Document

advertisement

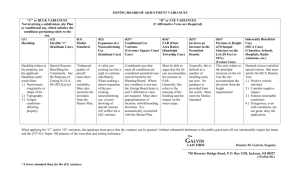

A standard is understood to be a rule of measurement established by authority. An inch, an ounce, a gallon, a kilometer, a rupee--- is an example of a standard of measurement, established by duly constituted authority, accepted by all to whom it applies. Management, in assigning responsibility for the actual results of operations, wants to know that those results were measured accurately. 2 A meaningful standard must bear the stamp of duly constituted authority, the standards used to measure performance must have been propagated by management and recognized and accepted by those whose performance is being evaluated. The technique of using standard costs for the purpose of cost control is known as standard costing. The standard costing has been defined by the London Institute of Cost and Works Accountants as “An estimate cost, prepared in advance of production or supply correlating a technical specification of material, and labour to the price and wages rates estimated for a selected period of time, with an addition of the appointment of overheads expenses estimated for a selected period within a prescribed set of working conditions.” 4 1. The determination of standard cost. 2. The recording of actual cost. 3. The comparison between actual cost and standard cost. 4.The finding out of variances. 5. Reporting of variances to the competent authority, both favorable and otherwise. 6. Initiation of necessary corrective measures/steps, particularly in case of controllable variances. 5 Before, standards are drafted for the approval of competent authority, consultation is ordinarily undertaken with the operating personnel most directly affected by them. These persons can express intelligent opinion as to the realism of the standards proposed. It is generally conceded that standards are most effective as a cost control tool if they are attainable---not too easy to reach, but not impossible either. 6 Such standards prove to be motivating devices even before any formal analysis of performance is undertaken. Attainable standards stand a good chance of being accepted by all concerned because they should pose a challenge---but not an impossible one---to operating personnel. In the initial years the scope of standard costing was very much limited, as the standards were set unscientifically and without much of the involvement of the operative people. They were almost imposed and that is why not taken very seriously. With the passage of time the people at the operative level were made to understand that these standards were not to harass them but they are meant for the welfare of the employees as well as the organization. 8 They were told that the standards will be set with their active involvement and even if they go wrong somewhere they need not worry as they will get all type of help. Now a days the standards are set carefully, which are attainable, of course, are challenging. The variances are noted and analyzed, and if there are controllable variances, necessary steps are initiated to minimize the chances of recurrence. It has proved to be an effective measure of cost ascertainment and cost control. 1. It is concerned with the ascertainment of standard costs, under each element, i.e. materials, labour and overheads. 2. It is concerned with the measurement of actual cost. 3. It is concerned with the comparison of actual costs with the standard costs. 4. On the basis of comparison it is concerned with the analysis of variances, both favorable and otherwise. 5. It is concerned with the initiation of necessary steps in case of, unfavorable variances. 10 The setting of standards and the establishment of a standard cost system allow managers to follow the exception principle, which specifies that the manager will maximize his or her efficiency by concentrating on those operational factors which are deviations from the plan. A variance is the difference between the standard and the actual. CIMA has defined variance analysis as “Method of accounting by means of which planned activities are compared with actual results”. . 11 Realistic and attainable standards should be set and any deviation from such standards, has to be viewed seriously. When actual cost is less than standard cost, actual profit is more than the standard profit and actual yield is more than the standard yield, such variances are called favourable variances, and are considered to be the sign of efficiency and vice versa. Variances may also be classified as controllable non and controllable variances. 13 There are a number of reasons which give rise to variances, and analysis of variances will help in locating the reason and person or department responsible for a particular variance. Variance analysis, if properly used, can be of immense help. 1.Early Warning. 2. Performance Evaluation. 3. Evaluating strategy. 4. Makes the people more responsible. 5. Helpful because of management by exception. 6. Makes the job more challenging. 14 Variance analysis if implemented seriously and with good intention can work wonders and can help substantially in cost control. Analysis of variance can be done in respect of each element of cost and sales: 1. Direct Material Variances 2. Direct Labour Variance 3. Overhead Variance 4. Sales Variance 1.Standards provide yardstick against which actual costs are compared. 2. Helps in minimizing waste and inefficiency. 3. Management by exception is facilitated. 4. Improvement in the methods of production and sales. 5. Provides valuable guidance in the formulation of price and production policies. 6. Useful in planning and budgeting. 16 7. Makes everyone in the organization cost- conscious. 8. Effective delegation of authority is facilitated. 9. Helps the management in performing its functions in a better way. 10. Enhances the value of reports. 11. Economical means of costing. 12.Measuring Efficiency. 13.Determination of Variance. 14.Facilitates Cost Control. 15.Helpful in taking important decisions. Standard costing cannot be used in those concerns where non-standard products are produced. If the production is undertaken according to the customer’s specifications then it is not possible to set up standards for every job. The process of setting up standards is a difficult task as it requires technical skill. The time and motion study is required to be undertaken for this purpose. These studies require a lot of time and money. The conditions under which standards are fixed do not remain static. The reconsideration of standard is a costly process. 18 The fixing of responsibility is not an easy task. The variances are to be classified into controllable and uncontrollable variances. The industries liable for frequent technological changes will not be suitable for standard costing system.