MSE 352

advertisement

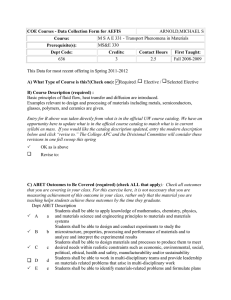

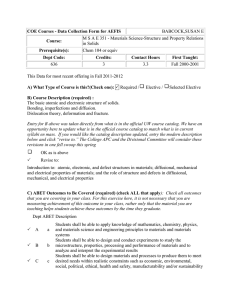

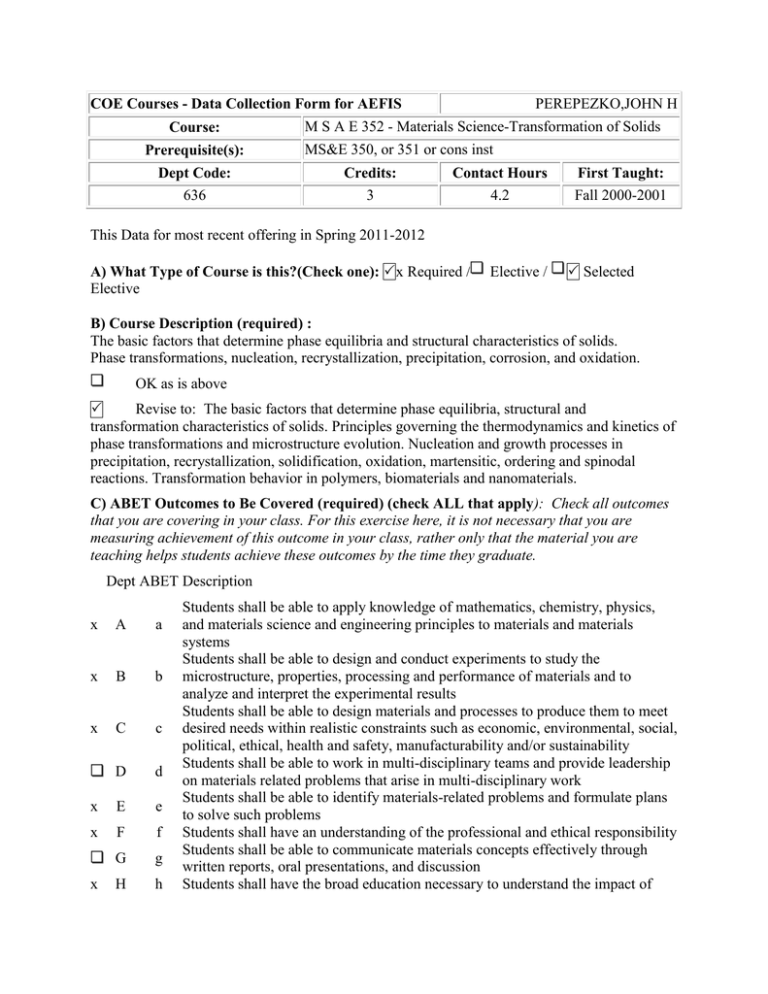

PEREPEZKO,JOHN H COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 636 M S A E 352 - Materials Science-Transformation of Solids MS&E 350, or 351 or cons inst Credits: 3 Contact Hours 4.2 First Taught: Fall 2000-2001 This Data for most recent offering in Spring 2011-2012 A) What Type of Course is this?(Check one): x Required / Elective Elective / Selected B) Course Description (required) : The basic factors that determine phase equilibria and structural characteristics of solids. Phase transformations, nucleation, recrystallization, precipitation, corrosion, and oxidation. OK as is above Revise to: The basic factors that determine phase equilibria, structural and transformation characteristics of solids. Principles governing the thermodynamics and kinetics of phase transformations and microstructure evolution. Nucleation and growth processes in precipitation, recrystallization, solidification, oxidation, martensitic, ordering and spinodal reactions. Transformation behavior in polymers, biomaterials and nanomaterials. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Check all outcomes that you are covering in your class. For this exercise here, it is not necessary that you are measuring achievement of this outcome in your class, rather only that the material you are teaching helps students achieve these outcomes by the time they graduate. Dept ABET Description x A a x B b x C c D d x E e x F f G g H h x Students shall be able to apply knowledge of mathematics, chemistry, physics, and materials science and engineering principles to materials and materials systems Students shall be able to design and conduct experiments to study the microstructure, properties, processing and performance of materials and to analyze and interpret the experimental results Students shall be able to design materials and processes to produce them to meet desired needs within realistic constraints such as economic, environmental, social, political, ethical, health and safety, manufacturability and/or sustainability Students shall be able to work in multi-disciplinary teams and provide leadership on materials related problems that arise in multi-disciplinary work Students shall be able to identify materials-related problems and formulate plans to solve such problems Students shall have an understanding of the professional and ethical responsibility Students shall be able to communicate materials concepts effectively through written reports, oral presentations, and discussion Students shall have the broad education necessary to understand the impact of x x I i J j K k materials science and engineering solutions in a global, economic, environmental, and societal context Students shall have the materials science and engineering foundation needed to succeed in materials science and engineering graduate programs, to pursue other forms of continuing education in materials science and engineering, and to engage in life-long learning of materials science and engineering Students shall have an awareness of contemporary and cultural issues Students shall be able to use the techniques, skills, and modern materials science and engineering tools necessary to practice materials science and engineering as a professional D) Default Specific Course Outcomes (required): •Fluency in the kinetics and thermodynamics of phase reactions used for understanding microstructural evolution during phase transformations.. •Fluency and breadth in foundational tools of materials science and engineering as a basis for subsequent courses. E) Textbook (required): Class notes-prepared by instructor. F) Supplemental Material (optional): "Phase Transformations in Metals and Alloys”, D. A. Porter and K. E. Easterling, Chapman & Hall (Second Edition (1992). “Physical Metallurgy Principles”, R. E. Reed-Hill, and R. Abbaschian (Third Edition) PWS-Kent (1992). "Materials Principles and Practice", C. Newey and G. Weaver, Butterworths (1990). "Fundamentals of Physical Metallurgy”, J. D. Verhoeven, J. W. Wiley (1972). Additional notes, homework problems and solutions are posted on course E-COW2 site. G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Dislocation energetic and dynamics Diffusion analysis/multiphase alloys Driving force and mobility Diffusion in glasses and nonmetallic systems Interface equilibrium and migration Nucleation behavior and kinetics Crystal growth/ Alloy solidification Recrystallization Thermodynamics of phase equilibria Spinodal decomposition Ordering reactions Martensite reactions/ shape memory effect Transitions in biomaterials Nanomaterial reactions COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 636 PEREPEZKO,JOHN H M S A E 463 - Materials for Elevated Temperature Service Cons inst or Sr st Credits: 3 Contact Hours 2.5 First Taught: Fall 2000-2001 This Data for most recent offering in Fall 2010-2011 A) What Type of Course is this?(Check one): Required /x Elective / Selected Elective B) Course Description (required) : Mechanical behavior of metals, cermets, and other nonmetallic materials considering composition, structure, environment, and service conditions; structural stability; creep and stressrupture. . Entry for B above was taken directly from what is in the official UW course catalog. We have an opportunity here to update what is in the official course catalog to match what is in current syllabi en mass. If you would like the catalog description updated, entry the modern description below and click “revise to.” The College APC and the Divisional Committee will consider these revisions in one fell swoop this spring OK as is above x Revise to: The design, properties, processing and selection of high temperature materials for structural applications. The fundamentals of diffusion, phase transformations, dislocation motion and oxidation governing the high temperature mechanic properties and structural performance of metallic and ceramic materials. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Check all outcomes that you are covering in your class. For this exercise here, it is not necessary that you are measuring achievement of this outcome in your class, rather only that the material you are teaching helps students achieve these outcomes by the time they graduate. Dept ABET Description Students shall be able to apply knowledge of mathematics, chemistry, physics, x A a and materials science and engineering principles to materials and materials systems Students shall be able to design and conduct experiments to study the x B b microstructure, properties, processing and performance of materials and to analyze and interpret the experimental results Students shall be able to design materials and processes to produce them to meet x C c desired needs within realistic constraints such as economic, environmental, social, political, ethical, health and safety, manufacturability and/or sustainability D d Students shall be able to work in multi-disciplinary teams and provide leadership x E e F f x G g x H h x I i J j K k x on materials related problems that arise in multi-disciplinary work Students shall be able to identify materials-related problems and formulate plans to solve such problems Students shall have an understanding of the professional and ethical responsibility Students shall be able to communicate materials concepts effectively through written reports, oral presentations, and discussion Students shall have the broad education necessary to understand the impact of materials science and engineering solutions in a global, economic, environmental, and societal context Students shall have the materials science and engineering foundation needed to succeed in materials science and engineering graduate programs, to pursue other forms of continuing education in materials science and engineering, and to engage in life-long learning of materials science and engineering Students shall have an awareness of contemporary and cultural issues Students shall be able to use the techniques, skills, and modern materials science and engineering tools necessary to practice materials science and engineering as a professional D) Default Specific Course Outcomes (required): These are things in addition to A-K above that would appear in your syllabus on opening day as the things you want the students to learn, for example, for MSE 360: hands-on skills in quantitative metallography. You might list three or four and they might look like technical in nature and should be consistent with the course description. Students shall develop a perspective on high temperature materials in terms of their design, properties, processing and selection for structural applications Fluency with an integrated analysis of several phenomena (e.g. diffusion, phase transformations, dislocation motion oxidation, etc.) that is necessary in order to account for high temperature material behavior and performance. E) Textbook (required): Give title, author last name(s), edition “Heat-Resistant Materials”, J.R. Davis , ASM International (1997). F) Supplemental Material (optional): “ Superalloys II” C.T. Sims, N.S. Stoloff and W.C. Hagel, J.Wiley, 1987 Additional notes posted on course E COW2 site G) Brief Topics to be covered in Addition to B) and any Additional Information (required): for example, field trip to local manufacturing plant is required. Elevated-Temperature Characteristics of Engineering Materials Corrosion at elevated temperature Superalloys: processing and heat treatment Coatings Elevated temperature titanium, refractory metal and intermetallic alloys Ceramic and carbon/carbon composites Elevated temperature mechanical properties Materials design for high temperature service COE Courses - Data Collection Form for AEFIS Course: Prerequisite(s): Dept Code: 636 PEREPEZKO,JOHN H M S A E 465 - Fundamentals of Heat Treatment Sr st Credits: 3 Contact Hours 2.5 First Taught: Fall 2001-2002 This Data for most recent offering in Fall 2006-2007 A) What Type of Course is this?(Check one): Required /x Elective / Selected Elective B) Course Description (required) : Principles of transformations, heat transfer, heat treatment, and mechanical properties as applied to ferrous metallurgical design. Entry for B above was taken directly from what is in the official UW course catalog. We have an opportunity here to update what is in the official course catalog to match what is in current syllabi en mass. If you would like the catalog description updated, entry the modern description below and click “revise to.” The College APC and the Divisional Committee will consider these revisions in one fell swoop this spring OK as is above x Revise to: Principles of phase transformations, heat transfer and mechanical properties as applied to heat treatment practice. The design, modeling and analysis of heat treatment processes. C) ABET Outcomes to Be Covered (required) (check ALL that apply): Check all outcomes that you are covering in your class. For this exercise here, it is not necessary that you are measuring achievement of this outcome in your class, rather only that the material you are teaching helps students achieve these outcomes by the time they graduate. x x x x Dept ABET Description Students shall be able to apply knowledge of mathematics, chemistry, physics, A A and materials science and engineering principles to materials and materials systems Students shall be able to design and conduct experiments to study the B B microstructure, properties, processing and performance of materials and to analyze and interpret the experimental results Students shall be able to design materials and processes to produce them to meet C C desired needs within realistic constraints such as economic, environmental, social, political, ethical, health and safety, manufacturability and/or sustainability Students shall be able to work in multi-disciplinary teams and provide leadership D D on materials related problems that arise in multi-disciplinary work E E Students shall be able to identify materials-related problems and formulate plans F F x G G x H h x I i J j K k x to solve such problems Students shall have an understanding of the professional and ethical responsibility Students shall be able to communicate materials concepts effectively through written reports, oral presentations, and discussion Students shall have the broad education necessary to understand the impact of materials science and engineering solutions in a global, economic, environmental, and societal context Students shall have the materials science and engineering foundation needed to succeed in materials science and engineering graduate programs, to pursue other forms of continuing education in materials science and engineering, and to engage in life-long learning of materials science and engineering Students shall have an awareness of contemporary and cultural issues Students shall be able to use the techniques, skills, and modern materials science and engineering tools necessary to practice materials science and engineering as a professional D) Default Specific Course Outcomes (required): •Students shall be able to identify the reasons that given heat treatments are employed. • Fluency in basic principles governing the effect of heat treatment on the microstructure and properties of materials E) Textbook (required): Give title, author last name(s), edition “Heat Treating” Metals Handbook, vol4, 10th Edition (Materials Park, OH) F) Supplemental Material (optional): Additional notes posted on course E COW2 site G) Brief Topics to be covered in Addition to B) and any Additional Information (required): Materials Selection/review Heat treatment principles Specific ferrous heat treatment processes Thermomechanical processing Surface treatment Computational modeling Statistical process control Heat treatment of metallic and ceramic materials