FLAIR 3.6

advertisement

IHTC Sydney

IHTC

Extending the Boundaries of Heat Transfer

by

Brian Spalding

The 13th International Heat Transfer Conference

August 16, 2006, Sydney, Australia

James P.Hartnett Lecture

Abstract

IHTC Sydney

IHTC

In keeping with Jim Hartnett's breadth

of vision, and of his readiness to be

controversial, this lecture questions

some common assumptions about the

subject of Heat Transfer.

Specifically, it is argued that:

1. Heat Transfer and its effects is our

proper field of study.

Abstract

IHTC Sydney

IHTC

2. Among the not-to-be neglected effects are the

resulting Stresses in Solids.

3. Numerical-Heat-Transfer techniques require

corresponding extension to displacements and

stresses, but without the needless complications

of finite-element methodology.

4. CFD ( i.e. Computational Fluid dynamics ) requires

extension to SFT ( i.e. Solid-Fluid-Thermal analysis ,

for which its finite-volume methods are fully

sufficient.

Abstract

IHTC Sydney

IHTC

4. Heat-exchanger designers should move from guess-theflow-pattern to compute-the-flow-pattern methods.

5. But conventional (detailed-geometry) CFD techniques are

inadequate for this; only space-averaged formulations

are practicable.

6. Still, data-input obstacles remain formidable. Heatexchanger designers need software which can:

(a) understand formulae, and

(b) accept data in the form of relations.

IHTC Sydney

Contents of this lecture

Part1

1. What is 'Heat Transfer'?

1. The received view

2. Reasons for enlargement

3. Some details by way of example.

2. Extending numerical heat transfer

1. Conventional methods for heat conduction

2. Simple extensions to chemical reaction

3. Extensions to displacements in solids

4. The research opportunities

3. CFD to SFT

1. Essential ideas

2. A simple example

3.A choice to be made

IHTC

IHTC Sydney

Contents of this lecture

Part 2

4. How not to design heat exchangers

1. What the Handbooks Say

2. Can CFD assist?

3. Why conventional packages fail to satisfy

5. Improving the input procedures

1. Input of formulae

2. Input of relations

3. Optimization

6. Concluding remarks

7. Acknowledgements

8. References

IHTC

What is ‘Heat Transfer’?

IHTC Sydney

IHTC

1. What is ‘Heat Transfer’?

1.1 The received view

The conventional answer to this question is given by the

chapter headings in the popular textbooks; they follow

the century-old pattern set by Nusselt and Jakob in

Germany.

1. conduction;

2. convection;

3. radiation;

then perhaps:

4. melting and freezing.

5. boiling;

6. condensation.

What is ‘Heat Transfer’?

IHTC Sydney

IHTC

But it need not have been so; for

• the action-at-a-distance laws of radiation are unlike the

close-contact laws of conduction and convection;

they might have been rtreated as belonging to optics; and

• the phase-change topics (melting, freezing, etc) might

have been left to thermodynamicists;

they concern more the effects of heat transfer than the

process itself.

Conversely, if some of the effects of heat transfer are to be

included, why not others? for example:

• ignition and extinction of flames? or

• stresses in solids?

They are surely of sufficient practical importance.

The argument

IHTC Sydney

IHTC

The existing boundaries of the subject of Heat Transfer are

historical rather than rational.

In the 1960s we added Mass Transfer to our territory, as

witness:

• IJHMT, the Journal published by Robert Maxwell, of which

AV Luikov, Jim Hartnett and I were editors at launch time.

• ICHMT, the Centre proposed by Naim Afgan and Zoran

Zaric and created with help from Jim and me.

I shall argue that it is time to extend the boundaries

further, so as to cover:

HMT and its chemical and mechanical effects.

Reasons for enlargement

IHTC Sydney

IHTC

Reason 1

Heat transfer is for engineers, who design

equipment; and this must both:

• meet performance requirements, and

• ensure safety.

They must therefore predict both the desired and

the undesired consequences of their actions.

Examples are:

chemical effects (explosions)

and

mechanical effects (distortions and fractures).

Reasons for enlargement

IHTC Sydney

IHTC

Reason 2

The necessary additional ideas are few, namely:

• that combustion phenomena result from temperaturedependent heat sources;

• that thermal stresses occur when heated bodies are

mechanically constrained;

• That stress is proportional to strain (Hooke's Law);

Heat-transfer engineers need not, however, become chemists

or metallurgists;

they need just enough extra knowledge, but no more.

Reasons for enlargement

IHTC Sydney

IHTC

Reason 3

Not equipping the heat-transfer engineer with the

necessary skills is:

• at best, uneconomical, and

• at worst, dangerous.

The alternative, calling in specialists is expensive,

time-consuming, and sometimes too late.

They speak different languages; and

misunderstandings are frequent.

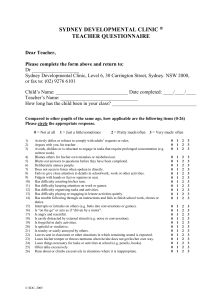

1.3 What heat-transfer engineers

should know about combustion

IHTC Sydney

IHTC

Flame-propagation speeds of fuel-air mixtures vary thus:

Experimental combustion data can then be

correlated thus:

IHTC Sydney

IHTC

This is from the 1954 thesis of Barry Tall, my first Australian student

1.4 What heat-transfer engineers

should know about stress analysis

IHTC Sydney

IHTC

:

• That the three material properties of importance are:

– Young's modulus,

– Poisson's ratio,

– thermal expansion coefficient.

• That (a few) formulae exist for stresses and strains in

solids when the boundary conditions are simple.

• Otherwise, numerical methods of calculation are

available.

• These can be of the 'finite-difference' or 'finite-volume'

kinds, familiar from studies of heat conduction;

• There is no need to learn the 'foreign language' associated

with 'finite elements'.

2. Extending Numerical Heat

Transfer

IHTC Sydney

IHTC

2.1 Numerical methods for heat conduction

Analytical formulae exist only for heatconduction problems which are simple in

respect of:

geometry (rectangular, cylindrical or

spherical),

boundary conditions (constant, or linear in

temperature),

material properties (uniform);

but these conditions prevail so seldom that

numerical methods are almost always used for

calculating temperature distributions.

Extending Numerical Heat

Transfer

IHTC Sydney

IHTC

The figure and

equation shown

here will be

familiar to all

users of such

methods.

How to solve the equations

IHTC Sydney

IHTC

There is one such equation for every volume into

which the space is divided.

The complete set of equations is soluble by

successive-substitution methods.

Before we had computers, the graphical method

pioneered by Ernst Schmidt was often used.

It was laborious, but profoundly educative.

I luckily encountered it early in my career as shown

by the following ‘reminiscence’. It concerns one

of the chemical effects of HMT, namely flame

propagation.

2.2 Numerical heat transfer

with chemical reaction

IHTC Sydney

IHTC

I used the Schmidt method for calculating the speed of

laminar flame propagation, 50 years ago.

Extending Numerical Heat

Transfer

IHTC Sydney

IHTC

The graphs on the left show successive temperature

distributions after two bodies of hot (burned) and cold

(unburned) gas are brought into contact

Extending Numerical Heat

Transfer

IHTC Sydney

IHTC

The graph on the right shows the source (horizontal) versus

temperature (vertical) function which represents (sufficient

of) the laws of chemical reaction.

Extending Numerical Heat

Transfer

IHTC Sydney

IHTC

When computers came along, of course, pencils and rulers

were pushed aside; but I am glad that I started work before

then.

I would want every student in my imagined "HMT and Its

Effects" course to have 'flame ignition and propagation' as

an obligatory homework item.

2.3 Extension to

displacements in solids

IHTC Sydney

IHTC

The numerical methods used for heat-conduction problems

can also be extended to the calculation of stresses and

strains in solids.

There are many ways of doing so; but probably the simplest

is to solve the equations for the displacement

components.

The Figure and Equation shown below are a little more

complex than those for temperature; but not much.

Control-volume for vertical

displacement v

IHTC Sydney

IHTC

First the Figure

Extending Numerical Heat

Transfer

IHTC Sydney

IHTC

then the equation

The slight complication of the displacement-component

problem is that there are three sets of equations ( for U,

V and W); and they are linked together in special (but

easily-formulated) ways.

Solving the equations

IHTC Sydney

IHTC

I now show some results of solving the

equations by the same successivesubstitution method as is used for heat

conduction.

It is applied to the case of a square-sectioned

beam having a square hole, filled with

fluid, along its axis.

Contours and vectors of displacement are

shown.

1/4 of square beam with fluid

in square hole

IHTC Sydney

IHTC

When the outer-wall temperature is raised;

1/4 of square beam with fluid

in square hole

IHTC Sydney

IHTC

When the inner-duct pressure is raised;

1/4 of square beam with fluid

in square hole

IHTC Sydney

IHTC

When both changes are made simultaneously.

Consequential stresses

IHTC Sydney

IHTC

From the

displacement

fields may be

deduced the

distributions of

the direct

stresses in the

horizontal

direction...

Consequential stresses

IHTC Sydney

IHTC

… and in the vertical direction.

Comparison with

solutions made

by the finiteelement code

Elcut showed

close agreement,

of course;

for the finitevolume and finiteelement methods

solve the same

differential

equations.

2.4 The research

opportunities

IHTC Sydney

IHTC

The computer time needed for solving the 3 displacement

equations is more than 3 times that needed for the temperature

equation.

The reason is that the equations for the 3 displacement

components are inter-linked.

Naive sequential solution procedures may (depending on geometry)

converge rather slowly.

More refined procedures are needed, and are being developed;

but there is still much to do.

Researchers seeking little-exploited territories may therefore find

them here; and the world still awaits compilation and publication

of the definitive textbook.

Why? The numerical-stress-analysis field was devastated in the

1960's by the finite-element tsunami. Recovery takes time.

3. Extending Computational

Fluid Dynamics to SFT

IHTC Sydney

IHTC

3.1 Essential Ideas

When Numerical Heat Transfer concerns

itself with convection as well as

conduction, it becomes a part of CFD..

This also came into existence in the late

1960s.

It uses equations similar to those governing

heat conduction, shown above, with

additional features, namely:

The additional features of

the CFD equations

IHTC Sydney

IHTC

the dependent variables include the components of

velocity;

the coefficients (aN, aS, etc). account for convective as

well as diffusive interactions between adjacent control

volumes;

the sources include pressure gradients, gravity, centrifugal

and Coriolis forces; and

the effective transport properties vary with position over

many orders of magnitude.

The CFD equations is thus more complex than the

thermal-stress problem; yet satisfactory iterative solution

procedures have been in widespread use since the early

1970s.

Use of CFD procedures for

solid-stress problems

IHTC Sydney

IHTC

•

CFD solution procedures have been successfully applied to solid-stress

problems. Both Steven Beale and I independently showed this in 1990,

as did Demirdzic and Mustaferija soon after.

•

Mark Cross's group at Greenwich University has also made significant

use of such methods for fluid-solid-interaction problems.

•

Since the fluids and the solids occupy geometrically separate

volumes, a single computer program can predict the behaviour of

both solids and fluids simultaneously.

•

This possibility has not been widely exploited because of the popular

misconception that solid-stress problems must be solved by finiteelement methods.

•

It is therefore high time that CFD should enlarge to become SFT, i.e.

Solid-Fluid-Thermal.

3.2 A simple example

IHTC Sydney

IHTC

Let us consider a primitive counterflow heat exchanger,

consisting of two concentric tubes.

Let us also suppose that because of:

• natural convection in the cross-stream plane, or

• non-uniformity of external surface temperature, or

• turbulence-promoting baffles within one or both of the

tubes ,

the distributions of temperature and pressure, and therefore

also of stress and strain in the tubes, are not

axisymmetrical.

The concentric-tube heat

exchanger

IHTC Sydney

IHTC

How are the stresses and strains to be computed?

Numerically, of course; and, if (misguided !) common practice

is followed, one computer code will be used for the

fluids and another for the solids.

Then means must be devised for transferring information

between them.

How much more convenient it will be to use one computer

code for the whole job!

Extending CFD to SFT

IHTC Sydney

IHTC

A true SFT code can do just that by:

solving for velocities and pressure in the space occupied

by fluid;

solving for displacements and strains in that occupied by

solid;

solving simultaneously for temperature in both spaces.

The following images relate to the heat exchanger in question,

with the radial dimension magnified four-fold.

Concentric tube heat

exchanger

IHTC Sydney

IHTC

1. Pressures in the two fluids causing mechanical stresses;

Concentric tube heat

exchanger

IHTC Sydney

IHTC

2. The temperature distribution, causing thermal stresses.

Concentric tube heat

exchanger

IHTC Sydney

IHTC

The circumferential variation of temperature imposed on the

outer surface has produced 3D variations of

temperature, stress and strain, as follows:

3. radial-direction

strains (positive

being extensions,

negative

compressions);

Concentric tube heat

exchanger

IHTC Sydney

IHTC

4. circumferential-direction strains;

Concentric tube heat

exchanger

IHTC Sydney

IHTC

5. radial-direction stresses (positive being tensile, and

negative compressive);

Concentric tube heat

exchanger

IHTC Sydney

IHTC

6. circumferential-direction stresses;

Concentric tube heat

exchanger

IHTC Sydney

IHTC

7. axial-direction stresses.

Extending CFD to SFT

IHTC Sydney

IHTC

Three questions:

1. Are the predictions correct?

Probably, because:

• the code produces the analytically-derived exact solutions for

all cases in which these exist;

• the displacement equations, are, after all, very simple.

2. Did solving for stress and strain increase the computer time?

Not noticeably. Calculating finite values of displacement is not

much more expensive then setting velocities to zero; and

convergence of the velocity and pressure fields dictated

how many iterations were needed.

3. Could the same result have been achieved by coupling a finitevolume and a finite-element code?

Certainly, but with much greater difficulty; so why bother?

3.3 A choice to be made

IHTC Sydney

IHTC

Which forms the better method for SFT? Finite-volume or

finite-element?

The printed version of the lecture discusses the question at

length. Here I summarise thus:

The general-purpose SFT codes needed by heat-transfer

engineers could be based on finite-element methods). But..

The highly-demanding F part of SFT, is handled so much

better by finite-volume methods than finite-element ones

[Why else did Ansys buy Fluent and CFX?],

that the best SFT codes are likely to be FV-based.

Early arguments that FE methods are better for awkward

geometries lost their force more than twenty years ago.

It is only mental and commercial inertia that keeps the finiteelement juggernaut in motion.

Final examples

IHTC Sydney

IHTC

1. distortions of a sea-bed structure by ocean

waves,

Final examples

IHTC Sydney

IHTC

2. flapping of a wing, courtesy of K Pericleous:

Part 2. How not to design

heat exchangers

IHTC Sydney

IHTC

4.1 What the handbooks say

AC Mueller, in Hartnett and Rohsenow's 'Handbook of Heat

Transfer' states:

"Heat exchangers are designed by the usual equation:; q =

U*A*MTD"

wherein:

U is the overall heat-transfer coefficient,

A is the area of the heat-exchange surface, and

MTD is the Mean Temperature Difference.

The area, A, is fairly easy to estimate; otherwise we can be

sure only that:

U is not a constant, and that

MTD can be determined only for simple flow patterns

which never exist in practice.

How not to design heat

exchangers

IHTC Sydney

IHTC

Ah! But that’s why we have ‘correction factors.’

Yes, we do; and we have all seen, and perhaps used, such

charts as this from Hartnett and Rohsenow; but they based

on unrealistic idealised flow patterns.

How not to design heat

exchangers

IHTC Sydney

IHTC

The Tinker-Bell-Devore corrections

Then there are allowances for leakages between baffles and

shell , and for 'by-pass streams', based on experiments

carried out long ago, at the University of Delaware and

elsewhere.

How not to design heat

exchangers

IHTC Sydney

IHTC

But the experiments are of course too few. Indeed to carry

out enough experiments, and then to express their results

as formulae, is an impossible task.

Nowadays, few designers use the charts and correction

formulae directly; for they have been embodied in software

which reduces labour.

Alas, it also reduces the doubt which their users ought to

maintain; for the underlying concepts are based on

fictions, not physics.

4.2 Can CFD assist?

IHTC Sydney

IHTC

Computational Fluid Dynamics is based on physics. Can CFD

then be a better basis for heat-exchanger design? My

answers are:

1. Yes, in principle , but heat exchangers have many closetogether solid-fluid interfaces;

2. Therefore flow details can not be simulated.

3. However, the space-averaged (also called porous medium)

approach works well, especially for 'difficult' equipment,

e.g. power-station steam condensers and nuclear boilers.

4. Its lack of adoption by the heat-exchanger fraternity may

have resulted from data-input difficulties, which are now

being removed.

Before turning to the difficulties, I show results from a recent

study of a baffled shell-and-tube heat exchanger.

Computed flow patterns

IHTC Sydney

IHTC

The baffles produce a complex three-dimensional flow,

different for each configuration.

Computed temperature

distributions

IHTC Sydney

IHTC

No handbook 'correction factor' can represent temperature

distributions like this.

Computed fluid property

distributions

IHTC Sydney

IHTC

Material properties vary throughout; and so must heattransfer coefficients.

Computed Nusselt numbers

IHTC Sydney

IHTC

Note the wide variation of values of the dimensionless heattransfer coefficient.

Space-averaged CFD is

needed; and it’s available

IHTC Sydney

IHTC

In Summary

Hand-book methods of heat-exchanger design make

assumptions about:

uniformity of properties;

uniformity of heat-transfer coefficient;

existence of idealised flow patterns;

calculability therefrom of the mean temperature

difference.

Every physics-based numerical simulation of practical heat

exchangers shows that the assumptions are wrong.

The numerical simulations also rest on assumptions; but

these, being local rather than global, are far more reliable.

The computer time needed for calculating rather than

presuming the flow and temperature distributions is trivial,

Heat-exchanger-design software should therefore embody

physics-based space-averaged CFD flow simulations.

4.3 Why conventional packages

fail to satisfy

IHTC Sydney

IHTC

1.CFD specialists distrust conventional heat-exchangerdesign packages because the packages lack physics.

2. Some experienced heat-exchanger designers distrust

them for other reasons. Thus, J Taborek [5] in the

Hemisphere Handbook of Heat Exchanger Design, states:

"Only if calculations are performed manually will the

engineer develop a 'feel' for the design process as

compared to the impersonal 'black box' calculations of a

computer program".

3. The package designers seem to distrust their users: they

treat them as capable only of making selections by

mouse-clicks on tick boxes.

The mouse’s revenge

IHTC Sydney

IHTC

Being restricted to the choices provided by the package

designer is indeed to be a ‘prisoner of the mouse’, in fact

rather like this:

Heat exchanger design is for

men not mice

IHTC Sydney

IHTC

Engineers who prefer 'manual calculation‘ do so because they

like to decide for themselves what formulae for:

heat-transfer coefficients;

pressure-drop coefficients;

fouling factors;

etc.

are to be used in the various parts to exchanger.

What is needed is software which respects their experience,

and enables them to use it, freeing them from the

constraints which mouse-click codes impose.

But the software should also allow them to used calculated

flow patterns, not out-dated guesses.

5. Improving the input

procedures

IHTC Sydney

IHTC

5.1 Input of formulae; the history

Early '80s CFD codes contained built-in modules for

calculating, say:

viscosity from temperature, pressure and composition of

fluids;

Nusselt from Reynolds and Prandtl numbers for specific

geometries.

There were never enough of these; so provision was

made for users to add their own Fortran or C coding.

Mid-'90s codes contained self-programming features, to

which users simply supplied formulae.

Input of formulae

IHTC Sydney

IHTC

The latest codes react to formulae directly:

If the user writes lines like:

Nusselt is 0.023*Reynolds**0.8*Prandtl**0.33

the computer code works out for itself what to do.

The formulae can be of arbitrary complexity.

Therefore anyone who can write a formula can "do

CFD".

Input of formulae was reported at the 2005 ASME Summer

Heat Transfer Conference in San Francisco. I therefore turn

to a newer development: the input of relations.

5.2 Input of relations

IHTC Sydney

IHTC

The main steps in setting up a heat-exchanger simulation

are:

a. assemble all component objects (shell, nozzles, headers,

baffles, tubes, etc);

b. specify their proper dimensions and positions;

c. assign the property formulae to the various solids and

fluids;

d. select the heat-transfer and friction formulae to be used;

e. assign the inlet flows and temperatures, and any other

relevant thermal, or mechanical conditions;

f. let the computer work out the consequential 3D

temperature distributions (and stresses) as functions of

time.

I shall now show some parts of the process, conducted by

way of the relational input module, PRELUDE.

Shell-and-tube heatexchanger in PRELUDE

IHTC Sydney

IHTC

Objects, position, size and attributes

The shell-and-tube exchanger (one half only) might, in the

course of assembly, look like this:

The family of objects

IHTC Sydney

IHTC

• It is a collection of inter-linked objects, having names on

the left of this picture which shows them linked as 'parent'

and 'child'.

Attributes of objects; the

dialogue box for the shell

IHTC Sydney

IHTC

•Each object has attributes, expressed as numbers,

variables, relationships or file-names.

The size- and position

dialogue box

IHTC Sydney

IHTC

Each object has also size and position which may be

similarly expressed.

Further details of the

relational-input module

IHTC Sydney

IHTC

• Attributes, position and size may be:

created by a generic shell-and-tube heat-exchanger

script; or

read in from a particular shell-and-tube heatexchanger file (e.g. one of those which the desiner has

used before); or

entered interactively.

As soon as any value or relationship is changed

interactively, all consequential changes, for all objects, are

made, and seen, at once.

At the end of the interactive session, all positions, sizes

and attributes, including relations, are saved, into a file, for

later re-use.

How the relations and formulae

appear in the file

IHTC Sydney

IHTC

Here, in italics, are the some of the relations governing 'bundle'.

Although they have their own vocabulary, it is easy to learn,

and use.

position and size:

xmid(bundle) = Xmidcoord(SHELL)

ymid(bundle) = Ymidcoord(SHELL)

zmin(bundle) = Zmaxcoord(HEAD1)

radius(bundle) = inradius

shape:

disk bundle ! Disk is an object type; bundle is one of them

shell-side heat-transfer coefficient:

nuss at bundle is 0.2*reys^0.6*prns^0.33) ! shell-side Nu

coes at bundle is aoverv*nuss*cond/diam) ! and coeff.

Formulae for Reynolds,

Prandtl & Nusselt numbers

IHTC Sydney

IHTC

tube-side coefficient:

reyt at bundle is diam*tubvel/enut ! tube-side Re

prnt at bundle is cpt*rho2*enu2/cont ! and Pr

nust at bundle is max(2.0,0.328*(reyt*prnt)^0.33) ! and Nu

coet at bundle is aoverv*nust*cont/diam) ! and coefficient

overall coefficient:

coeU at bundle is 1/(1/coes+1/coet)

the heat flux:

flux at bundle is coeu*(temt-tems) ! *temperature difference

These statements may be edited manually or interactively.

Doing so gives the engineer the freedom which he needs,

and which the wretched mouse-prisoner can never enjoy.

Co-ordinated changes

IHTC Sydney

IHTC

Changing the number of baffles

When the user changes the baffle number from 3 to 4, they

jump into their new positions at once; and the outlet nozzle

moves from the top to the bottom, as seen here

A deeper-level script

IHTC Sydney

IHTC

This is because of lines in the set-up script like this:

if {$oddeven>0} { ! oddeven refers to baffle number

$baff1 setposition [list wallthick/2. ysize($parname)/2.0\

$ic*(Zmincoord($d2)-Zmaxcoord($d1))/$nmax ]

} else { $baff1 setposition [list Xsize($parname)-wallthick/2.

\ ysize($parname)/2.0 $ic*(Zmincoord($d2)Zmaxcoord($d1))/$nmax ]

$baff1 setzrot 180.

}

Heat-exchanger designers would NOT be expected to look at

such details; but their computer-specialist colleagues could

do so, if some new functionality were required.

A common difficulty

concerned with re-use

IHTC Sydney

IHTC

Most CFD packages have graphical user interfaces which

enable:

flow-simulation scenarios to be set up;

objects to be brought in from solid-modelling packages;

material properties to be assigned to the objects;

boundary conditions to be attached to them; and

computation-controlling settings to be made.

Many also allow for the data-input files to be stored and reused.

However, when re-use involves changing the numbers,

materials, sizes, shapes or positions of the objects, the

labour required for the second scenario is nearly as great

as for the first.

The advantage of relational

input modules

IHTC Sydney

IHTC

A code equipped with a relational input module greatly reduces

that labour; for it remembers why the objects in the first

scenario were placed where they were, recording these in its

'Book of Rules'

Then, unless instructed otherwise, it will apply the same rules

for the second scenario as were laid down for the first.

For example, if the shell-length of a heat exchanger is increased,

the headers will move appropriately further apart.

Any desired relationship can be built in, including those linking

geometric with thermal or computational conditions.

Relational input modules are especially useful for handling SFT

problems, in which objects, their supports and their

applied loads must move together.

5.3 Optimization

IHTC Sydney

IHTC

Finally, for completeness, I mention that the designer's true

task is not 'merely' that of predicting the performance of a

prescribed heat exchanger.

What is needed is the ability to determine the dimensions

and configuration of the best-possible heat-exchanger for

the prescribed duty, with prescribed constraints.

Provided that a parameterised input procedure is

available, of the PRELUDE kind, computers can be

instructed systematically to search for the optimal

parameter set.

This is rarely done at present; but it can and should become

the norm.

6. Concluding Remarks, 1

IHTC Sydney

IHTC

In remembrance of Jim Hartnett, I have sought to be

controversial, having asserted that:

• the territory of 'Heat Transfer' should be enlarged so as to

include more of its 'Effects';

• CFD should become SFT;

• inclusion of stress analysis is best done without finite

elements;

• heat-exchanger design should be based on physics, not

fiction;

• software packages should allow input of arbitrary formulae;

• objects are best assembled via algebraic relations which

packages must understand;

• enforced restriction to mouse-clicking can damage one's

mental health..

Concluding Remarks, 2

IHTC Sydney

IHTC

These recommendations now appear to be such

obvious commonsense as to be totally noncontroversial.

Sorry, Jim!

But probably I have not explained my meaning

well enough for some of you; so you may

disagree with what you think that I said.

Perhaps that will produce controversy after all.

!!!! Thank you for your attention !!!!

Acknowledgements

IHTC Sydney

IHTC

The author gratefully acknowledges the assistance of:

Dr Valeriy Artemov of the Moscow Power Engineering

Institute in developing and testing the SFT technique,

Dr Elena Pankova of the Moscow Baumann Institute in the

preparation of diagrams,

Dr Geoff Michel of CHAM in developing PRELUDE, the

'relational input module‘; and of

My sons Peter and Jeremy in ‘Power-Pointing’ this lecture,

References

IHTC Sydney

IHTC

Regarding the subject of Heat Transfer

Bosch M, Ten 1936 "Die Waermeuebertragung, 3rd Ed",

Springer, Berlin

Jakob M , 1949, Heat Transfer, John Wiley, New York

Ganic, E, Rohsenow, W. M. and Hartnett, JP (Eds), 1973,

Handbook of Heat Transfer Fundamentals, McGraw Hill.

Rohsenow, WM and Hartnett, JP (Eds), 1973, Handbook of

Heat Transfer, McGraw Hill.

References

IHTC Sydney

IHTC

Regarding ignition, propagation and extinction of flames

Botha JP and Spalding DB, 1954, Proc Poy Soc A vol 225

pp 71-96

Spalding DB and Tall BS, 1954, vol 5 p 195

Spalding DB 1955, "Some Fundamentals of Combustion",

Butterworths, London

References

IHTC Sydney

IHTC

Regarding numerical methods generally

Richardson LF ,1910, Trans Roy Soc A, vol 210, p 307

Schmidt, E, 1924, "On the application of the calculus of

finite differences to technical heating and cooling

problems", August Foeppl Festschrift, Springer

Minkowicz, W M, Sparrow, E, Schneider, G E and Pletcher,

R H, (Eds), 1988, Handbook of Numerical Heat Transfer,

John Wiley

Patankar SV, Spalding DB, "A calculation procedure for

heat, mass and momentum transfer in three-dimensional

parabolic flows"; Int J Heat Mass Transfer vol 15 p 1787

(1972)

References

IHTC Sydney

IHTC

Regarding the finite-volume approach to stress-analysis

Spalding, D B, 1993. Simulation of Fluid Flow, Heat

Transfer and Solid Deformation Simultaneously, NAFEMS

Conference no 4, Brighton.

Demirdzic, I. and Muzaferija, S., 1994, Finite-Volume

Method for Stress Analysis in Complex Domains, Int J for

Numerical Methods in Engineering vol 37, pp 3751-3766.

Bailey C, Cross M, Lai C-H, 1995, "A finite-volume

procedure for solving the elastic stress-strain equations on

an unstructured mesh."

Int. J. Num. Meth. in Eng. vol 38,1757-1776

References

IHTC Sydney

IHTC

Regarding the currently-used methods of heat-exchanger

design

• Devore, A., 1961, Try this simplified method for rating

baffled exchangers, Pet. Refiner, vol 40, p 221.

T Tinker J. Heat Transfer vol 80 pp 36-52 1958

KJ Bell "Final report of the cooperative research program

on shell-and-tube heat exchangers" University of Delaware

Exp.Sta.Bull. 5 1993

J Taborek "Recommended method: principles and

limitations" in "Hemisphere Handbook of Heat Exchanger

Design" ed. by GF Hewitt, Hemisphere, New York 1983

References

IHTC Sydney

IHTC

Regarding the use of formulae in heat-exchanger design

Spalding DB 2005 "Solid-fluid-thermal analysis of heat

exchangers", ASME Summer Heat Transfer Conference,

San Francisco

Regarding the use of relational input procedures

Michel GM and Spalding DB 2006 "PRELUDE User Guide",

unpublished

IHTC Sydney

IHTC

The End !!!