes for 4-40 evenly spaced on 1.813 BC. .38 .25 .87 5.33 1.25 Ring welded inside tube 4.87 6 holes tapped for 6-32, evenly spaced on 5.69 BC 2-260 O-ring 2.13 1.81 2-029 O-ring .38 5.31 .50 1.88 .38 7.06 .38 7.37 8.00 8 equally spaced 8-32 screws on 7.06 BC 8 equally spaced 3/8 ID holes on 8.00 BC Rotated 22.5° into view 9.00 6 November, 1998 HOPI FAA Safety PDR 15 Overview • The HOPI dewars will be made from 6061-T6 aluminum tubing and pipe to reduce welding. • Outside dimensions will be approximately 8.5” diameter by 9” long with a 2” long fill stem. The vacuum vessel walls will be 0.148” thick. • The nitrogen can will be 7” ID by 5” long. Its walls will be 0.125” thick. • The end plates on both the dewar and the nitrogen can will be 0.5” thick. 6 November, 1998 HOPI FAA Safety PDR 16 Overview HOPI High-Level System Design - Electronics & Data System GP S An te nn a Stepping Motors Fi l ter # 1 Al l 8 PC-48 ch ann el s i nclu de l i mi ts & ho me Fo cu s # 1 Pu pi l 1 X Chopper to MCCS VG A Di sp la y & kbd for deb ug o nl y Mo to r dri ve r bri ck Hair Box Linux PC Industrial Chassis 1 fi ber 1Hz, 1MHz 2 fi bers Le ach #1 OMS P C4 8 NI P C-TIO Ho meb re w Processor card Fl a sh d isk Fl o ppy Sh utter # 2 Ro om for IMC PID & am pl ifi ers & 2 nd OMS b oa rd fo r IR. Tri gg ers Sh utter # 1 Pu pi l 1 Y Fi l ter # 2 10/100 BT Network TT L/Fi be r & Fi b er/T TL Trak GPS Se ri a l Fi b er p ai r Ne twork Con ne cti on To Move PC Sun Sparc Ultra 30 Se ri a l 21 " d ispl a y, keyboa rd an d mo use PCI Bus Disk & CD-ROM Se ri a l PCI card 23 Gb Di sk Ch an nel 1 2 fi bers Le ach #2 2 fi bers Le ach ca rd #2 Stub - 2 fi bers Pu pi l 2 X Stub IMC Fo cu s DL T 70 00 Stub fo r IR 23 Gb Di sk Le ach IR Stub Le ach IMC Stub Sun Sparc Ultra 5 IMC Stub Stub - 2 fi bers TELESCOPE SIDE 6 November, 1998 23 Gb Di sk Ch an nel 2 Stub Lea ch IR Pu pi l 2 Y Stub - IR fil ter & pu pi l X Y SCSI Le ach ca rd #1 Fo cu s # 2 RACK SIDE HOPI FAA Safety PDR Stub Lea ch IMC 10/100 BT Network Sma l l di sp kbd & mo use 17 Overview • Certification Philosophy – Goal - Preserve as much optical flexibility as possible within the original certification. – Large margins to allow for FLITECAM mount – Certify main structure, electronics mounts, and optical mounting method, but not exact locations of optical elements. Include sufficient margin to allow for different configurations. – New elements would need new certification. 6 November, 1998 HOPI FAA Safety PDR 18 Schedule • Schedule Chart Placeholder 6 November, 1998 HOPI FAA Safety PDR 19 FHA • Overview – – – – – – – Cryogen Boiloff Pressure Vessel issues Aircraft Pressure Boundary Mass Budget G Loading Lasers & Gases Electrical Hazards 6 November, 1998 HOPI FAA Safety PDR 20 FHA • Cryogen Boiloff – Liquid nitrogen only, no helium – Normal boiloff rate is 1.5 cu ft/hour per dewar – Maximum boiloff rate for a dewar at ambient internal pressure is ~2 cu ft/min at STP. – Total liquid capacity is 3 liters per dewar, corresponding to 70 cu ft of gas at STP. – Worst case - both dewars boil dry in ~35 minutes and displace 0.2% of the cabin volume. 6 November, 1998 HOPI FAA Safety PDR 21 FHA • Pressure Vessel Issues – Dewars will be made by Precision Cryogenics, like FORCAST and EXES. – If the dewar neck tube is blocked, rising pressure could rupture the dewar – Burst disks with an operating pressure of 30 psi will be used, a cryogenic one on the nitrogen can, a room temperaure one on the dewar case. – There is no oxygen displacement hazard. 6 November, 1998 HOPI FAA Safety PDR 22 FHA • Aircraft Pressure Boundary – Formed by windows in the vacuum pipe. The instrument case is not a pressure vessel. – 6.5” diameter windows will be either CaF2 (20 mm thick) or sapphire (6 mm thick) depending on cost. – Window thicknesses are appropriate for a 1 atmosphere pressure differential with a safety factor of at least 20. – DC-8 windows have safety factors ranging from 7-14. 6 November, 1998 HOPI FAA Safety PDR 23 FHA • Mass Budget – – – – – – – – – – CCD Electronics 20 lb x 2 CCD Pwr. Supply 15 lb x 2 “Hair” box 25 lb Dewars 25 lb x 2 Vacuum pipe 20 lb Blue dichroic/field lens 6 lb Blue collimator assy 15 lb Blue fold mirror 6 lb Blue camera lens 4 lb Blue filter/focus assy 15 lb – – – – – – – – – – – Red collimator assy Red fold mirror Red camera lens Red filter/focus assy Hartmann optics Mounting plate Base plate Side walls Top and back plates Additional bracing Add’l contingency – TOTAL 6 November, 1998 HOPI FAA Safety PDR 40 lbs 6 lb 4 lb 15 lb 10 lb 100 lb 150 lb 66 lb 20 lb 33 lb 45 lb 700 lb 24 FHA • G Loading – Failure of 3/4” thick flange in: • • • • • • Tension failure, one pin location only Shear tear-out, one pin location only bearing failure, one pin location only pin shear, one pin only bolt hole shear tear-out Estimated CG is on-axis (side-side), 4” below the optical axis (top-bottom), and 10” forward of the mounting flange (fore-aft). 6 November, 1998 HOPI FAA Safety PDR 25 FHA • Flange failure in tension – Here the “cap” on the flange above the center of the top pin tears off. Flange diameter = 41” D = 6.361” Bolt/pin circle diameter = 990 mm = 38.976” 6 November, 1998 HOPI FAA Safety PDR 26 FHA • Flange failure in tension, continued – The distance along the bottom of the “cap” from the pin to the edge of the plate is D = sqrt(20.52 - 19.4882) = 6.361 inches – The area under tension is A = (2D - dpin) * tp = 8.79 sq. in. – Here dpin is the pin diameter (1”) and tp is the plate thickness (3/4”). 6 November, 1998 HOPI FAA Safety PDR 27 FHA • Flange failure in tension, continued – The ultimate tensile strength of 6061-T6 aluminum (Ftu), from the FAA SI handbook, accounting for a safety factor of 1.5, is 25.3 ksi. – The margin of safety, MS, is MS = AFtu/Mg - 1 = 8.79*25300/1320*6-1= 27 – Here M is the instrument mass, taken to be the maximum SOFIA SI weight to allow for FLITECAM, and g is the 6g downward load. 6 November, 1998 HOPI FAA Safety PDR 28 FHA • Flange shear tear-out – Here a triangular piece of the flange tears out. – The two lengths that fail are D = d/cos(40) - rpin = 0.82” – The shear area is A = 2D tp = 1.23 sq in. 6 November, 1998 HOPI FAA Safety PDR 29 FHA • Flange shear tear-out, continued – The ultimate shear strength of 6061-T6 aluminum (Fsu), from the FAA SI handbook, accounting for a safety factor of 1.5, is 16.7 ksi. – The margin of safety, MS, is MS = AFsu/Mg-1 = 1.23*16700/1320*6 -1= 1.6 – Here M is the instrument mass, taken to be the maximum SOFIA SI weight to allow for FLITECAM, and g is the 6g downward load. 6 November, 1998 HOPI FAA Safety PDR 30 FHA • Flange bearing failure – Here the pin causes an inelastic deformation of the mounting plate and the hole deforms. – The bearing area A = p rpin tp = 1.18 sq in – The allowable yield stress from the FAA SI Handbook, Fbru, accounting for the safety factor of 1.5, is 40.7 ksi. 6 November, 1998 HOPI FAA Safety PDR 31 FHA • Flange bearing failure, continued – The margin of safety, MS, is MS = AFbru/Mg-1 = 1.18*40700/1320*6-1 = 5 – Here M is the instrument mass, taken to be the maximum SOFIA SI weight to allow for FLITECAM, and g is the 6g downward load. 6 November, 1998 HOPI FAA Safety PDR 32 FHA • Flange pin shear – Here the pin shears off. – Shear area is the cross-sectional area of the 1” diameter pin, A = prpin2 = 0.79 sq in. – The pin material is stainless steel with a shear strength exceeding that of 6061-T6 aluminum. The ultimate shear strength for the aluminum material, (Fsu), from the FAA SI handbook, accounting for a safety factor of 1.5, is 16.7 ksi. 6 November, 1998 HOPI FAA Safety PDR 33 FHA • Flange pin shear, continued – The margin of safety is MS = AFsu/Mg-1 = 0.79*16700/1320*6-1 = 0.7 – Here M is the instrument mass, taken to be the maximum SOFIA SI weight to allow for FLITECAM, and g is the 6g downward load. – The actual margin of safety will be larger by the ratio of the shear strength of the pin material to that of 6061-T6 aluminum. 6 November, 1998 HOPI FAA Safety PDR 34 FHA • Flange bolt hole shear tear-out – Here the bolt heads tear through the flange either because of the 9g forward load or the moment applied to the top of the flange by the 6g downward load acting on the instrument’s moment. – 9g forward load: • The total shear area is given by A = p dbh tp nbolts = p * 0.74” * 0.75” * 20 = 34.9 sq in. Here dbh is the bolt head diameter (washers would help), tp is the plate thickness, and nbolts is the number of bolts. 6 November, 1998 HOPI FAA Safety PDR 35 FHA • Flange bolt hole shear tear-out, continued – 9g forward load, continued • The margin of safety is given by MS = AFsu/Mg-1 = 34.9*16700/1320*9-1 = 48 – 6g downward load coupled through instrument CG • Assume the full load is taken on the two top bolts so the shear area is given by A = p dbh tp nbolts = p * 0.74” * 0.75” * 2 = 3.49 sq in. Here dbh is the bolt head diameter (washers would help), tp is the plate thickness, and nbolts is the number of bolts. 6 November, 1998 HOPI FAA Safety PDR 36 FHA • Flange bolt hole shear tear-out, continued • The tear-out load is smaller than the downward load by the ratio dcg/dbc. • The tear-out load is then Lt = dcg/dbc M g = 10/39 * 1320 * 6 = 2030 lbs • The margin of safety is given by MS = A Fsu / Lt - 1 = 3.49*16700/2030-1 = 28 6 November, 1998 HOPI FAA Safety PDR dcg CG, 10” from flange Downward 6g load dbc Bolt circle, 39” in diameter Tear-out component of load 37 FHA • G Loading Summary – – – – – Tension failure MS = 27. Unrealistic failure mode Shear tear-out MS = 1.6 Bearing failure MS = 5 Pin shear failure MS = 0.7 (for aluminum pin) Bolt hole shear tear-out • 9g forward load case MS = 48 • 6g down coupled load case MS = 28 6 November, 1998 HOPI FAA Safety PDR 38 FHA • Containment and Penetration Analysis – Not done in the FAA SI handbook, so not done here either. 6 November, 1998 HOPI FAA Safety PDR 39 FHA • Lasers and Gases – NONE 6 November, 1998 HOPI FAA Safety PDR 40 FHA • Electrical Hazards – No high voltages (AC power is the highest) – No high currents – Most electronics is COTS • Sun, SDSU, industrial PC chassis & boards, Trak GPS, motor driver “bricks”, fiber modems – Some homemade electronics • Small timing circuit, fiber interfaces, and cables with Teflon or Tefzel insulation. 6 November, 1998 HOPI FAA Safety PDR 41 FHA HOPI High-Level System Design - Electronics & Data System GP S An te nn a Stepping Motors Fi l ter # 1 Al l 8 PC-48 ch ann el s i nclu de l i mi ts & ho me Fo cu s # 1 Pu pi l 1 X Chopper to MCCS VG A Di sp la y & kbd for deb ug o nl y Mo to r dri ve r bri ck Hair Box Linux PC Industrial Chassis 1 fi ber 1Hz, 1MHz 2 fi bers Le ach #1 OMS P C4 8 NI P C-TIO Ho meb re w Processor card Fl a sh d isk Fl o ppy Sh utter # 2 Ro om for IMC PID & am pl ifi ers & 2 nd OMS b oa rd fo r IR. Tri gg ers Sh utter # 1 Pu pi l 1 Y Fi l ter # 2 10/100 BT Network TT L/Fi be r & Fi b er/T TL Trak GPS Se ri a l Fi b er p ai r Ne twork Con ne cti on To Move PC Sun Sparc Ultra 30 Se ri a l 21 " d ispl a y, keyboa rd an d mo use PCI Bus Disk & CD-ROM Se ri a l PCI card 23 Gb Di sk Ch an nel 1 2 fi bers Le ach #2 2 fi bers Le ach ca rd #2 Stub - 2 fi bers Pu pi l 2 X Stub IMC Fo cu s DL T 70 00 Stub fo r IR 23 Gb Di sk Le ach IR Stub Le ach IMC Stub Sun Sparc Ultra 5 IMC Stub Stub - 2 fi bers TELESCOPE SIDE 6 November, 1998 23 Gb Di sk Ch an nel 2 Stub Lea ch IR Pu pi l 2 Y Stub - IR fil ter & pu pi l X Y SCSI Le ach ca rd #1 Fo cu s # 2 RACK SIDE HOPI FAA Safety PDR Stub Lea ch IMC 10/100 BT Network Sma l l di sp kbd & mo use 42 Stress Analysis • Main Work Surface – Top and bottom plates are 5mm 304 stainless. – Both plates will be attached to the mounting flange and side plates with angle and screws. – Additional braces will be attached to both plates with angle and screws also. – Optical components will be mounted to the top plate, electronics to the bottom. 6 November, 1998 HOPI FAA Safety PDR 43 Stress Analysis • Main Work Surface, continued – What kind of stress calculations are needed for the envisioned angle bracket mounting method? – Will we need to fasten the top and bottom plates together by means other than the attachments to the main structure? – The optical breadboard normally comes with 1/4-20 tapped holes. 1/4-28 is possible to get if necessary. Should we do this? 6 November, 1998 HOPI FAA Safety PDR 44 Stress Analysis • Major Optical Components – The optics will be mounted as clusters of connected lenses in modules. – The modules will be fastened to the work surface by either 1/4-20 or 1/4-28 screws. – The worst case component is the 40 lb red collimator lenses and fold mirror assembly. – Analyses will be done assuming a 9g load for simplicity although this load is often too high. 6 November, 1998 HOPI FAA Safety PDR 45 Stress Analysis • Major Optical Components, continued – Ignore the failure in tension case since shear tear-out is always more of a problem. – All analyses done for only one bolt. – The safety margins are as in the FHA section: • • • • Shear tear-out: MS = Fsu 2(d/cos40-rb)t /Mg - 1 Pin (screw) shear: MS = Lmax / M g - 1 Bolt head tear-out: MS = Fsu pdbht / M g - 1 Bearing failure: MS = Fbru prbt / M g - 1 6 November, 1998 HOPI FAA Safety PDR 46 Stress Analysis • Major Optical Components, continued – The variable definitions are: • Fsu = ultimate shear strength, 16.7 ksi for 6061-T6 • Fbru = max. bearing strength, 40.7 ksi for 6061-T6 • Lmax = max. screw shear load from MIL-HDBK-5G, 992 lbs for #10, 1718 lbs for 1/4”, assuming 35ksi material • d = distance of bolt hole center to edge of plate, 1/2” • t = thickness of plate, 1/8” • rb = radius of bolt hole, 0.095” for #10, 0.125” for 1/4 • dbh = diameter of bolt head, 0.30” for #10, 0.37” for 1/4 • Mg = mass of unit times g load. 6 November, 1998 HOPI FAA Safety PDR 47 Stress Analysis • Major Optical Components, continued – The results are summarized in the table below: Load Case Shear Tear-out Pin (screw) shear Bolt head tear-out Bearing Failure 6 November, 1998 Margin of Safety 5.2 3.8 5.7 4.5 HOPI FAA Safety PDR 48 Stress Analysis • Electronics Enclosures – The worst case enclosure is the industrial PC chassis for the “hair” box at 25 lbs. – Analyses will be done assuming a 9g load for simplicity although this load is often too high. – The enclosures will be held in place with 1”x1/8” angle brackets made of 6061-T6 aluminum and fastened to the main work surface and braces with 10-32 screws. 6 November, 1998 HOPI FAA Safety PDR 49 Stress Analysis • Electronics Enclosures, continued – Ignore the failure in tension case since shear tear-out is always more of a problem. – All analyses done for only one bolt. – Use the equations for margin of safety and the values for screw dimensions etc. from the Major Optical Components section. 6 November, 1998 HOPI FAA Safety PDR 50 Stress Analysis • Electronics Enclosures, continued – The results are summarized in the table below: Load Case Shear Tear-out Pin (screw) shear Bolt head tear-out Bearing Failure 6 November, 1998 Margin of Safety 9 3.4 8 5.7 HOPI FAA Safety PDR 51 Stress Analysis • Dewar Overpressure • For a cylinder, tensile stress due to pressure is Fs = P * r / t where P is the pressure difference, r is the cylinder radius and t is the cylinder’s wall thickness. • The margin of safety is MS = Ftu/Fs - 1 where Ftu is the ultimate tensile strength of the material, 25.3 ksi for 6061-T6 aluminum. 6 November, 1998 HOPI FAA Safety PDR 52 Stress Analysis • Dewar Overpressure, continued • For the dewar, r=4.16”, t=0.148”, and P = 90 psi (a factor of three more than the burst disk pressure). The tensile stress is 90*4.16/0.148 = 2500 psi. • For the nitrogen can, r=3.5”, t=0.125”, and P = 90 psi. The tensile stress is 90*3.5/0.125 = 2500 psi. • The margin of safety is 25300/2500 - 1 = 9.1 6 November, 1998 HOPI FAA Safety PDR 53 Stress Analysis • Dewar Overpressure, continued • The safety factor for a flat circular plate (I think of it as a dewar window) is MS = (4*Ftu/kP) * (t/D)2 - 1 • Ftu is the ultimate tensile strength of the material k is 1.125 for a simply supported circular plate P is the pressure differential t is the plate thickness D is the plate diameter 6 November, 1998 HOPI FAA Safety PDR 54 Stress Analysis • Dewar Overpressure, continued • For the nitrogen can ends, t=0.5”, D=7.25” MS = (4*25,300/1.125*90) * (0.5/7.25)2 - 1 = 3.8 • For the dewar ends, t=0.5”, D=8.625” MS = (4*25,300/1.125*90) * (0.5/8.625)2 - 1 = 2.4 • For the dewar window, t = 3mm, D = 38mm, and the tensile strength for fused silica is 7100 psi. (4700 psi with a safety factor of 1.5). Then MS = (4*4700/1.125*90) * (3/38)2 - 1 = 0.16 • If the dewar’s burst disk fails to rupture, the dewar window will fail before the dewar end plates fail. 6 November, 1998 HOPI FAA Safety PDR 55 Stress Analysis • Instrument Cart – Floor loading is the issue here – The cart has not been designed, but we assume it weighs less than 300 lbs, for a total weight of cart + instrument, including FLITECAM, of 1600 lbs, the maximum SI weight. – The wheel contact area must be adequate to avoid floor damage when the weight is held by three wheels, at 530 lbs per wheel. – The floor load limit in ICD SIC-TA-01 is TBD. 6 November, 1998 HOPI FAA Safety PDR 56 Operations • Installation Timeline – – – – – Arrive with equipment a week before installation Integrate instrument in the lab on its cart Transport to and mount on TAAS for checkout Transport to aircraft and install on the telescope Store cart in the lab 6 November, 1998 HOPI FAA Safety PDR 57 Operations • Ground Operations – – – – Dewar fills will occur nominally twice a day. Over weekends, dewars can warm up. Cooldown should take < 8 hours (TBD). Instrument tests and data transfer operations will occur during the days. – Power will be required with the aircraft out of the hangar for two hours prior to takeoff. 6 November, 1998 HOPI FAA Safety PDR 58 Operations • Instrument Interfaces – – – – Mechanical interface to telescope and rack Cart carrying instrument to the telescope GPS antenna required on the aircraft 120V/60Hz power required at rack and on telescope – Vacuum line for the evacuated gate valve pipe 6 November, 1998 HOPI FAA Safety PDR 59 Operations • Power Budget • Power Budget – Telescope-mounted parts • • • • – Rack-mounted parts Blue electronics 120 W Red electronics 120 W “Hair” box 150 W Contingency 100 W • TOTAL 6 November, 1998 490 W HOPI FAA Safety PDR • • • • • • Computer Monitor Tape drive 2 disk drives GPS receiver Contingency • TOTAL 140 W 180 W 90 W 150 W 40 W 100 W 700 W 60 Operations • Motorized reconfiguration during flight – – – – – Done during normal telescope operation Focus of red and blue channels Pupil stop positioning Filter wheel rotation During Hartmann operation, MLM and setup lens are in the filter wheel and can be changed. 6 November, 1998 HOPI FAA Safety PDR 61 Operations • Manual reconfiguration during flight – Cage the telescope before reconfiguration – Insert/remove Hartmann collimator, folding mirrors, and beamsplitter/LED source – Insert/remove pupil imaging optics and knife edge for Focault test – Dummy weights provided to maintain balance – Swap dewars or electronics in case of failure – Simple repairs in case of in-flight failure 6 November, 1998 HOPI FAA Safety PDR 62 Operations • Reconfiguration between flights – – – – Add or delete FLITECAM Bare CCD mode - one CCD dewar in upper posn. Change filter wheel contents, pupil stop size Change pressure seal. There are 4 configurations: • • • • 2 windows, vacuum pipe evacuated 1 window in gate valve assy, no pipe at all 1 window at gate valve end of pipe, no vacuum in pipe 1 window at instrument, no pipe. 6 November, 1998 HOPI FAA Safety PDR 63 Operations • Modifications and Upgrades – Possibilities still under consideration: • Image motion compensation camera system • Infrared system to take the place of FLITECAM? – Unknown modifications for future observations – These modifications would follow their own certification timeline. 6 November, 1998 HOPI FAA Safety PDR 64 Documentation • Safety and Airworthiness Documents – FAA Certification Notebook • This will be kept “live” by recording major maintenance and instrument upgrades as they occur. It will include procedures and certification docs. – Drawing Set. • The numbering system will be based on the HAWC system in the FAA book, but simplified for our instrument and modified to fit the existing Lowell drawing system as follows. 6 November, 1998 HOPI FAA Safety PDR 65 Documentation • Drawing numbers will be of the form: EXP083-XNNnnS EXP083 is HOPI’s Lowell project number. • Here X is a letter designation: – M for mechanical (including cryo and vacuum) systems – E is for electrical systems – O is for optical systems 6 November, 1998 HOPI FAA Safety PDR 66 Documentation • NN is a subsystem number. 00 is a table defining all the subsystems. The drawings under subsystem 01 are assembly drawings of the full system. • nn is a drawing number. 00 is a table of contents for all the drawings in this subsystem. Drawings may have more than one sheet. • S is a drawing size, ranging from A to E. • All drawings will have a title block similar to the one shown in the FAA certification manual. 6 November, 1998 HOPI FAA Safety PDR 67 Continued Airworthiness • Little expected airworthiness-related maintenance – Inspect pressure seal windows prior to each flight series. – Inspect cabling insulation prior to each flight series. – Check for loose fasteners prior to each flight series. – Test burst disks at intervals TBD? – Insure fasteners in good condition when changed. 6 November, 1998 HOPI FAA Safety PDR 68 Outstanding Issues • • • • FLITECAM development Burst disks Mounting large computer monitor on rack What modifications of COTS equipment will be required? • Need strength information on NAS hardware 6 November, 1998 HOPI FAA Safety PDR 69