Supply Chain Management - Eastern Kentucky University

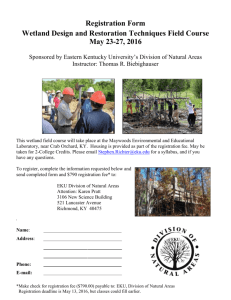

advertisement

Supply Chain Management Chang-Yang Lin, PhD Professor and Coordinator of CIS Eastern Kentucky University SCM and Inaccuracy Problems On a typical day in a U.S. supermarket, 8.2% of the items are out of stock. 33% of out-of-stock items are located in the store, just not in the correct location. The cost of stockouts in U.S. supermarkets are estimated at $7 to $12 billion of sales. Before being stored on store shelves, items pass through several processes, including order processing, fulfillment, staging, shipment, receiving, short-term storage, and finally shelving. EKU Business 2 a coordinated system of entities, activities, information and resources involved in moving a product or service from supplier to customer a network of organizations and facilities that transforms raw materials into products delivered to customers also includes transportation companies, warehouses, & inventories and some means for transmitting messages & information Dell’s own channel for manufacturing and selling eliminated • distributors and • retailers Supply Chain Management SCM is the process of planning, implementing, and controlling the operations of the supply chain with the purpose to satisfy customer requirements as efficiently as possible SCM spans all movement and storage of raw materials, work-in-process inventory, and finished goods from point-of-origin to point-of-consumption EKU Business 6 SCM Problems Distribution network configuration: Number and location of suppliers, production facilities, distribution centers, warehouses and customers. Distribution strategy: Centralized versus decentralized, direct shipment, pull or push strategies, third party logistics. Information: Integrate systems and processes through the supply chain to share valuable information, including demand signals, forecasts, inventory and transportation. Inventory management: Quantity and location of inventory including raw materials, work-in-process and finished goods. EKU Business 7 SCM Activities/Functions The purpose of SCM is to improve trust and collaboration among supply chain partners, thus improving inventory visibility and improving inventory velocity SCM activities can be grouped into strategic, tactical, and operational level of activities EKU Business 8 The Bullwhip Effect An observed phenomenon in forecast-driven distribution channels Because forecast errors are a given, companies often carry "safety stock" Moving up the supply chain from endconsumer to raw materials supplier, each supply chain participant has greater observed variation in demand and thus greater need for safety stock The effect is that variations are amplified the farther you get from the end-consumer EKU Business 9 The bullwhip effect is a phenomenon in which the variability in the size and timing of orders increase at each stage up the supply chain, from customer to supplier The Bullwhip Effect (continued) One way to eliminate the bullwhip effect is to give all participants in the supply chain access to consumer-demand information from the retailer. Each organization can thus plan its inventory or manufacturing based on true demand and not on the observed demand from the next organization up in the supply chain. An interorganizational information system is necessary to share such data. EKU Business 11 Stabilizing the Bullwhip Effect: A Demand-Driven Supply Chain Individual Wal-Mart stores transmit POS data from the cash register back to corporate headquarters several times a day This demand information is used to queue shipments from the Wal-Mart distribution center to the store and from the supplier to the Wal-Mart distribution center The result is near-perfect visibility of customer demand and inventory movement throughout the supply chain A demand-driven supply chain which reacts to actual customer orders. In manufacturing, this concept is called Kanban (カンバン 看板) EKU Business 12 B2B One Section of the Supply Chain Supplier Relationship Management (SRM) SRM is a business process for managing all contacts between an organizational and its suppliers. SRM applications support three basic processes: source, purchase, and settle. SRM examines inventory, determines that items are required, and automatically creates the order via its connection to the supplier’s CRM EKU Business 14 SRM Process Definition of Key Terms Inventory Inventory consists of a list of goods and materials held available in stock Manufacturing organizations usually divide their "goods for sale" inventory into: Materials and components (or Raw materials) scheduled for use in making a product Materials and components that have begun their transformation to finished goods (or Work in Process) Finished goods - goods ready for sale to customers EKU Business 16