Ensure - Nipissing University

advertisement

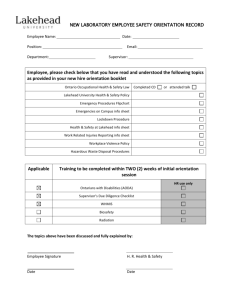

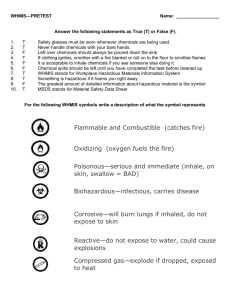

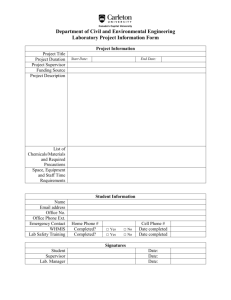

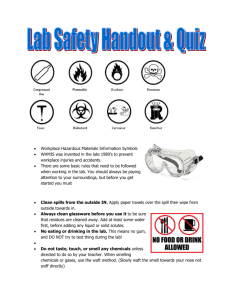

Laboratory Safety NIPISSING UNIVERSITY Course Outline Introduction Duties and Rights Employers Supervisors Workers and Non-Workers Laboratory Instruction Incident Reporting WHMIS Training Laboratory Safety Equipment Chemicals Waste Disposal BioSafety Introduction Laboratory Safety is everybody’s responsibility Employer (Nipissing University) Academic Administrators, Administrators Supervisor (Faculty, Post Doc, Technologist) Worker (Post Doc, Technologist,) Non-worker (Graduate Students, Thesis Students, Volunteers) Each have specific Rights and Responsibilities under Ontario Health and Safety Act (OHSA) and its regulations Ontario Health and Safety Act The main purpose of the Act is to protect workers from health and safety hazards on the job. It sets out responsibilities for all workplace parties and rights for workers. It establishes procedures for dealing with workplace hazards and provides for enforcement of the law where compliance has not been achieved voluntarily. Fundamental to the successful working of OHSA is the workplace Internal Responsibility System (IRS). Responsibilities of Employer Develop a health and safety policy. Develop programs to support this policy. Ensure that supervisors are competent. Ensure that equipment and materials provided are in good condition. Take every reasonable precaution. Supervisor Responsibilities Supervisors are responsible for ensuring that all lab personnel: Follow safe operating procedures. Use or wear all required personal protective equipment. Are aware of hazards. Know and understand emergency procedures. Are provided with written instructions where required. Supervisor Responsibilities (Continued) Supervisors must also: Ensure that an injury/incident report is completed for every injury or incident which occurs in his or her lab. Ensure that the manual is reviewed with all affected individuals and that a record is kept on file (can be delegated to the Biology Technologist) Ensure that all hazardous materials in the workplace are labelled in accordance with WHMIS regulations. Maintain a current electronic file of MSDS for all controlled substances used in the workplace (can be delegated to the Biology Technologist or other Technologist). Ensure that adequate emergency response equipment (e.g. first aid kit, emergency eye wash station, fire extinguisher) is available and in proper working order. Worker Responsibilities All workers must: Work in compliance with the OHSA and its associated regulations. Use or wear all required personal protective equipment. Report to the supervisor any contravention of the OHSA and regulations. Report to the supervisor any health and safety hazard. Worker Responsibilities (continued) Workers shall not: Remove or make ineffective any protective device. Use or operate any equipment, machine or device in a manner that endangers themselves or other workers. Engage in horseplay or pranks. Workers Rights The OHSA gives workers in Ontario three rights. They are: Right to know – about workplace hazards (e.g. WHMIS) Right to participate – in health and safety matters (e.g. JHSC) Right to refuse – work they deem to be unsafe These rights are outlined in the laboratory safety manual Non-workers Non-workers are student and/or student researchers or volunteers. They must: Follow all applicable safety procedures as outlined in the OHSA, this manual and by the supervisor. Attend and complete all applicable health and safety training courses as required by the supervisor and/or Nipissing University. Follow the rules as outlined in the Laboratory Safety Manual. Penalties for not complying with OHSA and its regulations The maximum penalties for a contravention of OHSA or its regulations are set out in OHSA Section 66. A successful prosecution could, for each conviction, result in: A fine of up to $25,000 for an individual person and/or up to 12 months imprisonment; A fine of up to $500,000 for a corporation. Bill C-45 (The Westray Bill) Received Royal Assent on Nov. 7, 2003 Adds a new section to the Criminal Code Establishes a duty in criminal law to protect the health and safety of everyone in the workplace. Sets out severe penalties of imprisonment if failure to protect worker health and safety results in: bodily harm (maximum penalty – 10years in prison) or death (maximum penalty – life imprisonment). Bill C-45 (The Westray Bill) “Every one who undertakes, or has the authority to direct how another person does work or performs a task is under a legal duty to take reasonable steps to prevent bodily harm to that person, or any other person, arising from that work or task”. What Bill C-45 Means to You Broadens the scope of who is responsible for worker health and safety The Law now encompasses all levels of management AND everyone else who can “direct how another person does work or performs a task.” Including: Academic Administrators Administrators Faculty Support Staff Post Docs Graduate Students “Supervisors” can be held Criminally Responsible for failure to ensure worker health and safety Teaching Activities Two types of teaching activities Indoor Activities Held on-site in teaching laboratory setting. Fully supervised Outdoor Activities Held off-site May be on University property or otherwise Fully supervised More chance for injuries Teaching and Due Diligence for In-Classroom Activities Instructors are considered experts and are qualified to teach the material covered. General laboratory safety talk. Attendance must be mandatory. Need students to complete a general sign-off sheet at the end of the talk. Sign-off sheet should include a check off list. Minor student is able to complete this sign-off sheet. Teaching and Due Diligence for Outdoor Activities Outdoor activities require a waiver to be signed. Waivers force an individual to disclose any health concern that may affect them during the outdoor activity. If not disclosed, the responsibility for health and safety is transferred back to the individual signing the waiver. Waivers are not binding on minors unless legal guardians have signed the waiver form. Waiver Forms “Waiver of Liability for Negligence” forms A means to transfer liability from organization back to the individual. The person who signs a waiver agrees to forfeit their legal right to pursue a legal remedy, should they come to harm as a result of their participation and should this harm be caused by the organization’s negligence. By signing a waiver a contract is formed between the individual and the organization. Waiver Forms (cont.) Waivers are not binding on minors unless the parents have signed them (contract between parents and organization). Waivers are only legally binding if the activity is entered into voluntarily. Must not be a required or mandatory activity. Will a waiver hold up? Only a court of law can decide. Centre for Sport and Law Inc Hazard and Incident Reporting Hazard Reporting Workers must report any health and safety concern to their supervisor. If no action is taken, then the worker may report to a workplace JHSC representative or Manager of Environmental Health and Safety. Hazard and Incident Reporting Incident Reporting All injuries/incidents, including those requiring first-aid treatment only, must be reported to your supervisor immediately. It is the instructor’s responsibility to contact the Manager of EH&S and fill out and forward the injury/incident forms within the timeframe required (24 hours). The purpose of reporting all injuries and incidents is so that they can be investigated and measures implemented to prevent them from reoccurring. http://www.nipissingu.ca/hr/downloa ds/IIRIF.pdf Workplace Hazardous Material Information System (WHMIS) Anyone working with a WHMIS controlled substance must first receive WHMIS training. Online WHMIS training is available to students, staff and faculty at no cost . The only acceptable proof of training is the WHMIS course completion certificate. Must be reviewed annually (accepted best practice) Material Safety Data Sheets (MSDS) MSDS Provides information on PPE, First Aid measures, spill clean-up procedures. Also provides information about the chemical and physical properties of a chemical or compound. Should be consulted BEFORE undertaking any experiment or procedure. Can be found in electronic form via: Online via http://intranet.nipissingu.ca/MSDS2 Off-line via CD-ROM in blue binders marked MSDS Training Every supervisor is responsible for: Ensuring every worker is trained: In the use of specific equipment All materials and procedures used in their work. Ensuring all workers know the location (and proper use of: Fire safety equipment (fire alarms, fire extinguishers and fire blankets), Emergency routes and exits, First aid and spill kits, Eye wash stations and safety showers. Laboratory Safety – Personal Protective Equipment To be used in addition to Engineering Controls E.g. Fume hoods, Biosafety Cabinets, etc. Personal Protective Equipment (PPE) Eye/Face protection Foot protection Hand protection Hearing protection Respiratory protection Personal Protective Equipment Minimal PPE to be used consists of: Lab coat (worn closed, not open) Lab safety glasses or goggles Appropriate gloves if handling chemicals or microbiological organisms. Shoes – low profile heel with full foot coverage. Consult glove manufacturer web-site for information on chemical compatibility OR talk to your supervisor or lab technologist Laboratory Safety – Workplace Labels All bottles, flasks and vials must have a workplace label containing information about: Contents Concentration Date Individual involved Exception Those chemicals which will be consumed in one session by one individual. Chemicals with the original supplier label affixed to the container. Chemicals from unlabelled containers are not to be used and their presence shall be reported to the supervisor. Laboratory Safety – Chemical Storage System used at Nipissing is the ‘Fisher Scientific’ system: Colour coded for different compatibility groups. Bottles are coded with coloured tape and stored based on colour. RED: Flammable. Store in area segregated for flammable reagents Explosive Flammable Toxic Corrosive Oxidizer Harmful or Irritant Compressed Gas Biohazard Toxic and Infectious Dangerous to the Environment Dangerously Reactive Keep away from Food BLUE: Health Hazard. Toxic if inhaled, ingested or absorbed through skin. Store in secure area. YELLOW: Reactive and oxidizing materials. May react violently with air, water or other substances. Store away from flammable and combustible materials. WHITE: Corrosive.. May harm skin, eyes, mucous membranes. Store away from red-yellow- and –blue coded reagents above. Laboratory Safety – Chemical Storage (Continued) Chemicals should not be stored in direct sunlight or near sources of heat. Labs are encouraged to purchase only what is required for immediate use. Long term storage of chemicals is to be discouraged Those chemicals no longer needed should be disposed of as hazardous waste Flammable chemicals or materials should not be stored in regular refrigerators. Use specially designed or modified refrigerators for storage of flammables. Laboratory Safety – Chemical Storage (Continued) Refer to the Laboratory Safety Manual for more complete information regarding the storage of specific types of chemicals Designated Substances Eleven ‘ Designated Substances” are regulated under the OHS Act due to their safety and health implications. acrylonitrile arsenic asbestos benzene coke oven emissions ethylene oxide isocyanates lead mercury silica vinyl chloride Designated Substances Use in teaching and research should be avoided. Use alternatives if possible Regulations have 3 key components: Assessment – the employer is required to consider the worker exposure or likelihood of exposure to the substance. Control program – a formal documented program is required if the assessment discloses that a worker is likely to be exposed to the substance. The program must include engineering controls, hygiene practices, work practices and facilities to ensure that the worker exposure to the substance is controlled. Monitoring – air emissions monitoring and medical surveillance are required to determine actual exposure to the substance. It is the responsibility of the laboratory supervisor to ensure that such a program exists in their area. Hazardous Waste Disposal Regulated through the Ministry of Environment (MOE) Hazardous waste must never be: Poured down the drain Evaporated in a fume hood (violates the certificate of air regulations). It is important to minimize waste generation due to: Environmental concerns Cost factors (it’s expensive to dispose of waste) Controlling Hazardous Waste Costs Purchase only what you need Miniaturize experiments, if possible Choose non-hazardous chemicals over hazardous Return unused supplies to the supplier Donate unused chemicals to other researchers within the same site. If not on-site, there are transportation regulations that will apply Recycle and/or recover materials when this can be done efficiently and safely Hazardous Waste Packaging and Labelling Requirements Incompatible materials may not be combined in a single waste container. Chemical liquid waste containers may not to be filled beyond approximately 75% of their capacity to allow for vapour expansion. Container materials must be compatible with the contained wastes Containers must be in good condition. Wastes must be identified appropriately (e.g. biohazard bags may not be used for chemical wastes if no biohazard exists). Non-hazardous wastes must be segregated from hazardous waste streams to avoid unnecessary expenses. Hazardous Waste Packaging and Labelling Requirements All waste must be labelled with a yellow waste tag The accumulation start date must be on the label Waste can only be stored on site for 3 months unless special permission is sought and granted by the MOE Tag must be completely filled out with the component and concentrations of each component BioSafety program at Nipissing Biosafety program is mandated through the Vice-President Research and Academic Overseen through the Biosafety Committee and the Biosafety Officer. All experiments/studies dealing with the culture of any microbial organism (fungi, bacteria or virus) must be vetted through the Biosafety Committee prior to beginning these experiments. Laboratory Biosafety Guidelines 3rd edition are in force. BioSafety Regulations Two government agencies involved Public Health Agency of Canada (PHAC) Office of Laboratory Safety (OLS) Canadian Food Inspection Agency (CFIA) Office of Biohazard Containment and Safety (OBCS) The legislation and regulations cover: Microbial and other organisms Human, animal and plant pathogens Genetically modified organisms (GMO) Plant and Animal Regulations are overlapping and sometimes contradictory BioSafety Law Human Pathogens and Toxins Act (HPTA) Requires all persons responsible for activities involving human pathogens or toxins to register their laboratory or facility (Nipissing University) To be implemented in three phases. Phase I obligation to take reasonable precautions when working with human pathogens and toxins An obligation to advise the Minister, on an annual basis, of the risk groups of human pathogens or toxins in a person's possession, and their location. BioSafety Law (continued) Human Pathogens and Toxins Act (HPTA) Phase 2 (now in this phase) Consultation phase to look at matters such as: Licensing, Security Screening, Inventory control, Transfer, Imports and Exports, Biological Safety Officer requirements. Phase 3 (2 – 3 years time) Implementation phase Set up of the licensing scheme. Prohibition from using human pathogens and toxins without a license Obligation to report an inadvertent release, or an incident that has caused or may cause disease. Summary Responsibility for safety lies with all members of the University community Specific safety guidelines are available in the Laboratory Safety Manual The Laboratory Safety Manual is the minimum standard for safety in the laboratory. Specific situations may require more rigorous safety protocols than contained in the Safety Manual = QUESTIONS?