PLN_0401_B1_Epp_M

advertisement

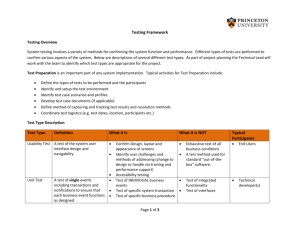

Three Views of Product Development Complexity Prof. Steven D. Eppinger Massachusetts Institute of Technology Sloan School of Management Engineering Systems Division Center for Innovation in Product Development MIT ESD ©2000 Steven D. Eppinger eppinger@mit.edu http://www.mit.edu/people/eppinger/ http://web.mit.edu/dsm Lean Aerospace Initiative Plenary Conference April 10, 2001 Information Density in Complex Product Development • • • • • • • • 400 people 5000 part numbers 2000 significant parts 125 subassemblies 2000 drawings 12,000 problems ~1,000,000 decisions ~1,000,000 info. flows Office copier by Xerox complex product = system Three Perspectives to Study Development of Complex Systems • Product/System-level • Process-level Planning • Organization-level Concept System-Level Development Design Detail Design Testing and Refinement Production Ramp-Up System Decomposition • Decompose a complex system into subsystems and components • Decompose a complex process into subprocesses and tasks • Decompose a large organization into teams and individuals Decompositions Exhibit Architectures • The pattern of interactions between the decomposed elements define the architecture – System architecture – Process architecture – Organization architecture Decompositions Exhibit Architectures • The pattern of interactions between the decomposed elements define the architecture – System architecture – Process architecture – Organization architecture Potential Complexity Metrics • The number of elements determines the complexity of the decomposition • The uncertainty of elements determines their difficulty in development and integration • The pattern of interaction among the elements indicates the complexity of the architecture • The alignment of the patterns determines the difficulty of developing the system in context Uncertainty of Elements Number of Elements ? Pattern of Interactions ? Alignment of Patterns An Approach to Studying the Patterns • We can study the patterns of interactions in three perspectives in order to better understand system complexity: – System example: Pratt & Whitney 4098 jet engine – Process example: Intel semiconductor development – Organization example: GM Powertrain organization • We can also compare the patterns across the perspectives: – System vs. Organization example: Pratt & Whitney engine – Process vs. Organization example: electrical connectors System Architecture Example: P&W 4098 Jet Engine •9 Systems •54 Components •569 Interfaces Design Interfaces: •Spatial, Structural •Energy, Materials •Data, Controls HPC LPC HPT FAN B/D LPT Mechanical Components Externals and Controls (2) Modular Systems Distributed Systems Lessons Learned: System Architecture • Hierarchical system decompositions are evident. • System architecting principles are at work. • There is a disparity between known interfaces and unknown interactions. • Integrating elements may be functional and/or physical. • Hypothesis: Density of known interactions– novel experienced optimization learning sparse mature dense clustered Process Architecture Example: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Set customer target Estimate sales volumes Establish pricing direction Schedule project timeline Development methods Macro targets/constraints Financial analysis Develop program map Create initial QFD matrix Set technical requirements Write customer specification High-level modeling Write target specification Develop test plan Develop validation plan Build base prototype Functional modeling Develop product modules Lay out integration Integration modeling Random testing Develop test parameters Finalize schematics Validation simulation Reliability modeling Complete product layout Continuity verification Design rule check Design package Generate masks Verify masks in fab Run wafers Sort wafers Create test programs Debug products Package products Functionality testing Send samples to customers Feedback from customers Verify sample functionality Approve packaged products Environmental validation Complete product validation Develop tech. publications Develop service courses Determine marketing name Licensing strategy Create demonstration Confirm quality goals Life testing Infant mortality testing Mfg. process stabilization Develop field support plan Thermal testing Confirm process standards Confirm package standards Final certification Volume production Prepare distribution network Deliver product to customers 1 2 • x • x x x x x Intel Semiconductor Development Process 3 x x • 4 5 6 x x x • x x • x x • x x x x x x x x x x x x x x x x x x x x x x x 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 • x x x x x • • x x x • x x x x x x x x x x • x x x x x x x x x x x x • x • x x x x x x x x x x x x x x x x x x x x x x O O O O x x x • x x • x x • x x • x x x x x x x x x x x x O • x x x x x • x • x • x • x x x x x x x x x x x x x x x x x x x • x x • x x x x x x x x x x x x x x x x x x x x x • x x • x x x x x • x x x • x • x • x x x x x x x x x x x x x x x x x x x x x x • • x x x x x x inside O O O O O O O O • x x • x • x • O O O O O O O O O x O O O O O O O O O • x x x • O x x • x x • x • x • x x x x x x x x O O • • x • x x x • • x x x • x x • x • x x • x x x x x x x x x x • • x x x • x x x • x x x x x x x x x x x x x x x = Information Flows x x x x x x x O = Unplanned Iterations = Planned Iterations O O • x x O O x x O O O O • = Generational Learning x x • x • x x x x x x x x x x x x x x x • x x • x • x x • x • Lessons Learned: Process Architecture • Information flows describe the PD process more completely than task networks. • PDTs report their inputs more reliably than their output flows. • We find parallel and sequential stages within the (CDIO) phases of the PD process. • Planned iterations can be facilitated to accelerate the process. • Unplanned iterations require special attention to make the process more robust. Organization Architecture Example: Engine Development • Organization: General Motors Powertrain Division • Product: “new-generation” engine (small-block V8) • Structure: 22 PDTs involved simultaneously Decomposition of the Engine Development Project 22 PDTs Design Engine Engine Block Cylinder Heads Camshaft/Valve Train Pistons Connecting Rods Crankshaft Flywheel Accessory Drive Lubrication Water Pump/Cooling Intake Manifold Exhaust E.G.R. Air Cleaner A.I.R. Fuel System Throttle Body EVAP Ignition System Electronic Control Module Electrical System Engine Assembly PDT composition 1 product release engineer 1 CAD designer 3 manufacturing engineers 2 purchasing representatives 2 casting engineers machine tool supplier 1 production control analyst 1 financial planner production personnel PDT Interactions Engine Block Cylinder Heads Camshaft/Valve Train Pistons Connecting Rods Crankshaft Flywheel Accessory Drive Lubrication Water Pump/Cooling Intake Manifold Exhaust E.G.R. Air Cleaner A.I.R. Fuel System Throttle Body EVAP Ignition E.C.M. Electrical System Engine Assembly A B C D E F G H A A l l l l l l l B l C l D l E l F l G l H l I l J l K l L l M l N O l B P l Q l R S T U l l I J K L M N O P Q R S T U V l l l l l l l l l l l C l l l l D l l l l E l l l l F l l l l G l l H l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l I l l l l l l l l l l l l J l l K l l l l Frequency of PDT Interactions l l Weekly Daily Monthly l l l l l l l l l l l l l l V l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l L l l l l l M l l N l l l l l l O l P l l l l l l l Q l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l R l l l l l l l T l l l l U l l l l V S l l System Team Assignments Short Block Engine Block Crankshaft Flywheel Pistons Connecting Rods Lubrication Induction Intake Manifold Accessory Drive Fuel System Air Cleaner Throttle Body A.I.R. Valve Train Cylinder Heads Camshaft/Valve Train Water Pump/Cooling Emissions/Electrical Exhaust E.G.R. E.V.A.P. Electrical System Electronic Control Ignition Existing System Teams Engine Block Crankshaft Flywheel Pistons Connecting Rods Lubrication Cylinder Heads Camshaft/Valve Train Water Pump/Cooling Intake Manifold Fuel System Accessory Drive Air Cleaner A.I.R. Throttle Body Exhaust E.G.R. EVAP Ignition E.C.M. Electrical System Engine Assembly A F G D E I B C J K P H N O Q L M R S T U l l A A l l l l l l l l l l l l l l l l l l F l F l l l l l l G l l G l l l l l l l l l D l D l l E l l l E l l l l l l I l l l l l I l l l B C J l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l V l l l l l l l l l l l l l l l l l l l l l l l l l Frequency of PDT Interactions l l Weekly Monthly l Daily l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l Q U l l P L M R S T B l K l H N O l l l l l l C l l l J l l l l K l l l l l l l l l P l l l l l H l l l l l l l N l l l l l l O l l l l l l l l Q l l L l l l l l l M l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l V l l l l l l l l l l l l l R l l l l l l T l l l l U l l l l V S l l Proposed System Teams Crankshaft Flywheel Connecting Rods Pistons Lubrication Engine Block Camshaft/Valve Train Cylinder Heads Intake Manifold Water Pump/Cooling Fuel System Air Cleaner Throttle Body EVAP Cylinder Heads Intake Manifold A.I.R. Exhaust E.G.R. Accessory Drive Ignition E.C.M. Electrical System Engine Assembly F G E D I A C B1 K1 F G E D I A C B1 K1 J P N Q R B2 K2 O L M H S T U V l l l l l F l l l l l l l l l l l l G Team 1 l l l l l E l l l l l l l D l l l l l l l l l l l l l l l l l l I l l Team 2 l l l l l l l A l l l l l l l l l l l l l l l l C l l l l l l l l B1 l l l l l l l l Team 3 l l l K1 l l l l J l l l l l P N Q R B2 K2 O L M H S T U V J l l l l P l l l N l l l Integration Team l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l Q l l R l l l l l l l l l l l l l l l l l l l l Team 4 l B2 l l l l l l l l K2 l l l l l l l l O l l l l l l l l L l l l l M l l l l l l l H l S l l l l l l l l l l T l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l Frequency of PDT Interactions l l Weekly Daily Monthly l l l l l l l l U l l V Team 4 Exhaust E.G.R. Team 3 Team 1 Pistons Flywheel Connecting Rods Engine Block Lubrication Crankshaft Team 2 A.I.R. Water Pump/ Cooling Camshaft/ Valve Train Cylinder Heads Intake Manifold E.V.A.P. Fuel System Air Cleaner Throttle Body Accessory Drive Electrical System Ignition Engine Assembly Electronic Control Module Integration Team PDT-to-System-Team Assignments Lessons Learned: Organization Architecture • Organization architecture can also be mapped in terms of interactions – across individuals or PDTs. • We usually find a (partial, at least) one-to-one mapping from system decomposition to organization structure. • Organizations can be designed based on the underlying technical structure of the system being developed. • Co-Evolution Hypotheses: – Organizations evolve to address deficiencies in their ability to implement the system architecture. – System architectures evolve to address deficiencies in the development organization. Arch Org Comparing the System Architecture to the Organization Architecture Product Decomposition into Systems Development Organization into Teams Technical interactions define the architecture Team interactions implement the architecture How does product architecture drive development team interaction? Research Method: Mapping Design Interfaces to Team Interactions No Team Interaction Design Interface Matrix Yes Yes No Design Interface Resultant Matrix Task assignment assumption: Each team designs one component Team Interaction Matrix Design Interfaces: P&W 4098 Jet Engine •9 Systems •54 Components •569 Interfaces Design Interfaces: •Spatial, Structural •Energy, Materials •Data, Controls HPC LPC HPT FAN B/D LPT Mechanical Components Externals and Controls (2) Modular Systems Distributed Systems Development Organization: P&W 4098 Jet Engine • 60 design teams clustered into 10 groups. • Teams interaction intensity: Low intensity interaction High intensity interaction – Capture frequency and importance of coordination-type communications (scale from 0 to 5). – Interactions that took place during the detailed design period of the product development process. – Design executed concurrently. Six system integration teams Team Interactions Overall Results No (2453) Team Interactions Yes (409) 228 (8%) 2225 (78%) 341 (12%) 68 (2%) Yes No (569) (2293) Design Interfaces We reject the null hypothesis that “team interactions are independent of design interfaces”. 2 = 1208 >> Critical 2(0.99,1) = 6.635 Design Interfaces Not Matched by Team Interactions No (2453) Team Interactions Yes (409) 228 (40.1%) (59.9%) 341 2225 68 Yes No (569) (2293) Design Interfaces HYPOTHESES: H1: Across boundaries, design interfaces are less likely to be matched by team interactions. H2: Weak design interfaces are less likely to be matched by team interactions. Effect of Organization/System Boundaries No Data set: 569 design interfaces Team Interactions Yes Yes No Design Interfaces First criterion: Design interfaces matched by team interactions 59.9% Design interfaces NOT matched by team interactions 40.1% Second criterion: Design interfaces WITHIN organizational boundaries 78.8% are matched Design interfaces ACROSS organizational boundaries 47.8% are matched Effects of Organizational/System Boundaries (modular vs. integrative systems) No Team Interactions Data set: 569 design interfaces Yes Yes No Design Interfaces Overall: Design interfaces WITHIN organizational boundaries Design interfaces ACROSS organizational boundaries 78.8% are matched 47.8% are matched 36.4% of ACROSS design interfaces are matched 53.2% of ACROSS design interfaces are matched Lessons Learned: No Team Interactions Architecture and Organization Yes Yes No Design Interfaces • We can predict coordination-type communications by studying the architecture of the product – 83% of coordination-type communication were predicted • Teams that share design interfaces may not communicate when – Design interfaces cross organizational boundaries – Design interfaces are weak (within organizational boundaries) – Teams communicate indirectly through other design teams (across organizational boundaries) • Teams that do not share design interfaces may still communicate when – Unknown design interfaces are discovered – Design interfaces are system-level dependencies Lessons Learned about Development of Complex Products • Product (system) complexity must be considered in the context of the process and organization which are developing it. • Processes and organizations can be designed to facilitate development of specific product architectures. • System concepts such as modularity and architectural knowledge apply at the level of sub-system interactions.