500 - Cengage Learning

advertisement

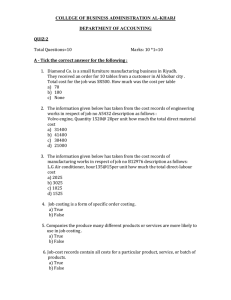

Cost Accounting Foundations and Evolutions Kinney, Prather, Raiborn Chapter 4 Job Order Costing Learning Objectives (1 of 3) • Contrast the job order and process costing systems and their valuation methods • Define what the term ‘job’ means • Explain the purpose of the documents used in a job order costing system Learning Objectives (2 of 3) • List the journal entries used to accumulate costs in a job order costing system • Identify how technology impacts the gathering and use of information in job order costing systems Learning Objectives (3of 3) • Explain how standard costs are used in a job order costing system • Describe how job order costing information supports management decision making • Explain how losses are treated in a job order costing system Job Order or Process Costing • • • • Job Order Small quantities Batches of identifiable, tailor-made products User-specific services Tracks costs by job Process • Large quantities • Homogeneous goods • Tracks costs by batch of goods by department Job Order Costing • A job is a single unit or group of units identifiable as being produced to distinct customer specifications • A job can be a – – – – Client Engagement Project Contract Methods of Product Costing • Cost Accumulation System defines – cost object – method of assigning costs to production • Valuation Method specifies – how product costs will be measured Six Possibilities V A L U A T I O N COSTING SYSTEM M E T H O D Job Order Process • Actual • Normal • Standard • Actual • Normal • Standard Job Order Costing System • Each job is a cost object • Costs are accumulated for each job • A job can consist of one or more units of output • There is a subsidiary ledger for each job Job Order Costing System WIP Subsidiary Ledger Job 1 Job 2 Job 3 100 200 500 Job 1 + Job 2 + Job 3 = = WIP Control Job 1 Job 2 Job 3 Total 100 200 500 800 WIP Control Material Requisition Form • Tracks who is responsible for materials • Verifies flow of materials from warehouse to department to job Job Order Cost Sheet • All financial information about a job – – – – direct material (from material requisition) direct labor (from time sheets or labor tickets) applied overhead budgeted cost information • When job is complete, use job order cost sheet to analyze actual costs to budgeted costs Employee Time Sheet • Time worked on each job Job Order Costing and Technology • Automate data collection and data entry • Accounting software includes job costing modules • Share information using intranet Intranet Restricted network for sharing information and delivering data from corporate databases to local-area network (LAN) desktops Standard Cost System • Actual cost • Normal cost • Standard cost – Predetermined norms (or standards) for materials, labor, and overhead – Compare actual costs to standard costs difference is a variance Management Use of Job Order Costing Systems • • • • • • Estimate future job costs Establish realistic bids and selling prices Develop budgets and standards Compare actual costs to estimated costs Determine which jobs are profitable Manage inventory Product and Material Losses • Shrinkage – Evaporation – Leakage – Oxidation • Production errors – Defects can be economically reworked – Spoilage cannot be economically reworked Product and Material Losses • Normal Loss – expected during production • Abnormal Loss – exceeds that expected during production Product and Material Losses Normal Loss Abnormal Loss Loss for most jobs In overhead rate Period cost Loss identified with a specific job Charge to specific job Period cost Questions • What is the difference between job order and process costing systems? • How do actual, normal, and standard costing valuation methods differ? • How is the job order cost sheet used?