Notes 2 - UniMAP Portal

advertisement

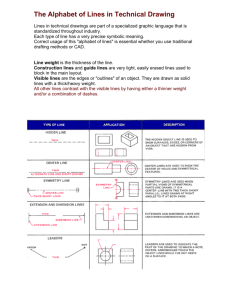

ERT249 CAD FOR BIOSYSTEMS ENGINEERING 2-D Transformation And Projection Geometric Transformation Graphics is at the core of any CAD/CAM system to produce the functionality and interactivity of the system. Some are: • geometric transformation • modelling and object hierarchy • algorithms for removing hidden edges and surfaces, shading and colouring, and clipping and windowing 1. 2D Transformation: Scaling 2. 2D Transformation: Rotation (a) Rotation about Coordinate Origin (b) Concatenation (c) Rotation about an Arbitrary Point (a) (b) (c) 3. 2D Transformation: Translation Examples of Transformation in AutoCAD 3-D Transformation And Projection Planar Geometric Projections Standard projections project onto a plane Projectors are lines that either converge at a center of projection and are parallel. Such projections preserve lines but not necessarily angles Non-planar projections are needed for applications such as map construction Taxonomy of Planar Geometric Projections Planar Geometric Projections Parallel Perspective Multiview orthographic Axonometric Oblique isometric dimetric trimetric 1 point 2 point 3 point 1. Parallel Projection a. Orthographic Projection Projectors are orthogonal to projection plane Multiview Orthographic Projection Projection plane parallel to principal face Usually form front, top, side views isometric (not multiview orthographic view) front in CAD and architecture, we often display three multiviews plus isometric top side b. Axonometric projection Same as perspective projection except that the projectors are parallel. This means that there are no vanishing points. Depending on the orientation of the object, Axonometric projection can be divided into three classes: • 1.Trimetric. • 2.Dimetric. • 3.Isometric. di: means there are two sets of axes. iso: means similar c. Oblique Projection The object is aligned such that one face (the front face) is parallel to the picture plane. The projection lines are still parallel but they are not perpendicular to the picture plane. 2. Perspective Projection Projectors converge at center of projection Vanishing Points Parallel lines (not parallel to the projection plan) on the object converge at a single point in the projection (the vanishing point) Drawing simple perspectives by hand uses these vanishing point(s) vanishing point a. One-Point Perspective One principal face parallel to projection plane One vanishing point for cube b. Two-Point Perspective On principal direction parallel to projection plane Two vanishing points for cube c. Three-Point Perspective Three-point perspective is usually used for buildings seen from above (or below). In addition to the two vanishing points from before, one for each wall. This third vanishing point will be below the ground Some Frequently used 3D Terms Model • 3D objects made in AutoCAD called models • 2D work referred to as drawing/drafting Model in 3D 1. Wireframe Model • Object by its edges only • Wireframe cannot hide object that are behind them • Hole has no meaning in a wireframe model because there is nothing in which to make a hole 2. Surface Model • Surface model; solid + empty shell • Surface model often use wireframe models as a frame for their surfaces • Surface model; part wireframe + part surface 3. Solid Model • Wireframe, surface model & computer-calculated mass; • eg: volume, centre of gravity, mass moment of inertia • Solid models look like wireframe unless a hidden line removal command is in effect 4. Rendering • Shaded, realistic-looking picture of a surface solid model is called a rendering • Two type: • Grayscale rendering • Fully capable of colour rendering Reasons For Using 3D Closer to representing real object than a 2D Show design more clearly Good for verifying design as well as for use in presentation and documentation as well. Multi-view Drawing Projection Theory Engineering and technical graphics are depend on projection methods. Two methods primarily used: a) Parallel: object positioned at infinity & viewed from multiple points on an imaginary line parallel to the object. b) Perspective: object positioned at finite distance & viewed from a single point. Multi-view Projection Multi-view projection is an orthographic projection for which the object is behind the plane of projection. The object is orientated such that only two of its dimension are shown. Orthographic projection: A parallel projection technique. The projection plane is placed between observer and object. The projection plane is also perpendicular to the parallel line of sight. Multi-view drawings Employ multi-view projection technique Generally 3 views of an object are drawn Each view is a 2D flat image Example: Multi-view Projection Multi-view Lines Multi-view: Planes Multi-view: Planes View Placement View Placement Angle Projection There are two standard arrangement of all six views of an object First-angle projection Third-angle projection Each uses different symbol The names are derived from the method used to view the object being drawn In 1st angle projection, the object is placed in the first quadrant. In 3rd angle projection, the object is placed in third quadrant. Rules: 1st angle projection 3rd angle projection View from above is placed underneath View from above is placed above View from below is placed above View from below is placed below View from left is placed on right View from left is placed on left View from right is placed on left View from right is placed on right Symbols (a) 1st angle projection (b) 3rd angle projection Example: 1st and 3rd angle view projection 1, 2 and 3 view drawing View Selection View Selection Natural position Unnatural position View Selection Sectioning PREPARED BY: SAMERA BINTI SAMSUDDIN SAH SCHOOL OF BIOPROCESS ENGINEERING Outline Cutting Plane Section Lines Several Types of Section Drawings Purpose To demonstrate the proper use of section views which show internal features of objects that are not easily understood in standard multiview drawings To demonstrate the use of CAD tools in generating section views Sectioned Drawings Definition: A multiview technical drawing that reveals details about internal features by displaying the part as if cut by an imaginary cutting plane. Objective: To make the drawing more understandable, especially the internal details of the part Since the sectioned drawing shows internal features there is generally no need to show hidden lines Especially helpful for assembly drawings The Cutting Plane The Cutting Plane Cutting planes may be labeled at their endpoints if multiple cutting plane lines are used When using multiple cutting planes each sectioned drawing is drawn as if the other cutting plane lines do not exist The cutting plane line takes precedence over center lines Occasionally cutting plane lines are not shown when their location is obvious Section Lines Section lines are drawn where the object passes through the cutting plane If a saw was used to cut the part then section lines represent the cutting marks left by the saw blade Different materials may be represented by the use of different section line types The general section line type which may be used for any material is the line type for iron Section Lines Section lines should not be parallel or perpendicular to object lines Section lines are generally drawn at 45 degrees unless this conflicts with other rules Section lines should be oriented at different angles for separate parts Occasionally section lines are only drawn on the perimeter of large areas Section lines are not used for thin parts rather they are filled in solid (Do not use closely spaced section lines) Section Drawing Types Full Section Half Section Assembly Section Offset Section Broken-Out Section Revolved Section Removed Section Special Section Conventions Full Section The cutting plane passes completely through the part as a single flat plane Half Section The cutting plane only passes half way through the part The other half is drawn as usual Hidden lines are not shown on either half of the part A center line is used to separate the two halves Mostly used on cylindrical parts Assembly Section Shows how parts fit together Different parts have different section line orientation Different materials use different section line types Standard parts (shafts, pins, dowels, rivets, screws, washers, gears, etc.) are not sectioned Assembly Section Cut each part of the assembly and section each part with the appropriate section line type Put the parts together in their assembled position Assembly Section The shaft is not sectioned because it is a standard part and section lines would provide no additional information The other two part are made from the same material The orientation of section lines clearly shows the location of the different parts Assembly Section The top and bottom mating part are made from different materials in the part shown below A center line is added to the shaft to show that it is a circular feature Offset Section The internal features of many part can not be shown using a single straight cut to create the sectioned drawing An offset section is used for such parts Offset Section The multiview drawing is often difficult to interpret when there are several hidden features on the object A sectioned view makes the object much easier to understand Offset Section An offset section allows the cutting plane to pass through all of the internal features There may be several bends in the cutting plane Offset Section The actual part would show a new visible line at the bend in the cutting plane Since the cutting plane bend is arbitrary, do not show the line representing this bend in the sectioned drawing Offset Section The sectioned view does not show the bend in the cutting plane Hidden lines are not shown Be sure to include object lines that are behind the cutting plane Broken-Out Section Only a portion of the view is sectioned A jagged break line is used to divide the sectioned and unsectioned portion of the drawing Revolved Section A cross section of the part is revolved 90 degrees and superimposed on the drawing A jagged break line may be used to divide the revolved section from the rest of the drawing Removed Section Similar to the revolved section except that the sectioned drawing is not superimposed on the drawing but placed next to it The view and the cutting plane are labeled (Section A-A) The removed section may be drawn at a different scale Special Section Conventions There are special rules (conventions) that are followed to make some parts more understandable Some features are rotated to their true radial position in sectioned views Special Section Conventions The object is difficult to understand using standard multiview drawings where hidden lines are used to represent internal features Special Section Conventions If the part is sectioned as it would actually appear if cut the details of the ribs and holes would not be clear Since the objective is to make the drawing easy to interpret the drawing is modified following standard conventions Special Section Conventions The cutting plane shows that the features are revolved to their true radial position Hidden features are not shown The sectioned drawing produced is a distorted but clearer picture of the object The section drawing appear as a full section The arrows show the direction of the view Special Section Conventions Ribs are not sectioned when the cutting plane passes through them lengthwise Ribs are sectioned if the cutting plane passes through them at other orientations Special Section Conventions The front view is replaced by a full section view The cutting plane shown in the top view shows the direction of the line of sight The holes and ribs have been revolved to their true radial position The ribs are not sectioned in this orientation The section lines are all drawn at the same angle since the object is one solid part Sectioning With Solid Models Slice cuts the solid object at the specified cutting plane using the current color breaks the objects into two parts one part may be deleted or moved Section creates a 2-D drawing of the section only draws the portion of the object that is cut (i.e. the portion of the object that has section lines) Sectioning With Solid Models SLICE command SECTION command Sectioning With AutoCAD Use BHATCH Use the correct scale Default line orientation is 45 degrees The general line type is ANSI31 Use different line types for different materials Use PICK POINTS to select an internal point in the sectioned portion of the drawing THE END…