Personal Protective Equipment

advertisement

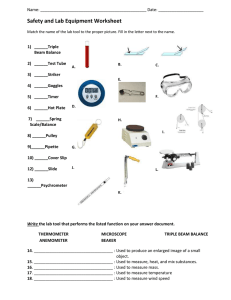

Personal Protective Equipment Department of University Safety & Assurances www.safety.uwm.edu US&A (v. 2/07) Why PPE is Important • Personal protective equipment (PPE) is designed to prevent or lessen the severity of injuries to workers. • The employer must assess the workplace and determine what hazards may necessitate the use of PPE before assigning PPE to workers. US&A (v. 2/07) Topics of Discussion • What is Included? – – – – – Head Eye Face Hearing Respiratory Protection – Hands – Foot – Clothing US&A (v. 2/07) Head Protection • Hardhats • Helmets US&A (v. 2/07) How Hard Hats Protect You • A rigid shell that resists and deflects blows to the head; • Suspension system inside acts as a shock absorber • Some hats serve as an insulator against electrical shocks • Shields your scalp, face, neck, and shoulders against splashes, spills, and drips • Some can be modified so you can add face shields, goggles, hoods or hearing protection US&A (v. 2/07) Hardhat Inspection • Shells should be inspected for dents, cracks, gouges & any damage from impact, penetration, abrasions, rough treatment or wear. • Degradation of thermoplastic material may be apparent when the shell becomes stiff, brittle, faded, dull in color or chalky in appearance. • Replace at the first sign of any of these conditions US&A (v. 2/07) US&A (v. 2/07) PPE for Impact Hazards • Safety Glasses: Primary protectors intended to shield the eyes from a variety of impact hazards • Goggles: Primary protectors intended to shield the eyes against flying fragments, objects, large chips, and particles. • Face Shields: Secondary protectors intended to protect the entire face against exposure to impact hazards US&A (v. 2/07) Eyewear • Some models have molded-in side shields and brow-guard for extra protection above and around eyes US&A (v. 2/07) Eyes: Goggles and Glasses • Goggles – Chemical Splash – Impact • Safety glasses US&A (v. 2/07) Ventilated Goggles • Ventilated goggles allow air circulation while providing protection against airborne particles, dust, liquids or light. Available with either Direct or Indirect ventilation • Direct ventilation goggles: – US&A (v. 2/07) Where strenuous work is done in hot conditions, 'direct ventilation' goggles may be more suitable. However these are unsuitable for protection against chemicals, gases and dust Indirect Ventilation • Indirect ventilation Goggles: 'Indirect ventilation' goggles are not perforated, but are fitted with baffled ventilators to prevent liquids and dust from entering. Indirect ventilation goggles will not protect against gas or vapor. US&A (v. 2/07) Non-Ventilated Goggles • Non-Ventilated Goggles: – Do not allow the passage of air into the goggle – Prevent splash entry – May fog and require frequent lens cleaning US&A (v. 2/07) Faceshields • DO NOT use any faceshield unless you also wear suitable primary eye protection devices (spectacles or goggles). • Faceshields are heavier & bulkier than other types of eye protector but are comfortable if fitted with an adjustable head harness. • Faceshields protect the face but do not fully enclose the eyes and therefore do not protect against dusts, mist or gases – Transparent face shields must be replaced when warped, scratched or brittle with age US&A (v. 2/07) An Eye Saved by Safety Glasses • While applying siding with an air powered staple gun, a staple hit a metal plate behind the siding, ricocheted back and one leg of the staple penetrated the wearer’s safety glasses' lens US&A (v. 2/07) US&A (v. 2/07) EPA and ANSI • EPA is responsible for determining adequacy of hearing protector attenuation (NRR). • EPA adopts ANSI’s protocol for making the determination • ANSI has issued a new protocol for the labeling regulation for hearing protectors that has yet to be adopted by EPA • EPA is collecting information on revising their labeling regulation US&A (v. 2/07) Hearing Protection • Ear plugs • Ear muffs • Audiometric testing • More information provided in training on hearing conservation US&A (v. 2/07) US&A (v. 2/07) Respirators • A hazardous task assessment may be done to determine if you need to wear a respirator • If you are required to wear a respirator you will be included in our respiratory protection program • You must be medically cleared to wear a respirator US&A (v. 2/07) Respirator Selection US&A (v. 2/07) Respirators • In addition to the initial fit-test, wearers must check the seal of their respirators every time they put them on • User seal checks are necessary to ensure that the respirator has been put on correctly US&A (v. 2/07) Dust Masks • Only suitable for non-hazardous, non-respirable nuisance dusts. • If your employer provides respirators for your voluntary use, or if you provide your own respirator, you need to take certain precautions to be sure that the respirator itself does not present a hazard. US&A (v. 2/07) Respirator Ratings Many different types available • “N” if they are not resistant to oil • “R” if somewhat resistant to oil, and • “P” if strongly resistant (oil proof). US&A (v. 2/07) Hood Respirators Helmet or hood respirators can be effective in protecting workers with facial hair, or in other applications where conventional respirators do not provide adequate fit, comfort or protection. HEPA filtered powered air purifying respirator (PAPR) US&A (v. 2/07) US&A (v. 2/07) Why It’s Important • It has been estimated that almost 20% of all disabling accidents on the job involve the hands • Some examples of traumatic injuries to your hands: – Cuts: Tools and machines with a sharp edges – Punctures: Staples, screwdrivers, nails, chisels and stiff wire – Sprains, Crushing Injuries: Getting your hands caught in machinery US&A (v. 2/07) Hand Protection • Gloves – – – – – – – – – Cotton Leather Latex Viton Butyl Neoprene PVC Nitrile Other US&A (v. 2/07) Disposable Vinyl • Deliver comfort, flexibility, sensitivity • Translucent white, 5-mil vinyl • Non-allergenic alternative to latex • Lightly-powdered or powder-free US&A (v. 2/07) Coated Gloves • Provide cut, puncture and abrasionresistance • Latex coating on palm, fingertips and thumb • Crinkle finish for superior grip in wet and dry applications US&A (v. 2/07) Coated Gloves • Tacky nitrile coating for sure grip • Light nylon shell for dexterity • Offers better fit and grip than uncoated cotton or string knit gloves US&A (v. 2/07) Reusable Latex • Versatile, reusable Latex • 18-mil, 100% natural latex – excellent tensile strength and sensitivity; good grip • Resists detergents, acids, salts, caustics, fats and alcohol • Cotton lining for ease of donning • 12” length protects wrists and forearm US&A (v. 2/07) Disposable Latex • Strong, comfortable and economical • Textured fingertips for secure grip • Available lightly powdered or powder-free US&A (v. 2/07) Latex + Neoprene • Comfort of latex plus the chemical protection of neoprene • Provides excellent chemical resistance against acids, oils, grease, salts, animal fats and battery acid • Resist puncture, tears and abrasion • Ideal for auto and battery manufacturing, chemical plants, cleaning printing presses and wiping down machinery US&A (v. 2/07) Butyl • Offers greater resistance to gas and water vapors than Neoprene • Provides greater safety when handling toxic substances like ketones, esters, etc US&A (v. 2/07) PVC/Nitrile Gloves • Gloves are PVC with nitrilereinforced coating • Textured to improve wet grip • Cotton interlock liner for comfort US&A (v. 2/07) Reusable Nitrile • Excellent resistance to a variety of solvents and petroleum products • Resist most liquids • Resist cuts, snags, punctures, swelling and degradation by organic solvents and hydrocarbons US&A (v. 2/07) Glove Selection Be sure you know which glove is appropriate for the chemical you are using US&A (v. 2/07) US&A (v. 2/07) Why It’s Important • Compression Injuries Heavy machinery, equipment, and other objects can roll over your feet. The result of these types of accidents is often broken or crushed bones. • Injuries from Spills and Splashes Liquids such as acids, caustics, and molten metals can spill into your shoes and boots. These hazardous materials can cause chemical and heat burns. US&A (v. 2/07) Foot Protection What kind of shoe should electricians wear? – Shoes with nonconductive soles meeting the requirements of ANSI Z41 PT9l (M/F) I-75 C-75 EH. "EH" represents the "electrical hazard" designation. US&A (v. 2/07) Types of Foot Protection • Work shoes • Boots • Steel-toed shoes & boots US&A (v. 2/07) Foot Protection • Other options in steel-toed shoes US&A (v. 2/07) Protective Clothing and Vests • Uniforms • Disposable clothing • Vests – Cooling – Visibility • Cold weather protection US&A (v. 2/07)