Elements of Computational Metrology

advertisement

Elements of

Computational Metrology

Vijay Srinivasan

IBM & Columbia U.

DIMACS Workshop on CAD/CAM, Rutgers U., October 7, 2003.

A Very Old Problem …

How tall is the pyramid of Cheops?

“Measure

the length of the pyramid’s

shadow when your own shadow exactly

equals your height.”

- Thales, ca. 600 B.C.

“Add

the measured heights of each of the

203 steps. Its uncertainty is 14 times the

uncertainty in measuring a single step.”

- Fourier, ca. 1800 A.D.

2

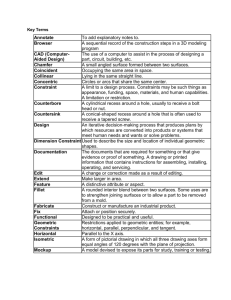

First, Some Definitions …

Metrology is the art and science of

measurements.

Measurement is the association of one or

more numerical values to physical objects

and characteristics.

Our focus today in on geometric

measurements and computations on them.

Specifically, our focus is on fitting and

filtering discrete geometric data.

3

The Big Picture …

Metrology

Dimensional (Geometric) Metrology

Coordinate and Surface Metrology

Computational Metrology

- Fitting and Filtering

4

In our context …

Fitting

Optimization

Continuous

optimization (e.g., least

squares fitting)

Combinatorial optimization (e.g., minimax

fitting)

Filtering

Convolution

Convolutions

of functions (e.g., Gaussian

filters)

Convolutions of sets (e.g., envelope filters

using Minkowski sums)

5

Industrial Setting …

Why do we bother?

Product

Is the manufactured object within

designer-specified tolerances?

Process

Conformance

Characterization

What is the capability of the manufacturing

process?

Is it under control over time?

These are major questions that arise in

computer-aided design and manufacture

6

Two Basic Axioms …

Axiom

All manufacturing processes are inherently

imprecise and produce parts that vary.

Axiom

of manufacturing imprecision:

of measurement uncertainty:

No measurement can be absolutely

accurate and with every measurement

there is some finite uncertainty about the

measured value or measured attribute.

These are independent axioms and

both should be considered operative in any real situation.

7

Imprecision in Manufacturing

No man-made artifact has ideal geometric

form.

No manufactured object can be perfectly planar, or

cylindrical, and so on.

There is experimental evidence that the

geometry of an engineered surface is more

like a fractal.

Over the range of engineering scales - from a

nanometer to a kilometer. (A dynamic range of

1012)

8

Uncertainty in Measurement

C.H.Meyer (NIST) reporting on his measurement of the

heat capacity of ammonia (circa 1970):

“We think our reported value is good to 1 part in

10,000: we are willing to bet our own money

at even odds that it is correct to 2 parts in

10,000. Furthermore, if by chance our value

is shown to be in error by more than 1 part in

1000, we are prepared to eat the apparatus

and drink the ammonia”

Results of our computations should be accompanied by a statement

of their uncertainty.

9

Fitting

Fitting …What is it and Why

do we care?

Associating ideal geometric form(s) to a

discrete set of points sampled on a

manufactured surface.

Datum establishment – for relative

positioning geometric objects.

Deviation assessment – how far has a

part deviated from its intended ideal

form?

11

Some Form Tolerances …

Syntax

Ø2 ± 0.1

0.05

0.04

Semantics

radial separation

between two coaxial

cylinders = 0.05 units

distance between two

parallel planes = 0.04 units

12

A flatness assessment

…Good old way

Part under inspection

Inspection plate

Dial indicator

13

Other form tolerances …

Type

Characteristic

Straightness

Symbol

—

Flatness

Form

Roundness

Cylindricity

… and many more types of tolerances.

14

Fitting as an optimization problem …

Given a set of points X, fit ideal geometric

element(s) Y that minimize an objective

function involving distances between X and Y,

subject to certain constraints.

Two popular fits:

Least Squares Fit – when the objective

function uses L2 norm.

Chebyshev Fit – when the objective function

uses L or other norm.

… and report the uncertainty in Y

if you know uncertainties in X.

15

TLS Plane Problem

Input: set of points X

Output: a point “x0” on the plane and

a direction vector “a” normal to it.

(Total Least Squares plane minimizes the sum of

the squares of the perpendicular distances of the

points from the plane.)

Solution:

• X0 is the centroid of the input set X.

• a is the singular vector associated with the

smallest singular value of the central

coordinate matrix of the input set X.

16

A sample code for TLS Plane

Input: set of points X

Output: a point “x0” on the plane and

a direction vector “a” normal to it.

function [x0, a] = lsplane(X)

x0 = mean(X)';

A = [(X(:, 1) - x0(1)) (X(:, 2) - x0(2)) (X(:, 3) - x0(3))];

[U, S, V] = svd(A, 0);

[s, i] = min(diag(S));

a = V(:, i);

17

Minimax Plane

A plane

that minimizes the maximum

(perpendicular) distance of the input set

of points.

Equivalent to the “width of a set”

problem.

A good example of combinatorial

optimization.

Implementation

is more challenging than

the TLS plane.

18

Some Interesting Questions …

Given uncertainties in the input data points,

what is the uncertainty of the computed

“width”?

Can the TLS fit give us a statistical estimate

of the “out-of-flatness”?

RMS deviation from the TLS plane?

Can TLS plane or Minimax plane help us to

establish a planar datum?

Supporting plane that minimizes the sum of the

distances of the input points from that plane?

19

Soft Gaging

Set Containment Problem

Deterministic Version: Given two

sets A and B, is there a rigid motion

r such that A rB (subject to some

constraints)?

Probabilistic Version: If A is given

with some uncertainty, what is the

probability that A rB ?

20

Filtering

Filtering … What is it and Why

do We Care?

Geometry

of engineered surface is

more like a fractal, in the engineering

range of scale.

Engineering function is scale dependent

– rough versus smooth surfaces.

Main purpose of filtering is to extract

scale dependent information

– and not compression of data!

22

Filtering as Convolution …

Of

Functions

y ( x)

z (s) K ( x s)ds

Of

Sets

A B {x y : x A, y B}

… and their discrete versions.

23

Gaussian Filter (Mean-line

Filter)

24

Morphological Operations

Primary operations

Dilation

D( A, B) A B

E ( A, B) A B

Secondary operations

Erosion

Opening

Closing

O( A, B) D( E ( A, B), B)

C ( A, B) E ( D( A, B), B)

… and alternating sequence operations.

25

Types of Morphological Filters

Same as morphological operations

Dilation filters

Erosion filters

Opening filters

Closing filters

… and alternating sequence filters

Most commonly used structuring elements

are disks (balls) and line-segments (flats).

26

Erosion Filter

All dimensions are in micrometers

Input profile

Output profile

27

Closing Filter (Envelope Filter)

All dimensions are in micrometers;

disk radius 50 micrometer

Input profile

Output profile

28

Alternating Sequence Filter

29

Columbia Lectures on

Elements of Computational Metrology

Introduction

A Brief History of Engineering Metrology

Linear and Orthogonal Regression

Fitting lines and planes

Width and Convex Hulls

Non-linear Least Squares

Other fits

Circular Elements and Proximity Diagrams

More Chebyshev Fits

Geometry of Engineered Surfaces

Introduce fractals

Integral Transforms and Convolutions

Filtering

Wavelets

Morphological Transforms

30

Summary

Computational Metrology - A discipline in its

own right.

Seemingly different practices are being

consolidated under optimization (fitting) and

convolution (filtering).

We can now provide better scientific basis.

Industrial need is the driver.

Several problems still remain open, especially

involving measurement uncertainty.

31