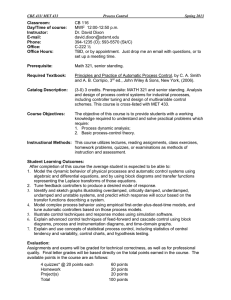

Course Prefix, Number, Title, Credit Hours: CBE, 464, Chemical

advertisement

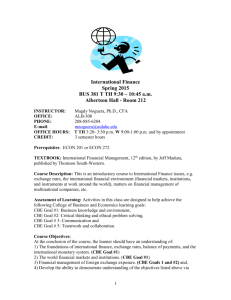

Course Prefix, Number, Title, Credit Hours: CBE, 465, Advanced Process and Equipment Design (2) University Name: South Dakota School of Mines and Technology Academic Term, Year: Fall, 2012 Course Meeting Time and Location: 08:00 – 08:50 M, W, F, CBEC 113 Instructor’s Contact Information Name: David Dixon Office location: C-222.5 Office hours: by appointment Office phone number: 605-394-1235 Email address: david.dixon@sdsmt.edu Course Description Catalog description: Course topics featuring design of processes and equipment unit operations, such as: filtration, cyclones/hydrocyclones, sedimentation, centrifuges, vacuum system sizing and leakages, particle sizing analysis via sieves, PSA, SEM, TEM, mixers (HT, MT, etc.), dispersion of 2nd phase and droplet sizes, S, L, V dispersions, compressors, removal of liquid, size reduction/enlargement, process piping/equipment, and crushers. Coverage may also include the principles of heat exchange networks, heat integration, and process optimization. Additional course description (optional): Course Prerequisites Previous courses/experience: CBE 317 or permission of instructor. Technology skills: Students entering this course are expected to know: pump selection and design of simple piping systems; design of heat exchangers, absorbers, and distillation columns; fundamentals of unit operations; engineering economics; elementary process control (CBE 333); thermodynamics and reaction engineering; PFD and PID formats Aspen Plus software package; literature and patent search procedures. Description of Instructional Methods: The main types of instructional methods utilized in this class include classroom lecture and discussions. Either method will utilize communication technologies available in the classroom provided. Course Requirements Required textbook(s) and other materials: Turton, R., R.C. Bailie, W.B. Whiting, J.A. Shaeiwitz: Analysis, Synthesis, and Design of Chemical Processes, 3rd ed., Prentice Hall PTR, 2009. Crowl, D.A., and J.F. Louvar, Chemical Process Safety: Fundamentals with Applications, 3rd ed., Prentice Hall PTR, 2011. Branan, C., Rules of Thumb for Chemical Engineers, 2nd edition (or most recent), Gulf Publishing Company, Houston, TX, 1998. Supplementary materials: Perry, R.H., and D. Green, Chemical Engineers’ Handbook, 6th ed (or others as needed), McGraw-Hill, 1984. Ulrich, G.D., A Guide to Chemical Engineering Process Design and Economics, John Wiley & Sons, Inc., 1984. Peters, M.S., and K.D. Timmerhaus, Plant Design and Economics for Chemical Engineers, 4th ed., McGraw-Hill, 2003. Walas, S.M., Chemical Process Equipment Selection and Design, Butterworth, 1988. Sinnott, R.K., Coulson & Richardson’s Chemical Engineering, Volume 6, Chemical Engineering Design, 3rd ed., Butterworth/Heinemann, 1999. Coulson, J.M., and J.F. Richardson, Coulson & Richardson’s Chemical Engineering, Volume 1, Fluid Flow, Heat Transfer and Mass Transfer, 6th ed., Butterworth/Heinemann, 1999. Woods, D.R., Rules of Thumb in Engineering Practice, Wiley-VCH, 2007. Chemical Abstracts USPTO: http://www.uspto.gov/ Various technical journals; for example, ”Industrial and Engineering Chemistry Research”, ACS Publications. Class attendance policy See current SDSMT catalog Cheating and plagiarism policy See current SDSMT catalog: Policy Governing Academic Integrity Make-up policy If a class meeting or deadline is missed due to pre-planned or unforeseen circumstances the instructor should be contacted as soon as possible to arrange for possible makeup work. Late work is not accepted for full credit, except under extenuating circumstances. Course Goals Include specific reference to System General Education Goals if applicable. Students in this course should expect to be able to apply their knowledge of chemical engineering, chemistry, mathematics, economics, and ethical factors to expand their knowledge of process engineering . Student Learning Outcomes (Course Outcomes): After completion of this course and depending on the material coverage, the average student is expected to be able to: understand and be able to apply principles of safety to process engineering; perform simple optimization calculations; set up a simple heat exchanger network; understand the role of different regulatory government institutions; apply design concepts for fire and explosion protection; perform safety analysis of a chemical installation; work both individually and as a group member Evaluation Procedures Assessments Tests, projects, assignments, etc. The final course grade will be the result of evaluation of a combination instruments that could include; tests, quizzes, homework, design projects, participation in a team, writing and oral presentation. 100 points in the course are assigned the following distribution: 2 exams 50 pts homework and possible quizzes 25 pts project assignments 25 pts Performance standards/grading policy Final grading will be by letter grades according to the following percentages: 90-100 =>A; 80-89 => B; 70-79 => C; 60-69 => D; <60 => F. Homework and exams are used to reinforce learning of the material and to allow assessment of understanding of lecture material, reading assignments, and homework problems. Homework is due at the start of each class period when it is requested. Homework to be graded will be chosen at random. Work should be done professionally. From time to time homework may be assigned to be done and turned in as a group. Other homework can be worked on in group study sessions, however individual solutions are to be turned in. Teams and individual efforts. The project assignment(s) will be problems more extensive from typical homework. These will likely be assigned to a group (team) of 3-5 members. It is important for each member of the team to continue to participate actively and to contribute meaningfully to the team’s project work. Full credit is given to those members who do so. Electronic Devices Policy Professional decorum. Tentative Course Outline/Schedule Note, this is a tentative list of topics and is subject to change depending on the class needs and the instructor. All topics in the chapters may not be covered and some may be covered to a greater depth than others. Process Safety Toxicology Reactive systems Heuristics Hazards Identification Ethics and Professionalism Codes and Standards Vessels Vacuum Equipment Solid Separation Optimization/Linear Programming HE Network Design (Pinch Technology) Pumps/Piping Reactors Additional Course Information A selection from the following list of videos at the CSB site (www.csb.gov) will be chosen for viewing, however, students are encouraged to watch as many as they can: o o o o o Anatomy of a Disaster (BP Texas City Refinery) Ethylene Oxide Explosion at Sterigenics Combustible Dust: An Insidious Hazard Runaway: Explosion at T2 Laboratories Reactive Hazards o o o o Explosion at Formosa Plastics (Illinois) Dangers of Hot Work Hazards of Nitrogen Asphyxiation Fire from Ice ADA Statement Students with special needs or requiring special accommodations should contact the instructor, (David Dixon, at 605-394-1235) and/or the campus ADA coordinator, Jolie McCoy, at 394-1924 at the earliest opportunity. Freedom in Learning Statement Freedom in learning. Under Board of Regents and University policy student academic performance may be evaluated solely on an academic basis, not on opinions or conduct in matters unrelated to academic standards. Students should be free to take reasoned exception to the data or views offered in any course of study and to reserve judgment about matters of opinion, but they are responsible for learning the content of any course of study for which they are enrolled. Students who believe that an academic evaluation reflects prejudiced or capricious consideration of student opinions or conduct unrelated to academic standards should contact the dean of the college which offers the class to initiate a review of the evaluation. RELATION OF COURSE OUTCOMES TO PROGRAM OUTCOMES (2011 - ): The following table indicates the relative strengths of each course outcomes in addressing the program outcomes (on a scale of 1 to 4 where 4 indicates a strong emphasis) Course Outcomes CBE 465 Program Outcomes (1) (2) (3) (4) (5) (6) (7) (8) Outcome 1 a b 4 3 2 2 3 Outcome 2 a b ChE Program Outcomes* Outcome 3 Outcome 4 a b a b a 1 1 4 4 4 4 4 Outcome 5 b c d 1 1 Outcome 6 a b 4 4 3 2 2 *For a list of Program Objectives and Program Outcomes, please go to: http://cbe.sdsmt.edu/undergraduate Revised Aug 2007 from BOR June 2004 3