Mars 90

advertisement

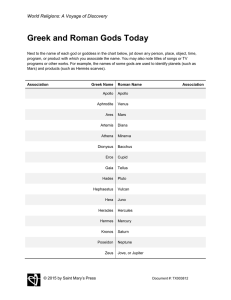

Mars 90 燃气轮机技术 VP90100(98)-001 Mars 90燃气轮机 1977年投入运行 售出550台机组 22.5百万运行小时 输出功率范围 - 13,000 to 15,000 hp (CS / MD) - 9285 to 10 695 kWe (GS) VP90100(98)-002 Mars 燃气轮机 发电机,压缩机&机械驱动应用方式 VP90100(98)-003 Mars 压缩机组 VP90100(98)-004 Mars 机械驱动 VP90100(98)-005 Mars发电机组 VP90100(98)-006 Mars燃气轮机 运行经验概要 至1998年九月 售出 机组 运行 小时 (百万 压缩机组 166 7.6 机械驱动 201 6.6 发电机组 其他相关机组 总计 164 8.0 37 1.3 568 23.5 VP90100(98)-007 Mars燃气轮机 设计特点 排气收集器 涡轮排气扩散器 燃料歧管 燃料喷嘴 压缩机转子总成 动力涡轮转子总成 燃气发生器透平转子总成 燃烧室总成 压缩机壳体总成 进口空气 压缩机可变导叶总成 VP90100(98)-008 Mars 附属驱动 独立驱动 附件驱动组件 VP90100(98)-009 Mars附属驱动 整合机组固定的附属驱动 附件驱动组件 VP90100(98)-010 Mars 附属驱动 机组固定 1996年投入 容许更短的箱体设计 消除对中的问题 大修时可进行改进 VP90100(98)-011 基本特性 15-级轴流压缩机 配备21个(扩散火焰)燃料喷嘴和14个燃料喷嘴(SoLoNOx)的环 形燃烧室 可倾瓦块轴径轴承 倾瓦块推力轴承 大致尺寸(L x W x H) 和重量 GS 47’8” x 9’2” x 12’0” CS 41’3” x 9’0” x 11’3” MD 28’3” x 9’0” x 11’3” 142,500 lb (Mars 90) 89,700 lb (Single Compressor) 52,700 lb (Driver Only) VP90100(98)-012 Mars 压缩机 高效率 压比为17:1 15级 压缩机可变进口导叶 垂直分开结构 特宽的一级叶片 VP90100(98)-013 Mars 压缩机转子动平衡 VP90100(98)-014 Mars 压缩机叶片安装 转动部分 - INCO 718 可调定子* - 7-4 PHSS 静止定子* - 410 SS *恺装提供在异常环境下的额外防护 VP90100(98)-015 Mars 燃烧室 环形设计 外部可拆喷嘴 相同的温度场分布 VP90100(98)-016 Mars 燃烧室衬垫 VP90100(98)-017 Mars 燃料喷嘴 SoLoNOx 标准型 VP90100(98)-018 Mars 燃气发生器透平 1级和2级定子喷嘴采用内部风冷形式 1级转子叶片采用内部风冷形式 VP90100(98)-019 Mars 透平材料 级 旋转叶片 喷嘴 轮盘 第一级 CM 247 LC (Mars 90) CMSX-4* (Mars 100) CM 247 LC Waspaloy INCO 792* CM 247 LC Waspaloy INCO 792 N-155 INCO 718 第二级 第三 & 四级 恺装提供在异常环境下的额外防护 VP90100(98)-020 Mars 转子轴承 在所有转子上采用轴向可倾瓦块轴承 在所有转子上采用可倾瓦块推力轴承 推力轴承易于安装 VP90100(98)-021 Mars轴向可倾瓦块推力轴承 VP90100(98)-022 Mars可倾瓦块径向轴承 VP90100(98)-023 Mars 动力涡轮 两级自由涡轮 性能范围扩大 VP90100(98)-024 Mars 燃气轮机性能 16 15 77 0 20 40 59 90 95 14 80 13 100 12 11 10 INLET AIR TEMPERATURE, F 17 Heat Rate, 78 79 Btu/hp-hr (00) 80 81 83 85 -20 76 75 Maximum Continuous Speed OUTPUT POWER PARAMETER, hpSL (000) 18 9 40 50 60 70 80 90 100 POWER TURBINE SPEED, % NPT (100% = 6825 rpm) VP90100(98)-025 Mars 燃气轮机升级 1980 Mars 90 11,150 hp, 32.8% 1825F 1983 Mars 90 12,600 hp, 33.0% 1935F 1990 Mars 100 14,100 hp, 33.5% 2050F 1995 Mars 90 13,000 hp, 33.1% 1935F 1994 Mars 100 15,000 hp, 34.0% 2050F VP90100(98)-026 Mars 燃气轮机演化 1980 Mars 90 8.3 MW, 32.8% 996C 1983 Mars 90 9.4 MW, 33.0% 1057C 1990 Mars 100 10.5 MW, 33.5% 1121C 1995 Mars 90 9.7 MW, 33.1% 1057C 1994 Mars 100 11.2 MW, 34.0% 1121C VP90100(98)-027 Mars Gas Turbine Evolution Component Change from Mars 90 to Mars 100 Combustor Liner Hastelloy X to Haynes 230 Fuel Injectors Tip Material Hastelloy X to Haynes 214 Stage-1 Blades MAR-M-247 to Single-Crystal CMSX-4 Coating Added Stage-2, 3 & 4 Blades IN 792 Ni Alloy Tip Seals Hastelloy X to MAR-M-509 Stage 1 & 2 Nozzles FSX414 to CM247 LC Coating Added Stage 3 & 4 Nozzles FSX414 to N-155 Coating Added VP90100(98)-028 Mars Compressor Design Modifications TIP MODIFICATION IGV STG 1R STG 1S STG 2S STG 2R = New Components VP90100(98)-029 Mars Gas Turbine Evolution Redesigned IGV and First Two Compressor Stages to Open Up Flow Path Improved Performance - Increased Power by 6.3% - 34% Thermal Efficiency - Increased Mass Flow by 7% - Increased Pressure Ratio (17.4:1) - Improved Compressor Efficiency by 1% - No Increase in Firing Temperature or Speed VP90100(98)-030 Mars Gas Turbine Ratings Model Application Mars 90 Mars 100 CS / MD GS CS / MD GS Power 13,000 hp 9285 kWe 15,000 hp 10,695 kWe Efficiency, % 33.1 31.7 34.0 32.5 TRIT, F 1935 1935 2050 2050 Heat Rate 7690 Btu/hp-hr 10,765 Btu/kWe-hr 7490 Btu/hp-hr 10,505 Btu/kWe-hr VP90100(98)-031 Mars 90 Gas Turbine Operating Experience Summary As of September 1998 Units Sold Estimated Hours (Million) Compressor Sets 86 5.7 Mechanical Drives 88 4.4 Generator Sets 87 6.8 7 0.6 268 17.5 Packager Associates Totals VP90100(98)-032 Mars 100 Gas Turbine Operating Experience Summary As of September 1998 Units Sold Estimated Hours (Million) Compressor Sets 80 1.9 Mechanical Drives 113 2.2 Generator Sets 77 1.2 Packager Associates 30 0.8 300 6.1 Totals VP90100(98)-033 Mars Gas Turbine Life Objectives 30-Year Core Engine Service Life 30,000 Hours Time Between Inspections (TBI) Interval 60,000 Hours Gas Generator Hot Section Component Service Life 100,000 Hours / 10,000 Start Cycles Turbine Disks and Compressors Rotating Component Service Life VP90100(98)-034 Mars Gas Turbine Maintainability Design Quick Gas Turbine Change Modularized Disassembly VP90100(98)-035 Mars Gas Turbine Major Maintenance Capability COMPRESSOR ROTOR BLADE AND STATORS NO. 5 ENGINE BEARING COMPRESSOR CASE HALF (BOTH SIDES) NO. 1 ENGINE BEARING ENGINE AFT THRUST BEARING POWER TURBINE ENGINE FWD THRUST BEARING GAS GENERATOR TURBINE ASSEMBLY COMBUSTION CHAMBER COMPRESSOR VP90100(98)-036 Mars Gas Turbine Major Demonstrated Maintenance Replacement Task Involves Quick Gas Turbine Change Elapsed Time, hr 8 Includes Realignment Gas Producer 10 Alignment Check Power Turbine 6 Alignment Check Gas Producer Turbine 20 PT Removal Combustor 24 PT Removal 3 Realignment Accessory Drive Gearbox VP90100(98)-037 Mars Gas Turbine Advanced Maintenance Techniques Borescope Inspection Vibration Detection Equipment Alignment VP90100(98)-038 Mars Gas Turbine Borescope Access Locations 15-SPECIAL INSPECTION PORTS REMOVABLE AIR INLET SCREEN 6-DIFFUSER PORTS REMOVABLE TORCH COMPRESSOR PORT CASE HALF GAS 14-FUEL 12-T5 (Either Side) INJECTOR GENERATOR TEMP. TURBINE PORTS PORTS PORTS 8-SPECIAL POWER TURBINE PORTS VP90100(98)-039 Mars Compressor Set TURBINE EXHAUST 3400 mm (11’3”) TURBINE AIR INLET 8600 mm (28’3”) 4267 mm (14’) Typical Package Weight = 52 255 kg (115,200 lb) Width = 2700 mm (9’) VP90100(98)-040 Mars Compressor Set Driven Equipment Options Solar Compressors - C65 for Pipeline Service - Various Multistage Solutions Other Compressors - Experience with All Manufacturers - More than 300 Total Units VP90100(98)-041 Mars Mechanical-Drive Package TURBINE EXHAUST 1994 mm (6’ 6 1/2”) 3400 mm (11’ 3”) TURBINE AIR INLET 8600 mm (28’ 3”) Typical Package Weight = 23 905 kg (52,700 lb) Width = 2700 mm (9’) VP90100(98)-042 Mars Generator Set TURBINE EXHAUST 3600 mm (12’) TURBINE AIR INLET 14 500 mm (47’ 6”) Typical Package Weight = 73 028 kg (161,000 lb) - Mars 100 Typical Package Weight = 64 698 kg (142,500 lb) - Mars 90 Width = 2800 mm (9’ 2”) VP90100(98)-043 Mars Generator Set GAS TURBINE EXHAUST COLLECTOR TURBINE ASSEMBLY GEARBOX GENERATOR MICROPROCESSORBASED CONTROLS COMBUSTOR COMPRESSOR AIR INLET BASE FRAME FUEL SYSTEM OIL SYSTEM CUSTOMER CONNECTIONS VP90100(98)-044 Mars Gas Turbine Package Skid Construction 3-Point Mount on Engine Skid Direct AC Start Lube Oil Tank Runs Length of Engine Skid All Subsystems Are Standard Assemblies Designed for Easier Maintainability VP90100(98)-045 Mars Gas Turbine Start System Features Two Options for Reliable Service IPG and O&G AC Electric VFD - Low Noise - No Fugitive Emissions O&G Pneumatic - No Parasitic Losses - No AC to Start Unit VP90100(98)-046 Mars Gas Turbine Lube Oil System Features Main Lube Supply Options - Engine Driven - Two 100% AC Motors AC Pre / Post Lube Oil Supply DC Post-Lube Oil Backup for CS / MD AC Motor Post-Lube Oil Backup with VFD Off DC Battery for GS Dual Filter with Transfer Valve VP90100(98)-047 Mars Gas Turbine Control / Combustion System Features Common Electric Actuators Gas Fuel Metering Variable Geometry Bleed Valve Inlet Guide Vanes VP90100(98)-048 Mars Gas Turbine Turbotronic Options Onskid PLC (Div 2) - Turbine Control Box - Optional Remote Display VP90100(98)-049 Mars Gas Turbine Turbotronic Options Onskid PLC (Div 2) - Turbine Control Box - Optional Console Remote PLC (Div 1) - Standard Console - Onskid Digital VP90100(98)-050 Mars Gas Turbine Controls Allen-Bradley Based Engine and Sequence Control Is A-B 5/20 Display Is A-B T36 - Industrial 386sx-25 Processor 4 MB RAM 14” SVGA Monitor 1.44 MB Floppy Disk Drive Integrated Vibration Monitoring - Bently Nevada 2201 - Vibration Data Available on Serial Link Network through A-B DH+ or Modbus VP90100(98)-051 Mars Gas Turbine Controls Standard Options Surge Control Predictive Emissions Monitoring System (PEMS) Condition Monitoring - Trending - Performance Evaluation B&W or Color Printer Station Controls VP90100(98)-052 Mars Gas Turbine Enclosure Common Design Features Indoor or Outdoor Installation Base-Skid Mounted Sound Attenuated for 85 dBA Maximum 120 mph Wind Load Up Inlet to 90 Left or Right Clocking Capability Up Inlet (Two-Shaft) Up or 90 Left or Right Exhaust (Two-Shaft) VP90100(98)-053 Mars Gas Turbine Ancillary Equipment ENCLOSURE VENT EXHAUST TURBINE EXHAUST TURBINE AIR INLET VENT FAN ENCLOSURE VENT INLET VENT SILENCER Forward End Aft End Left Side MOVABLE TURBINE HANDLING BEAM ACCESSORY HANDLING BEAM VP90100(98)-054 Mars Gas Turbine Ancillary Equipment TURBINE EXHAUST EXHAUST DUCT (Optional) EXHAUST SILENCER (Optional) TRANSITION DUCT (Optional) TURBINE TURBINE AIR INLET AIR INLET Forward End INLET SUPPORT STRUCTURE (Optional) Aft End EXHAUST SILENCER SUPPORT STRUCTURE (Optional) VP90100(98)-055 Mars Gas Turbine Enclosure Features Availability - Engine Skid - Entire Package Sound Attenuation 89 dBA at (1 m) 3 ft Doors Strategically Located for Easy Maintenance Access All Enclosure Panels Are Removable Customer Connections Are External to Enclosure Ventilation by AC-Driven Fan VP90100(98)-056 Mars Gas Turbine Enclosure Options Interior AC Lights Fire Detection / Suppression System (CO2) Combustible Gas Monitoring Dust Protection Systems Ancillary Support Frame - Inlet System - Exhaust System - Oil Cooler Gas Turbine Handling Kit VP90100(98)-057 Mars Gas Turbine Enclosure Maintenance Capabilities Internal Frame for Engine Removal Removal from Either Package Side Internal Removal of Major Components Access Doors for Maintenance and Inspection VP90100(98)-058 Summary High-Efficiency, Simple-Cycle Gas Turbine Designed for Long-Life Industrial Applications Designed-In Maintainability Capability VP90100(98)-059