TM 675 * Ethics and Professionalism for Managers

ENGM 620: Quality Management

21 November 2012

• FMEA

• Reliability

Repeatability and

Reproducibility

• Repeatability

– Equipment variation

– Multiple measurements by one person using the same instrument

• Reproducibility

– Operator variation

– Same instrument and parts, different people

Reliability

• Reliability is the probability that a product, piece of equipment, or system performs its intended function for a stated period of time under specified operating conditions.

Reliability

• Reliability is the probability that a product, piece of equipment, or system performs its intended function for a stated period of time under specified operating conditions.

• Numerical measure with precise meaning

• Valid basis for comparison

Reliability

• Reliability is the probability that a product, piece of equipment, or system performs its intended function for a stated period of time under specified operating conditions.

• Reliability of 0.95 for 5,000 hrs better than reliability of 0.95 for 1,000 hrs

Reliability

• Reliability is the probability that a product, piece of equipment, or system performs its intended function for a stated period of time under specified operating conditions.

• Functional failure

• Reliability failure after some time period

Types of Failures

• Functional failure – failure that occurs at the start of product life due to manufacturing or material detects

• Reliability failure – failure after some period of use

Reliability

• Reliability is the probability that a product, piece of equipment, or system performs its intended function for a stated period of time under specified operating conditions .

• Type and amount of usage in environment for which product is used

Maintainability

• The probability that a system or product can be retained in, or one that has failed can be restored to, operating condition in a specified amount of time.

Types of Reliability

• Inherent reliability – predicted by product design

• Achieved reliability – observed during use

Reliability Measurement

• Failure rate ( l

) – number of failures per unit time

• Alternative measures

– Mean time to failure (MTTF)

– Mean time between failures (MTBF)

Failure Rate Curve

Failure

Rate 0.05

0.04

0.03

0.02

0.01

Time

Failure

Rate 0.05

0.04

0.03

0.02

0.01

Failure Rate Curve

Infant

Mortality

Normal

Failure Rate

Age Time

Cumulative Failure Rate Curve

Cum

%

Failure

100

80

60

40

20

Time

Cumulative Failure Rate Curve

Cum

%

Failure

100

80

60

40

20

Slope = 0.04

Time

Cumulative Failure Rate Curve

Cum

%

Failure

100

80

60

40

20

Slope = 0.04

Time

Cumulative Failure Rate Curve

Cum

%

Failure

100

80

60

40

20

Slope = 0.02

Time

Classroom Question

• J.D. Power’s Initial Quality Survey asks vehicle owners to report the number of quality problems in the first 90 days of ownership. Based on the product life characteristics curve, what are pros and cons of this approach?

F t

=

λe l t

Exponential

P fail in 0 T

=

P X

<

T }

= ∫

0

T l t e dt e

l

T

Exponential

Reliability Function

R T

= >

}

= e

l

T

Experimental Data

• Suppose we wish to make some estimates on time to fail for a new power supply. 40 units are randomly selected and tested to failure.

Failure times are recorded follow:

2.7

25.8

19.6

4.5

0.5

6.4

18.3

41.6

5.8

73.8

13.9

32.2

27.7

5.1

12.0

34.9

21.0

10.2

46.1

37.9

14.9

24.1

1.0

29.8

3.3

7.1

59.9

9.4

12.9

7.9

11.1

2.1

16.0

22.5

8.6

3.8

51.8

1.6

17.1

14.7

Histogram

• Histograms give the analyst a feel for the distribution from which the data was obtained.

• Count observations with a set of ranges

– Average 5 observations per interval class

• Range for power supply data: 0.5-73.8

• Intervals: 0.0 - 10.0

10.1 - 20.0

20.1 - 30.0

30.1 - 40.0

40.1 - 50.0

50.1 - 60.0

60.1 - 70.0

70.1 - 80.0

Histogram

• Class Interval 0.0 - 10.0

Count = 15

2.7

25.8

19.6

4.5

0.5

6.4

18.3

41.6

5.8

73.8

13.9

32.2

27.7

5.1

12.0

34.9

21.0

10.2

46.1

37.9

14.9

24.1

1.0

29.8

3.3

7.1

59.9

9.4

12.9

7.9

11.1

2.1

16.0

22.5

8.6

3.8

51.8

1.6

17.1

14.7

Histogram

• Class Interval 10.1 - 20.0

Count = 11

2.7

25.8

19.6

4.5

0.5

6.4

18.3

41.6

5.8

73.8

13.9

32.2

27.7

5.1

12.0

34.9

21.0

10.2

46.1

37.9

14.9

24.1

1.0

29.8

3.3

7.1

59.9

9.4

12.9

7.9

11.1

2.1

16.0

22.5

8.6

3.8

51.8

1.6

17.1

14.7

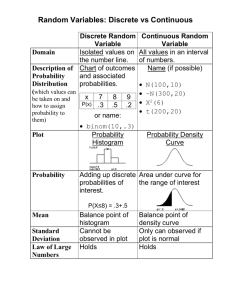

Histogram

Frequency Count

Class Intervals

Frequency

0.0 - 10.0

15

10.1 - 20.0

20.1 - 30.0

30.1 - 40.0

40.1 - 50.0

11

6

3

2

50.1 - 60.0

60.1 - 70.0

70.1 - 80.0

2

0

1

Power Supply Failure Times

20

15

10

5

0

0-

10

10-

20

20-

30

30-

40

40-

50

Time Class

50-

60

60-

70

70-

80

Class Intervals

Frequency

0.0 - 10.0

10.1 - 20.0

15

11

20.1 - 30.0

30.1 - 40.0

40.1 - 50.0

50.1 - 60.0

60.1 - 70.0

70.1 - 80.0

0

1

2

2

6

3

Histogram

Power Supply Failure Times

20

15

10

5

0

0-

10

10-

20

20-

30

30-

40

40-

50

Time Class

50-

60

60-

70

70-

80

Failure (hazard) rate

Item has survived t hours, what is prob. it will not survive an additional time dt ?

P X

t t

+ dt ) | X t }

P X

t t

+ dt ) X t }

P X

> t }

= P X

t t

+ dt

P X

> t }

)}

1

dt

Failure (hazard) Rate l =

1

-

Exponential Failure Rate l =

1

-

=

= l e

l t l e

l t

MTBF

MTBF = Mean Time Between Failures

= 1/ l

Ex: Machine operating 5,000 hrs has experienced 3 failures that are immediately repaired.

MTBF = 5,000/3 = 1,667 hrs l = 1/MTBF = 0.0006

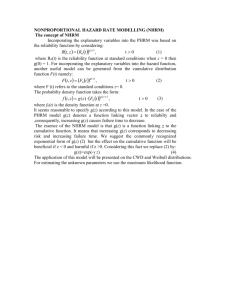

Weibull

Density = t

-

1 e

t

, t

>

0

Cumulative

1 e

t

Mean Variance

2

2

2

-

1

1

2

1.5

= 1

= 1

1.0

0.5

0.0

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

Density

Cumulative

Weibull

= t

-

1 e

t

1 e

t

, t

>

0

1.5

= 1

= 2

1.0

0.5

0.0

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

Density

Cumulative

Weibull

= t

-

1 e

t

e

t

, t

>

0

1.5

= 1

= 3

1.0

0.5

0.0

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

Weibull

= -

1

t e

t

, t

>

0 e

T

R T

= e

T

Weibull

= -

1

t e

t

, t

>

0 e

T

l

R T

= e

T

= f ( t )

R ( t )

=

t

-

1 e

t

e

t

= t

-

1

Series Reliability

• Components are in a series if the performance of the entire system depends on all the components functioning properly

• The Components need not be physically wired sequentially

• All parts must function for the system to function

Series Systems

0.9 0.95 0.95 0.85

1 2 3 4

P SysWorks }

=

{

1

2

S

3

S

4

=

P S P S

2

}

P S P S

4

=

. ( .

)( .

)( . )

=

Series Systems

0.9 0.95 0.95 0.85

1 2 3 4

R T

S

=

R T R T R T R T

1 2 3 4

( )

Series Systems

0.9 0.95 0.95 0.85

1 2 3 4

R T

S

=

R T R T R T R T

1 2 3 4

( )

= e

l

1

T e

l

2

T e

l

3

T e

l

4

T

= e

-

( l

1

+ l

2

+ l

3

+ l

4

) T

Series Systems

0.9 0.95 0.95 0.85

1 2 3 4

R T

S

=

R T R T R T R T

1 2 3 4

( )

= e

l

1

T e

l

2

T e

l

3

T e

l

4

T

= e

-

( l

1

+ l

2

+ l

3

+ l

4

) T

Complex systems are more likely to fail

Parallel Reliability

• High reliability systems often require extremely require high component reliability

• When it is impossible an alternative is to use a backup system

• Another word for backup is redundant or parallel

0.9

1

0.95

2

0.95

3

Parallel Systems

P Work } P Fail }

P S S S Fail }

1 2 3

{

1

} {

2

} {

3

}

0.9

1

0.95

2

0.95

3

Parallel Systems

P Work } P Fail }

P S S S Fail }

1 2 3

{

1

} {

2

} {

3

= -

(. )(. )(.

)

=

}

0.9

1

0.95

2

0.95

3

Parallel Systems

P Work }

R s

P Fail }

P S S S Fail }

1 2 3

( 1

-

R k

)

0.9

1

0.95

2

0.95

3

Parallel Systems

P Work } P Fail }

P S S S Fail }

1 2 3

R s

( 1

-

R k

)

Redundancy Increases Reliability

Series-Parallel Systems

R

A

A

R

B

B

C

R

C

R

D

D

C

R

C

• Convert to equivalent series system

R

A

A

R

B

B C’

R

C’

= 1 – (1-R

C

)(1-R

C

)

R

D

D

0.95

Series/Parallel

0.9

0.8

0.95

0.95

0.9

Series/Parallel

.95

R

2

R

2

=1- (.1)(.2)(.1)

= .998

.95

.95

Series/Parallel

.95

R

2

R s

=(.95)(.998)(.95)(.95)

= .856

.95

.95

K-n systems

• Series – n out of n – all must work

• Parallel – 1 out of n – one must work

• k out of n – k of n must work

1

2

1

Ex: 2 out of 3

2

3

3

Bridge Systems

2

1

3

4

5

Bridge Systems

2

1

3

4

5

1 4

1 3 5

2

2

3

5

4

Reliability Engineering

• Standardization

• Redundancy

• Physics of failure

• Reliability testing

• Burn-in

• Failure mode and effects analysis

• Fault tree analysis

FMEA

• F ailure M ode E ffects A nalysis

Failure Mode – how can component fail

Cause of Failure

Effect on the Product

Corrective Action

FMEA Rating

• Useful tool for prioritizing

• Rating based on

– Severity of the potential failure

– Occurrence probability of the failure

– Probability that the system will detect the failure

Reliability Management

• Define customer performance requirements

• Determine important economic factors and relationship with reliability requirements

• Define the environment and conditions of product use

• Select components, designs, and vendors that meet reliability and cost criteria

• Determine reliability requirements for machines and equipment

• Analyze field reliability for improvement

Quality Management

• System Design

• Parameter Design

• Tolerance Design

Next Class

• Homework

– Ch. 12 # 24, 28, 31, next slide

• Six Sigma

– Implementing and Sustaining TQ

• Preparation

– Chapters 13

Additional problem

• An electronic missile guidance system consist of the following components: A,

B, C, and D with reliabilities of 0.96,

0.98, 0.90, and 0.99 respectively.

Given the system design below, what is the reliability of the entire system?

C

A B D

C