Groep1 Voorlopig Tussenrapport - HelhaPHL2010-01

advertisement

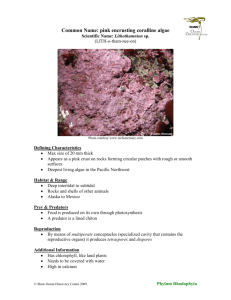

Assignment: Production of algae coupled to anaerobic digestion in a closed vessel system for bio-fuel production. Project management: Interim report Production of algae coupled to anaerobic digestion in a closed vessel system for bio-fuel production. Name: Pieter Sas, Elke Knoops, Benjamin Maris, Serpil Dirikan Christophe Lisbe, Mouna Tajeddine en Jonatan Wauthier Group: 1 Name project leader: Bart Cornelis Start date: 11 Oktober 2010 End date: 15 November 2010 Assignment: Production of algae coupled to anaerobic digestion in a closed vessel system for bio-fuel production. Contents Introduction............................................................................................................................................. 0 1. What is renewable energy ? ............................................................................................................ 1 2. What is Bio-fuel and how can it be produced? ............................................................................... 1 3. What are algae’s and their composition? ....................................................................................... 1 4. Advantages and disadvantages of using algae. ............................................................................... 2 5. Cultivation methods of algae’s ........................................................................................................ 2 6. How does the production process of bio-fuel with algae’s occurs? ............................................... 3 7. Which species of algae is the best for bio-fuel production? ........................................................... 4 8. Positioning of the algae research and applications within the bio-energy field. ............................ 4 9. Manipulation of algae to obtain a higher profitability .................................................................... 5 10. References ................................................................................................................................... 6 Assignment: Production of algae coupled to anaerobic digestion in a closed vessel system for bio-fuel production. Introduction Algae, everyone knows it. It's green, slimy and when you are swimming in the sea it tickles your toes. Algae are just a disaster for your aquarium or your swimming pool. Already, several projects have demonstrated that algae are also a very convenient so they can be used as food additives: thickening agents, but they can also be a solution to the rising global fuel prices and the global warming issue because the usage of algae is a CO 2 neutral process. Namely, they are also an important sustainable source of biomass for biogas production as well as lipid for biodiesel production, with several advantages over the current biomass sources such as rapeseed. This semi-scientific article, we will speak of the cultivation of algae, the production of biofuels, The Advantages and disadvantages and the genetic engineering or algae to obtain a higher yield of both oil to biomass. Want to know more about it? Assignment: Production of algae coupled to anaerobic digestion in a closed vessel system for bio-fuel production. 1. What is renewable plants. They replace the fossil fuels such as gasoline or energy ? Renewable energy is energy from inexhaustible (re)sources. Thus, hydroelectric, wind, geothermal, biomass and all forms of solar energy are a example of an inexhaustible source. Using renewable energy is better for the environment and makes us less dependent on fossil fuels which exhaustive and highly polluting. Further the European top had decided to switch over on renewable energy sources by 10% against 2020 (for transport fuels). Besides renewable energy is also durable energy, often as synonyms. This is incorrect, durable energy has been a broader term than renewable energy. It is the energy that mankind has indefinitely, extracted from an inexhaustible source, and whose use is not detrimental to our environment as well as for the economy. In other words, durable energy is always a renewable energy, but renewable energy is not always a durable energy. As recently reported in the media is bio-fuel from rapeseed not a durable source of energy, if for the growth of these rapeseed fields the has to be forests cut down for it. 2. What is Bio-fuel and how can it be produced? Bio-fuels are fuels obtained from biomass (from any biological origin), such as diesel replacement, with the advantage that bio-fuels emit less particulate matter and carbon dioxide. There are several distinct types of bio-fuels such as bioethanol (may include sugar beet and cereals are produced) for petrol and diesel cars (includes rape, maize and soybeans) for diesel cars. The raw materials for producing the bio-fuels can be divided into three generations: 1) Bio-fuels of the first generation : These are biofuels based on sugars, starches, vegetable oils or animal fats with conventional chemical or fermentation processes are converted into fuels. These are usually food crops as fuel. The following fuels belong to this generation: Bio-ethanol, Biogas(methane gas), Bio-diesel and pure vegetable oil. Figure 1 Microalgae Chlorella 3. What are algae’s and their composition? (Micro-) algae are eukaryotic photosynthetic organisms, which occur in aquatic environments. They are classified under the separate kingdom Protista and can be unicellular (microalgae) and multicellular organisms. The presence of chlorophyll in photosynthesis, they do, in other words they use sunlight as an energy source for building their biomass such as sugar and lipids. For this they need the necessary nutrients like nitrogen and phosphorus in a ratio of 16N:1P. To get these nutrients, they could use waste water, which possible has a concentration 2) Bio-fuels of the second on nutrients. generation: bio-fuels that are not produced from food crops, Useful components from algae especially from plants, grown Polyunsaturated Docosahexaenoic acid (DHA), for energy production from fatty acids Eicosapentaenoic food crops or inedible portion. acid (EPA), palmitolleic acid, Example of this used cooking oleic acid, αoil, straw, willow, wood, Linolenic acid and garden waste. The fuels that triacylglycerol catalases, belong to this generation are Antioxidants superoxide, and cellulosic ethanol, Bio Fischerpolyphenols. tropsch diesel, biomethanol, Pigmenten lutein, chlorophyll, fucoxanthin and … biobutanol and pyrolysis oil. Vitamins Vitamins A, B1, B6, B12, C, E, Biotin, nicotinic acid, folic acid and riboflavin. proteins, amino acids, sterols, antifugal, antimicrobial and antiviral agents. 3) Bio-fuels of the third generation: this generation includes new developments (+ Other genetic modifications). This generation includes the use of algae to produce bio-fuel. This biomass has the advantage that it does not compete with Table 1 useful components from algae food crops or others. 1 Assignment: Production of algae coupled to anaerobic digestion in a closed vessel system for bio-fuel production. They are remarkably efficient biological factories capable of taking a waste form of carbon (CO2) and converting it into a high density liquid form of energy (natural oil). The four most abundant classes of micro algae are diatoms (Bacillariophyceae), green algae (Chlorophyceae), bluegreen algae (Cyanophyceae), and golden algae (Chrysophyceae). Otherwise, the huge diversity of microalgae, it is estimated that approximately 500,000 species of which only 35,000 would consist of known / described. The chemical composition of microalgae is not constant and can vary depending on the species and growing conditions. This also means that the desired products can be obtained by changing environmental factors (growing conditions): temperature, light, pH, CO2 concentration, salinity and nutrients present. The composition of the algae’s can u see in “table 1: useful components from algae” Plant source Biodiesel (Liter/Ha/year) soybean Sunflower Rapeseed Oil palm Algae (30% 446 952 1.190 5.950 12.000 Triacylglycerids) Algae (50% Triacylglycerids) 98.500 Table 2 Feedstock's 4. Advantages and disadvantages of using algae. use of bio-fuel is equal to the recordings of CO2 during the growth of the algae. They can be harvested all seasons. They grow on non-can-Arable land or in Brackish water. They can be grown in fresh or salt water, contaminated water can also be used. They are not in competition with crops for land. They grow very quickly 20 to 30 times faster than crops. (harvesting cycles of 1-10 days). They are oil-rich contains as much as 60% dry weight in oil or ITS. Total (net) energy production is positive. Microalgae oils per hectare yield more than some traditional biodiesel feedstock’s. see “table 2: feedstock’s”. Disadvantages algae: of using High costs for separating the algae and the oil. They need nutrients. They need to be kept in a water culture The production depends on the amount of sunlight the algae get , this depends on the geographic location of the algae culture. 5. Cultivation methods of algae’s Photobioreactors (see figure1) are tubes made of transparent material (glass or plastic), side pipes are also summarized. The tubes are in most cases placed as vertical columns/in height increase the surface algae / increase light capture per m² ground. A disadvantage of such systems is that they need to inject CO2 and O2 removal. Pounds open system (open loop system) This is an open system because it is in contact with the atmosphere, in addition, currently most algae on the market produced by this system. It is a kind of open system of shallow channels, which the water flow is a little pumped. This is done to prevent the algae sink making them less able to do photosynthesis. A disadvantage of open systems is that, only a limited number of algal species can be raised such as Chlorella and Spirulina, other species are grown in closed systems. The above standing methods are examples of “Photoautotrophic Cultivation”; here do the algae need (sun)light to grow. But there is also a method, where the algae’s don’t need (sun)light to grow, but where they use a carbon source, Such As sugars, to generate new biomass. This method is called Besides " heterotrophic cultivation ". Figure 2 Photobioreactor A) Cultivation methods: Advantages of using algae: Photobioreactor (PBR) / It is a CO2 neutral process: the gesloten systeem amount of CO2 released in the 2 Assignment: Production of algae coupled to anaerobic digestion in a closed vessel system for bio-fuel production. B) Advantages and will bind to the algae. In disadvantages of addition, the algae can also closed versus open have biological flocculation culture systems: using a co - culture of other Advantages of a closed organisms in terms of system versus an open precipitation promoted. system: Besides sediment and No losses of water by precipitation, the algae can evaporation. also collect by using filtration Can be placed indoors and / or centrifugation. After No contamination of having collected the algae the the used algal culture are getting dried, by heating by unknown micro- using an oven or by drying in organism. the sun to obtain a high Stabile temperature biomass concentration to through the day and which the released water and night. nutrients are recycled for Higher production of another culture. biomass. Note: macroalgae algae must Carbon dioxide is first wash, then crushed and efficiently incorporated finally drying. (because no gas exchange can happen Further processing for to the atmosphere). production of biogas: The biogas can be The production of biogas can collected. be further divided into four biological and chemical steps, Disadvantages of a closed namely hydrolysis, system versus an open acidogenesis, acetogenesis system: and methanogenesis. Higher cost (compared to the open system). The remaining biomass You need to inject CO2 consists mainly of long The produced oxygen polymers and thus must first should be removed be broken down into smaller since too high O2 chains by hydrolysis, allowing content inhibits the bacteria to reach the photosynthesis and energy-rich areas. Thus, hence growth of proteins are broken down into biomass. amino acids and polysaccharides into simple 6. How does the sugars. After the hydrolysis production process step occurs acidogenesis of bio-fuel with with the remaining algae’s occurs? components are fermented / General preparation: degraded by acidogenic The first time that has to be bacteria, into CO2, ammonia done after the cultivation of and volatie fatty acids. microalgae is the harvesting of micro algae. This is done The next step is then by precipitating and/or acetogenesis in which the flocculation of the microalgae. components formed in the This can be achieved by acidogenesis step further adding additives such as processed into acetic acid, alum, lime, salt and ... which CO2 and H2 by the acetogens bacteria. Finally, we arrive at the final step of “Anaerobic Digestion” namely methanogenesis. Here in the molded products such as acetate, hydrogen, ammonia, water and CO2, are converted into methane gas by the bacteria "methane-forming archaea (methanogens). The CO2 released from the use of the methane gas is/will bee recycled back into the system of cultivating a new culture photosynthetic algae. For this reason it is very useful to place algae culture plant next to a power plant sites which produced carbon dioxide from energy production, which can be used for algae production. Further processing production of bio-fuel: Should developed be for further 3 Assignment: Production of algae coupled to anaerobic digestion in a closed vessel system for bio-fuel production. 7. Which species of the location of the culture algae is the best for plant). bio-fuel production? Microalgae Lipid Selecting the (micro) algae species is best used for biofuel production isn’t simple. We seek a type of algae that is rich in oil components, mainly saturated fatty acids, also the algae are growing rapidly and has a high primary production of oil. Most common microalgae (Botryococcus, Chlamydomonas, Chlorella, Dunaliella, Neochloris, etc.) have oil levels Between 20 and 75% by weight of dry biomass. They are all potential sources for biodiesel production. Though we should note that a lower oil content of algae grow faster than micro algae with high oil content. Thus, micro-algae with a 30% oil content grow 30 times faster than micro-algae with an oil content of 80%. We may not forget that oil from micro algae are composed of unsaturated fatty acids such as linolenic acid, may influence the bio-fuel for example: biodiesel with a high content of unsaturated sources will oxidizes rapidly than the conventional diesel, causing problems with the diesel engine. Therefore it is very important to note the ratio of saturated and unsaturated fatty acids in microalgae, though they want to use as biodiesel feedstock. In other words, one should look at various parameters in selecting a type of algae: among others on fat content, growth rate, fatty acid composition and culture conditions ( determined the formation of final products and species Botryococcus braunii Chlorella emersonii Zitzschia sp. Nannochloris sp. Pavlova salina Chlorella sp. Dunaliella salina Euglena gracilis content(%dry weight biomass) 25 - 75 25 - 63 45 - 47 20 - 56 30 10 - 48 6 - 25 14-20 Table 3 Algae species and there lipid content 8. Positioning of the algae research and applications within the bio-energy field. Should developed be further 4 Assignment: Production of algae coupled to anaerobic digestion in a closed vessel system for bio-fuel production. 9. Manipulation of (2007) Reported That They the successful algae to obtain a Reduced regulation of LHCs in higher profitability We may can genetic modify algae’s for obtaining a higher yield of biomass and lipid content. We can do this by increasing the number of chloroplasts in the algae by genetic engineering, or modify the metabolism (manipulation of the production of enzymes for lipid production) which would increase the efficiency of photosynthesis or less sensitive to oxygen concentration causing no inhibition of photosynthesis occurs. We can also potentially increase the growth rate. Chlamydomonas reinhardtii Photosynthetic efficiency and for improved light penetration in liquid culture. The LHC results tion mutant offerings more efficient conversion of solar energy to biomass. Should developed be further Most of the work to improve / increase in yield is mainly studied by selecting species (strain improvement) and adjusting the cultivation techniques. Genetic engineering gets more attention only recently begun to manipulate algae. As already mentioned, we can increase the efficiency of photosynthesis. However, the damage can-Excessive light photo systems and to trigger cell was photo-protective Mechanisms That must or Radiated energy is captured as heat or fluorescence. In the interest of engineering a strain microalgae to effectively capture light energy, researches focused on Reducing the number of lightharvesting antenna complexes (LHCs) Which capture sunlight and transfer the derived energy to drive photosynthesis and PSA to the Photosynthetic Reaction. For example Mussgnug et al 5 Assignment: Production of algae coupled to anaerobic digestion in a closed vessel system for bio-fuel production. 10. References 19-8-2008a. Algae:Biofuel of the future?, Science Daily. 2008b, Life-Cycle Assessment of BiodieselProduction from Microalgae France. Microalgae: A promising feedstock for biodiesel. Microalgae: A promising feedstock for biodiesel , 1. 2009a. African Journal of Microbiology Research. Ref Type: Journal (Full) NASA Develops Algae Bioreactor as Sustainable Energy Source-SPX. 24-11-2009b. Ref Type: Online Source Algal Oil Yields . 2010. Ref Type: Online Source 70centsagallon 2010, Algae Photo Bioreactors, Biofuel Technologies, Sarasota,Florida. A.B.M.Sharif Hossain, Aishah Salleh, Amru Nasrulhaq Boyce, Partha chowdhury, & Mohd Naqiuddin. Biodiesel fuel Production from Algae us Renewable Energy. American Journal of Biochemistry and Biotechnology , 250-254. 2008. University of Malaya,Maleysia, 2008 Science Publications. Ref Type: Journal (Full) Abayobi O.Alabi & Martin Tambier. Microalgae technologies and processes for biofuelsbioenergy production in Britisch Columbia. 1-88. 14-1-2009. Columbia, University of Manitoba. Ref Type: Online Source Biocycle Energy 2009, Cultivating Algae in Wastewater for Biofuel, Biocycle Energy. Bond Beter Leefmilieu. Hernieuwbare Energie. 2010. Bond Beter Leefmilieu. Ref Type: Online Source C.G.Golueke, W.J.Oswald, & H.B.Gotaas. Anaerobic Digestion of Algae. Anaerobic Digestion of Algae , 47-55. 1957. Berkeley,California, Sanitary Engineering Research Laboraty,Departement of Engineering,University of California,Berkeley,California. Ref Type: Journal (Full) Energy Business Daily, 10-3-2010. NASA Develops Algae Bioreactor as a Sustainable Enegy Source, Energy Business Daily. Ethan Goffman. Running on Algae. The Environmental Magazine . 2010. The Environmental Magazine. Ref Type: Magazine Article Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB 2010, Microalgae-A Sustainable Resource for Valuable Compounds and Energy, Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, Germany. Green Futures. Algae biofuels race hots up. Green Futures . 1-10-2009. Environment Complete Ebsco, PHL Bibliotheek,Online Databanken. Ref Type: Online Source 6 Assignment: Production of algae coupled to anaerobic digestion in a closed vessel system for bio-fuel production. Green Peace. Deep Green. 4-11-2008. Green Peace. Ref Type: Online Source Jeff Tester & Brian Neltner 2008, Algae Based Biodiesel. John Ferrell and Valerie Sarisky-Reed, 2008. National Algal Biofuels Technology Roadmap, U.S.: Department of Energy ,Office of Energy Efficiency and Renewable Energy,Office of the Biomass Program. Kris De Decker. Biobrandstoffen:Laat de algen met rust. Lowtech Magazine . 6-4-2008. Lowtech Magazine. Ref Type: Magazine Article Lars-Erik Nalson, 12-12-1997. Cutting Through Fog Surrounding Global Warming, Science Daily. Liam Brennan & Philip Owende. Biofuels from microalgae-A review of technologies for production,processing, and extractions of biofuels and co-products. Power Engineering . 2910-2009. Science Direct. Ref Type: Abstract Lindsay McGraw. The Ethics of Adaptation and Development of Alage-based Biofuels. 1-83. 14-12-2009. Ref Type: Case Maria Ghirardi & Michael Seibert. DIY Algae/Hydrogen Kit. 1995. Ref Type: Case Milieu Centraal. Duurzame energiebronnen. 2010. Ref Type: Online Source Nick Sazdanoff 2006, Modeling and Simulation of the Algae to Biodiesel Fuel Cycle, The College of Engineering Honors Commitee,College of Engineering,The Ohio State University, Departement of Mechanical Engineering The College of Engineering Honors Committee College of Engineering 122 Hitchcock Hall The Ohio State University. Organisatie Duurzame Energie. Bio energie. 2010. 0DE(Organisatie Duurzame EnergieVlaanderen. Ref Type: Online Source R.H.Wijffels & M.J.Barbosa. Biodiesel uit algen is haalbaar. 13-8-2010. Ref Type: Online Source Rachel Brand. Engines may be powered by biofuel plundered from algae,brewer's CO2. 9-22007. Ref Type: Online Source SBAE Industries. SBAE The Algae Company. 2010. Dillenburg,Germany, SBAE-Company. Ref Type: Online Source Simon Tanner 2009, Biofuels of the Third Generation-Do Microalgae Solve the Energy Problem? Germany. 7 Assignment: Production of algae coupled to anaerobic digestion in a closed vessel system for bio-fuel production. Stephen Mayfield. Genetic Engineering of Algae for Biofuel Production. 1-44. 2010. The Scripps Research Institute, Department of Cell Biology and The Skaggs Institute for Chemical Biology The Scripps Research Institute. Ref Type: Online Source Technische Universiteit Eindhoven. Chemische Conversie-Biomassa. 2010. Eindhoven,Nederland, Technische Universiteit Eindhoven. Ref Type: Online Source The Warren Centre. Algae Bioreactor to Generate Biofuels from Smokestack CO2. The Warren Centre for Advanced Engineering . 2006. The Warren Centre for Advanced Engineering. Ref Type: Online Source Vlaams Infocentrum voor land- en tuinbouw. Biodiesel uit algen wordt brandstof van de toekomst. 12-8-2010. Vlaams Infocentrum voor land- en tuinbouw. Ref Type: Online Source Wageningen University. Facts on Algae. 2010. Wageningen University. Ref Type: Online Source Wout Boerjan. Biobrandstoffen. UGent . 2010. VIB. Ref Type: Online Source Yusuf Chisti 2010, Biodiesel from microalgae beatsbioethanol, School of Engineering, Massey University, Private Bag 11 222, Palmerston North, New Zealand, School of Engineering, Massey University, Private Bag 11 222, Palmerston North, New Zealand. 8 Assignment: Production of algae coupled to anaerobic digestion in a closed vessel system for bio-fuel production. datum 10/11/2010 11/11/2010 15/11/2010 16/11/2010 18/11/2010 23/11/2010 25/11/2010 30/11/2010 2/12/2010 3/12/2010 7/12/2010 9/12/2010 14/12/2010 16/12/2010 16/12/2010 23/12/2010 activity hand in temporary interim report General meeting + last correction of the interim report (if necessary) hand in final interim report General meeting with the students of Helha Further processing Task: Manipulation of algae to obtain a higher profitability Positioning of the algae research and applications within the bio-energy field How does the production process of bio-fuel with algae’s occurs? General meeting General meeting with the students of Helha Discussion on the state of affairs. General meeting General meeting with the students of Helha General meeting hand in temporary Final Report General meeting with the students of Helha General meeting + Last corrections of the Final report General meeting with the students of Helha + preparation of the presentation hand in Final Report General meeting + Presentation practice Presentation (given by Elke Knoops and Jonathan Wauthier) We zitten tot nu toe goed op schema, we hoeven nog enkel punten verder en dieper uitwerken. Verder moeten ook nog de referenties geplaatst worden onder ieder puntje afzonderlijk. 9