Quality by Design Regulatory Update FDA Pilot Program Conformia

advertisement

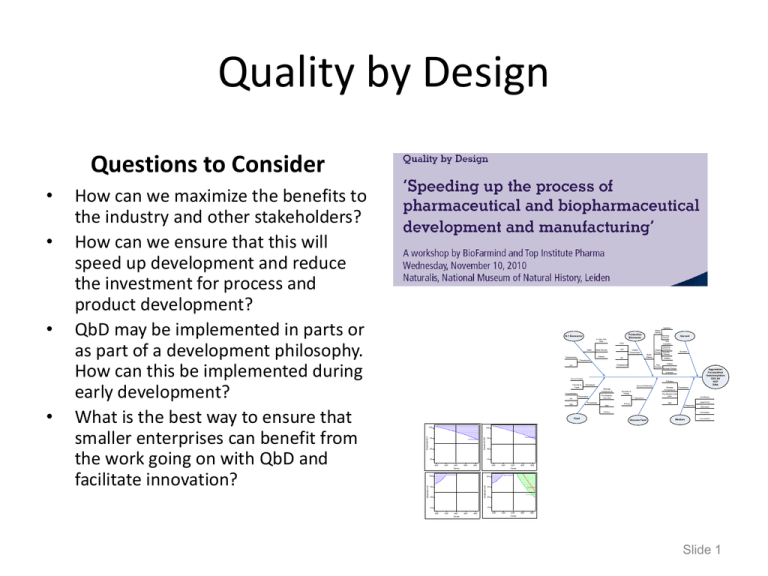

Quality by Design Questions to Consider Seed Seed Density Viability Temperature Working Volume Harvest # of Impellers CO2 DO Control Parameters Scale Effects pH Nominal Vessel Volumne Design Impeller Design Duration Baffles Procedures Gas Transfer Temperature pH Airflow Sparger Design Aggredates Fucosylation Galactosylation CEX AV HCP DNA Antifoam Contour Profiler Horiz Vert Factor Temperature DO Dissolved CO2 Split Ratio Basal Strength (Dilution) Feed Strength (Dilution) Feed Neutralization Osmo Duration Filtration Current Horiz Vert X Factor 35 Temperature 50 DO 70 Dissolved CO2 3.7 Split Ratio 100 Basal Strength (Dilution) 100 Feed Strength (Dilution) 90 Feed Neutralization 440 Osmo 17.5 Duration Response Productivity aFucosylation Galactosylation Contour 3 11 25 Current Y Lo Limit Response 8.644125 3 Productivity 6.1354189 3 aFucosylation 32.452376 Galactosylation 25 100 Current X 37 50 70 3.7 100 100 90 440 17.5 Hi Limit . 11 55 Contour 3 11 25 Current Y 8.951625 7.5034189 32.837639 Volume of Feed Operations Amount Delivered Storage Temperature Concentration Preparation pH Age Lo Limit 3 3 25 Hi Limit . Feed 11 55 Number of Feeds Pre-filtration hold time Procedures Age Operations Procedures Storage Temperature Pre-filtration hold time [Antifoam] [NaHCO3] Age Timing Preparation [Glucose] Osmolality Filtration Glucose Feed Medium Concentration 100 Contour Profiler Contour Profiler Horiz Vert Factor Temperature 80 DO Dissolved CO2 Split Ratio Basal Strength (Dilution) 60 Feed Strength (Dilution) Feed Neutralization Osmo Duration 40 Response Productivity 400 420 440 aFucosylation Osmo Galactosylation Current Horiz Vert XFactor 35Temperature 80 50 DO 70Dissolved CO2 4.9Split Ratio 100Basal Strength (Dilution) 60 100Feed Strength (Dilution) 90Feed Neutralization 440Osmo 17.5Duration 40 Contour Current Y Lo Limit Hi Limit Response 3 6.896625 . 460 Productivity 480 400 420 3 440 11 6.1244052 3 aFucosylation Osmo 11 25 30.595296 55 Galactosylation 25 Galactosylation 460 Galactosylation 100 Time of Feeding Contour Profiler Dissolved CO2 • Agitation In Vitro Cell Age Shear/ Mixing Production Bioreactor N-1 Bioreactor 80 60 Galactosylation Contour 3 480 11 25 Current X 37 50 70 4.9 100 100 90 440 17.5 Current Y 5.974125 9.5011447 30.980559 Lo Limit 3 3 25 Hi Limit . 11 55 Galactosylation 100 Dissolved CO2 • Dissolved CO2 • How can we maximize the benefits to the industry and other stakeholders? How can we ensure that this will speed up development and reduce the investment for process and product development? QbD may be implemented in parts or as part of a development philosophy. How can this be implemented during early development? What is the best way to ensure that smaller enterprises can benefit from the work going on with QbD and facilitate innovation? Dissolved CO2 • 80 Productivity aFucosylation 60 40 40 400 420 440 Osmo 460 480 400 420 440 460 480 Osmo Slide 1 A-Mab: a Case Study in Bioprocess Development CMC Biotech Working Group Background and Goal • To create a publicly available case study that helps translate the ‘what’ of ICH guidelines into practical ‘how’ for a biological molecule with emphasis on Quality by Design • Started in August 2008 • 7 companies divided across the various sections into teams – GlaxoSmithKline, Abbott, Lilly, Pfizer, Genentech, MedImmune, Amgen – John Berridge, Sam Venugopal, and Ken Seamon, co-facilitators • Combination of regular telecon and in- person meetings • Relentless focus on science and risk-based approaches, not traditional ways • Colleagues from regulatory authorities provided unique insights to help stimulate our case study Slide 3 Creating a Biotech Case Study: “A-Mab” • Based on a monoclonal antibody drug substance and drug product – – – – – “A-Mab” Humanized IgG1 IV Administered Drug (liquid) Expressed in Cho Cells Treatment of NHL • Publicly and freely available as a teaching tool for industry and agencies Why Monoclonal Antibody? Represents a significant number of products in development Good product and process experience in development and manufacture Slide 4 Outline and Intent of Case Study Content • Structure • Introduction • Quality Attributes • Upstream • Downstream • Drug Product • Control Strategy • Regulatory Intent • Contains pieces/ sections that appear realistic and represent selected QbD principles • Illustrates the benefits of a QbD development approach • Information represents real data or appropriate fictitious data • Not a mock CTD-Q • Not a Gold Standard Slide 5 A-Mab is a Public Document • Publication and Sponsorship – CASSS – ISPE • • • • http://www.casss.org http://www.ispe.org Maintain CMC Working Group interactions Coordinate workshops Develop training Facilitate regulatory interactions Slide 6 Background and Linkage to ICH CMC Biotech Working Group The New Qs underwrite the Quality Paradigm Product and Process Understanding Q8 (R1) Q9, Q10 Q11 Quality Risk Management Pharmaceutical Quality System Q9 Q10 21st Century Quality Paradigm Lower Risk Operations Innovation and Continual Improvement Optimized Change Management Process Enhanced Regulatory Approaches Slide 8 Historical Perspective Historical Perspective • Companies have always used science and risk based processes to develop new products and gain process understanding – But they often did not submit knowledge or information to regulators • Focus on minimum controversy registration, launch and then compliance – Processes became fixed Future Goal • Knowledge management and risk management processes more extensively used, documented and submitted – Intention of clearer communication of product and process understanding • Opportunities for flexibility and post-approval process optimisation – A challenge to do this well – Leads to opportunities Slide 9 Overall Goals of the A-mAb Case Study To illustrate options to achieve enhanced product and process understanding Demonstrate Industry’s vision for QbD as applied to biotech product realisation • Identification of CQAs – Examples of CQA risk ranking tools • • • Use of prior knowledge and platform technologies Risk based approaches Use of DoEs and statistical approaches – To identify CPPs and their linkage to CQAs • • • • Approaches to define and describe Design Spaces Upstream , Downstream and Drug Product Rational approach to defining a Control Strategy that reflects product & process understanding and risk Risk-based, lifecycle approach to managing continual improvement Slide 10 Our Focus is on the key differentiators of QbD (from ICH Q8R1) • An enhanced, quality by design approach to product development would additionally include the following elements: • A systematic evaluation, understanding and refining of the formulation and manufacturing process, including; – Identifying, through e.g., prior knowledge, experimentation, and risk assessment, the material attributes and process parameters that can have an effect on product CQAs; – Determining the functional relationships that link material attributes and process parameters to product CQAs; • Using the enhanced product and process understanding in combination with quality risk management to establish an appropriate control strategy that includes proposals for a design space(s) and/or real-time release testing Slide 11 Linking Product and Process Understanding Animal In-Vitro Studies Studies Input Material Controls High Criticality Attributes Product Quality Attributes 1.Quality attributes to be considered and/or controlled by manufacturing process Criticality Assessment 2. Acceptable ranges for quality attributes to ensure drug safety and efficacy Procedural Controls Process Targets for Quality Attributes Process Development and Characterization Design Space Control Strategy Elements Safety and Efficacy Data Process Controls Process Parameter Controls Testing In-Process Testing Specifications Characterization & Comparability Testing Attributes that do not need to be considered or controlled by manufacturing process Continuous Process Verification Prior Clinical Knowledge Studies Process Monitoring Low Criticality Attributes Product Understanding Process Understanding Slide 12 “Systematic Evaluation” Agitation In Vitro Cell Age Seed Working Volume DO Viability Harvest # of Impellers CO2 Seed Density Temperature Shear/ Mixing Production Bioreactor N-1 Bioreactor Control Parameters Scale Effects pH Nominal Vessel Volumne Design Impeller Design Duration Baffles Procedures Operations Amount Delivered Storage Temperature Pre-filtration hold time Preparation pH Age Pre-filtration hold time Operations Procedures [Antifoam] [NaHCO3] Age Timing Age Procedures Storage Temperature Number of Feeds Concentration Preparation [Glucose] Osmolality Filtration Feed Concentration Medium Glucose Feed Platform Knowledge Tox 500L Optimization DOE I - 2L PhI/PhII 1,000L PhIII 5,000L Optimization DOE II - 2L Prediction Profiler 40 35 Contour Profiler 36 Temperature 70 Dissolved CO2 50 DO Response Productivity aFucosylation Galactosylation Contour 3 11 25 Hi Limit . 11 55 Contour 3 11 25 Current Y 8.951625 7.5034189 32.837639 440 Osmo Lo Limit 3 3 25 100 Feed Strength (Dilution) 18 17.6 94 17.2 92 90 Feed Neutralization 16.8 90 88 86 110 95 105 100 480 90 460 440 420 110 400 95 105 90 100 Current X 37 50 70 3.7 100 100 90 440 17.5 100 Basal Strength (Dilution) 4.3 Split Ratio Current Y Lo Limit Response 8.644125 3 Productivity 6.1354189 3 aFucosylation 32.452376 Galactosylation 25 100 17.3778 Duration Hi Limit . 11 55 100 Contour Profiler Contour Profiler Horiz Vert Factor Temperature 80 DO Dissolved CO2 Split Ratio Basal Strength (Dilution) 60 Feed Strength (Dilution) Feed Neutralization Osmo Duration 40 Response Productivity 400 420 440 aFucosylation Osmo Galactosylation Current Horiz Vert XFactor 35Temperature 80 50 DO 70Dissolved CO2 4.9Split Ratio 100Basal Strength (Dilution) 60 100Feed Strength (Dilution) 90Feed Neutralization 440Osmo 17.5Duration 40 Contour Current Y Lo Limit Hi Limit Response 3 6.896625 . 460 Productivity 480 400 420 3 440 11 6.1244052 3 aFucosylation Osmo 11 25 30.595296 55 Galactosylation 25 Galactosylation 460 Galactosylation 100 3.8 4 4.2 4.4 4.6 4.8 Current Horiz Vert X Factor 35 Temperature 50 DO 70 Dissolved CO2 3.7 Split Ratio 100 Basal Strength (Dilution) 100 Feed Strength (Dilution) 90 Feed Neutralization 440 Osmo 17.5 Duration 70 40 50 60 70 80 90 100 60 50 40 37 30 36 36.5 35 Contour Profiler Horiz Vert Factor Temperature DO Dissolved CO2 Split Ratio Basal Strength (Dilution) Feed Strength (Dilution) Feed Neutralization Osmo Duration 35.5 25 Dissolved CO2 30 80 60 Galactosylation Contour 3 11 25 480 Current X 37 50 70 4.9 100 100 90 440 17.5 Current Y 5.974125 9.5011447 30.980559 Lo Limit 3 3 25 Hi Limit . 11 55 Galactosylation 100 Dissolved CO2 5. Filtration Volume of Feed Dissolved CO2 3. 4. Aggredates Fucosylation Galactosylation CEX AV HCP DNA Time of Feeding Dissolved CO2 2. Use of prior platform knowledge and process risk assessments to identify CQAs and those steps that need additional experimentation. Demonstration that laboratory scale models are representative of the full-scale operations. DOE to determine CPPs & KPPs Linkage of process parameters to product Quality Attributes to create a Design Spaces. Final risk assessment and categorization of process parameters to develop control strategy. Airflow Sparger Design Antifoam Galactosylation 32.02279 ±0.930555 1. Gas Transfer Temperature pH 80 Productivity aFucosylation 60 40 40 400 420 440 Osmo 460 480 400 420 440 460 480 Osmo Slide 13 “Prior knowledge” • Extensive use of prior knowledge and platform technologies – Previous Mabs extensively leveraged to assist in risk assessments • Seed Expansion from frozen WCB to N-1 Bioreactor not critical and not dependent on process format – Use engineering and process characterization to define design space for production bioreactor • Demonstrate that Design Space is valid at multiple scales of operation • Parametric control of selected critical quality attributes Slide 14 Critical Quality Attributes (CQAs) • One of the greatest challenges is identifying CQAs • In the case study, we focus on severity, not process capability – Risk assessment is based on: • prior knowledge (encompasses laboratory to clinic) • nonclinical studies and biological characterization throughout clinical development • clinical experience – Key Decisions: • Assign a Criticality Level (continuum) instead of critical/non-critical • Criticality based on potential impact to safety and efficacy – Key Issues that were discussed: • Is there a cutoff for critical? • What would make critical into non-critical? • Linkage of QA ranking to Control Strategy Slide 15 Risk Assessment Approach used through A-MAb development lifecycle Process 2 Quality Attributes Process 1 2 Life Cycle Management Design Space Prior Knowledge Process Understanding Process Development Process Characterization Product Understanding Draft Control Strategy Process Performance Verification Final Control Strategy Process Parameters Risk Assessment Risk Assessment Risk Assessment Risk Assessment Slide 16 CQA Risk Ranking & Filtering Approach Severity = Impact x Uncertainty • Severity = risk that attribute impacts safety or efficacy • Assess relative safety and efficacy risks using two factors: – Impact and Uncertainty • Impact = impact on safety or efficacy, i.e. consequences – Determined by available knowledge for attribute in question – More severe impact = higher score • Uncertainty = uncertainty that attribute has expected impact – Determined by relevance of knowledge for each attribute – High uncertainty = high score – Low uncertainty = low score Slide 17 Impact Definition & Scale Impact (Scor e) Biological Activity or PK/PDa Immunogenicity Safety Very significant change Significant change on PK ATA detected and confers limits on safety Irreversible AEs High (16) Significant change Moderate change with impact on PD ATA detected and confers limits on efficacy Reversible AEs Moderate (12) Moderate change Moderate change with no impact on PD ATA detected with in vivo effect that can be managed Manageable AEs Low (4) Acceptable change Acceptable change with no impact on PD ATA detected with minimal in vivo effect Minor, transient AEs None (2) No change No impact on PK or PD ATA not detected or ATA detected with no relevant in vivo effect No AEs Very High (20) Efficacya AE = adverse event; ATA = anti-therapeutic antibody aQuantitative criteria should be established for biological activity/efficacy and PK/PD. Significance of the change is assessed relative to assay variability. Uncertainty Definition & Scale Uncertainty (Score) Description (Variants and Host Related Impurities) Description (Process Raw Material) a 7 (Very High) No information (new variant) No information (new impurity) 5 (High) Published external literature for variant in related molecule. --- 3 (Moderate) Nonclinical or in vitro data with this molecule. Data (nonclinical, in vitro or clinical) from a similar class of molecule. Component used in previous processes 2 (Low) Variant has been present in material used in clinical trials. --- 1 (Very Low) Impact of specific variant established in Clinical Studies with this molecule. GRAS or studied in clinical trials GRAS = generally regarded as safe a Assesses the impact of a raw material as an impurity. Impact of the raw material on the product during manufacturing is assessed during process development. Only a Subset of Quality Attributes is Evaluated in the Case Study Attribute Criticality Aggregation 48 Glycosylation 48 Deamidation 4 Oxidation 12 HCP 24 DNA 12 Protein A 12 C-terminal lysine variants (charge variants) 4 High Criticality Impacted by multiple steps in the process Exemplify linkage across multiple unit ops through Design Space and Control Strategy High Criticality Primarily impacted by production BioRx ; no clearance or modification in DS or DP Provide example of Parametric Control Low Criticality Impacted by multiple steps in the process Exemplify linkage to Control Strategy Medium Criticality Impacted by multiple steps in DS but not affected by DP Exemplify linkage to Control Strategy Slide 20 A-Mab Case Study Upstream Process Development CMC Biotech Working Group Upstream Process Thaw Working Cell Bank STEP 1 Seed Culture Expansion in disposable shake flasks and/ or bags Seed Maintenance STEP 2 Seed Culture Expansion in fixed stirred tank reactors Seed Maintenance N-1 Seed Culture Bioreactor 3,000L WV STEP 3 Nutrient Feed Leverage Prior Knowledge with platform process Risk-based approach to demonstrate no impact to product quality Engineering and process characterization to define Design Space and Control Strategy Production Bioreactor 15,000L WV Glucose Feeds STEP 4 Harvest Centrifugation & Depth Filtration Demonstrate that Design Space is applicable to multiple scales of operation Clarified Bulk Lifecycle validation approach that includes continued process verification Slide 22 A-Mab Batch History Process Scale Batches Process 1 500 L 2 Pre-clinical studies 3 Phase 1 & 2 Product/process understanding. 5 Phase 3 Confirm end-to-end process performance. 2 Commercial launch supplies Confirm Design Space and Control Strategy at commercial scale Process 1 Process 2 Process 2 1,000 L 5,000 L 15,000 L Disposition Clinical Exposure Slide 23 Upstream Process Steps 1 & 2: Seed expansion Non-Critical based on Risk Assessment 1. 2. 3. 4. No product is accumulated during seed expansion steps. Prior knowledge with platform process (X-Mab, Y-Mab, and Z-Mab) shows that process performance is consistent and robust Prior knowledge also demonstrates that process is flexible: successful use of multiple formats and scales (shake flasks, cell bags, spinners, bioreactors) Risk Assessments of seed steps up to N-2 stage shows no impact on product quality Seed Culture Steps Product Accumulation Risk of Impact to Product Quality Seed Expansion in Spinner or Shake Flasks Negligible Very Low Seed Expansion in Wave Bag Bioreactor Negligible Very Low Seed Expansion in Fixed Bioreactor Negligible Very Low Seed expansion process is not part of the Design Space and is not included in the registered detail Slide 24 N-1 Seed Impacts Process Performance but NOT Product Quality P-Values Process Parameters N-1 Seed Bioreactor Performance Parameters Production Bioreactor Performance Production Bioreacotr Product Quality Variables Peak VCC % Viab Culture Duration Titer aFucos. Galact. HCP Aggreg. pH 0.03 0.24 0.04 0.001 0.27 0.53 0.63 0.64 0.31 0.25 0.19 0.35 0.77 0.73 0.31 0.49 Temperature 0.02 0.05 0.03 0.005 0.43 0.22 0.23 0.60 pH × Dissolved Oxygen 0.04 0.78 0.65 0.37 0.17 0.78 0.59 0.85 pH × Temperature 0.32 0.26 0.32 0.02 0.98 0.36 0.80 0.36 Dissolved Oxygen × Temperature 0.42 0.86 0.74 0.37 0.80 0.38 0.61 0.26 Dissolved oxygen Seed expansion process is not part of the Design Space and is not included in the registered detail Slide 25 Upstream Process: Production Bioreactor Approach to Define a Design Space Leverage Prior Knowledge and A-Mab Development Experience Data from other MAbs Platform Knowledge A-Mab Data Process 1 Process 1 Tox 500L Ph 1/Ph 2 1,000L Process Development (2L) Ph 3 5,000L Process 2 Slide 26 Example of Risk Assessment Approach to Process Characterization Step 1. Use a Fish-bone (Ishikawa ) diagram to identify parameters and attributes that might affect product quality and process performance Agitation Production Bioreactor N-1 Bioreactor In Vitro Cell Age Seed Seed Density Viability Temperature Shear/ Mixing Working Volume Harvest # of Impellers CO2 DO Control Parameters Scale Effects pH Nominal Vessel Volumne Design Impeller Design Duration Baffles Procedures Gas Transfer Temperature pH Airflow Sparger Design Aggredates Fucosylation Galactosylation CEX AV HCP DNA Antifoam Time of Feeding Filtration Volume of Feed Operations Amount Delivered Storage Temperature Concentration Preparation pH Pre-filtration hold time Procedures Age Number of Feeds Age Operations Procedures Storage Temperature Pre-filtration hold time [Antifoam] [NaHCO3] Age Timing Preparation Osmolality Filtration Feed [Glucose] Glucose Feed Medium Concentration Slide 27 Example of Risk Assessment Approach Step 2: Rank parameters and attributes from Step 1 based on severity of impact and control capability. Identify interactions to include in DOE studies Inoculum Viable Cell Concentr Inoculum Viability Inoculum In Vitro Cell Age N-1 Bioreactor pH N-1 Bioreactor Temperature Osmolality Antifoam Concentration Nutrient Concentration in medium Medium storage temperature Medium hold time before filtration Medium Filtration Medium Age Timing of Feed addition Volume of Feed addition Component Concentration in Feed Timing of glucose feed addition Amount of Glucose fed Dissolved Oxygen Dissolved Carbon Dioxide Temperature pH Culture Duration (days) Remnant Glucose Concentration Risk Mitigation Viability at Harvest Turbidity at harvest Product Yield DNA Process Attributes HCP Deamidation Galactosylation aFucosylation Process Parameter in Production Bioreactor Aggregate Quality Attributes DOE Linkage Studies EOPC Study Linkage Studies Linkage Studies DOE Not Required Potential impact to significantly affect a process attribute such as yield or viability DOE Medium Hold Studies Medium Hold Studies Medium Hold Studies Medium Hold Studies Not Required DOE DOE Potential impact to QA with effective control of parameter or less robust control DOE-Indirect DOE-Indirect DOE DOE DOE DOE DOE DOE-Indirect Slide 28 35 Temperature (C) 50 DO (%) 100 CO2 (%) 6.85 pH 1.2 [Medium] (X) 400 Osmo (mOsm) 12 Feed (X) 1 IVCC (e6 cells/mL) 19 -0.1 .1 .3 .5 .7 18 17 16 440 9 10 11 12 13 14 15 .7 .8 .9 1 1.1 1.2 1.3 15 420 400 380 1.6 360 1.4 1.2 1 7.1 .8 7 6.9 6.8 6.7 70 40 60 80 100 120 140 160 6.6 60 50 40 36 30 35.5 35 34.5 34 Aggregates (%) 2.515119 ±0.03524 CEX % Acidic Variants 27.66898 ±0.480814 DNA (ppm) 1935.343 ±89.55908 HCP (ppm) Galactosylation aFucosylation 695538 (%) 6.439933 ±16518.3 29.28939 ±0.226948 ±0.674582 Titer (g/L) 3.743131 ±0.076052 DOE Studies to Define Design Space: Identify CPPs and Interactions Example of DOE Results Prediction Profiler 5 4 3 8 6 4 32 28 24 1e+6 8e+5 6e+5 4e+5 2500 2000 1500 32 28 3.0 24 2.6 2.2 1.8 17 Duration (d) 0.21 Curvature 29 Classification of Process Parameters based on Risk Assessment Process Parameter Within Design Space Regulatory-Sensitive Yes High Risk Risk Assessment Severity of Impact, ability to control within Design Space Not in Design Space Managed through QMS Risk Assessment Does variability in parameter significantly impact CQAs No Risk Assessment Low Risk No Does variability in parameter impact process performance or consistency? Yes Critical Process Parameter (CPP) Well Controlled Critical Process Parameter (WC-CPP) High Risk Key Process Parameter (KPP) Risk Assessment Severity of Impact, ability to control within acceptable ranges Low Risk General Process Parameter (GPP) Slide 30 Control Strategy for Upstream Production Quality-linked Process Parameters (WC-CPPs) Key Process Parameters (KPPs) Temperature Time Temperature pH Dissolved CO2 Culture Duration Osmolality Remnant Glucose Working Cell Bank Step 1 Seed Culture Expansion in Disposable Shake Flasks and/or bags Viable Cell Concentration Viability Temperature pH Dissolved Oxygen Culture Duration Initial VCC/Split Ratio Step 2 Seed Culture Expansion in Fixed Stirred Tank Bioreactors Viable Cell Concentration Viability Antifoam Concentration Time of Nutrient Feed Volume of Nutrient Feed Time of Glucose Feed Volume of Glucose Feed Dissolved Oxygen Step 3 Production Culture Step 4 Centrifugation and Depth Filtration Clarified Bulk In-Process Quality Attributes Viable Cell Concentration Viability Temperature Culture Duration Initial VCC/Split Ratio Flow Rate Pressure Controlled within the Design Space to ensure consistent product quality and process performance Key Process Attributes Product Yield Viability at Harvest Turbity at Harvest Bioburden MMV Mycoplama Adventitious Virus Product Yield Turbidity Controlled within acceptable limits to ensure consistent process performance Assay results part of batch release specifications Slide 31 Define Engineering Design Space for Production Bioreactor Analogous to the design space defined by scaleindependent parameters, the engineering design space is a multidimensional combination of bioreactor design characteristics and engineering parameters that provide assurance that the production bioreactor performance will be robust and consistent and will meet product quality targets Slide 32 Engineering Design Space Design Space applicability to multiple operation scales demonstrated using PCA/MVA models 500 L – 25,000 L Randal All en Design Space for scaleindependent parameters was developed using qualified scaledown models 2L Scale Engineering Design Space includes bioreactors of multiple scales and designs (2L -25K L) Based on keeping microenvironment experienced by cells equivalent between scales Characterization of bioreactor design, operation parameters, control capabilities, product quality and cell culture process performance provide basis for scientific understanding of the impact of scale/design Includes bioreactor design considerations and scale-dependent process parameters linked to fluid dynamics and mass transfer Slide 33 Lifecycle Approach to Validation 1. Multivariate model based on process characterization (e.g. DOE) - Model 1 A comprehensive Design Space based on 2-L characterization studies as well as 500L, and 5000L experience for A-Mab. Includes scale-independent operational parameters: iVCC, temp, pH, pCO2 etc 2. Design Space for Scale-up, based on BioRx engineering parameters- Model 2 Based on engineering characterization and DOE studies. Establish 2L as a reliable model system by: a) Establishing hydrodynamic similarity and ensuring appropriate equipment design and operation; b) Establishing scalability through demonstration of overlapping performance of either scale in a MVA model that includes process inputs, outputs and product quality – for previous aMAb product (Model 3) 3. Demonstration of scalability and Design Space for A-Mab by execution of 2 batches at the intended commercial scale (15K) 4. Use process monitoring during routine manufacturing for continuous verification that process is in state of control Build MVA model for A-Mab; define acceptance criteria Slide 34 Case Study Downstream Process and Drug Product CMC Biotech Working Group Downstream Process Clarified Bulk Leverages Prior Knowledge with platform process to define Design Space Leverages prior knowledge and A-Mab results to justify a modular approach to viral clearance Justification of two process changes post-launch : 1. Change resin for Protein A 2. Change from resin to membrane format for AEX Step 5 Protein A Affinity Chromatography Step 6 Low pH Incubation Step 7 Cation Exchange Chromatography Step 8 Anion Exchange Chromatography Step 9 Small Virus Retentive Filtration Step 10 Formulation: Ultrafiltration and Diafiltraion Step 11 Final Filtration, Fill and Freeze Design Space based on worst case scenario for AMab stability and worst case for viral inactivation Design Space based on multivariate model that links all three purifications steps (Protein A, AEX and CEX) A-mAb Slide 37 Multi-step Design Space for Chromatography Columns • Design Space is defined based on model that links performance of the 3 purification steps – HCP clearance example • Model based on results of individual DOE studies • No extrapolation of parameters outside ranges tested allowed in design space • No interaction of parameters from different steps assumed. – Assumption was experimentally verified. • 99.5% prediction interval added to mean predicted HCP levels – To reflect high level of assurance specifications will be met if process operated in design space. Slide 38 Protein A CEX 6 5 4 3 10 20 30 40 50 10 Protein A 30 20 30 1.6 7.2 40 5 4 50 10 15 20 25 3.6 2.6 1.6 30 7.2 Equil Wash Conductivity 5 4 Protein Load 20 7.6 7.8 AEX 6 15 7.4 Load pH 7 10 7.8 4.6 Protein Load 50 7.6 5.6 CEX 40 7.4 AEX 3 10 2.6 Load pH 6 Protein A 3.9 3.8 3.7 3.6 3.5 3.4 3.3 3.2 3.6 30 3 20 4.6 CEX Wash Conductivity Elution pH 25 7 Protein Load Full range on axis is range explored in DOE 20 Equil Wash Conductivity 3.9 3.8 3.7 3.6 3.5 3.4 3.3 3.2 10 Case 3: If full range allowed in Protein A and AEX, CEX is constrained 15 5.6 Protein Load Wash Conductivity Elution pH Protein Load Case 2: Constraining Protein A and CEX ranges allows full ranges for AEX AEX 7 Equil Wash Conductivity 3.9 3.8 3.7 3.6 3.5 3.4 3.3 3.2 Wash Conductivity Case 1: If full range allowed in Protein A and CEX, AEX is constrained Elution pH Acceptable range for each step depends on acceptable ranges for other two steps 25 Protein Load 30 5.6 4.6 3.6 2.6 1.6 7.2 7.4 7.6 Load pH Acceptable Range Slide 39 7.8 Drug product process steps exemplifying QbD supported by optimized formulation design A-Mab Drug Substance Step 1 Step 2 Drug substance preparation/handling Compounding Step 3 Sterile filtration Step 4 Filling, stoppering and Capping Packaged A-Mab Drug Product Design spaces Multiple or single lots/container Frozen or unfrozen Unclassified or class 100,000 50-1500 L Stir time Hold time Tank configuration 50-1500 L Hold time Filter configuration Risk Assessment Design Space Control Strategy Reservoir pressure Pumping configuration Capper spring pressure 40 A- Mab Case Study Control Strategy CMC Biotech Working Group Control Strategy: Linking Product and Process Understanding Animal In-Vitro Studies Studies Input Material Controls High Criticality Attributes Product Quality Attributes 1.Quality attributes to be considered and/or controlled by manufacturing process Criticality Assessment 2. Acceptable ranges for quality attributes to ensure drug safety and efficacy Procedural Controls Process Targets for Quality Attributes Process Development and Characterization Design Space Control Strategy Elements Safety and Efficacy Data Process Controls Process Parameter Controls Testing In-Process Testing Specifications Characterization & Comparability Testing Attributes that do not need to be considered or controlled by manufacturing process Continuous Process Verification Prior Clinical Knowledge Studies Process Monitoring Low Criticality Attributes Product Understanding Process Understanding Slide 42 Control Strategy is based on a final Risk Assessment for each CQA Overall CQA Risk Assessment RPN = CQA Criticality Assessment X Process Capability X Testing Strategy Severity Occurrence Detectability Risk Assessment Risk Assessment In-Process Controls RPN = SxOxD Specifications Severity of Impact x Certainty Design Space Categorization of Process Parameters Slide 43 Example of Control Strategy for selected CQAs CQA Criticality Process Capability Testing Spec Limits Other Control Elements Aggregate High (48) High Risk DS and DP release Yes Parametric Control of DS/DP steps aFucosylation High (48) Low Risk DS Process Monitoring Yes Parametric Control of Production BioRx Very Low Risk Charact. Comparability Yes Parametric Control of Prod BioRx, ProA, pH inact, CEX , AEX steps Yes Parametric Control of Prod Biox and AEX Steps No Parametric Control of Production BioRx Host Cell Protein High (24) DNA High (24) Very Low Risk Charact. Comparability Deamidated Isoforms Low (12) Low Risk Charact. Comparability From A-Mab Case Study www.casss.org Drug Substance & Product Release Testing is Only one Element of Control Strategy Example: Drug Substance Release Testing Attribute Test Acceptance Criteria Release Stability Identity CEX Consistent with Ref Std and No New Peaks Yes No Monomer HPSEC NLT 97% Yes Yes Aggregates HPSEC NMT 3% Yes Yes Endotoxin (LAL) USP <85> NMT 12.5 EU/mL Yes No Reduced testing in comparison with traditional approaches Slide 45 A-Mab Case Study Regulatory Considerations CMC Biotech Working Group Regulatory Aspects of the Case Study • Objectives of the Regulatory section of the case study: – Describe information that is provided in the filing to convey process & product understanding -vs- license commitments – Describe how elements not covered by license commitments will be addressed in the Quality System – Describe how development and monitoring of process knowledge throughout the product’s lifecycle will differ from traditional process validation activities and lead to continued improvement – Propose a general risk-based approach for managing post-approval changes within and outside the design space and provide specific examples Slide 47 Linking Product and Process Understanding to Regulatory Commitments & Process Lifecycle Quality Attributes Life Cycle Managemen t Design Space Prior Knowledge Process Understanding Process Development Process Characterization Product Understanding Draft Control Strategy Process Performance Verification Final Control Strategy BLA/MAA Process Parameters Risk Assessment Risk Assessment Risk Assessment Risk Assessment The regulatory filing presents a summary of the risk assessment methodology and accumulated process & product knowledge Regulatory commitments are the critical elements of the overall control strategy developed based on the outcomes of the overall risk assessments The overall approach to risk-based process management becomes the basis for lifecycle and change management Design space controls In-process tests Lot release tests Stability commitments Slide 48 Justification of the Design Space • The overall knowledge that justifies the Design Space is based on – Product and process specific knowledge – Historical and platform data • Summary of the knowledge that justifies the outcomes of the risk assessment and the limits for design space will be presented in the Process Development History section – Conclusions will be supported by process characterization reports available upon request or inspection • The design space may be applied across many scales, or pieces of equipment (different bioreactors, columns of different widths), provided data sufficient justification is provided in the application • The design space is not “validated” at manufacturing scale in the traditional sense Slide 49 Lifecycle Approach to Process Validation • Begins during development and continues post-launch • Builds on knowledge from multiple scales • Departure from the traditional 3-batch validation approach prior to submission – Process validation encompasses cumulative knowledge – Includes continued process verification • To demonstrate validity of Design Space • To maintain validity of models Slide 50 Lifecycle Management of Process Improvements & Changes • Movements within the design space are managed without regulatory notification • Changes outside the design space will involve a regulatory action – From notification to pre-approval depending on risk assessment • Specific examples addressed in case study – – – – Scale-up of production culture Replace new chromatography resin with similar from same vendor Replace new chromatography resin with new technology (membrane) Manufacturing Site Changes for DS and DP Slide 51 Assessing Change: Scope of Change is Initially Assessed at the Unit Operation Level Movement w/in approved DS Output from previous step Unchanged MATERIAL INPUTS (Vendor, Scale, Technology) Changed DS Parameters Unchanged Outputs from previous step & other material inputs Same Minor Change Major change Major change Design Space Parameters Same Same, Data not in original filing New New Step Outputs Same Same Same New DS Parameters Changed Output Output Changes outside approved DS Output Degree to which outputs overlap denotes risk associated with change Risk Changes which represent more risk drive more extensive data collection Slide 52 Quality by Design Questions to Consider Seed Seed Density Viability Temperature Working Volume Harvest # of Impellers CO2 DO Control Parameters Scale Effects pH Nominal Vessel Volumne Design Impeller Design Duration Baffles Procedures Gas Transfer Temperature pH Airflow Sparger Design Aggredates Fucosylation Galactosylation CEX AV HCP DNA Antifoam Contour Profiler Horiz Vert Factor Temperature DO Dissolved CO2 Split Ratio Basal Strength (Dilution) Feed Strength (Dilution) Feed Neutralization Osmo Duration Filtration Current Horiz Vert X Factor 35 Temperature 50 DO 70 Dissolved CO2 3.7 Split Ratio 100 Basal Strength (Dilution) 100 Feed Strength (Dilution) 90 Feed Neutralization 440 Osmo 17.5 Duration Response Productivity aFucosylation Galactosylation Contour 3 11 25 Current Y Lo Limit Response 8.644125 3 Productivity 6.1354189 3 aFucosylation 32.452376 Galactosylation 25 100 Current X 37 50 70 3.7 100 100 90 440 17.5 Hi Limit . 11 55 Contour 3 11 25 Current Y 8.951625 7.5034189 32.837639 Volume of Feed Operations Amount Delivered Storage Temperature Concentration Preparation pH Age Lo Limit 3 3 25 Hi Limit . Feed 11 55 Number of Feeds Pre-filtration hold time Procedures Age Operations Procedures Storage Temperature Pre-filtration hold time [Antifoam] [NaHCO3] Age Timing Preparation [Glucose] Osmolality Filtration Glucose Feed Medium Concentration 100 Contour Profiler Contour Profiler Horiz Vert Factor Temperature 80 DO Dissolved CO2 Split Ratio Basal Strength (Dilution) 60 Feed Strength (Dilution) Feed Neutralization Osmo Duration 40 Response Productivity 400 420 440 aFucosylation Osmo Galactosylation Current Horiz Vert XFactor 35Temperature 80 50 DO 70Dissolved CO2 4.9Split Ratio 100Basal Strength (Dilution) 60 100Feed Strength (Dilution) 90Feed Neutralization 440Osmo 17.5Duration 40 Contour Current Y Lo Limit Hi Limit Response 3 6.896625 . 460 Productivity 480 400 420 3 440 11 6.1244052 3 aFucosylation Osmo 11 25 30.595296 55 Galactosylation 25 Galactosylation 460 Galactosylation 100 Time of Feeding Contour Profiler Dissolved CO2 • Agitation In Vitro Cell Age Shear/ Mixing Production Bioreactor N-1 Bioreactor 80 60 Galactosylation Contour 3 480 11 25 Current X 37 50 70 4.9 100 100 90 440 17.5 Current Y 5.974125 9.5011447 30.980559 Lo Limit 3 3 25 Hi Limit . 11 55 Galactosylation 100 Dissolved CO2 • Dissolved CO2 • How can we maximize the benefits to the industry and other stakeholders? How can we ensure that this will speed up development and reduce the investment for process and product development? QbD may be implemented in parts or as part of a development philosophy. How can this be implemented during early development? What is the best way to ensure that smaller enterprises can benefit from the work going on with QbD and facilitate innovation? Dissolved CO2 • 80 Productivity aFucosylation 60 40 40 400 420 440 Osmo 460 480 400 420 440 460 480 Osmo Slide 53 What are Biosimilars? • Biosimilars – Are biological products that claim to be similar to an innovator biological product – The innovator’s product is off-patent and no regulatory data protection remains – Are manufactured by a second manufacturer with new cell line, new process and new analytical methods – Require original data for approval EMEA Approach for Biosimilar Medicines: Guideline on Similar Biological Medicinal Products (CHMP/437/04) • Overall Approach – Similar biological medicinal products are not generic medicinal products – Comparability studies need to demonstrate the similar nature in terms of quality, safety, and efficacy • Biosimilars will be different from the reference – It is not expected that the quality attributes in the biosimilar and reference product will be identical – The biosimilar product may exhibit a different safety profile (in terms of nature, seriousness, or incidence of adverse reactions) US Definition of Biosimilarity • Biosimilarity – The biological product is highly similar to the reference product not withstanding minor differences in clinically inactive components – There are no clinically meaningful differences between the biological product and the reference product in terms of the safety, purity, and potency of the product. Criteria for Biosimilar EU US – BPCA • Similar nature to reference product based on: • – Quality – Safety – Efficacy • Should be similar in molecular and biological terms • Pharmaceutical form, strength, and route should be the same or if different additional data should be provided • Class specific guidelines are referenced Highly similar to reference product based on: – Analytical studies – Animal studies – Clinical study or studies • • • • • Utilizes same mechanism of action Conditions of use have been approved Route of administration, dosage form, and strength are the same Not all data elements may be necessary Allows for a determination of interchangeability US Definition of Interchangeability • The biological product may be substituted for the reference product without the intervention of the health care provider • Determination of Interchangeability – Finding of biosimilarity and expectation to produce the same clinical result in any patient – For a product that is administered more than once • The risk in terms of safety or diminished efficacy of alternating or switching between use of the biological product and the reference product is not greater than using the reference product alone Specification Limits Vs. Control Limits Differentiate Specification Limits from Control Limits Based on process capability to provide assurance of process consistency Regulatory Commitment Managed through QMS Design Space enabled Process Improvements enabled Process Monitoring Continued Process Verification Product Understanding Process Understanding Design Space Control Limits Control Space Specification Limits Based on clinical relevance to provide assurance of safety and efficacy CQA 1 CQA 2 CQA 3 Specifications are linked to clinical relevance not process capability Changes in specifications during product lifecycle reflect improved understanding of relationship between product and clinical relevance From Ilse Blumentals, GSK Step 2: Consider Impact to Other Unit Operations and Requirements for Extended Characterization Movement in approved DS Change outside approved DS Outputs from previous step & other material inputs Same Minor Change Major change Major change Major change Design Space Parameters Same Same, Data not in original filing New New New Step Outputs Other Unit Operations Affected Meets IP & Lot Release Criteria Same Minor Changes New New ReportingSame requirements are based on the reassessment by Multiple the Single Single Singleof risk posed Multiple change including results of new Yes Yes Yes Lot release met, Lot release some IPCs met, some design and testing if necessary changed IPCs changed Comparability required __________________ Results Observed no no Yes, __________ No changes Yes __________ minor changes Yes __________ new peaks Supportive non-clin/clin data no no no maybe Yes Reporting Requirement No Reporting Notification Pre-approval Slide 66