Definition: Total Quality Management

advertisement

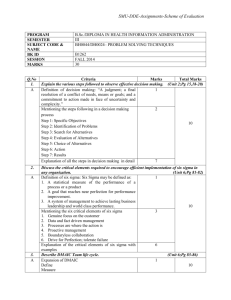

Modern Importance of Quality “The first job we have is to turn out quality merchandise that consumers will buy and keep on buying. If we produce it efficiently and economically, we will earn a profit, in which you will share.” - William Cooper Procter Definitions of Quality • Transcendent definition: excellence • Product-based definition: quantities of product attributes • User-based definition: fitness for intended use • Value-based definition: quality vs. price • Manufacturing-based definition: conformance to specifications Quality Perspectives transcendent & product-based user-based needs Marketing Customer products and services value-based Design manufacturingbased Manufacturing Distribution Information flow Product flow Customer-Driven Quality • “Meeting or exceeding customer expectations” • Customers can be... – Consumers – External customers – Internal customers Total Quality • People-focused management system • Focus on increasing customer satisfaction and reducing costs • A systems approach that integrates organizational functions and the entire supply chain • Stresses learning and adaptation to change • Based on the scientific method Principles of Total Quality • • • Customer and stakeholder focus Participation and teamwork Process focus and continuous improvement ...supported by an integrated organizational infrastructure, a set of management practices, and a set of tools and techniques Customer and Stakeholder Focus • • • • Customer is principal judge of quality Organizations must first understand customers’ needs and expectations in order to meet and exceed them Organizations must build relationships with customers Customers include employees and society at large Participation and Teamwork • • • • Employees know their jobs best and therefore, how to improve them Management must develop the systems and procedures that foster participation and teamwork Empowerment better serves customers, and creates trust and motivation Teamwork and partnerships must exist both horizontally and vertically Process Focus and Continuous Improvement • A process is a sequence of activities that is intended to achieve some result Competitive Advantage • Is driven by customer wants and needs • Makes significant contribution to business success • Matches organization’s unique resources with opportunities • Is durable and lasting • Provides basis for further improvement • Provides direction and motivation Quality supports each of these characteristics Quality and Profitability Improved quality of design Improved quality of conformance Higher perceived value Higher prices Increased market share Increased revenues Higher profitability Lower manufacturing and service costs Evidence that Quality Impacts Business Results • General Accounting Office study of Baldrige Award applicants • Baldrige stock study (see www.quality.nist.gov) • Hendricks and Singhal study of quality award winners • Performance results of Baldrige Award winners GAO TQ Model Reliability Product and service quality On-time delivery Error/defects Leadership for continuous improvement Quality systems and employee involvement Overall satisfaction Customer satisfaction Customer retention Complaints Competitiveness Market share Profits Organization benefits Costs Cycle time Turnover Satisfaction Safety & health Productivity Three Levels of Quality • Organizational level: meeting external customer requirements • Process level: linking external and internal customer requirements • Performer/job level: meeting internal customer requirements Quality and Personal Values • Personal initiative has a positive impact on business success • Quality begins with personal attitudes • Quality-focused individuals often exceed customer expectations • Attitudes can be changed through awareness and effort (e.g., personal quality checklists) Definition: Total Quality Management • Total Quality Management (TQ, QM or TQM) and Six Sigma (6) are sweeping “culture change” efforts to position a company for greater customer satisfaction, profitability and competitiveness. • TQ may be defined as managing the entire organization so that it excels on all dimensions of products and services that are important to the customer. • We often think of features when we think of the quality of a product or service; TQ is about conformance quality, not features. Another meaning of TQM Total Quality Management means that the organization's culture is defined by and supports the constant attainment of customer satisfaction through an integrated system of tools, techniques, and training. This involves the continuous improvement of organizational processes, resulting in high quality products and services. What’s the goal of TQM? “Do the right things right the first time, every time.” Another way to put it • At it’s simplest, TQM is all managers leading and facilitating all contributors in everyone’s two main objectives: (1) total client satisfaction through quality products and services; and (2) continuous improvements to processes, systems, people, suppliers, partners, products, and services. Total Quality also is… • Meeting Our Customer’s Requirements • Doing Things Right the First Time; Freedom from Failure (Defects) • Consistency (Reduction in Variation) • Continuous Improvement • Quality in Everything We Do A Quality Management System is… • A belief in the employee’s ability to solve problems • A belief that people doing the work are best able to improve it • A belief that everyone is responsible for quality Elements for Success • • • • • • • • • Management Support Mission Statement Proper Planning Customer and Bottom Line Focus Measurement Empowerment Teamwork/Effective Meetings Continuous Process Improvement Dedicated Resources The Continuous Improvement Process Empowerment/ Shared Leadership Customer Satisfaction Business Results Team Management Process Improvement/ Problem Solving Measurement Measurement Measurement ... Measurement Modern History of Quality Management • Frederick W. Taylor wrote Principles of Scientific Management in 1911. • Walter A. Shewhart used statistics in quality control and inspection, and showed that productivity improves when variation is reduced (1924); wrote Economic Control of Manufactured Product in 1931. • W. Edwards Deming and Joseph M. Juran, students of Shewhart, went to Japan in 1950; began transformation from “shoddy” to “world class” goods. • In 1960, Dr. K. Ishikawa formalized “quality circles” - the use of small groups to eliminate variation and improve processes. • In the late ‘70’s and early ‘80’s: – Deming returned from Japan to write Out of the Crisis, and began his famous 4-day seminars in the United States – Phil Crosby wrote Quality is Free – NBC ran “If Japan can do it, why can’t we?” – Motorola began 6 Sigma History of Quality Management Deming’s 14 Points 1. Create constancy of purpose for improvement 2. Adopt a new philosophy 3. Cease dependence on mass inspection 4. Do not award business on price alone 5. Work continually on the system of production and service 6. Institute modern methods of training 7. Institute modern methods of supervision of workers 8. Drive out fear 9. Break down barriers between departments 10. Eliminate slogans, exhortations, and targets for the work force 11. Eliminate numerical quotas 12. Remove barriers preventing pride of workmanship 13. Institute a vigorous program of education and retraining 14. Take action to accomplish the transformation History of Quality Management Deming’s Concept of “Profound Knowledge” Understanding (and appreciation) of Systems - optimizing sub-systems sub-optimizes the total system - the majority of defects come from systems, the responsibility of management (e.g., machines not in good order, defective material, etc. Knowledge of Statistics (variation, capability, uncertainty in data, etc.) - to identify where problems are, and point managers and workers toward solutions Knowledge of Psychology (Motivation) - people are afraid of failing and not being recognized, so they fear how data will be used against them Theory of Knowledge - understanding that management in any form is a prediction, and is based on assumptions History of Total Quality According to Dr. Joseph M. Juran (1991): “On the assembly line at the Ford Motor Company in 1923, most of the workers producing Model T’s were immigrants and could not speak English. Many were also illiterate. Workers learned their trade by modeling the actions of other workers. They were unable to plan, problem-solve, and make decisions. As a result, the Taylor scientific school of management flourished, and MBAs and industrial engineers were invented to do this work. Today, however, the workforce is educated. Workers know what is needed to improve their jobs, and companies that do not tap into this significant source of knowledge will truly be at a competitive disadvantage.” History of Total Quality According to Phil Crosby, Quality is . . . An attitude: - Zero Defects - Continuous Improvement A measurement: - Price of Conformance, plus - Price of Nonconformance (defects) TQ: Transforming an Organization From To Motivation through fear and loyalty Motivation through shared vision Attitude: “It’s their problem” Ownership of every problem affecting the customer Attitude: “the way we’ve always done it” Continuous improvement Decisions based on assumptions/ judgment calls Decisions based on data and facts Everything begins and ends with management Everything begins and ends with customers Crisis management and recovery Doing it right the first time Choosing participative OR scientific management Choosing scientific AND participative management What is Six Sigma? • A goal of near perfection in meeting customer requirements • A sweeping culture change effort to position a company for greater customer satisfaction, profitability and competitiveness • A comprehensive and flexible system for achieving, sustaining and maximizing business success; uniquely driven by close understanding of customer needs, disciplined use of facts, data, and statistical analysis, and diligent attention to managing, improving and reinventing business processes (Source:The Six Sigma Way by Pande, Neuman and Cavanagh) Is 99% Quality Good Enough? • 22,000 checks will be deducted from the wrong bank accounts in the next 60 minutes. • 20,000 incorrect drug prescriptions will be written in the next 12 months. • 12 babies will be given to the wrong parents each day. Six Sigma Quality The objective of Six Sigma quality is 3.4 defects per million opportunities! (Number of Standard Deviations) 3 Sigma 4 Sigma 5 Sigma 6 Sigma 0.0 2700 63 0.57 0.002 0.5 6440 236 3.4 0.019 1.0 22832 1350 32 0.019 1.5 66803 6200 233 3.4 2.0 158,700 22800 1300 32 Defects Per Million Opportunities (DPMO) · 100K But is Six Sigma Realistic? · IRS – Tax Advice (phone-in) (66810 ppm) 10K 41 Average Company 1K 31 ···· ··· Restaurant Bills Doctor Prescription Writing Payroll Processing Order Write-up Journal Vouchers Wire Transfers Air Line Baggage Handling Purchased Material Lot Reject Rate 100 21 · (233 ppm) 10 11 Best in Class 1 1 Domestic Airline Flight Fatality Rate (3.4 ppm) 2 3 3 4 4 SIGMA 5 5 6 6 7 (0.43 ppm) 7 Six Sigma Improvement Methods DMAIC vs. DMADV Define Measure Analyze Continuous Improvement Reengineering Improve Design Control Validate Six Sigma DMAIC Process Control Improve Define Analyze Measure Define: Define who your customers are, and what their requirements are for your products and services – Their expectations. Define your team goals, project boundaries, what you will focus on and what you won’t. Define the process you are striving to improve by mapping the process. Six Sigma DMAIC Process Control Improve Define Analyze Measure Measure: Eliminate guesswork and assumptions about what customers need and expect and how well processes are working. Collect data from many sources to determine speed in responding to customer requests, defect types and how frequently they occur, client feedback on how processes fit their needs, how clients rate us over time, etc. The data collection may suggest Charter revision. Six Sigma DMAIC Process Control Improve Define Analyze Measure Analyze: Grounded in the context of the customer and competitive environment, analyze is used to organize data and look for process problems and opportunities. This step helps to identify gaps between current and goal performance, prioritize opportunities to improve, identify sources of variation and root causes of problems in the process. Six Sigma DMAIC Process Control Improve Define Analyze Measure Improve: Generate both obvious and creative solutions to fix and prevent problems. Finding creative solutions by correcting root causes requires innovation, technology and discipline. Six Sigma DMAIC Process Control Improve Define Analyze Measure Control: Insure that the process improvements, once implemented, will “hold the gains” rather than revert to the same problems again. Various control tools such as statistical process control can be used. Other tools such as procedure documentation helps institutionalize the improvement. Six Sigma DMADV Process Validate Design Define Analyze Measure Design: Develop detailed design for new process. Determine and evaluate enabling elements. Create control and testing plan for new design. Use tools such as simulation, benchmarking, DOE, Quality Function Deployment (QFD), FMECA analysis, and cost/benefit analysis. Six Sigma DMADV Process Validate Design Define Analyze Measure Validate: Test detailed design with a pilot implementation. If successful, develop and execute a full-scale implementation. Tools in this step include: planning tools, flowcharts/other process management techniques, and work documentation. History of Quality Assurance (1 of 2) • Skilled craftsmanship during Middle Ages • Industrial Revolution: rise of inspection and separate quality departments • Statistical methods at Bell System • Quality control during World War II • Quality management in Japan History of Quality Assurance (2 of 2) • Quality awareness in U.S. manufacturing industry during 1980s: “Total Quality Management” • Malcolm Baldrige National Quality Award (1987) • Quality in service industries, government, health care, and education • Current and future challenge: keep progress in quality management alive Productivity and TQM • Traditional view: – Quality cannot be improved without significant losses in productivity. • TQM view: – Improved quality leads to improved productivity. Basic Tenets of TQM • 1. The customer makes the ultimate determination of quality. • 2. Top management must provide leadership and support for all quality initiatives. • 3. Preventing variability is the key to producing high quality. • 4. Quality goals are a moving target, thereby requiring a commitment toward continuous improvement. • 5. Improving quality requires the establishment of effective metrics. We must speak with data and facts not just opinions. The three aspects of TQM Counting Customers Culture Tools, techniques, and training in their use for analyzing, understanding, and solving quality problems Quality for the customer as a driving force and central concern. Shared values and beliefs, expressed by leaders, that define and support quality. Quality Throughout • “A Customer’s impression of quality begins with the initial contact with the company and continues through the life of the product.” – Customers look to the total package - sales, service during the sale, packaging, deliver, and service after the sale. – Quality extends to how the receptionist answers the phone, how managers treat subordinates, how courteous sales and repair people are, and how the product is serviced after the sale. • “All departments of the company must strive to improve the quality of their operations.” Value-based Approach • Manufacturing Dimensions – – – – – – – – Performance Features Reliability Conformance Durability Serviceability Aesthetics Perceived quality • Service Dimensions – – – – – Reliability Responsiveness Assurance Empathy Tangibles The TQM System Continuous Improvement Objective Principles Elements Customer Focus Process Improvement Total Involvement Leadership Education and Training Supportive structure Communications Reward and recognition Measurement