View Document

advertisement

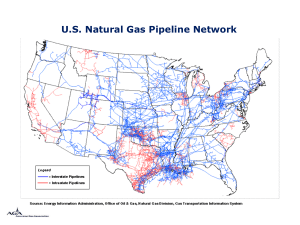

Natural Gas Contracts: Sale of the Product Drafting and Negotiating an Agreement for Purchase of Natural Gas Products Advanced Oil and Gas Short Course Sponsored by University of Houston Law Foundation Houston, TX – June 11-12, 2009 – Hilton University of Houston Hotel Dallas, TX – June 18-19, 2009 – Cityplace Conference Center Arthur J. Wright 1722 Routh Street, Suite 1500 Dallas, Texas 75201 214.969.1303 Arthur.Wright@tklaw.com (999905 000003 Dallas 2497293.1) The Man - Andy Weissman Gas Market 09/07/06 to 09/07/08 ► ► ► IS GAS MARKET HEADED FOR PRICE CRASH? Absent a Monster Hurricane – we had one LNG Imports Up Did not happen; US oversupplied in 2008 Storage will be at record levels ► ► ► Record storage and production Coldest Winter in 10/11 years Prices headed down 2 Fracs Time for the Fracs of Life US Petrochemical plants dying No consumer; Ethane rejected! Industrial demand bottomed Cheap oil – cheap NGLs Frac spreads cause NGLs to go into gas 1-2 Bcfd additional supply 3 Canada Production 2007 - 16 Bcfd ► ► 2010 – 10 Bcfd 2014 with unconventional gas – 16 Bcfd Canadian potential growth ► ► ► Coalbed Shale Tight Total all sources: - 660 trillion cubic ft. - 600 trillion cubic ft. - 565 trillion cubic ft. - 2,150 trillion cubic ft. 4 Canada (cont’d.) British Columbia, Muskwa shale and Horn River and Montreal Quebec shale may replace Alberta ► ► ► ► ► Horn River 15-150 wells by end of 2010 EOG, Nexen, Devon, EnCana and Apache are players Montreal (tight gas) 240-300 wells by end of 2010 Issues – Pipelines, gas volatility and people to man rigs 6/30/08 – Horn River two wells produce 5 & 6 MMcfd day 5 Canada (cont’d.) Utica Shale (4,000 ft.) ► ► Triangle Petroleum: ► ► Talisman drilled well in QuebecLorraine shale below Utica Forrest testing wells also (269,000 acres) 516,000 acre shale play Nova Scotia 68,000 acre shale play New Brunswick Mackenzie pipeline: ► ► ► ► Planned to be on-line 2009 No approvals given Earliest date 2014 Needed? – US market supply up! 6 Marcellus ► ► ► US Shales 8/25 Range 100 wells drilled 25 horizontal last 4 wells – 4.9 Mcft per day 850,000 acres – reserves 15 Tcf to 22 Tcf Water procurement and disposal a key 2 years or longer – moratorium in NY Atlas Energy – 580,000 acres ► 80 mostly vertical wells, 60 MMcfd production Atlas – 2 stage vertical frac Doubles per well production Also drilling horizontal Atlas plans 100 horizontal wells in New Albany Shale through 2009. CNX - Marcellus horizontal well rate of 6.5 MMcfd 7 US Shales (cont’d.) Marcellus ► CHK says no rapid expansion as in Barnett due to regulatory, topographic, water and infrastructure issues How big? Too early Gothic Shale Colorado – Bill Barrett Corp. Pearsall Shale in Maverick County ► Encana, TXCO, and Anadarko hold positions in Far West Texas Play Equitable developing Huron and Cleveland shales 8 US Shales (cont’d.) Haynesville ► ► 8 weeks production – wells show no significant decline 8-11 Devon announces Goodrich Petroleum flows ► 73 Tcf under their 483,000 acres 7 MMcfd Panola County Well CHK – Haynesville ► ► has 440,000 acres potential reserve ► 20 trillion cubic feet Barnett is 2 trillion Spent 2005 to evaluate data from 450 wells studied 9 Shales Haynesville - 12/08/08 - Exco announces 23 Mcf well – Petrohawk announces wells 23 to 30 Mcf Woodford 9/22/08 ► ► ► ► ► ► production 550 Mcft (Barnett 3.6 Bcft) Newfield – 40% of production BP buys CHK acreage (25% - 1.75 billion) 4,100 ft. laterals Devon (6 rigs), Continental (5 rigs), XTO (5 rigs), Antero (4 rigs), BP (4 rigs) and Newfield (12 rigs) Woodford wells 7.1 MMcfd and 6.7 MMcfd 10 Shales (cont’d.) North Louisiana has CBM at 2,500 ft. - 4,000 ft. that Equals to Powder River players ► Geomet, EnerVest, Southwestern and Samson Fayetteville ► 08/08/08 Southwest Energy – 500MMcf/d (200 in 2007) 22 rigs running 80 acre spacing 619 wells 554 horizontal 10/27/08 - Petrohawk announces S. TX play in Eagle Ford Shale – two wells 15 miles apart over 9.1 million cubic ft equivalent 11 Shales (cont’d.) 12/03/08 - Energen chases Conasauga and Chattanooga shales without CHK Tristone is assuming $8.50 gas shale production to go from 6.8 Bcfd to 19 Bcfd by 2018 ► ► Short term Haynesville and Fayetteville will dominate Montney, Marcellus, Utica and Horn River – thicker may require stacked horizontal well bores more gas per well bore Shale production ► ► ► 1998 – 1 Bcfd Today – 5 Bcfd Compounded rate over 20% 12 Shales (cont’d.) Deutsche Bank-Study Shale initial 1st year declines 65-75% ► Flattens out in 3rd/4th year (10-15%) (MI) 2000 1 Bcfd in Antrum and Devonian Shales Appla - 84% of Shale 2007 4 Bcfd Plus Marcellus and Horn River will trump Barnett ► One Commentator Haynesville to pass Barnett in 5 years Shale plays most significant discovery in 50 years 21 Shale basins 13 Shales Technology Technology – Horizontal Laterals ► ► ► ► ► ► Contact more shale – longer laterals Better fracing - high frac rates and “packers” – 20 stages Fluids out of cracks and flow back Decrease drilling time – use of coiled tubing Better control of pressure and tool placement Dissolve calcite in rocks with chemicals Williams ► Barnett – using sequential and simultaneous fracs 2 wells – one week job ExxonMobil ► 30 new technologies to extract oil from shale 14 Shales Technology (cont’d.) 6/30/08 Encana Technology Bighorn well costs - down $2.4 Mcf per well Haliburton “swellable packer” ► ► ► reduces frac time and costs – 2-3 days vs. 30 days fit for purpose rigs 20%-30% faster Multi-well pads cut cost 15% Barnett – EOG recovery factor: ► 10-12% in 2004 ► 20% in 2005 ► 30% in 2007 ► 50-55% late 2007 XTO in Barnett: ► ► ► 28 days to drill well 2005 20 days to drill well 2007 16-17 wells permits per rig vs. 12 CHK ► 14 days to drill well and 1.5M cost 15 Shales Technology Breakeven ► ► ► ► Marcellus Haynesville Fayetteville Barnett (Core) - $3.17 $4.73 $5.00 $5.00 (cont’d.) Plus $35 Billion to develop Haynesville ► ► ► ► ► ► Break even 10% pretax IRR Barnett – Core $5.12; Non-Core $6.32 Fayetteville $5.07 Haynesville $4.73 Marcellus $3.17 Woodford $6.11 16 Prices Market supplied without Marcellus or Horn River and LNG to increase to avoid flooding lucrative Asian and European markets. 17 Prices (cont’d.) 01/10/08 – Raymond James forecasts $6.50 for 2008 03/19/08 – Raymond James – says prices to fall in summer 06/09/08 – Raymond James up forecast for 2008 to 10 MMBtu vs. 8 MMBtu 08/31/08 – EIA says shale production could reduce LNG demand in US 09/10/08 Raymond James drops price projection ► for 4 Qtr. $7.50 vs. $10 ► Wall Street consensus $11 plus 09/10/08 – EIA – If hurricane, onshore supply will prevent run-up in prices 10/15/08 ► 50% Gulf Production shut in ► Future prices drop 50% from 7/08 ► 200 Bcf goes to pipe and storage pressure 18 Prices (cont’d.) Gas Storage ► 06/14/09 - Storage at 2,213 Bcf – 31% above year-to-year and normal EIA Reserve largest gain since 1977 (year began review) ► 12/22/08 – EIA by 2030: Natural gas prices will allow production to equal 24 trillion Cft Electricity production to rise by 25% and natural gas to 22% of production Electric growth majority gas and renewables Hybrid vehicles 38% of market Rex Maintenance ► 20% plus above normal injections Start of season – 20% plus above 5 year average Near record ’08-09 winter heating season Rockies gas below $1.00 (45¢) Third quarter 08 worst for commodities since 1970 19 Pipelines Rex brings gas to Mid Cont TX / NM markets cannot go east Haynesville shale TX and Gulf Gas prices to drop relative to Rockies and LA 20 Pipelines (cont’d.) MLPs need credit ► Model Cash flow to distribution Large capital needs debt or stock (dilution) Demand Strong for services Producers drilling new fields not HBP No Pipe in area MLPs ► Outspending Cash Flow with distributions 21 Pipelines (cont’d.) Midstreams Cut backs Maturity of debt MLP’s need capital - where? MLP’s - who will build infrastructure? E&P ► ► spend drilling money on pipe? pay private equity for pipe? 22 Pipelines (cont’d.) 2007-2008 Ziff study – Mackenzie and Alaska gas MacKenzie ► $33 Billion for 6 Bcfd Alaska ► ► $20 Billion for 1 Bcfd vs. LNG $10 Billion for 1 Bcfd What about $5.00 gas? 23 LNG LNG – 4 built in ’90’s and ’80’s – Everett, MA; Cove Point, MD; Elba Island, GA and Lake Charles, LA ► ► ► Two idle; two little activity US surplus supply / low prices Freeport and Cheniere permits to export US gas 4 New US facilities in 2009 to receive gas – most without supply ► ► Freeport opens – no supply – one tanker scheduled – 08/09 Cheniere for sale – no dedicated supply 19 New “trains” at 12 plants to produce LNG Winter “world” 08-09 LNG prices 24-30 MMBtu ► ► ► ► Algeria outage in LNG plant Freeport LNG – set to EXPORT! US LNG not needed until 2012 or beyond Wood Mackenzie says LNG could be 14% of US supply after 2012 and 20% in 2020 24 LNG (cont’d.) LNG – 2008 ► ► Tankers – usually 8 built per year ► 17 counties import 29 importers – 2012 - US has storage 57 in 2008 and 42 in 2009 and 40% larger New Exxon “QMax” Technology increases ship capacity 80% - decrease energy consumption 40% per unit Pritchard Capital forecasts LNG surge ► ► ► U.S. prices $3/Mcf Qatar production cost in pennies Plus $2 Mcf to transport 25 Production/Reserves EIA reports: 2007 – 46.1 Tcf ► ► ► record high reserve additions doubled 19.5 Tcf produced; highest 31 years 13% increase over 2006 reserves 2007 Shale - 9% of US reserves: 50% increase year to year TX - 17% gain - 13.3 Tcf Rockies - 26% gain - 6.2 Tcf Horizontal rigs ► ► 133 – 2005 600 - 2008 26 Production/Reserves (cont’d.) 2006 plus 2.1 Bcf/d + 4.7% 2007 plus 2.5 Bcf/d + 5.3% 2008 plus 3.5 Bcf/d + 7% (TX ½ - Barnett) Last drop 2002 – 2 Bcf/d – 3.8% - 400 fewer rigs US has 2,247 Tcf of gas ► ► 118 years at 2007 demand Every EIA projection exceeded by actual production 27 World Turned Upside Down JAPAN – Ten years from commercial production Methane Hydrates US Federal Waters “100s” of Tcfs of gas in Methane Hydrates North slope 85.4 Tcf in Methane Hydrates 28 World Turned Upside Down (cont’d.) In 1st half 08 half of gas consumed was from wells drilled in last 40 months In 2006, was 48 months US unconventional gas 10 times recoverable volume conventional gas Worldwide – translate US shale lessons? Ziff forecasts ► Unconventional Gas “53%” of production by 2020 ► N.A. production 87 Bcfd in 2020 vs. 70 Bcfd in 2000 ► Shales the key 29 NGLs NGLs-the heavier components of the natural gas stream ► ► ► ► ► C2 C3 iC4 nC4 C+5 ETHANE PROPANE ISO – BUTANE NOR – BUTANE COMMONLY CALLED NATURAL GASOLINE 30 NGLs (cont’d.) Comparison of Gas and NGL Value ► NATURAL GAS ► ETHANE ¢/GALLON MMBTU/GALLON $/MMBTU --19.33 --.066320 2.022 2.91 31 NGLs (cont’d.) Uses for Natural Gas Liquids Component: primary uses Ethane: petrochemical feedstock for the manufacture of ethylene, which is the building block for the manufacture of polyethylene, styrene and many other products. Propane: liquid fuel for homes, industry and transportation (60%); petrochemical feedstock (23%); and farm use, exports and miscellaneous (17%). Iso-butane: refinery feedstock for the manufacture of alklylates and mtbe which are used as high-octane blending components in motor gasoline. Normal-butane: refinery feedstock for direct gasoline blending or isomerization (66%); petrochemical feedstock (24%); and fuel (10%). Diminishing use for direct gasoline blending with EPA RVP limitations. Natural gasoline: primarily used as a blending agent in motor gasoline. Also, refinery and petrochemical feedstock. 32 NGLs (cont’d.) Keepwhole and ‘At Risk’ Contracts "Producer (seller, buyer, etc.) is "keptwhole" on the Btu valve of the gas delivered to the plant." Risk is borne 100% by the processor. Processor is "at risk" as to financial relationship between the raw material value (the keepwhole value) and finished product value (NGL prices). Netback Pricing 33 NGLs (cont’d.) NGLs from crude is competition Crude drives NGL prices Unconventional gas fewer NGL’s MARKET PROBLEMS ► ► Price Fluctuations Conflict of Interest CONFLICT ENCOURAGES ► ► Inefficient Plants Low Plant Prices 34 NGLs (cont’d.) ► REMEDIES "Drop out" Clause Look at Plant Statements Are fuel/shrinkage unusually high? Avoid processor net backs Or Conway Kansas or M. Bellview Avoid netback at plant or county Negotiate fixed charges/fuel, etc., up front. 35 NGLs (cont’d.) Humble Oil and Refining Humble Oil and Refining Company and Pan American Petroleum Corporation just completed an audit of Champlin's books covering our Carthage Plant operations for the period from August 1, 1955, through December 31, 1957. Since commencement of processing at the Carthage Plant in 1946, these two companies have audited the operation of this plant for themselves and on behalf of others four separate tines starting in the year 1950. During this most recent audit (just completed in 1958) a question was raised for the first time as to the language in the processing agreements as compared to the actual procedure used by Champlin for the allocation of plant liquids which procedure was agreed upon and set forth in a letter agreement dated June 8, 1948, between the Panola County Royalty Owners Association to The Chicago Corporation dated June 11, 1952. The procedure used in allocating plant liquids, since this agreement was made with the Royalty Owners Association, is fully reflected in the Gas and Liquid Production and Disposition Report. After a review of the matter, Humble agrees with Champlin that this procedure, which has been in actual use since 1948 and as adjusted slightly in 1952, is most equitable; and after reviewing the entire matter, Pan American expresses no disagreement with the procedure. Certainly, a prime requisite for a fair and equitable allocation of liquid products derived from a commingled stream of gas is that the allocation method and procedures for each and every source of gas be identical. We have, therefore, been employing the procedure worked out with the Royalty Owners Association consistently during all this time, and all parties have been fully advised of the allocation through the monthly reports mentioned above. We take this opportunity of advising you that it will be our practice to continue to employ the aforementioned procedure as to all producers connected to our plant. If you have any question as to the procedure as heretofore employed, and which we propose to continue, or as to any other matters pertaining to our processing agreement with you, we will be glad to discuss the matter with you. Unless we hear from you to the contrary within thirty (30) days, we will consider that our suggestion for continuing this procedure meets with your approval. 36 NGLs (cont’d.) Plant Allocations ► ► ► ► ► ► No formulas followed Audit formulas for liquid downstream Audit residue gas stream Audit measurement 85% netback can be better than 90% Fixed allocation -- not actual Processing Contracts ► Fee for Service ► Percent of Proceeds ► Fee and % of Proceeds ► Keep Whole 37 NGLs (cont’d.) Processing Key Issues ► Duty to Process Uneconomic Unprofitable Good Faith ► ► ► ► Keepwhole Rights When is 85% of the liquids (NGLs) better than 90% Conflict of Interest Fuel and Shrinkage – Incentive 38 NGLs (cont’d.) “Trigger Words” ► ► Economic – prudent and thrifty in management; intended to save money; efficient Profitable – the return on a business after expenses; an advantageous gain or return; income; payment for a commodity in excess of cost (American Heritage College Dictionary – 3rd Edition.) 39