Liquid-Liquid Equilibrium

advertisement

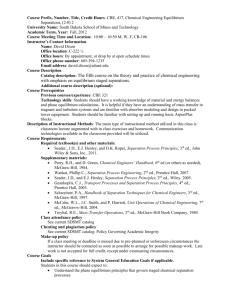

Liquid-Liquid Equilibrium Ternary System Most practical situations involving liquid-liquid equilibrium involve three or more components. Our attention is with three component systems. In this process, a solute is removed from a feed stream by contacting it with a solvent. The solute is quite soluble in the solvent, while the other component in the feed is less soluble. ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Equilibrium Terminology Solute ≡ Component (1) Original solvent ≡ Component (2) Extractive solvent ≡ Component (3) x1S, x2S and x3S are the composition of the three components in (solvent rich phase) 1,2,3 respectively. x1R, x2R and x3R are the composition of the Three components in the (raffinate phase) 1,2,3 respectively. Feed (component +original solvent) Raffinate-rich phase (x1R1, x2R1 , x3R1) solvent-rich phase Extractive solvent ChE 334: Separation Processes (x1S1, x2S1 , x3S1) Dr Saad Al-Shahrani Liquid-Liquid Equilibrium The solvent phase is rich in solvent and preferentially soaks up component 1 (the solute), which we are trying to separate from the other component in the feed (component 2, raffinate). The raffinate phase is the liquid phase which is rich in the component 2 (raffinate) and from which the solute (component 1) is being removed. The original feed is usually a mixture of solute (component 1) and raffinate (component 2). The solvent-rich phase contains mostly solvent (component 3) and solute (component 1) and only a small amount of raffinate (component 2) The raffinate-rich phase contains mostly solute (component 1) and raffinate (component 2), but also possibly some small amount of solvent. ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Equilibrium ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Equilibrium Triangular Diagrams Ternary systems are represented on two types of triangular diagrams: 1. Equilateral triangles ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Equilibrium 2. Right Triangles ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Equilibrium Mixture [50% Acetic + 20 H2O + 30%vinyl acetate (Solute) . Original solvent ChE 334: Separation Processes Extractive solvent Dr Saad Al-Shahrani Liquid-Liquid Equilibrium b) Liquid-liquid Equilibrium tie lines (LLE Tie lines) Different chemical systems give different types of triangular diagrams. ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Equilibrium The phase boundary, called the solubility line, is the solid line. Within the two-phase region, liquid-liquid equilibrium lines (the dashed lines) connect compositions of the two phases that are in equilibrium with each other The left side of the phase boundary gives the compositions of the raffinate-rich liquid phase (xjR). The right side of the phase boundary gives the compositions of the solvent-rich liquid phase (xjS). The LLE tie-lines and the equilibrium phase boundary are normally found by laboratory experimentation. A mixture that has an overall composition inside the two-phase region will split into two liquid phases with compositions given at the two ends of the LLE tie-line. ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Equilibrium A conjugate line can be used to locate the tie-lines. From point A on-the left phase boundary, the other end of the tie-line is found by drawing a horizontal line to the conjugate line. A vertical line is then drawn from the point M intersection to the right phase boundary. The point of intersection of this line and the right phase boundary (point B in the figure) is the other end of the tie-line. ChE 334: Separation Processes M Dr Saad Al-Shahrani Liquid-Liquid Equilibrium As the system becomes richer in solute, the tie-lines get shorter and ultimately become just a point at the plait point P. Outside the twophase region, a single, homogeneous liquid phase exists. Effect of Temperature on solubility Usually, the solubility increases as the temperature increases, for this reason, most liquid-liquid extraction systems operate at low temperatures and some times even require refrigeration. Pressure, on the other hand, has little effect on solubility. ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Equilibrium if we specify only one concentration of one liquid phase, all the other concentrations can be immediately determined from the phase diagram For example, if we fix the concentration of component 1 in the raffinate-rich phase (x1R), we can read from the diagram: 1. The concentration of component 3 in the raffinate-rich phase (x3R), by using the left side of the solubility curve. 2. The concentrations of components 1 and 3 in the solvent-rich phase that is in equilibrium with the raffinate-rich phase, by going to the other end of the LLE tie-line. The concentrations x1S and x3S are read from the right side of the solubility curve. ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Equilibrium Example: Thirty thousand kg/hr of a ternary mixture of 19 weight percent isopropyl alcohol (IPA), 41 weight percent toluene, and 40 weight percent water are fed into a, decanter operating at 25°C. the figure gives the LLE data for the system. Determine the compositions and flow rates of the two liquid streams leaving the decanter. ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Equilibrium The overall compositions of the feed (z1 = 19 percent and z2 = 40 percent) are located on the diagram. The compositions of the two liquid phases are read off the diagram at the two ends of the LLE tie-line. The raffinate-rich phase is 14 percent IPA and 2 percent water (the rest being toluene). The solvent-rich phase is 23 percent IPA and 74 percent water. ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Equilibrium Total mass: 30000 = S + R Water = (30000)(0.4) = S(0.74) + R(0.02) Solving the last two equations simultaneously gives S = 15833 kg/h R = 14176 kg/h IPA in = (30000)(0.19) = 5700 kg/h IPA out = S(0.23) + R(0.14) = (15833)(0.23) + (14176)(0.14) = 5625 kg/h The difference is due to the accuracy of reading composition from the diagram ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Extraction In liquid-liquid extraction, a liquid of two or more components to be separated is contacted with a second liquid phase, called the solvent, which is immiscible or partially miscible with one or more components of the liquid feed. The simplest liquid-liquid extraction involves only a ternary system. The feed consists of two miscible components, the carrier (C) and the solute (A). Solvent (S) is a pure component. Components (C,S) are at most only partially soluble in each other. Solute (A) is soluble in (C) and completely or partially soluble in S. During the extraction process, mass transfer of (A) from the feed to the solvent occurs, with less transfer of (C) to the solvent, or (S) to the feed. ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Extraction Liquid-liquid extraction is used to separate components in situations where: 1. Relative volatilities are quite close to unity ( < 1.1), making distillation very costly. (Distillation requires tall towers due to the existence of many trays, and high energy consumption because of high reflux ratios.) e.g. A mixture of benzene and cyclohexane. The normal boiling points of these organics are 80.1°C and 80.7°C, respectively, making their separation by distillation impractical 2. Thermally sensitive components will not permit high enough temperatures to produce a vapor-liquid system at reasonable pressures (pressures greater than 10-50 mm Hg). ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Extraction EQUIPMENT Different mechanical devices are used in liquid-liquid extraction such as: 1. The simplest is a mixer/settler, or decanter, in which the two liquid phases are separated. 2. Plate towers, packed towers, and mechanically agitated mixers (rotating disk contactors) the number of stages tends to be much smaller than in distillation columns. This is due to the larger settling times required for liquid-liquid separation because of the small density differences between the liquid phases. Liquid-liquid extraction columns are sometimes operated in a pulsed mode. ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Extraction Extractor/stripper process. ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Extraction 1. Mixer/ Settler Mixing vessel with variable-speed turbine agitator ChE 334: Separation Processes Horizontal gravity-settling vessel. Dr Saad Al-Shahrani Liquid-Liquid Extraction 2. Spray column ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Extraction 3. Packed column Extract Single-section cascade ChE 334: Separation Processes Two-section cascade Dual solvent with two-section cascade Dr Saad Al-Shahrani Liquid-Liquid Extraction ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Extraction ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Extraction GRAPHICAL MIXING RULES If we have two streams that contain three components and mix them together. Let one of these streams be stream A with flow rate FA (kg/h) and composition x1A, x2A and x3A (weight fractions of components 1,2, and 3), and let the other be stream FB with corresponding composition x1B, x2B and x3B . The mixed stream leaving the mixer will have a flow rate FM and composition x1M, x2M and x3M . A flow diagram is as follows: FA x1A, x2A , x3A FM x1M, x2M , x3M FB x1B, x2B , x3B ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Extraction To determine the location of the mixture composition on a graph, since there are three components, only two coordinates are needed to completely specify the composition of any stream. We can use either right or equilateral triangular plots. If we use right-triangular plot. locate point A with coordinates (x1A, x2A ) and point B with coordinates (x1B, x2B). The point M with coordinates (x1M, x2M ) representing the mixture will lie some place on the graph. ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Extraction After mixing point M is supposed to lie on a straight line joining the A and B points. If we can show that the angles and in the figure are equal, then M must lie on a straight line between A and B. The total mass balance for the system is (1) Component balances for components 1 and 2 are (2) and ChE 334: Separation Processes (3) Dr Saad Al-Shahrani Liquid-Liquid Extraction Rearranging these two equations, we obtain: Solving for the ratio FAIFB, we have: or ChE 334: Separation Processes Dr Saad Al-Shahrani Liquid-Liquid Extraction These two ratios are the tangents of the angles and , hence, tan = tan . Therefore, = , and we have proven that the line AMB is a straight line. The coordinates of the point M can be solved for analytically by using equations (1), (2), and (3). Alternatively, M can be located graphically where the distance from the point A to the point M divided by the distance from the point M to the point B is equal to the ratio FB/FA. ChE 334: Separation Processes Dr Saad Al-Shahrani