compounding of sterile products - LaGuardia Community College

advertisement

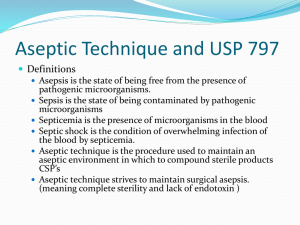

Aseptic Technique and USP 797 Definitions Asepsis is the state of being free from the presence of pathogenic microorganisms. Septicemia is the presence of microorganisms in the blood Septic shock is the condition of overwhelming infection of the blood by septicemia. Aseptic technique is the procedure used to maintain an aseptic environment in which to compound sterile products CSP’s Aseptic technique strives to maintain surgical asepsis. (meaning complete sterility and lack of endotoxin ) USP 797 rules United States Pharmacopeia 797 chapter on compounding of sterile products (CSP) was published in the 27th revision to USP on January 1st, 2004 USP 797 is applicable to all facilities where compounded sterile products (CSP) are made, stored and sent to the patient USP 797 applies to the aseptic technique used to make CSPs as well as the environment in which it is done (secondary engineering controls) Issues addressed by USP 797 Aseptic techniques used to prepare CSP Evaluation of personnel in USP 797 standards Growth medium testing (media fill test with soy/casein) Fingertip testing Cleanroom and antiroom construction Class of BSC Air cleaness, defined as ISO5 or in old terminology class 100 Microbial Risk Levels in USP 797 Low risk CSP Made under ISO5 conditions Involves aseptic transfer of manufacturer based sterile products using sterile equipment (i.e Needles and syringes) to compound IV admixtures. Does not involve open systems and no more than 3 components Medium Risk CSP More than three components are a part of the IV admixture (i.e TPN’s) CSP don’t contain antimicrobial preservative and product is given over more than 2 days Complex preparation involved High Risk CSP Compounding of manufactured ingredients that are non sterile and then performing terminal sterilization Performing compounding in conditions outside ISO5 Risk Levels and Expiration Dating Low Risk CSP 48 hrs at room temperature 14 days under refrigeration 45 days frozen state Medium Risk CSP 30 hrs at room temperature 7 days at refrigeration 45 days at a frozen state High Risk CSP 24 hours at room temperature 72 hours refrigerated 45 days at a frozen state. Hospital Compounding For the most part you may be preparing only low or medium risk CSP’s Example of a low risk CSP Making a 250 ml SVP with 1.25 gram of vancomycin under ISO5 conditions Example of a medium risk CSP Compound a triple mix TPN with additional additives of insulin, multiple vitamin injections, and other electrolytes Example of high risk CSP Compounding a sterile ophthalmic solution from a manufactured product that is not sterile and passing solution through a 0.22 micron filter several times Air Quality and Cleanness ISO stands for international organization for standardization ISO was formed in 1947 in Geneva Switzerland Provides different levels of air quality cleanness ISO 5 means no more than 100,000 particulates micrometer or larger per cubic meter of air. By contrast, room air is classified as ISO9 which is no more than 1,000,000,000 particulates per cubic meter. (a ten thousand fold difference) Anteroom Usually consists of a storage area, an area for records, computers and printers, an buffer area for gowning Has ISO class 8 standard Has a sink equipped with surgical scrub soap (Chlorhexidine), and has handfree or pedal activated water systems Has the following characteristics: Smooth walls with panels locked and sealed Vinyl covered floor with seals heated together Joints and junctures between walls and ceilings must be chauked with no visible cracks. Clean Room The room where the LAFW hoods are located Means same physical characteristics as anteroom No sinks and floor drains If facility only compounds low and/or medium risk CSPs the clean and ante rooms need not be separated. Area immediately next to LAFW hoods is called buffer area If all risk levels are compounded clean and ante rooms must be separated. Must be maintained as a positive room air pressure environment if separated. Structure of USP 797 defined Cleanroom Cleanroom: Positively pressured, Houses BSC Vinyl flooring ISO 8 environment Negatively pressured for chemo or hazardous drugs Anteroom Vinyl flooring Maybe ISO 8 environment Contains sink for hand hygiene Gowning apparel REST OF THE PHARMACY Maintaining of ante and Cleanrooms Cleaning requirement BSC or LAFW = beginning of shift, before each preparation, 30 minutes into the procedure, when surface is visible contaminated Cleaning of all floor surfaces daily from the buffer area outwards, from the clean room out to anteroom. Countertops: daily Cleaning and disinfection of all shelving surfaces at least monthly Walls, Ceilings: monthly Documentation of such maintained Cleaning solvent required by USP for ISO5 and countertops: Isopropyl Alcohol USP 70% Laminar Air Flow Hoods and Workbenchs LAFH and workbenchs are designed to blow parallel sheets of sterilized clean air over a work surface The hood is usually washed and disinfected with 70% isopropranol by a pharmacist at the beginning and end of the shift. Washing is from top to bottom of the hood and back to front in the direction of laminar flow. HEPA filters remove over 99% of particles, including microorganism 0.3 microns or larger. When cleaning the HEPA filter grill do not spray the filter always spray the sterile gauze pads and clean the surface of the grill If the HEPA Laminar flow hood is turn off for any reason then it must be turn on for at least 30 minutes before commencing any IV preparation. Horizontal Laminar Flow Hood: the HEPA filter is at the back of the hood and blows laminar air towards the operator Vertical Laminar Flow Hoods: the HEPA filter is on the top of the hood and laminar air flow sheets are blown to the work surface and not to the operator Also called a biological safety cabinet Must be recertified every 6 months Biological Safety Cabinets Class I open system that draws air from the cleanroom Class II air is recirculated through vents in the front and back and passed though a HEPA filter on the top of the cabinet back down to the worksurfaces. Four types A, B1, B2, and B3 Type A is not vented to the outside Type B1,B2,B3 all provide some or all exhaust to the facility’s external vent system. Class III are completely enclosed system under negative pressure which are vented. Manipulation by the operator are with a gloved apparatus through the front of the cabinet Preparing to make an IV product Enter the antiroom with slow and deliberate movement. Remove jewelry and tie back loose hair. Put on shoe coverings (booties) and then proceed to anteroom. Don hair cap, beard cover (if needed) and surgical mask if working with a hood with no front panel then don lint free “bunny suit”. This equipment is called Personal Protective Equipment (PPE) Wash hands up to the elbows for 30 seconds and rinse hands first allowing water to drip down to elbows Donn powder free surgical latex gloves Enter cleanroom When in the cleanroom Before placing the drug product, IV bag, etc in the BSC Clean the BSC From top to bottom From the inside outside direction Clean with 70% isopropyl alcohol Clean the surface of all IV vials, IV bags with 70% isopropyl alcohol Sterilize gloves or replace Remove all caps to vials. Swab each vial with alcohol swab from back to front once with swab. Swab medication port of the IV bag that you will use. All products should be 6 inches inside the hood. Arrange materials in such as way as to not block any of the laminar flow air currents. Once inside the hood, your hands should not leave the inside of the hood. If they do you will need to sanitize your gloves before returning to the hood area. Always remember not to touch critical areas The following are critical areas which must not be touched. All parts of the needle. The hub of a luer lok syringe The ribs of the piston of the syringe. The injection port of the IV bag. The rubber entry port of the vial Remember, touch is the number one cause of product contamination. Human skin harbors many organisms: Staphylococci, Streptococci, Actinobacter, Candida, Tricophyton Rubrum fungi, Pseudomonas, etc. Contaminated IV products can cause bacteremia and fungemia, septic shock and death. I will demonstrate aseptic technique in class with reference to drug manipulation. The Finished products If you are a pharmacy technicians that will be performing IV admixtures. Always leave the following item for the RPH to check: All vials used in the process All syringes used in the process drawn back to the volume you used. All information recorded in the IV prep log book: Patient’s name, medical record number, drugs, concentrations, volumes used, lot number and manufacturer’s expiration. Assigned a pharmacy expiration date (usually 24 hours at room temperature) A great reference to use to determine drug-drug, drug-IV solution compatibilities is a book called, Trissel’s Handbook on Injectable Drugs® Common causes of physical and chemical incompatibilities are: Drugs mixed in low pH solutions, like D5W Drugs mixed in hypertonic solutions, like D5WNS Drugs mixed in incorrect IV mediums. Such drugs are not compatibility in the PVC container of an IV bags; these drug are mixed in glass IV containers. A class example is nitroglycerin which is used for patients with acute MI. Drugs mixed with other drugs that “complex” each other. Type of Parenteral Products Injections are products that are already mixed into solutions. Solutions are pH buffered, sterile, pyrogen free with methylparabens, benzyl alcohol preservatives Packaged in Vials Ampules Single doses Vials Have no preservatives Once open, use and discard Multiple Doses Vials Have preservatives Once open 28 days exp Courtesy of :http://www.hospira.com/en/products_and_services/drugs/FENTANYL_CITRATE Type of Parenteral Products For Injections : products that are lyophilized powders that require addition of water to form a solution a given concentration. Usually these products are single dose Courtesy of :http://www.hospira.com/en/products_and_services/drugs/CEFTRIAXONE IV Labeling Labeling rules are governed by the state, non governmental agencies guidelines (JCAOH, USP797) Include the following: Patient’s name, location in institution, MRN Drug and strength Base fluid Name of other additives and quantities of The intended time of administration of drug Rate of administration if LVP (or hang time if SVP) Prep by field and Verified by field Product expiration field In addition a nursing label may be attached detailing: When product was “hung” (i.e. started) By whom the product was hung IV products that require special handling Some IV products require special handling and precautions These drugs are loved to be tested by PTCE Paclitaxel (Taxol®) requires non PVC IV tubing Nitroglycerin Injection requires glass container for IV and non PVC IV tubing Nitroprusside Injections requires the same as nitroglycerin and the IV tube must be covered by a light resistant material to prevent from light degradation Lipid Emulsion also require non PVC, non DHEP IV tubing Parenteral Therapy Intravenous Therapy (IV) involves injecting a medication directly into the blood via venous access devices IV products must be sterile and pyrogen free with no particulate matter in the solution Intramuscular Injection (IM) involves injection into the large belly of a muscle Subcutaneous Injection (SubQ) involves injection in the hypodermis of the skin Epidural Injection involves injection next to the dura mater of the spinal cord Intrathecal Injection involves injection into the subarchnoid space of the meninges ALL THESE PRODUCTS MUST BE STERILE AND PYROGEN FREE IN ADDITION EPIDURAL AND INTRATHECAL INJECTION MUST BE PRESERVATIVE FREE IN ADDITION TO STERILITY Preservative free is required for epidural injections Coutesy of: http://www.drugs.com/pro/duramorph.htm l Type of IV Therapy IVP or Intravenous push involves insert a needle and syringe directly in a VAD (vascular access device) IV Infusion Large Volume Parenteral involves a large volume of fluid given IV over a long period of time (1,000 ml) Often called a “drip” with given continuously SVP or a small volume parenteral is a small volume of fluid (50 ml to 100 ml) given IV over a short period of time (10 minutes or so) Often called an intermittent infusion IVPB, intravenous piggyback is a type of SVP that is infused along with a LVP Source: wikimedia commons page Venous Access Devices Catheters that are inserted into the antecubital vein and is called a peripheral line The catheter is usually made of Teflon (a material that does not trigger phlebitis) Entry into the vein is evident with blood in the flash back chamber The hub of the catheter is a female connection that is made to receive a connection called a male luer lok connection Often a short tube with a access port called a heparin or saline lock is attached to the hub of the catheter to provide a port to inject IV therapy http://www.youtube.com/watch?v=s-vTzQkUQd8 A larger catheter that is inserted into the larger vein of the neck (commonly the subclavian vein) is commonly called a “central line” Central Lines are used to deliver TPN, and larger volumes of hypertonic fluids rapidly. Also it is meant to deliver vasopressor agents in the ICU Types of Central Catheters Hickman Lines are tunneled to the jugular vein under the skin and is used to deliver chemo and other potent drugs. Broviac lines are similar and used in children Primary IV Infusion Sets These infusion sets are made of PVC and DHEP and meant to carry the fluid from an IV bag to the hub of a IV catheter or a saline/Heparin lock This tube consists of a piercing pin, drip chamber, an in line filter and several Y site IV ports for the administration of the secondary IV fluids through a piggyback system Used to deliver a LVP over several hours Secondary IV administration sets Secondary IV administration sets are used to deliver smaller volumes of drug containing fluids of about 50100 ml In general this tube has a piercing pin, drip chamber, and a roller clamp and male luerlok. In general this tubing has no Y site ports The connection is attached to the Y site of a primary line INFUSION SET UP 1 liter of NS or D5W Addition port Administration set port Drip chamber http://www.youtube.com/watch?v=N0rCuC2XE1U