Frequency control (MW-Hz) with wind

advertisement

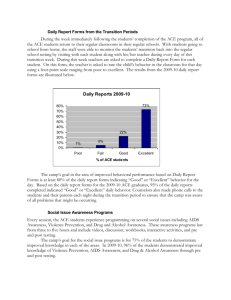

Frequency control (MW-Hz) with wind Wind Generation Technology Short Course October 27, 2010 Iowa State University James D. McCalley Harpole Professor of Electrical & Computer Engineering 1 Outline 1. 2. 3. 4. 5. 6. 7. MW-Hz time frames Transient frequency control Frequency governing CPS1, CPS2 Simulations Solutions Conclusions 2 MW-Hz Time Frames 0+<t<2s; Inertial t=0+; Proximity 2s<t<10s; Speed-governors 3 10s<t<5m; AGC 5m, ED MW-Hz Time Frames This is load decrease, shown here as a gen increase. 4 Source: FERC Office of Electric Reliability available at: www.ferc.gov/EventCalendar/Files/20100923101022-Complete%20list%20of%20all%20slides.pdf MW-Hz Time Frames = 100 80 REGULATION IN MEGAWATTS 60 + 40 20 0 -20 -40 -60 -80 -100 07:00 07:20 07:40 08:00 08:20 08:40 09:00 09:20 09:40 10:00 Regulation Load Following Regulation 5 Source: Steve Enyeart, “Large Wind Integration Challenges for Operations / System Reliability,” presentation by Bonneville Power Administration, Feb 12, 2008, available at http://cialab.ee.washington.edu/nwess/2008/presentations/stephen.ppt. Transient frequency control What can happen if frequency dips too low? • For f<59.75 Hz, underfrequency relays can trip load. • For f<59 Hz, loss of life on turbine blades • Violation of NERC criteria with penalties • N-1: Frequency not below 59.6 Hz for >6 cycles at load buses • N-2: Frequency not below 59.0 Hz for >6 cycles at load buses 6 Transient frequency control Frequen cy(Hz) 60 d f PL f Re mf n dt 2 H i t 1 mf1 60-mf1t1 60-mf2t1 i 1 Time (sec) mf2 mf3 60-mf3t1 The greater the rate of change of frequency (ROCOF) following loss of a generator ∆PL, the lower will be the frequency dip. ROCOF increases as total system inertia ΣHi decreases. Therefore, frequency dip increases as ΣHi decreases. 7 Transient frequency control Example: Ireland: ∆PL =432 MW=4.32 pu. ΣHi =475 sec 2.75 sec Nadir 1. Governors 2. Load frequency sensitivity 49.35 mf PL f Re d f 4.32(50) 0.227 Hz / sec n dt 2 * 475 2 H i i 1 50-0.227*2.75=49.38Hz 8 Transient frequency control Example: Estrn Interconnection: ∆PL =2900 MW=29 pu. ΣHi =32286 sec mf PL f Re d f n dt 2 H i i 1 59.9828 Hz 29(60) 0.0269 Hz / sec 2 * 32286 60-0.0269*1.5=59.9597Hz Nadir 59.9725z 9 Transient frequency control So what is the issue with wind….? 1. Increasing wind penetrations tend to displace (decommit) conventional generation. 2. DFIGs, without specialized control, do not contribute inertia. This “lightens” the system d f P f L Re mf (decreases denominator) n dt 2 H i i 1 Let’s see an example…. 10 Transient frequency control • • • • Green: Base Case Dark Blue: 2% Wind Penetration Light Blue: 4% Wind Penetration Red: 8% Wind Penetration Estrn Interconnection: Frequency dip after 2.9GW Gen drop for Unit DeCommitment scenario at different wind penetration levels (0.6, 2, 4, 8%) 11 Transient frequency control Why do DFIGs not contribute inertia? They do not decelerate in response to a frequency drop. Fuel supply control Steam valve control Generator Steam Boiler FUEL STEAMTURBINE MVARvoltage control CONTROL SYSTEM Generator Wind speed WINDTURBINE Gear Box Real power output control MVARvoltage control CONTROL SYSTEM 12 The ability to control mech torque applied to the generator using pitch control & electromagnetic torque using rotor current control (to optimize Cp and to avoid gusting) enables avoidance of mismatch between mechanical torque and electromagnetic torque and, therefore, also avoidance of rotor deceleration under network frequency decline. Transient frequency control What is the fix for this? Consider DFIG control system 13 Source: J. Ekanayake, L. Holdsworth, and N. Jenkins, “Control of DFIG Wind Turbines,” Proc. Instl Electr. Eng., Power Eng., vol. 17, no. 1, pp. 28-32, Feb 2003. Transient frequency control Add “inertial emulation,” a signal dω/dt scaled by 2H -2H dω / dt 14 Transient frequency control Several European grid operators have imposed requirements on wind plants in regards to inertial emulation, including Nordic countries [1,2]. North American interconnections have so far not imposed requirements on wind farms in regards to frequency contributions, with the exception of Hydro-Quebec. The Hydro-Quebec requirement states [3, 4], “The frequency control system must reduce large, short-term frequency deviations at least as much as does the inertial response of a conventional generator whose inertia (H) equals 3.5 sec.” 15 [1] “Wind Turbines Connected to Grids with Voltages above 100 kV – Technical Regulation for the Properties and the Regulation of Wind Turbines, Elkraft System and Eltra Regulation, Draft version TF 3.2.5, Dec., 2004. [2] “Nordic Grid Code 2007 (Nordic Collection of Rules), Nordel. Tech. Rep., Jan 2004, updated 2007. [3] N. Ullah, T. Thiringer, and D. Karlsson, “Temporary Primary Frequency Control Support by Variable Speed Wind Turbines – Potential and Applications,” IEEE Transactions on Power Systems, Vol. 23, No. 2, May 2008. [4] “Technical Requirements for the Connection of Generation Facilities to the Hydro-Quebec Transmission System: Supplementary Requirements for Wind Generation,” Hydro Quebec, Tech. Rp., May 2003, revised 2005. β, Frequency Governing Characteristic, β “If Beta were to continue to decline, sudden frequency declines due to loss of large units will bottom out at lower frequencies, and recoveries will take longer.” Source: J. Ingleson and E. Allen, “Tracking the Eastern Interconnection Frequency 16 Governing Characteristic,” Proc. of the IEEE PES General Meeting, July 2010. Reasons for decrease in β • Fossil-steam plant changes, motivated to increasing economic efficiency: • Use of larger governor deadband settings, exceeding the historical typical setting of ±36 millihertz (mHz); • Use of steam turbine sliding pressure controls; • Loading units to 100 percent of capacity leaving no “headroom” for response to losses of generation; • Blocked governor response (nuclear licensing may also cause this); • Use of once-through boilers; • Gas Turbine inverse response; • Changes in the frequency response characteristics of the load: • Less heavy manufacturing, therefore less induction motor load • More speed drives which may reduce frequency sensitivity of induction motors “These changes have been evolving for some time and are not the direct result of the emergence of renewable resources such as wind and solar.” Source: “Comments Of The North American Electric Reliability Corporation Following September 23 Frequency Response Technical Conference,” Oct. 14, 2010. See www.ferc.gov/EventCalendar/EventDetails.aspx?ID=5402&CalType=%20&CalendarI 17 D=116&Date=09/23/2010&View=Listview Two Comments 1. Wind is small now, so the NERC comment that decreasing β is not due to wind is correct, but…this will not be true if, at higher wind penetrations, non-wind units with speed governing are displaced with wind units without speed governing. 2. Decreasing β will risk violation of NERC Standard BAL-001-0.1a — Real Power Balancing Control Performance Each Balancing Authority shall achieve, as a minimum, • Requirement 1: CPS1 compliance of 100% • Requirement 2: CPS2 compliance of 90% and $ penalties apply for non-compliance. So what are CPS1 and CPS2? Ref: N. Jaleeli and L. Van Slyck, “NERC’s New Control Performance Standards,” IEEE Transactions on Pwr Systems, Vol 14, No 3, Aug 1999. CPS1 is a measure of a balancing area’s long term (12 month) frequency performance. The targeted control objective underlying CPS1 is to bound excursions of 1-minute average frequency error over 12 months in the interconnection. As the interconnection frequency error is proportional to the sum of all balancing areas’ ACEs, maintaining averages of ACEs within proper statistical bounds will therefore maintain the corresponding averages of frequency error within related bounds. With the interconnection frequency control responsibilities being distributed among balancing areas, CPS1 measures control performance by comparing how well a balancing area’s ACE performs in conjunction with the frequency error of the interconnection. ACE ( Ptie ,s Ptie ,a ) | B | F CP1min CF ACE1min F1min 10 | B | (CP1min )12Month (1 ) 2 ε1 is maximum acceptable steady-state freq deviation- 0.018Hz in east interconnection. CPS1 (2 CF ) 100% 19 CPS1 If ACE is positive, the control area will be increasing its generation, and if ACE is negative, the control area will be decreasing its generation. If ∆F is positive, then the overall interconnection needs to decrease its generation, and if ∆F is negative, then the overall interconnection needs to increase its generation. Therefore if the sign of the product ACE×∆F is positive, then the control area is hindering the needed frequency correction, and if the sign of the product ACE×∆F is negative, then the control area is contributing to the needed frequency correction. The minimum score of CPS1 compliance is 100%. If an area has a compliance of 100%, they are supplying exactly the amount of frequency support required. Anything above 100 is “helping” interconnection frequency whereas anything below 100 is “hurting” interconnection frequency. CPS2is a measure of a balancing area’s ACE over all 10-minute periods in a month. The control objective is to bound unscheduled power flows between balancing areas. It was put in place to address the concern that a balancing area could grossly over- or under-generate (as long as it was opposite the frequency error) and get very good CPS1, yet impact its neighbors with excessive flows. Num ACE 10min L10 CPS2 100(1 )% L10 1.6510 10 Bi 10 Bs Num all ACE 10min • Num(.) denotes “number of times that…” over 1 month. • (ACE) 10min is the 10 min average of ACE • L10 describes the interval within which |(ACE) 10min| should be controlled. • BS=sum of B values for all control areas. • ε10 =targeted 10-minute average frequency error bound for Interconnection Simulation System •Two Area System (Area A and Area B) Wind power is assumed in area A •Each area consists of 10 conventional units, with inertia and with speed governing • 24 hour UC is run based on a load and wind forecast •Wind penetration levels- 6%, 10%, 25%, and 31% (Pw/Pnw) are considered (by capacity), without inertia or speed governing (would be 5, 9, 20, 24% Pw/(Pw+Pnw)). • Wind is assumed to displace conventional units • Actual sec-by-sec p.u. value of load and of wind power data from one wind farm is used. Con Wind A B Con Simulation Results 180.00% 160.00% 140.00% 100.00% CPS1 Score under different wind penetration levels 80.00% Minimum CPS1 score for CPS1 compliance 60.00% 40.00% 20.00% 0.00% 0% 6% 15% 25% 30% Wind Penetration Level 120.00% 100.00% 80.00% CPS2 CPS1 120.00% CPS2 Score under different wind penetration levels 60.00% 40.00% Minimum CPS2 score for CPS1 compliance 20.00% 0.00% 0% 6% 15% 25% Wind Penetration Level 30% Simulation Results Measures 0% wind penetration CPS1 CPS2 160% 100% Reference case at 25% wind penetration 78.80% 88.89% Provide primary frequency control to wind turbines 98.84% 83.33% Provide wind with inertial emulation & primary frequency control 109.58% 88.89% Increase ramp rate of committed non-wind units by 50% 116.04% 94.44% Increase ramp rate of committed non-wind units by 100% 156.02% 100.00% Control fast variations of wind power within +- 2% of forecast 91.92% 88.89% Control fast variations of wind power within +- 1% of forecast 124.64% 94.44% Conclusion: Wind degrades frequency performance due to inertia, no control, and variability. These 3 issues need to be and can be addressed. Regulation via rotor speed & pitch control Fuel supply control Generator Steam Boiler FUEL STEAMTURBINE Pitch control Steam valve control MVARvoltage control CONTROL SYSTEM Generator Wind speed WINDTURBINE Gear Box Real power output control MVARvoltage control Rotor speed 25 control Rotor speed control is well suited for continuous, fine, frequency regulation; blade pitch control provides fast acting, coarse control both for frequency regulation as well as emergency spinning reserve. CONTROL SYSTEM Sources: Rogério G. de Almeida and J. A. Peças Lopes, “Participation of Doubly Fed Induction Wind Generators in System Frequency Regulation,” IEEE Trans On Pwr Sys, Vol. 22, No. 3, Aug. 2007. B. Fox, D. Flynn, L. Bryans, N. Jenkins, D. Milborrow, M. O’Malley, R. Watson, and O. Anaya-Lara, “Wind Power Integration: Connection and system operational aspects,” Institution of engineering and technology, 2007. Manufacturers & some wind farms have it See http://www.gepower.com/prod_serv/products/wind_turbines/en/downloads/wind_plant_perf2.pdf. Then why don’t they use it? Regulation via rotor speed & pitch control Review of the websites from TSOs (in Europe), reliability councils (i.e., NERC and regional organizations) and ISOs (in North America) suggest that there are no hard requirements regarding use of primary frequency control in wind turbines. There are soft requirements [1]: •BCTC will specify “on a site by site basis,” •Hydro Quebec requires that wind turbines be “designed so that they can be equipped with a frequency control system (>10MW)” •Manitoba Hydro “reserves the right for future wind generators” NERC [2], said, “Interconnection procedures and standards should be enhanced to address voltage and frequency ride-through, reactive and real power control, frequency and inertial response and must be applied in a consistent manner to all generation technologies.” [1] “Wind Generation Interconnection Requirements,” Technical Workshop, November 7, 2007, available at www.bctc.com/NR/rdonlyres/13465E96-E02C-47C2-B63427 F3BCC715D602/0/November7WindInterconnectionWorkshop.pdf. [2] [North American Electric Reliability Corporation, “Special Report: Accommodating High Levels of Variable Generation,” April 2009, available at http://www.nerc.com/files/IVGTF_Report_041609.pdf. Regulation via rotor speed & pitch control ERCOT says [1], “…as wind generation becomes a bigger percentage of the on line generation, wind generation will have to contribute to automatic frequency control. Wind generator control systems can provide an automatic response to frequency that is similar to governor response on steam turbine generators. The following draft protocol/operating guide concept is proposed for all new wind generators: All WGRs with signed interconnect agreements dated after March 1, 2009 shall have an automatic response to frequency deviations. …” [15] Draft White Paper, “Wind Generation White Paper: Governor Response Requirement,” Feb, 2009, available at www.ercot.com/content/meetings/ros/keydocs/2009/0331/WIND_GENERATION_GOVERNOR_RE SPONSE_REQUIREMENT_draft.doc.. 28 Solutions to degraded frequency performance 1. Increase control of the wind generation a. Provide wind with inertial emulation & speed governing b. Limit wind generation ramp rates • Limit of increasing ramp is easy to do • Limit of decreasing ramp is harder, but good forecasting can warn of impending decrease and plant can begin decreasing in advance 2. Increase non-wind MW ramping capability during periods of expected high variability using one or more of the below: a. Conventional generation Steam turbine plants 1- 5 %/min b. Load control Nuclear plants 1- 5 %/min c. Storage GT Combined Cycle 5 -10 %/min Combustion turbines 20 %/min Diesel engines 40 %/min 29 12 Wind Speed (s) Hybrid Wind Systems – Save Money, Enhance Frequency Regulation 10 8 6 4 2 0 200 400 600 400 800 1000 1200 1400 1600 1800 Time (s) Wind Power CAES Power NaS Battery Power ×10 350 HUNTVILL Power Command (MW) 300 NANTCOKE HOLDEN REDBRIDG CHENAUX CHFALLS MARTDALE BRIGHTON STINSON CEYLON RICHVIEW LAKEVIEW PICTON 250 200 150 100 50 0 HEARN -50 WALDEN COBDEN MTOWN MITCHELL HANOVER 0 200 400 600 KINCARD 60.04 800 1000 Time (s) 1200 JVILLE STRATFRD PARKHILL DOUGLAS System Frequency (Hz) BVILLE WVILLE Wind Power Capacity Compressor CAES Power Capacity Gas Turbine CAES Energy Capacity NaS Battery Power Capacity NaS Battery Energy Capacity Cost ($M) Investment Cost Operation Cost 155.15 221.83 Life time: 20 years 60 25 96 6,110MW 10,995MW 1800 60.02 60.01 60 59.99 59.98 59.97 59.96 545MW 30MW 75MW 17,000MWh 5.5MW 1.25MWh 0 200 400 600 800 1000 Time (S) 1200 1400 1600 1800 100 With Storage No Storage 80 Mismatch (MW) Number of buses Number of generators Number of branches Peak Load Total Generation Capacity 1600 Wind plant Hybrid Wind Systems 60.03 GOLDEN 1400 60 40 20 0 -20 -40 Saving ($M) -60 481.40 -80 30 -100 0 200 400 600 800 1000 1200 1400 1600 1800 How to decide? First, primary frequency control for over-frequency conditions, which requires generation reduction, can be effectively handled by pitching the blades and thus reducing the power output of the machine. Although this action “spills” wind, it is effective in providing the necessary frequency control. Second, primary frequency control for under-frequency conditions requires some “headroom” so that the wind turbine can increase its power output. This means that it must be operating below its maximum power production capability on a continuous basis. This also implies a “spilling” of wind. Question: Should we “spill” wind in order to provide frequency control, in contrast to using all wind energy and relying on some 31 other means to provide the frequency control? Answer: Need to compare system economics between increased production costs from spilled wind, and increased production and investment costs from using storage and conventional generation. Conclusion: Select solution portfolio Wind Grid energy prblem attrbute caused by wind attrbute Solutions DFIG Control Inrtial emulation Inc. reserves Freq Fast Spnng 1 hour reg via rmping /10 min pitch+ cnvrtr Storage Fast Slow Load Cntrl Fast Slow Stochastic Unit Cmmt prgrm Dec forecast error Wind HVDC plant control remote trip (SPS) Geodiversity of wind Estimated relative costs/MW of solution technology (to be refined) 5 Decreased Transient inertia frequency dips, CPS2 perfrmance Increased 1 min MW variability Increased 10 min MW variability Increased 1 hr MW variability CPS2 perfrmance Balancing market perfrmance Increased day-ahead MW variability Increased transmissi on loading Day-ahead market perfrmance Low, variable capacity factor CPS1, CPS2 perfrmance Increased need for transmssio n More planning uncertainty 5 6 10 10 √ √ √ √ √ √ 9 9 9 9 4 4 6 10 10 √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ 32 √ √ √ √