Post-registration variations

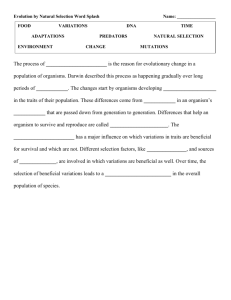

advertisement

Pharmaceutical Development Training Workshop on Pharmaceutical Development with focus on Paediatric Formulations Protea Hotel Victoria Junction, Waterfront Cape Town, South Africa Date: 16 to 20 April 2007 | Slide 1 April 2007 Introduction to the WHO Prequalification programme and Regulatory aspects Post- registration Variations Presenter: Maryam MEHMANDOUST, PhD Pre-qualification programme: Priority Essential Medicines WHO- HTP/PSM/QSM e-mail: | Slide 2 April 2007 mehmandoustm@who.int Variations to a medicinal product Throughout the lifecycle of a medicinal product, the Marketing Authorisation holder - is responsible for the product which circulates on the market place - is required to take into account technical and scientific progress and make any amendments required to enable the medicinal product to be manufactured and checked by means of generally accepted scientific methods - May wish to alter / improve the medicinal product or to introduce additional safeguard | Slide 3 April 2007 Variations to a medicinal product Such amendments have to be approved by the Competent Authority Same principles apply to a Pre-qualified product/dossier WHO Pre-qualification team should be informed of any changes by means of application for a variation Definition: a variation to the terms of a Pre-qualified dossier means an amendment to the contents of the documents, such as they existed at the moment the product was listed as Pre-qualified | Slide 4 April 2007 Variations to a Pre-qualified medicinal product Guidance on variations to a Pre-qualified dossier http://www.who.int/prequal/ , see under Information for applicants then Pre-qualification guidelines then medicinal products Adopted by the WHO Expert Committee on Specifications for pharmaceutical preparations in October 2006, applicable since January 2007 - Inspired technically and structurally from the EU guideline on dossier requirements for type IA and IB notifications but adapted to the WHO Prequalification environment | Slide 5 April 2007 Reminder on the EU system of variations to medicinal products for human use - EU Commission Regulations 1084/2003 and 1085/2003 including ● annex I (list and conditions for minor variations/notifications) ● annex II (changes leading to an extension application) separate guideline on dossier requirements for type IA and IB notifications (conditions and documentation required) - Regulation introduced in 2003 to ● simplify the procedures for execution and follow up of minor changes ● reduce the administrative workload of the competent authorities ● without reducing guarantees in terms of the quality, safety and efficacy of medicinal products Commission Regulation (EC) N0 1085/2003 of 3 June 2003 concerning the examination of variations to the terms of a marketing authorisation for medicinal products for human use and veterinary medicinal products falling within the scope of council Regulation (EEC) N0 2309/93 NTA, Guideline on dossier requirements for Type IA and IB notifications, Revision 1, July 2006 | Slide 6 April 2007 Reminder on the EU system of variations to medicinal products for human use - Some EU Member states have adopted the same system for application to national procedures some others not - Proposals have recently been made to revise the current system for a "Better Regulation" ● application to national authorisations in all Member States ● less prescriptive and more flexible regulatory approach by introduction/application of design space, risk management, … ICH Q8- Q9-Q10 ● "tell and do" notifications (IA) would become "do and tell" | Slide 7 April 2007 Reminder on the EU system of variations EU Regulation categorises variations into 3 types 1. Type IA notifications (very minor) - listed in annex I of the Regulation 2. Type IB notifications (minor) - listed in annex I 3. Type II variations (major) any change to the documentation proposed by the marketing authorisation (MA) holder which is not a type IA or a type IB notifications and which is not regarded as an extension to the MA (new application) : by default becomes a type II variation | Slide 8 April 2007 Reminder on the EU system of variations Different types of variations differ in timetables for validation and acceptance, sometimes different fees (for national procedures) - Type IA notifications (very minor): 14 days - Type IB notifications (minor): 30 days - Type II variations (major): 60 days a variation that cannot be deemed to be a minor variation or an extension of the MA | Slide 9 April 2007 Reminder on the EU system of variations Notifications - A variation notification normally concerns only one variation - Consequential variations: linked between each other and unavoidable e.g. change in a test procedure and in the specification - Parallel variations: not linked between each other but simply occurs at the same time e.g. registration of 2 new manufacturing sites - The EU notifications IA and IB apply to adult formulations and to paediatric formulations equally | Slide 10 April 2007 WHO Guidance on Variations to a Pre-qualified dossier - Applicable only to APIs and excipients manufactured by chemical synthesis or semi-synthetic processes and FPPs containing such APIs and excipients - Applicable to Multisource (generic) FPPs that have been pre-qualified by WHO including paediatric formulations - Variations to FPPs licensed by DRAs of ICH regions and associated countries and listed as Pre-qualified, should be also approved by corresponding original DRAs however WHO should be notified about the approval of the changes | Slide 11 April 2007 WHO Guidance on Variations to a Pre-qualified dossier To facilitate classification of various types of changes, the variation guide is composed of 4 annexes - Annex I: lists minor changes. - Annex II: definition and examples of major changes - Annex III: changes that make a new application /extension application necessary - Annex IV: stability requirements for variations and changes to Prequalified FPPs | Slide 12 April 2007 WHO Guidance on Variations to a Pre-qualified dossier Definition of changes - Minor change is a variation which can be found listed in Annex I. There are 40. - Major change is a change to the documentation which can neither be deemed to be a minor variation within the meaning of preceding definition (therefore exceeding the frame of a minor change) nor to be a change for which the submission of a new dossier would be necessary | Slide 13 April 2007 WHO Guidance on Variations to a Pre-qualified dossier Minor changes listed in annex I 1. Notifications designed by letter "N" ● Evaluation in 3 months ● Considered as approved if no correspondance by WHO with the applicant has been initiated within 3 months ● If validity cannot be acknowledged, correspondance will be started before the period of 3 months 2. Other minor changes in annex I | Slide 14 April 2007 WHO Guidance on Variations to a Pre-qualified dossier 3 points to consider - For all changes that are not considered as notifications, prior approval by WHO is always necessary before the change can be implemented - A justification should always be given why the change needs to be introduced - In case the change also implies a change in the pharmaceutical particulars in the Summary of Product Characteristics (SmPC), labelling and/or package leaflet/insert, this also forms part of the change. | Slide 15 April 2007 WHO Guidance on Variations to a Pre-qualified dossier ANNEX I – Minor changes Each change is numbered and subcategories depicted by letters and numbers. Conditions necessary for a given change are outlined for each subcategory and listed below each change. Documentation to be submitted is identified including all parts of the dossier that are affected by the variation according to the structure of the Pharmaceutical Quality Information Form (PQIF) | Slide 16 April 2007 WHO Guidance on Variations to a Pre-qualified dossier ANNEX I – Minor changes /example of a notification administrative change | Slide 17 April 2007 WHO Guidance on Variations to a Pre-qualified dossier ANNEX I – Minor changes List of administrative changes Var 1 - Change in the name and/or address of the supplier of the prequalified product Var 2 - Change in the name of the finished pharmaceutical product (FPP) Var 3 - Change in the name and/or address of a manufacturer of the active pharmaceutical ingredient (API) where no European Pharmacopoeia certificate of suitability (CEP) is available Var 4 - Change in the name and/or address of a manufacturer of the finished pharmaceutical product (FPP) Var 7 - Deletion of any manufacturing site (including for an API, intermediate or finished product, packaging site, manufacturer responsible for batch release, site where batch control takes place) | Slide 18 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Var 8: minor change in the manufacturing process of the API Conditions 1. No change in qualitative and quantitative impurity profile or in physicochemical properties 2. The route of synthesis remains the same, i.e. intermediates remain the same Documentation 1. Replacement of the relevant pages of the dossier according to the structure as listed in the PQIF and of the prequalified Drug Master File (where applicable), including a direct comparison of the prequalified process and the new process. 2. Batch analysis data (in comparative tabular format) of at least two batches (minimum pilot scale) manufactured according to the prequalified and the proposed process. 3. Copy of prequalified specifications of the API. | Slide 19 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Var 8: minor change in the manufacturing process of the API / Discussion The Pre-qualified applicant/ supplier should be able to have access to the appropriate information in order to judge about the 1st condition i.e. There is no change in qualitative and quantitative impurity profile or in physicochemical properties of the API ● Impurity profile: ordinary organic and inorganic impurities, residual solvents, catalysts residues, highly toxic impurities ● Physico-chemical impurities such as particle size (if applicable), polymorphism (if applicable) In order to fulfil condition 1 Either no confidential issue between the applicant / supplier to prequalification and the API manufacturer and data given in the dossier OR If confidential issue, the information should be submitted in the framework of the APIMF procedure | Slide 20 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Variations concerning introduction of a new source / a new manufacturer of the API Var 12 Change in the manufacturer of the API or final (ultimate) key intermediate in the manufacturing process of the API Var 13 Submission of a new or updated Ph. Eur. Certificate of Suitability for an API or starting chemical material/reagent/intermediate in the manufacturing process of the API Very frequent case in post-MA and also in post-prequalification - availability of APIs sources - to secure supply of APIs/ avoiding shortages - to optimise API costs | Slide 21 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Var 12: Change in the manufacturer of the API or final (ultimate) key intermediate in the manufacturing process of the API Conditions 1. The specifications (including in-process controls, methods of analysis of all materials), method of preparation (including batch size) and detailed route of synthesis are identical to those already prequalified. 2. Where materials of human or animal origin are used in the process, the manufacturer does not use any new supplier for which assessment is required of viral safety or of compliance with the current WHO Guideline on Transmissible Spongiform Encephalopathies in relation to Biological and Pharmaceutical Products or the Note for Guidance on Minimizing the Risk of Transmitting Animal Spongiform Encephalopathy Agents via Human and Veterinary Medicinal Products or an equivalent guideline of the ICH region and associated countries. | Slide 22 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Var 12: Change in the manufacturer of the API or final (ultimate) key intermediate in the manufacturing process of the API Documentation 1. Replacement of the relevant pages of the dossier according to the structure as listed in the PQIF. 2. A declaration from the supplier of the prequalified FPP that the route of synthesis, quality control procedures and specifications of the API and key (ultimate) intermediate in the manufacturing process of the API (if applicable) are the same as those already prequalified. 3. Either a TSE European Pharmacopoeia certificate of suitability for any new source of material or, where applicable, documentary evidence of absence of TSE risk material 4. Batch analysis data (in a comparative tabular format) for at least two (minimum pilot scale) batches of the API from the prequalified and proposed manufacturers/sites. 5. The application should clearly outline the ”prequalified” and “proposed” manufacturers. | Slide 23 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Var 12: Change in the manufacturer of the API or final (ultimate) key intermediate in the manufacturing process of the API Discussion The Pre-qualified applicant/ supplier should be able to have access to the appropriate information in order to judge about the 1st condition and be able to provide documentation 2 which is only limited to a "declaration". The 1st condition and the 2nd documentation together make that actually there should be no confidential issue between the pre-qualified applicant and the already approved API manufacturer and the future one i.e. no use of confidential dossier such as DMF/API master file. See differences with the EU guide | Slide 24 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Var 12: Change in the manufacturer of the API or final (ultimate) key intermediate in the manufacturing process of the API Problems From a general point of view, it is difficult to fulfil condition 1 i.e. 2 manufacturers of API who manufacture an API in the same details: specifications (including in-process controls, methods of analysis of all materials), method of preparation (including batch size) and detailed route of synthesis In most of the cases, the change would be a major change Remark applicable to the EU guideline equally | Slide 25 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Var 13: Submission of a new or updated CoS Conditions 1. The finished product release and end-of-shelf-life specifications remain the same. 2. Unchanged additional (to European Pharmacopoeia) specifications for impurities and product specific requirements (e.g. particle size profiles, polymorphic form), if applicable. 3. The API will be tested immediately prior to use if no retest period is included in the European Pharmacopoeia certificate of suitability or if data to support a retest period is not provided. 4. The manufacturing process of the API, starting material /reagent /intermediate does not include the use of materials of human or animal origin for which an assessment of viral safety data is required. | Slide 26 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Var 13: Submission of a new or updated CoS / discussion of conditions 1. The finished product release and end-of-shelf-life specifications remain the same. Preferable to check the feasibility on 1 batch of FPP 2. Unchanged additional (to European Pharmacopoeia) specifications for impurities and product specific requirements (e.g. particle size profiles, polymorphic form), if applicable. Attention to particle size and /or polymorphic forms if not covered by CoS 3. The API will be tested immediately prior to use if no retest period is included in the European Pharmacopoeia certificate of suitability or if data to support a retest period is not provided. If no retest period on the CoS, then stability data should be provided as complementary data or parallel variation 15: change in the re-test period of API 4. The manufacturing process of the API, starting material/reagent/intermediate does not include the use of materials of human or animal origin for which an assessment of viral safety data is required. Viral safety is not assessed within CoS scheme for instance. | Slide 27 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Var 13: Submission of a new or updated CoS / discussion of conditions Condition 2: Unchanged additional (to European Pharmacopoeia) specifications for impurities and product specific requirements (e.g. particle size profiles, polymorphic form), if applicable. Explanation Note Unchanged additional specifications for impurities refer to new additional impurities Excluded from this condition in EU practice - Tightened impurities - New residual solvents class II and class III complying with their option I ICH limits (nfg ICH Q3C) | Slide 28 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Introduction of a new source/ new manufacturer of API is often a major change The worst case would be an API - administered by oral route in a solid form/ suspension - insoluble in water and in acid pH - narrow therapeutic margin - used in a prolonged release form e.g. carbamazepine, ritonavir | Slide 29 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Introduction of a new source/ new manufacturer of API is often a major change Critical points related to co- existence of different sources of API - Physico-chemical characteristics which may have an impact on pharmaceutical quality and in-vivo performance of the FPP ● polymorphism: should be the same morphic form (if applicable, see ICH Q6A) ● particle size profile (if important, see ICH Q6A): identical method and norm used by the FPP manufacturer Common specifications Purity general tests, related substances (if route of synthesis identical), degradation impurities as inherent/ intrinsic to the substance Different specifications specific impurities related to one specific route of synthesis (related substances, residual solvents, catalysts, … Norms and methods can be different | Slide 30 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Introduction of a new source/ new manufacturer of API is often a major change Critical points to the attention of FPP manufacturers related to co- existence of different sources of API ● Check the feasibility on at least one lot of the FPP with the new source of API ● Try to keep master of particle size determination method ● Perform comparative dissolution testing with a discriminatory method ● Harmonise as much as possible the specifications of different sources of API | Slide 31 April 2007 - Variations to a Prequalified dossier ANNEX I – Minor changes Var 5: Replacement or addition of a manufacturing site for part or all of the manufacturing process of the FPP | Slide 32 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Var 5: Replacement or addition of a manufacturing site for part or all of the manufacturing process of the FPP Conditions | 1. Satisfactory inspection in the last three years either by WHO or a drug regulatory authority (DRA) in the International Conference on Harmonisation (ICH) region and associated countries. 2. Site appropriately authorized by a NDRA (to manufacture the pharmaceutical form and the product concerned). 3. Product concerned is not a sterile product. 4. Validation protocol is available or validation of the manufacture at the new site has been successfully carried out according to the current protocol with at least three production scale batches. Slide 33 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Var 5: Replacement or addition of a manufacturing site for part or all of the manufacturing process of the FPP Documentation | 1. Proof that the proposed site is appropriately authorized for the pharmaceutical form and the product concerned: – a copy of the current manufacturing authorization, a GMP certificate or equivalent document issued by the NDRA. – a GMP statement or equivalent issued by WHO or a Drug Regulatory Authority (DRA) in the International Conference on Harmonisation (ICH) region and associated countries. 2. The date of the last satisfactory inspection concerning the packaging facilities by WHO or drug regulatory authority (DRA) in the International Conference on Harmonisation (ICH) region and associated countries, in the last three years. 3. Date and scope (indicate if product specific, if related to a specific pharmaceutical form, etc.) of the last satisfactory inspection. 4. The batch numbers of batches ( 3) used in the validation study should be indicated and validation protocol (scheme) to be submitted. Slide 34 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Var 5: Replacement or addition of a manufacturing site for part or all of the manufacturing process of the FPP /documentation (cont.) 5. The variation application should clearly outline the “prequalified” and “proposed” finished product manufacturers. 6. Copy of prequalified release and end-of-shelf-life specifications. 7. Batch analysis data of three production batches and comparative data on the last three batches from the previous site; 8. For semisolid and liquid formulations in which the API is present in non-dissolved form, appropriate validation data including microscopic imaging of particle size distribution and morphology. 9. For solid dosage forms data of comparative dissolution tests [refer to Supplement 1of the Guideline on Submission of Documentation for Prequalification of Multi-source (Generic) Finished Pharmaceutical Products (FPPs) Used in the Treatment of HIV/AIDS, Malaria and Tuberculosis] with demonstration of dissolution profile similarity, performed on the last three batches from the previous site and the first three batches of the new site should be submitted. | Slide 35 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Var 5: Replacement or addition of a manufacturing site for part or all of the manufacturing process of the FPP discussion For Var 5c) | - 3 production batches for PQ versus 1 production batch and 2 pilot scale for EU - Documentation 9 on comparative dissolution testing for PQ instead of GMP compliance for manufacturing sites of API for EU - The French national regulation on variations has added an additional condition that the manufacturing process should be the same on the claimed new sites, PQ has added documentation 9: comparative dissolution testing. Slide 36 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Var 27: Minor change in supplier of packaging components or devices; spacer devices for metered dose inhalers are excluded Conditions 1. No deletion of packaging component or device. 2. The qualitative and quantitative composition of the packaging components/device remain the same. 3. The specifications and quality control method are at least equivalent. 4. The sterilization method and conditions remain the same, if applicable What to do if the condition 2 is not fulfilled? | Slide 37 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes Position correctly the variation ! - Why the condition 2 is not fulfilled? - Is it a change in supplier in reality? - Apply for a minor variation 26 together with a consequential variation 27: change in supplier | Slide 38 April 2007 Variations to a Prequalified dossier ANNEX I – Minor changes correct positioning Var 26: Minor change in the qualitative and/ or quantitative composition of the immediate packaging material Conditions 1. The product concerned is not a sterile product. 2. The packaging type and material remain the same (e.g. blister to blister). 3. The proposed packaging material must be at least equivalent to the prequalified material in respect of its relevant properties. 4. Relevant stability studies in accordance with the relevant guidelines have been started with at least two pilot scale or production scale batches and at least three months' stability data are at the disposal of the applicant…. | Slide 39 April 2007 Variations to a Pre-qualified dossier ANNEX II - Major changes Exceed the scope of minor changes as listed in annex I or they exceed/do not comply with the conditions to be fulfilled along with the change, but still do not cover the changes listed in annex III Examples - Change in the manufacturing process of the API - Change in the composition of the finished product - Change of immediate packaging of the product Applicant's responsibility to provide the relevant documentation (parts of the dossier affected by the change) to demonstrate that the major change will not affect the quality of the pre-qualified product and therefore will not have an impact on safety and efficacy of the product | Slide 40 April 2007 Variations to a Pre-qualified dossier ANNEX III - Changes making a new application /extension application necessary Changes to the API - change of the API to a different API - inclusion of an additional API to a multi-component product - removal of one API from a multi-component - change in the dose of one or more APIs | Slide 41 April 2007 Variations to a Pre-qualified dossier ANNEX III - Changes making a new application /extension application necessary Changes to the pharmaceutical form/dosage form - change or addition of a new strength / potency - change or addition of a new pharmaceutical form: change from tablets or capsules to an oral solution (for paediatric use) Change or addition of a new route of administration | Slide 42 April 2007 Variations to a Pre-qualified dossier ANNEX IV - Stability requirements for variations and changes to Pre-qualified FPPs Responsibility of the pre-qualified supplier to investigate whether or not the intended change will have an impact on the quality characteristics of APIs and /or FPPs and consequently on their stability. When stability data required, the choice of test conditions defined in annex IV refers to the guideline on the submission of Documentation for Prequalification of Multi-source (Generic) FPPs used in the treatment of HIV/AIDS, Malaria and Tuberculosis (main generic guide) | Slide 43 April 2007 Variations to a Pre-qualified dossier ANNEX IV - Stability requirements for variations and changes to Pre-qualified FPPs Minor changes as listed in annex I - minimum set of stability data to be submitted is defined in annex I - comparison of the new results, obtained in accelerated and long term conditions, to the stability results obtained on the unchanged API / FPP - to ensure that the change does not negatively impact the stability profile – that the specification limits of the API / FPP are still met at the end of the proposed retest period / shelf life. | Slide 44 April 2007 Variations to a Pre-qualified dossier ANNEX IV - Stability requirements for variations and changes to Pre-qualified FPPs Major changes: 3 examples dealt with in annex IV Change in the manufacturing process of the API if quality characteristics (eg physical characteristics, impurity profile) of the API are changed in such a way that stability may be compromised, comparative stability data required in accelerated and long term conditions on the API before and after the change: | API known to be stable 3 months on 1 batch of at least pilot scale API known to be unstable 6 months on 3 batches of at least pilot scale Slide 45 April 2007 Variations to a Pre-qualified dossier ANNEX IV - Stability requirements for variations and changes to Pre-qualified FPPs Major change: change in the manufacturing process of the API (cont.) if quality characteristics of the API are changed in a way that it may impact the stability of the FPP, additional stability data obtained in long term and accelerated testing : 3 months on 2 batches of at least pilot scale batches of FPP | - Physical quality characteristics: crystallinity and/or polymorphic state –if applicable- and charcteristics derived from crystallinity such as solubility, hygroscopicity, etc. - Chemical quality characteristics: impurity profile including degradation products Slide 46 April 2007 Variations to a Pre-qualified dossier ANNEX IV - Stability requirements for variations and changes to Pre-qualified FPPs Definition of a stable API An API is considered as stable if it remains within the initial specifications when stored at 25°C/60% RH or 30°C/65% RH, respectively, for 2 years and at 40°C/75% RH for 6 months and such data are available from the API manufacturer that applies for change. | Slide 47 April 2007 Variations to a Pre-qualified dossier ANNEX IV - Stability requirements for variations and changes to Pre-qualified FPPs Major change: change in composition of the finished product - Conventional dosage forms (conventional solid dosage forms, solutions) AND When the API is known to be stable Comparative stability data, at least 6 months duration on 2 pilot scale FPP batches - Critical dosage forms (eg prolonged release) OR API known to be unstable Comparative stability data, at least 6 months duration on 3 pilot scale FPP batches See definition of a pilot scale batch: 1/10 of production batch or 100 000 units whichever greater | Slide 48 April 2007 Variations to a Pre-qualified dossier ANNEX IV - Stability requirements for variations and changes to Pre-qualified FPPs Major change: change on immediate packaging of the finished product If less protective packaging or risk of interaction for semisolids or liquid dosage forms Comparative stability data in accelerated and long term conditions for at least 6 months on 3 pilot batches of FPP | Slide 49 April 2007 Variations to a Pre-qualified dossier ANNEX IV - Stability requirements for variations and changes to Pre-qualified FPPs Major changes requiring generation of new stability data - At least 1st production batch to be placed on long term stability testing as described in the approved protocol - Stability studies should be always continued to cover the entire shelf life accorded - Results should be made available to WHO on request or in case of OoS results Guideline on stability testing for applications for variations to a marketing authorisation, CPMP/QWP/576/96 Rev 1 | Slide 50 April 2007 CONCLUSION ● Any change to the content of the pre-qualified dossier should be reported to WHO PQ team ● The change should not adversely affect the quality, safety and efficacy of the pre-qualified product ● New experience and challenge in implementation of the guideline on variation for WHO prequalification team of assessors ● Same for applicants and suppliers to - understand the system and its mechanism, - position correctly the variation and to submit necessary data - not forget to apply for consequential variation when applicable and submit the corresponding documentation to avoid unnecessary additional data requested and additional rounds of assessments ● For instance, no fees in PQ Programme - Seriousness of applicants in the claimed variations ● No timetable except for those called notifications in WHO guidance main difference in major and minor changes is the extent of documentation submitted | Slide 51 April 2007