MEP 2nd Ed Worked solutions Chap 02

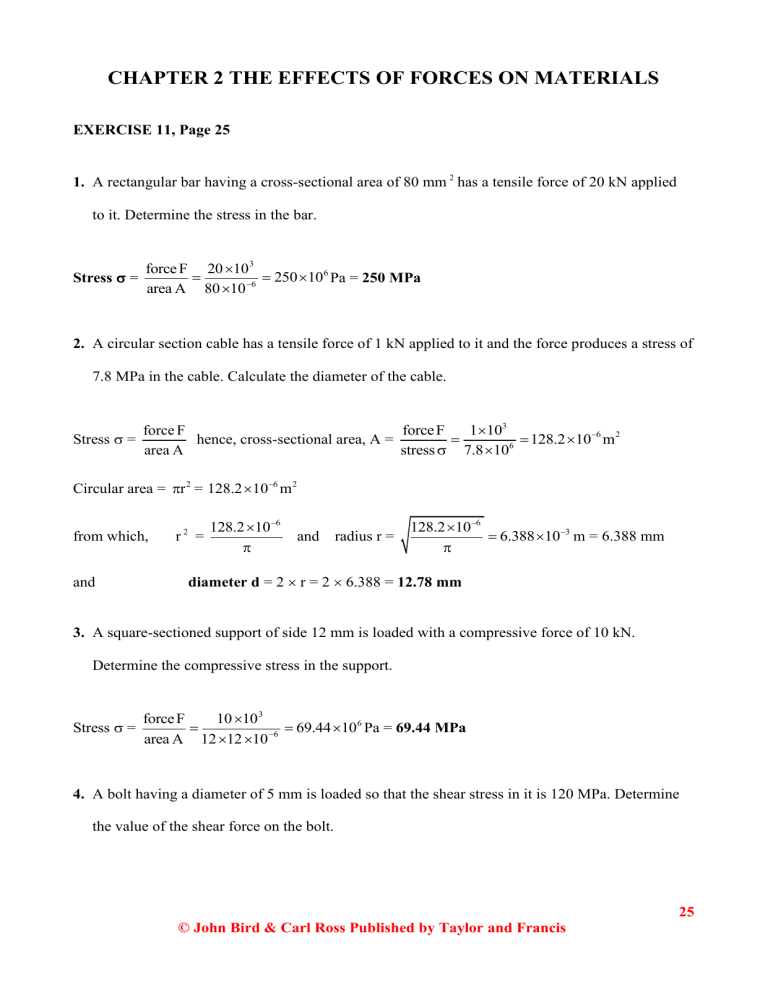

CHAPTER 2 THE EFFECTS OF FORCES ON MATERIALS

EXERCISE 11, Page 25

1.

A rectangular bar having a cross-sectional area of 80 mm

2 has a tensile force of 20 kN applied

to it. Determine the stress in the bar.

Stress

=

3 force F area A

20 10

6

250 10

6

Pa = 250 MPa

2.

A circular section cable has a tensile force of 1 kN applied to it and the force produces a stress of

7.8 MPa in the cable. Calculate the diameter of the cable.

Stress

= force F

hence, cross-sectional area, A = area A force F stress

3

6

6 2

Circular area =

r

2

=

6 2

6 from which, r

2

=

and radius r =

and diameter d = 2

r = 2

6.388 = 12.78 mm

6

3 m = 6.388 mm

3.

A square-sectioned support of side 12 mm is loaded with a compressive force of 10 kN.

Determine the compressive stress in the support.

Stress

= force F

3

area A 12 12 10

6

6

Pa = 69.44 MPa

4.

A bolt having a diameter of 5 mm is loaded so that the shear stress in it is 120 MPa. Determine

the value of the shear force on the bolt.

25

© John Bird & Carl Ross Published by Taylor and Francis

Stress

= force F

hence, force = stress

area = stress

r 2 area A

= 120 10 6

2

3

2

= 2356 N or 2.356 kN

5.

A split pin requires a force of 400 N to shear it. The maximum shear stress before shear occurs is

120 MPa. Determine the minimum diameter of the pin.

Stress

= force F

hence, cross-sectional area, A = area A force F stress

400

6

6

3.3333 10 m

2

Circular area =

r

2

=

6 2

6 from which, r

2

=

and radius r = and diameter d = 2

r = 2

1.030 = 2.06 mm

6

3 m = 1.030 mm

6.

A tube of outside diameter 60 mm and inside diameter 40 mm is subjected to a tensile load of

60 kN. Determine the stress in the tube.

Area of tube end (annulus) =

D

2

d

4 4

2

Stress

= force F

3

area A 1.5708 10

3

4

3

6

Pa = 38.2 MPa

4

3

2

= 1.5708

3

10 mm

2

26

© John Bird & Carl Ross Published by Taylor and Francis

EXERCISE 12, Page 27

1.

A wire of length 4.5 m has a percentage strain of 0.050% when loaded with a tensile force.

Determine the extension in the wire.

Original length of wire = 4.5 m = 4500 mm and strain =

0.050

100

= 0.00050

Strain

= extension x original length L

hence, extension x =

L = (0.00050)(4500) = 2.25 mm

2.

A metal bar 2.5 m long extends by 0.05 mm when a tensile load is applied to it. Determine

(a) the strain, (b) the percentage strain.

(a) Strain

= extension

0.05 mm

0.05

3 original lengh 2.5 10 mm 2500

= 0.00002

(b) Percentage strain = 0.00002

100 = 0.002%

3.

An 80 cm long bar contracts axially by 0.2 mm when a compressive load is applied to it.

Determine the strain and the percentage strain.

Strain

= contraction

0.2 mm original lengh 800 mm

= 0.00025

Percentage strain = 0.00025

100 = 0.025%

4.

A pipe has an outside diameter of 20 mm, an inside diameter of 10 mm and length 0.30 m and it

supports a compressive load of 50 kN. The pipe shortens by 0.6 mm when the load is applied.

Determine (a) the compressive stress, (b) the compressive strain in the pipe when supporting this

load.

Compressive force F = 50 kN = 50000 N, and cross-sectional area A =

4

D

2 d

2

,

27

© John Bird & Carl Ross Published by Taylor and Francis

where D = outside diameter = 20 mm and d = inside diameter = 10 mm.

Hence, A =

4

2 2

(20 10 ) mm

2

(20

2 2

6 2

4

4 2

(a) Compressive stress,

=

F

A

50000 N

4 2

= 212.2

10

6

Pa = 212.2 MPa

(b) Contraction of pipe when loaded, x = 0.6 mm = 0.0006 m, and original length L = 0.30 m.

Hence, compressive strain,

= x

0.0006

L 0.3

= 0.002

(or 0.20% )

5.

When a circular hole of diameter 40 mm is punched out of a 1.5 mm thick metal plate, the shear

stress needed to cause fracture is 100 MPa. Determine (a) the minimum force to be applied to the

punch, and (b) the compressive stress in the punch at this value.

(a) The area of metal to be sheared, A = perimeter of hole

thickness of plate.

Perimeter of hole =

d =

(40

10

3 ) = 0.12566 m.

Hence, shear area, A = 0.12566

1.5

10

3

= 1.885

10

4 m

2

Since shear stress = force area

, shear force = shear stress

area

= (100

10 6

1.885

10

4 )N

= 18.85 kN , which is the minimum force to be applied

to the punch.

(b) Area of punch =

d

2

4

(0.040)

2

4

= 0.0012566 m

2

Compressive stress = force area

3

18.85 10 N

=

0.0012566 m

2

= 15.0

10

6

Pa = 15.0 MPa , which is the

compressive stress in the punch.

6.

A rectangular block of plastic material 400 mm long by 15 mm wide by 300 mm high has its

lower face fixed to a bench and a force of 150 N is applied to the upper face and in line with it.

The upper face moves 12 mm relative to the lower face. Determine (a) the shear stress, and

28

© John Bird & Carl Ross Published by Taylor and Francis

(b) the shear strain in the upper face, assuming the deformation is uniform.

(a) Shear stress,

= force area parallel to the force

Area of any face parallel to the force = 400 mm

15 mm

= (0.4

0.015) m

2

= 0.006 m

2

Hence, shear stress,

=

150 N

0.006 m

2

= 25000 Pa or 25 kPa

(b) Shear strain,

= x

L

12

=

300

= 0.04

(or 4% )

© John Bird & Carl Ross Published by Taylor and Francis

29

EXERCISE 13, Page 31

1.

A wire is stretched 1.5 mm by a force of 300 N. Determine the force that would stretch the wire

4 mm, assuming the elastic limit of the wire is not exceeded.

Hooke's law states that extension x is proportional to force F, provided that the limit of proportionality is not exceeded, i.e. x

F or x = kF where k is a constant.

1.5

When x = 1.5 mm, F = 300 N, thus 1.5 = k(300), from which, constant k =

300

= 0.005

When x = 4 mm, then 4 = kF i.e. 4 = 0.005 F

4 from which, force F =

0.005

= 800 N

Thus to stretch the wire 4 mm, a force of 800 N is required.

2.

A rubber band extends 50 mm when a force of 300 N is applied to it. Assuming the band is

within the elastic limit, determine the extension produced by a force of 60 N.

Hooke's law states that extension x is proportional to force F, provided that the limit of proportionality is not exceeded, i.e. x

F or x = kF where k is a constant.

When x = 50 mm, F = 300 N, thus 50 = k(300), from which, constant k =

50

1

300 6

When F = 60 N, then x = k(60) i.e. x =

1

= 10 mm

Thus, a force of 60 N stretches the wire 10 mm.

3.

A force of 25 kN applied to a piece of steel produces an extension of 2 mm. Assuming the elastic

limit is not exceeded, determine (a) the force required to produce an extension of 3.5 mm, (b) the

extension when the applied force is 15 kN.

From Hooke’s law, extension x is proportional to force F within the limit of proportionality, i.e.

30

© John Bird & Carl Ross Published by Taylor and Francis

x

F or x = kF, where k is a constant. If a force of 25 kN produces an extension of 2 mm, then

2 = k(25), from which, constant k =

2

25

= 0.08

(a) When an extension x = 3.5 mm, then 3.5 = k(F), i.e. 3.5 = 0.08 F,

from which, force F =

3.5

0.08

= 43.75 kN

(b) When force F = 15 kN, then extension x = k(15) = (0.08)(15) = 1.2 mm

4.

A test to determine the load/extension graph for a specimen of copper gave the following results:

Load (kN) 8.5 15.0 23.5 30.0

Extension (mm) 0.04 0.07 0.11 0.14

Plot the load/extension graph, and from the graph determine (a) the load at an extension of

0.09 mm, and (b) the extension corresponding to a load of 12.0 kN.

A graph of load/extension is shown below.

(a) When the extension is 0.09 mm, the load is 19 kN

© John Bird & Carl Ross Published by Taylor and Francis

31

(b) When the load is 12.0 kN, the extension is 0.057 mm

5.

A circular section bar is 2.5 m long and has a diameter of 60 mm. When subjected to a

compressive load of 30 kN it shortens by 0.20 mm. Determine Young's modulus of elasticity for

the material of the bar.

Force, F = 30 kN = 30000 N and cross-sectional area A = r

2

3

2

Stress

=

F

A

30000

3

= 10.61 MPa

Bar shortens by 0.20 mm = 0.00020 m

Strain

= x

L

=

0.00020

= 0.00008

2.5

Modulus of elasticity, E = stress strain

=

6

= 132.6

10

9

= 132.6 GPa

0.00008

3 m

2

6.

A bar of thickness 20 mm and having a rectangular cross-section carries a load of 82.5 kN.

Determine (a) the minimum width of the bar to limit the maximum stress to 150 MPa, (b) the

modulus of elasticity of the material of the bar if the 150 mm long bar extends by 0.8 mm when

carrying a load of 200 kN.

(a) Force, F = 82.5 kN = 82500 N and cross-sectional area A = (20x)10

6 m

2

, where x is the width

of the rectangular bar in millimetres.

Stress

=

F

A

, from which, A =

F

82500 N

= 5.5

10

4 m 2 =

4 6

5.5 10 10 mm

2

= 5.5

10

2 mm

2

= 550 mm

2

Hence, 550 = 20x, from which, width of bar , x =

550

20

= 27.5 mm

(b) Stress

=

F

200000

A 550 10

6

= 363.64 MPa

Extension of bar = 0.8 mm

32

© John Bird & Carl Ross Published by Taylor and Francis

Strain

= x

L

0.8

=

150

= 0.005333 stress

Modulus of elasticity, E = strain

=

0.005333

6

= 68.2

10

9

= 68.2 GPa

7.

A metal rod of cross-sectional area 100 mm

2 carries a maximum tensile load of 20 kN. The

modulus of elasticity for the material of the rod is 200 GPa. Determine the percentage strain

when the rod is carrying its maximum load.

Stress

=

F

20000

A 100 10

6

= 200 MPa

Modulus of elasticity, E = stress strain

from which, strain = stress

200 10

E

9

6

= 0.001

Hence, percentage strain,

= 0.001

100% = 0.10%

8.

A metal tube 1.75 m long carries a tensile load and the maximum stress in the tube must not

exceed 50 MPa. Determine the extension of the tube when loaded if the modulus of elasticity for

the material is 70 GPa.

Modulus of elasticity, E = stress strain

from which, strain,

= stress

E

50 10

6

9

6

Hence, strain,

= extension x original length L from which, extension, x =

L = 714.3

10

6

1.75 m

= 1.25

10

3 m = 1.25 mm

9.

A piece of aluminium wire is 5 m long and has a cross-sectional area of 100 mm

2

. It is

subjected to increasing loads, the extension being recorded for each load applied. The results are:

Load (kN) 0 1.12 2.94 4.76 7.00 9.10

Extension (mm) 0 0.8 2.1 3.4 5.0 6.5

33

© John Bird & Carl Ross Published by Taylor and Francis

Draw the load/extension graph and hence determine the modulus of elasticity for the material of

the wire.

A graph of load/extension is shown below.

F

E =

A x

=

L

F L

F

is the gradient of the straight line part of the load/extension graph. x

Gradient,

F x

=

BC

AC

7000 N

3

5 10 m

= 1.4

10

6

N/m

Modulus of elasticity = (gradient of graph)

L

Length of specimen, L = 5 m and cross-sectional area A = 100 mm

2

6 2

Hence modulus of elasticity, E = (1.4

10

6

)

5

100 10

6

12 9

= 70 GPa

© John Bird & Carl Ross Published by Taylor and Francis

34

10.

In an experiment to determine the modulus of elasticity of a sample of copper, a wire is loaded

and the corresponding extension noted. The results are:

Load (N) 0 20 34 72 94 120

Extension (mm) 0 0.7 1.2 2.5 3.3 4.2

Draw the load/extension graph and determine the modulus of elasticity of the sample if the mean

diameter of the wire is 1.23 mm and its length is 4.0 m.

A graph of load/extension is shown below.

F

E =

A x

=

L

F L

F

is the gradient of the straight line part of the load/extension graph. x

Gradient,

F x

=

BC

AC

120 N

3

= 28.57

10

3

N/m

Modulus of elasticity = (gradient of graph)

L

© John Bird & Carl Ross Published by Taylor and Francis

35

Length of specimen, L = 4.0 m and cross-sectional area A =

d

2

4

3

2

4

= 1.1882

10

6 m 2

Hence modulus of elasticity, E = (28.57

10 3 )

4.0

6

9 = 96 GPa

© John Bird & Carl Ross Published by Taylor and Francis

36

EXERCISE 14, Page 33

1.

A steel rail may assumed to be stress free at 5

C. If the stress required to cause buckling of the

rail is - 50 MPa, at what temperature will the rail buckle?. It may be assumed that the rail is

rigidly fixed at its ‘ends’. Take E = 2

10

11

N/m

2 and

= 14

10

6

/

C.

Buckling stress of steel rail = - 50 MPa

Free expansion of rail =

LT

Hence, strain =

LT

L

T where T = temperature rise.

Stress = - E

T = -

11

6

T

= - 2800000T = -

Buckling stress = - 50 MPa = -

6

T

6

T from which, T =

6

6

= 17.86

C

Initial temperature at which the steel rail was stress-free = 5

C

Hence, the temperature at which the steel rail will buckle = 17.86

C + 5

C

= 23.86

C

© John Bird & Carl Ross Published by Taylor and Francis

37

EXERCISE 15, Page 36

1.

Two layers of carbon fibre are stuck to each other, so that their fibres lie at 90

to each other, as

shown below. If a tensile force of 1 kN were applied to this two-layer compound bar, determine

the stresses in each. For layer 1, E

1

= 300 GPa and A

1

= 10 mm

2

For layer 2, E

2

= 50 GPa and A

2

= A

1

= 10 mm 2

From equation (2.8) and (2.9),

1

= -

(A E

1 1

P E

1

A E )

2 2

and

2

= -

P E

2

(A E

1 1

A E )

2 2

1

= -

P E

1

(A E

1

A E )

= -

3 9

6 9

6 9

= -

14

6 5

14

6

= - 85.71

10

6

Pa

i.e. the stress in the steel,

1

= 85.71 MPa

2

= -

P E

2

(A E

1 1

A E )

2 2

= -

3 9

6 9

6 9

= -

7

6 5

7

6

= - 14.29

10

6

i.e. the stress in the concrete,

2

= 14.29 MPa

2.

If the compound bar of Problem 1 were subjected to a temperature rise of 25

C, what would the

resulting stresses be? Assume the coefficients of linear expansion are, for layer 1,

1

= 5

10

6

/

C, and for layer 2,

2

= 0.5

10

6

/

C.

38

© John Bird & Carl Ross Published by Taylor and Francis

As

1

is larger than

2

, the effect of a temperature rise will cause the ‘thermal stresses’ in the steel to be compressive and those in the concrete to be tensile.

From equation (2.5), the thermal stress in the steel,

1

=

(

1 2

) E E A T

1 2 2

(A E

1 1

A E )

2 2

= -

6

6

9 9

6

25

6

= -

13

6

= 4821428.57

= - 4.82 MPa

From equation (2.3), the thermal stress in the concrete,

2

=

A

1 1

A

2

= -

6

6

6

= 4.82 MPa

From Problem 1 above:

1

= 85.71 – 4.82 = 80.89 MPa and

2

= 14.29 + 4.82 = 19.11 MPa

EXERCISE 16, Page 36

Answers found from within the text of the chapter, pages 23 to 36.

EXERCISE 17, Page 37

1. (c) 2. (c) 3. (a) 4.

(b) 5.

(c) 6.

(c) 7.

(b) 8.

(d) 9.

(b) 10.

(c) 11.

(f) 12.

(h) 13.

(d)

14.

(b) 15.

(a)

39

© John Bird & Carl Ross Published by Taylor and Francis