Puttick Grid - University of Warwick

advertisement

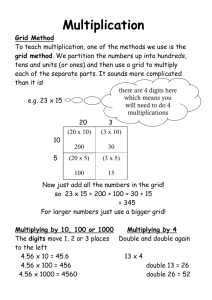

Puttick Grid Introduction The Puttick Grid was developed by John Puttick, originally at PA Consulting and subsequently at the University of Warwick, and first published by the DTI in ‘Factory for the Future’ (1995). The Grid was introduced as a methodology through which a manufacturing or service company could develop an operational strategy which was wholly aligned to delivering specific customer values. To this end, the Grid assists companies to evaluate: How does the market view a company’s product-market arena today How will the market view a company’s product-market arena tomorrow Thus the company is able to prepare its strategies and plans in the light of the how the customer views and appreciates the products it wishes to acquire and the characteristics of the acquisition process, rather than how the organisation views its own products, strengths and weaknesses. Product families are placed in one of four categories: Super Value Goods Products/Services with time-limited windows of opportunity (e.g. fashion goods, spares) Consumer Durables Commodities Placement is based on two key criteria: Uncertainty: Driven by changes in factors such as specification, quality, process reliability, level of demand, external influences (e.g. politics, weather), fashion changes, supply changes, competitors’ actions etc., which typically cannot be forecast with certainty Complexity: Determined by numbers of products and variants (including customisation), layers in bills of material, tiers in supply chain, purchased items, suppliers, contractors, processes, and transactions High High Product Complexity Low Super Value Goods Fashion / spares Consumer Durables Commodities Uncertainty Low TRANSFORMING CAPABILITY SUPPORT MATERIALS LEADING VISION CREATION Puttick Grid Super Value Goods: Highly complex products, specific requirements for which are highly uncertain. The lifecycle of these products is generally long, with up-grading and re-fitting common. Industries which best fit within this category are aerospace, defence, heavy electrical equipment and railway equipment. Differentiation is based on fitness for purpose and service support. Fashion / Spares etc.: These products are categorised by suddenly high demand, rapid depreciation and high rates of obsolescence, or the products are suddenly needed and demand is immediately fulfilled. Industry sectors which fit within this category are food and drink, cosmetics, mobile phones and emergency calls on contractors such as builders, plumbers and electricians. Emotional appeal and time to market within a limited window of opportunity are key methods of differentiating fashion or spares products. Consumer Durables: For consumer durables there is a medium term lifecycle with a strong focus on a second hand market. Industries such as automotive, white goods and machine tools fit within this category. Value for money and availability are important differentiators for the consumer durables products. Commodities: These products are generally consumables which can be recycled such as simple components, paper, primary metals and glass. Price is the key differentiator of commodity products. The underlying concept behind the Puttick Grid is understanding the product families from the customer’s point of view. Customer perceptions of products will determine where the product is placed in the grid: High Complexity Low High •Requirements present a real challenge •Few other suppliers have the capability •Some risk of failure must be accepted •Expect to pay for the privilege •Owning one will raise my image •“I must own one” •Prepared to pay for exceptional service •Rare capability that is urgently needed •Can put us ahead of competitors Uncertainty •Recognised as good make •Plenty of choice •Not expected to pay silly prices •Well proven products / services •Service exceeds expectations •Functionality satisfies needs •Prepared to pay for something extra •Numerous alternative suppliers •Requirements easy to satisfy •Expect low price today •Expect even lower price tomorrow •Service and quality are given Low TRANSFORMING CAPABILITY SUPPORT MATERIALS LEADING VISION CREATION Puttick Grid Product positioning should be used to ensure that all business processes and requirements are aligned, including business imperatives: Super Value Goods: leading edge technology; strong design and development; Fashion / Spares: market vision; rapid time to market; Consumer Durables: effective supply of defined product range; brand management; Commodities: low cost supply to wide customer base High High Machine Tools Low Product Complexity Power Gen. Equip Watches Trainers Mobile Telephone Uncertainty Light Bulbs Metal Windows Low All aspects of the business should be focused on delivering the value ‘specified’ by the customer; including, values and behaviours, skills, manufacturing technology (process, plant and equipment), supply chain management and financial configuration. However, positioning is not static and can change over time, for example: Broadly, there are three classes of strategies companies can adopt as a result of these evaluations: 1) Compete as a commodity provider 2) Differentiate their product(s) further in a specified quadrant 3) Create the means to move their product(s) ‘back up’ the Grid. TRANSFORMING CAPABILITY SUPPORT MATERIALS LEADING VISION CREATION Puttick Grid Further Information Overview: Turner, S., 2002, ‘Tools for Success: A Manager Guide’, McGraw Hill Professional, Berkshire, UK In-depth: Warwick Manufacturing group, University of Warwick Instructions The Puttick Grid on the next page may be used to capture your organisations product families from the customer’s point of view. TRANSFORMING CAPABILITY SUPPORT MATERIALS LEADING VISION CREATION Puttick Grid High Complexity Low High Uncertainty Low TRANSFORMING CAPABILITY SUPPORT MATERIALS LEADING VISION CREATION