Metals - UMW Blogs

advertisement

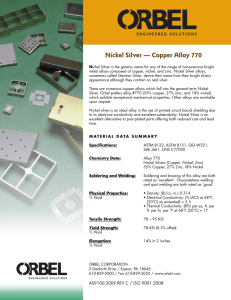

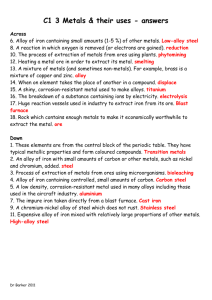

Metals 20th century building materials Pre-20th century metal use The 20th century has seen the rapid expansion of the number of metal blends used in the building process, both in the structural components and as decorative elements. Iron and lead were the seventeenth century metals of choice. Easily available, worked at low temperatures. Iron was the choice for fasteners (think nails) and structural elements because of its strength. Lead was used for its low solubility. It’s principal uses were in paints at lead oxides, or as sheets for flashing. Far less frequently were tin and copper used as lead substitutes. (used inside as metal blends) Aluminum One of the most abundant metals in the earth’s mantle but not a naturally occurring free metal. Fabulously expensive when finally identified in the mid-19th century. First architectural use of cast aluminum was on the Washington Monument in 1888. "It is desired that the cost be kept if possible, within the estimate ($75) which you submitted, but should that cost be necessarily and unavoidably exceeded ($256) in producing a perfect piece of workmanship, the account shall be submitted setting forth that fact." 20th century production The electrolysis (Hall-Heroult process) of Bauxite (named for the French village of Les Baux) allowed for a commercial process of recovery and rapidly declining cost. Process used cryolite (Na3AlF6) as a flux. First commercial use was in Chicago in 1892-93. for interior trim. Properties: Aluminum can be cast and extruded, but to be heat joined it must be welded in an inert environment. Annealing: Heat treated increased the hardness of the metal. Anodic coating. Using the natural oxidation of the surface. The aluminum oxide layer is made thicker by passing a DC current through a sulfuric acid solution, with the aluminum object serving as the negative electrode. Open crystaline structure can encapsulate dyes. Porcelain and baked enamels first applied to aluminum in the post WWII period. Trends in metal use Much of the progress of metals for construction in the 20th century came in alloys of metals to enhance strength and resistance to atmospheric borne corrosion. Another issue of considerable importance was the galvanic effects that plague metals Nickel blends Monel. An alloy of nickel, copper and trace metals. The original alloy had been a result of reduction of nickel ore in Sudbury, Ontario, Canada where the proportions of nickel and copper were naturally occurring in an iron ore deposit. Named for the president of the Orford Nickel and Copper Company, Ambrose Monel. Monel was isolated and described in 1901 and patented in 1906. Characteristics: Stronger than steel, with low weight to strength ratio it is highly ductile and worked easily into sheet, but it cannot be extruded (it stuck to the dies). It is resistant to corrosion and acids, and some alloys can withstand a fire in pure oxygen. It is commonly used in applications with highly corrosive conditions. Small additions of aluminum and titanium form an alloy with the same corrosion resistance, but with very high strength. dog tags Monel largely out of the market by 1950s because of the high cost of nickel, considered a strategic metal. First of the stainless metals on the market, replaced by stainless steel. Nickel Steel. Alloys of nickel, copper and zinc. German silver. a ductile copper-nickel-zinc alloy used to make utensils, drawing instruments, and the like. (It contains no silver, but is so named for its silvery appearance.) Also called nickel silver. Used as a base for silver electroplating beginning in the 1840s. Popularly used in Art Deco for the metallic color as polished nickel silver. Guardian Bldg, Detroit Nickel Silver is defined by % Ni Chicago Board of Trade--1929 German Silver, or Nickel Silver 1933 Gibson RB-3 Stainless Steel Stainless Steel is a chromium alloy of iron. Forms a tight skin of iron-chromium oxide that resists attack. Number of different alloys with a minimum of 10.5% chromium content. The name originates content. The name originates from the fact that stainless steel does not stain, corrode or rust as easily as ordinary steel. Used in marquis and exposed building areas. Also used as a fastener in acidic materials. In the United States and world-wide, particularly in the aviation industry, this material is also called corrosion resistant steel when it is not detailed exactly to its alloy type and grade. Misinformation cause manufacturers to avoid until 1910s Metal roofing initiative