Levers for improving supplier development

advertisement

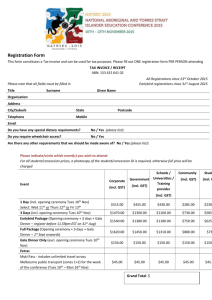

Levers for improving supplier development Productivity Working capital Logistic and planning Quality Product and specifications 1 Productivity Levers Themes Initiatives Production • Joint S&OP planning e.g. sharing of forecast • Batch size optimization e.g. using VMI • Minimise down time e.g. timely delivery • Reduce change over e.g. use of standard material Production • Reduce scrap e.g. by improved quality, see also “7 types of waste” • Increase volume e.g. more sales if lower unit cost • Avoid redundant processes e.g. in and outbound control • Investments e.g. possible if stronger customer commitment Administration • Process optimisation e.g. common standards and correct master data • IT integration e.g. on order and/or invoice Governance • Organisation and mandates incl. escalation of issues • Collaboration policies incl. process for continuous improvement • Alignment on goals and shared KPI’s • Joint Risk Management 2 Quality Levers Themes Initiatives Level of quality • Avoid over engineering e.g. on tolerances • Common standards e.g. on quality level • Transportation requirements e.g. on temperature QA/QC • Reduce excessive control e.g. level and placement of control • Right level of tracebility e.g. if recall • Use correct analysis methods e.g. knowledge transfer CSR • Shared code of conduct • Compliance gab and actions e.g. on safety and environmental • Traceability in supply chain Governance • Organisation and mandates incl. escalation of issues • Collaboration policies incl. process for continuous improvement • Alignment on goals and shared KPI’s • Joint Risk Management 3 Products & specifications Levers Product design & redesign Themes Initiatives • (Re) design to cost e.g. standard material selection, lower cost substitution, recycling • (Re) design for manufacturing e.g. lower change over time and scrap reduction • (Re) design for transport e.g. doublet stacking Product design & redesign • (Re) design for value e.g. commercial differentiation • Mass customisation • Make/buy business case & decision e.g. use BOM Process • Early supplier involvement • Common ECO process • Common standards e.g. on product specifications and certificates Governance • Organisation and mandates incl. escalation of issues • Collaboration policies incl. process for continuous improvement • Alignment on goals and shared KPI’s • Joint Risk Management 4 Logistic and planning Levers Planning and control Themes Initiatives • Joint S&OP process incl. sharing of forecast, capacity and manning • Differentiated service level and lead time on ABC products • Move push/pull upstream by changing trigger for • VMI/Consignment stock Planning and control • Increase flow and reduce lead time in supply chain by aligning batch size and pace for supply of materials into production • Ensure correct master data incl. correct parameter setting in ERP systems Logistic • Joint planning e.g. factory pick up • Transparency in transport cost and TCO • Transport optimisation e.g. double stacking, filling rate • Logistic optimisation e.g. correct labeling, units customised to warehouse Governance • Organisation and mandates incl. escalation of issues • Collaboration policies incl. process for continuous improvement • Alignment on goals and shared KPI’s • Joint Risk Management 5 Working capital Levers Stock reduction Themes Initiatives • Joint S&OP process incl. sharing of forecast and agreement on stock level • Increase forecast accuracy e.g. fix MRP noise that create to high purchase demand • Parameter tuning on safety stock, order quantity, service level Stock reduction Customer and supply outstanding • Capacity reservation instead of stock building • Improving timeline from invoice to payment e.g. by stop • Housekeeping, clean and unnecessary control processes up dead stock • Reduce/remove excessive stock e.g. both parties holding safety stock • Correct invoices for faster payment and/or automatic invoice approval • Optimise payment terms e.g. by using reverse factoring Governance • Organisation and mandates incl. escalation of issues • Collaboration policies incl. process for continuous improvement • Alignment on goals and shared KPI’s • Joint Risk Management 6