Sputtering of a standard medium b ALPI resonator

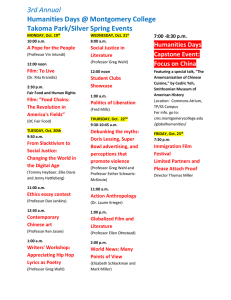

advertisement

Nb Sputtered Cu QWR: a 20 years experience from an idea to the routine beam acceleration A.M. Porcellato S. Stark V. Palmieri F. Stivanello 1 Once upon a time, 20 years ago... LNL started to think about ALPI, a heavy ion SC linac equipped with QW, Pb on Cu resonators, less expensive and easier to build than Nb QWR. Since the beginning we investigated the possibility to substitute in the future Pb with Nb. A laboratory for Nb QWR sputtering was set up and a devoted research project was funded in 1987. L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 2 TANDEM PIAVE ALPI COMPLEX SC Booster ALPI 70 SC Quarter Wave Resonators (Nb, Nb/Cu) Veq ~ 40 MV, species from 12C to 197Au Injected by Tandem or PIAVE PI Injector PIAVE VT ~ 14 MV (~13 MV at present) From H to 197Au, E = 30 ÷ 1.5 MeV/A CW or pulsed ECR on 350 kV platform SC-RFQs and QWRs Veq ~ 8 MV XTU-Tandem L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 3 ALPI resonators CR12 CR13 CR14 CR15CR16 CR17 CR18 CR19 CR20 B4 B3 COLD BOX CR10 CR9 CR8 CR7 CR6 CR5 CR4 CR3 B2 b=0.056, 80 MHz, full Nb b=0.13, 160 MHz, Nb/Cu b=0.11, 160 MHz,Nb/Cu b=0.11, 160 MHz,Pb/Cu L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 4 QWR Sputtering development strategy 1987: Funding a research project on QWR Nb sputtering 1988-1999: DC biased sputtering choice and system set-up 1990: Obtaining good SC performance on samples 1991: Sputtering on a simplified prototype 1994: Design of a ALPI high b resonator suitable for sputtering production and compatible with existing cryostats 1995/1998 Production and installation of 4 high b cavities in ALPI Sputtering of a standard medium b ALPI resonator (1998) Upgrading of the medium b ALPI resonators (2003) Sputtering on an Al substrate (2004) New design of medium b substrate (2005) L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 5 LNL QWR sputtering milestones 1991: first Nb sputtered prototype produced; 1993: three prototypes reach 6 MV/m @ 7 W 1995: Four high b QWRs installed in ALPI (4 MV/m @ 7W); 7 MV/m @ 7W reached in laboratory 1998: Installation of four high b QWRs, operating at 6 MV/m @ 7W in ALPI 1998: First medium b ALPI QWR reaches 4 MV/m @ 7W 1999: The upgrading of medium b resonators begin 2003 : All the old 44 accelerating cavities have their Pb superconducting layer replaced by Nb L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 6 ALPI high b QWRs 1.E+10 1W Q 3W 1.E+09 7W CR20-1 CR20-2 CR20-3 CR20-4 1.E+08 1.E+07 0 1 2 b=0.13, 160 MHz Drilled by a billet of OFHC 3 4 5 6 7 8 9 10 11 12 Ea [MV/m] Cu, 99.95% certificate grade No brazed joints, beam ports jointed by indium gaskets Rounded shorting plate Capacitive coupler CR20 resonators are in ALPI since 1988 The average operational accelerating field is 6 MV/m; the cavity CR20-3 is routinely amplitude and phase locked at 7.3 MV/m CR19, housing cavities similar in shape, but having a brazed substrate, was installed ALPI in 2001 No other cryostats are available for installation of further cavities L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 7 Upgrading of ALPI The possibility of an effective improvement of the medium b resonators by Nb/Pb replacement was shown in 1998 medium b QWRs Q 1.E+09 ALPI b=0.11, 160 MHz Brazed joints (especially the ones in the outer resonator surface) Flat shorting plate Beam ports shape Inductive coupler (hole in high current region) 3W 7W 15W 1.E+08 CR10-1 CR10-2 CR10-3 CR10-4 Average Q at 7W 1.E+07 0 2 4 6 8 Ea [MV/m] Limited the reached performance to 4.6MV/m @7W, a lower level than the ones of high b resonators. L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 8 ALPI upgrading results 46 Pb /Cu QWRs were upgraded by Nb sputtering. In spite of operating at about twice higher accelerating fields than before, the cavities maintain the same cryostat, the same control system, the same rf hardware and software. The performance is lower than that obtained by sputtering on new substrates, but the gap both in Q and Ea has been improving with time. Q0-value of 7x108 and Ea of 6 MV/m at 7 W were obtained in the last produced resonators. The average Ea in ALPI is however limited to 4.6 MV/m at 7 W, due to the lower Ea of resonators produced in between 2001 and 2002, when only bad substrates were available and the production schedule was very tight. The upgrading of medium b ALPI resonators gave a substantial increase in ALPI performance being the average Ea value of previously installed Pb/Cu resonators limited to 2.4 MV/m. L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 9 Substrate influence 7.5 MeV/m 6.5 Medium b Best performance on line @ 7W High b Measured/foreseen performance @ 7W 5.5 4.5 3.5 2.5 HB4 HB3 HB2 HB1 hb4 hb3 hb2 hb1 PP7 PP6 PP5 PP4 PP3 PP2 PP1 FC47 FC46 FC45 FC44 FC43 FC42 FC41 FC40 FC39 FC38 FC37 FC36 FC35 FC34 FC33 FC32 FC31 FC30 FC29 FC28 FC27 FC26 FC25 FC24 FC23 FC22 FC21 FC20 FC19 FC18 FC17 FC16 FC15 FC14 FC13 FC12 FC11 FC10 FC9 FC8 FC7 FC6 FC5 FC4 FC3 FC2 FC1 3 2 Cavity The cavity shape is important: high b series (HB), having rounded shorting plate, no beam ports or brazed joints, have the best performance. We have reduced performance in medium b (FC) and also in high b (hb) cavities in case of impurities delivered during the sputtering process from brazed joints. The PP series has joints in the outer cavity surface and an extra hole in the high current region, which both contribute to spoil the performance. 10 L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 Production Experience Ea [MV/m] 8 Best performance on line @ 7W Measured/foreseen performance @ 7W 6 • Ea=freq.dependent • PP cavity series 4 • Feed trough leak • Q degradation Production date after venting 2 • first Cu prototypes 7 8 9 0 1 2 3 7 8 9 0 1 2 3 -9 -9 -9 -0 -0 -0 -0 -9 -9 -9 -0 -0 -0 -0 • New cathode Jun Dec Jun Dec Jun Dec Jun Dec Jun Dec Jun Dec Jun Dec • No In joint, but Most of the ALPI cavities were produced in between June 00 and stronger end plate December 03 after an initial prototyping phase. contact The performance has been improving with time mainly because of: - Better substrate adjustment - HPW resonator rinsing before mounting the cavity in the line cryostat - Use of a new cathode In the production stage every cavity reaching 4 MV/m was installed, but sometimes, because of lack of time, we had to install also resonators which had inconvenience during the chemical or sputtering process and resulted in lower performance. L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 11 Q 1.E+09 1W 3W 7W 15 W 1.E+08 CR14-1 CR14-3 CR18-1 CR18-3 1W 7W 1.E+07 0 1 2 3 4 5 CR14-2 CR14-4 CR18-2 CR18-4 3W 15 W 6 7 8 Ea [MV/m] Q- curve of resonators in the last two installed cryostats, CR14 and CR18 Example of lack of time constraints During CR14-4 sputtering there were discharges in a feed-through, which forced to vent the sputtering chamber for maintenance. The process was continued later on without performing any chemical treatment. The resonator performance was reduced, however the cavity had to be accepted because of the necessity of installing the cryostat on line. The repeating of the chemical treatment and a new sputtering process would have allowed to reach standard results. L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 12 Cavities at work L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 ALPI Equivalent voltage 50 45 40 35 30 25 20 15 10 5 0 06 20 05 20 04 20 03 20 02 20 01 20 00 20 99 19 98 19 97 19 96 19 19 95 Nb/Cu high beta Nb/Cu medium beta Pb/Cu medium beta Nb, low beta Year Number of operating cavities in ALPI 70 Nb/Cu high beta Nb/Cu medium beta Pb/Cu medium beta Nb, low beta 60 50 40 30 20 10 06 20 05 20 04 20 03 20 02 20 01 20 00 20 99 19 98 19 97 19 96 19 95 0 19 MV Since 2001 most of the ALPI equivalent voltage is provided by Nb/Cu cavities, medium and high b types: They do not need of continuous or fast tuning They can operate at the accelerating field determined by the available cryogenic power. There is no degradation with time after installation. The average fields is still improving. The low b resonators, which can reach average field of 6 MV/m at 7 W, have to be presently locked at an average field lower than 3 MV/m in the ALPI environment. A plan is now funded to raise the operational accelerating field by increasing the rf driving power. That will ask for new rf cryostat lines and a cooled coupler. Year 13 More accurate “Lifting” the old Cu substrate (the opening of all the trapped enclaves was not well performed in the first produced resonators) Better tuning plate contact to avoid Indium joint (modifying the end plate and doubling its fixing screws) Cleaner assembling condition before and after sputtering Longer high power rf conditioning (not enough devoted time up to now) Possible improvements maintaining old substrates , L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 14 Low cost ways to improve the performance further We do not have a clean room for cryostat assembling. We have to align the resonators with their beam port open to air. We have to close the cryogenic circuits after the resonator assembling It would surely help: – Avoid cryostat venting to air (because of cryogenic circuits leaks) – Perform high pressure rinsing after resonator alignment (possible if we have not the In joint) – Longer rf and He conditioning (5 MV/m reachable @ 7W in old substrate) L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 15 Further possible improvement in low b QWR performance We are building 4 new substrates, using spare Cu parts with: – – – – – New beam port design A rounded shorting plate A capacitive coupler Without holes in high current regions Without brazing in the outer resonator body First test foreseen by the end of 2006 L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 16 Two S.C. Nb SRFQs are operating at Legnaro in PIAVE, the new ALPI injector. Each of them is provided with a couple of sputtered Nb/Cu plates. They demonstrate that by enough strength, the junction between the Nb cavity body and the end plates gives a sufficient good rf joint. The ALPI and PIAVE QWR Nb cavities are also provided with sputtered Nb plates. L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 Nb/Cu end plates 17 Nb/Cu sputtering advantages Mechanical stability (mechanical vibrations are not an issue) Frequency not affected by changes He bath Dp (<0.01Hz/mbar) Reduced over-coupling (smaller amplifier, coupler do not need cooling, rf lines have reduced size and limited rf dissipation) High thermal stability (less prone to hot spots, conditioning easier) Stiffness (in case of loss of isolation vacuum leak…) Absence of Q-disease (less demand on cryogenic system cooling velocity and reliability) Insensitivity to small magnetic fields (no magnetic shielding) High Q of the N.C. cavity (easier coupling in N.C state) Absence of In vacuum joints (vacuum leaks less probable) Price (both material and construction) The lower performance of Nb/Cu cavities at high fields, due to the more pronounced Q-slope of Nb/Cu resonators, is not an issue in QWRs as it is in b>0.5 cavities, because beam dynamic constraints require to limit the accelerating gradient in the low b section of linacs to values well reachable by Nb sputtered resonators. L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 18 Surface finishing and chemical treatments . Electropolishing (20mm, 2 hours, phosphoric acid+butanol, computer controlled) Rinsing (water, ultrasonic water, HPR) Chemical polishing (10mm, 4 min, SUBU5) Passivation (sulphamic acid) Rinsing (water, ultrasonic water, HPR) Drying (ethanol, nitrogen) L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 19 The sputtering process Sputtering chamber . • Good vacuum • No discharges • High substrate temperature L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 Cu base Cathode: Nb tube 20 The sputtering parameters Argon pressure: 0.2 mbar Substrate temperature: 300-500°C Cathode voltage: 1KV . sustained by Power discharge: about 5 KW Bias: - 120 V The sputtering process Average film thickness: about 2 mm The cavity end plate is also Nb sputtered in a devoted chamber, set up for producing PIAVE SRFQs end plates L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 Operation sequence Mounting the resonator in the sputtering chamber Pumping the vacuum chamber Resonator bake-out, at about 500°C for a couple of days The sputtering process: in 12 steps of about 15 minutes each Cooling the resonator at room temperature in vacuum The sputtering cycle of a QWR requires 9 days 21 Conclusion The Nb sputtering technology shows to be very effective in producing reliable resonators, which have high performance, are very steadily phase locked and are easy to put into operation. Even better results can be obtained using suitable substrates. The high number of produced and operational resonators and the reliability of the sputtering process (rejection rate less than 10%) demonstrate that the technology is mature and very competitive and could be industrially applied. L.N.L, Thin film ... Workshp, Porcellato 9 Oct 2006 22