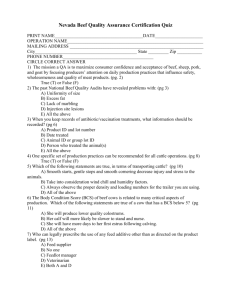

North Carolina Beef Quality Assurance

advertisement

Kentucky Beef Quality Assurance What is Beef Quality Assurance? “BQA is a process of figuring out what could go wrong, planning to avoid it – then validating and documenting what you have done. BQA is just part of good business,” Dee Griffin, DVM, associate professor at the University of Nebraska’s Great Plains Veterinary Education Center. What Does “Quality” Stand for In Beef Quality Assurance? • “Up until a few years ago, 25% or 1 out of every 4 people ordering beef at a restaurant had an unpleasant eating experience.” • Quality means wholesome and safe, but it also means providing a product to the consumer that delivers a desirable eating experience. 1 What is Certification? • Process by which producers accept responsibility for actions under which cattle in our production unit were produced. • Process allowing the beef industry to maintain its independence from regulatory agencies. What is BQA? • Based on recommended national guidelines and scientific research to meet the demands of today’s consumer • BQA Focuses on… – Care and Husbandry Practices – Feedstuffs – Feed Additives and Medications – Injectable Animal Health Products – Processing, Treatment and Record-Keeping www.BQA.org 19 History of BQA • 1970’s -Originally called Beef Safety Assurance. • In 1982 USDA-FSIS began working on the Preharvest Beef Safety Production Program. • By the mid to late 80’s the beef industry adopted the term Beef Quality Assurance began regulating themselves to avoid additional government regulation. • KY-BQA program began in 2000 More Than 30 Years of Beef Quality Assurance… Providing a Safe, Wholesome and Healthy Beef Supply National BQA Audit 2011 • Challenges 1995 – External Fat – Seam Fat – Overall Palatability – Tenderness – Overall Cutability – Marbling • Challenges 2011 – Food Safety – Eating Satisfaction – How/Where Cattle Raised – Lean, Fat, Bone – Weight and Size – Cattle Genetics Producer Findings • Healthy Cattle Equal Quality. To cattle producers, quality equals “raising healthy cattle and calves” and “producing safe and wholesome beef.” – 90% of producers have a working relationship with their veterinarian. • Though 95% had some level of routine vaccination and treatment protocols, only 31% had a written plan. Greater emphasis must be placed on documentation. • Injection Site Improvements. However, improvement is still needed, 41% of dairy producers still giving injections in the animal’s rump. • Low‐Stress Handling Is a Priority. Use of good stockmanship and animal‐handling skills is the • producer’s #1 method of intentionally influencing quality. Ninety‐eight percent do not use an electric prod as their primary driving tool. • Identification and Traceability. Seventy‐eight percent of respondents used individual animal ID (ear tag) as a means to keep track of withdrawal times for animal health products. Why Should You Become Certified? • Records allow for better business decisions • Eliminate carcass defects • Consumer confidence in meat and milk quality is vital to beef and dairy producers • We no longer just raise cattle, we are in the business of producing safe food! BQA Program Elements • Classroom or ChuteSide Training • Pass KY-BQA Post Test • Sign Production Contract • $5 Fee for to maintain database, create materials, etc. Other Resources • • • • Dairy BQA Transporter BQA Auction Market BQA On-farm Assessments The BQA Mission To maximize consumer confidence and acceptance of beef by focusing the producers’ attention to daily production practices that influence the safety, wholesomeness and quality of beef and beef products BQA Programs are driven by: • Producers • Government • Consumers – they purchase what they trust “Quality Assurance is everyone’s job, our future depends upon it ... and there are not most valuable players.” It is every producer’s obligation to utilize management and judgment that ultimately lead to a positive eating experience for the consumer. 2 BQA National Guidelines • • • • Care and Husbandry Practices Feedstuffs Feed Additives and Medications Processing, Treatment and RecordKeeping • Injectable Animal Health Products Employee Training and Education • Never assume that someone can properly handle cattle or use the proper techniques • Ongoing producer and worker education should be part of any management plan • Extension personnel can provide you with educational opportunities Care and Husbandry Practices • Handle/transport all cattle in such a fashion to minimize stress, injury and bruising • Regularly inspect facilities to help ensure proper care and ease of handling • Keep feed & water handling equipment clean • Provide appropriate nutritional and feedstuffs management • Maintain an environment appropriate to the production setting • Evaluating and enforce biosecurity • Keep records for a minimum of 2 years or longer as requirement by laws/regulations (ie. 3 years for Restricted Use Pesticides) Cattle Behavior • Sort cows from calves • Cattle have wide-angle vision – use solid sides • Eliminate shadows to prevent cattle from entering an area • Cattle move toward the light as long as it is not glaring • Minimize loud noises Cattle Behavior • Use animal's natural tendencies: – Cattle follow each other and have a natural tendency to circle • Use curved chutes – Flight Zone (aka personal space) and Point of Balance • Use to move cattle Source:http://www.grandin.com/behaviour/principles/flight.zone.html Tips for More Efficient Handling • Design and operate alleys and gates to avoid impeding cattle movement • Work cattle in groups • Call cattle rather than drive them • Use one-way gates • Avoid slippery surfaces • Quiet handling is essential Stock Trailer BQA • Loading/ Unloading – Low stress handling – Sorting • Equipment selection – Truck and Trailer – Floor space – Use proper facilities for loading cattle – Gates Stock Trailer BQA • Maintenance – Keep in good condition with all repairs made. – Tires – Wheels – Wires and Lights – Brakes – Floor – Clean out Stock Trailer BQA • Be sure tires are in good condition • Check age of tires • Check heels • Check bearings • Be sure a jack is available & accessible Driving Considerations •Defensive driving is highly encouraged •Plan your route ____ ____ Week Year Remember When Transporting Cattle • Before cattle leave the farm --Evaluate them for illness and severe lameness ---Do not sell cattle with – Cancer eye – Downers – Debilitated thin cows – Cattle which are sick – Cattle with antibiotic residues * DO NOT LOAD animals that are borderline non- ambulatory or downer animals, severely lame or sick Remember When Transporting Cattle • Allow for adequate room for cattle on the truck or trailer • Transport cattle during the cooler parts of the day– especially during summer or during times with elevated temperatures/humidity • To prevent cattle from failing, avoid sudden starts/stops and sharp turns • Schedule loading and unloading times to minimize the amount of time on trailer Transporting Cattle • Do not overcrowd cattle on trailers – Decrease number of head during hot conditions Cattle Weight, lbs Trailer Size 400 800 1200 1600 Total Weight 16 ft x 6 ft 18 9 6 4 < 7115 20 ft X 7 ft 26 13 9 6 < 10,370 24 ft X 7 ft 31 16 10 8 < 12,445 Non-Ambulatory Animals * Disabled or downer animals are not allowed in the food chain and SHOULD NOT be transported to the livestock marketing or harvest facility • Non-ambulatory cattle should be provided shade, water and feed, and housed in an area that provides good footing • Determining prognosis– Work with your veterinarian – More favorable prognosis when animal can sit upright and is eating and drinking– If not consider euthanizing animal 12 If the prognosis is unfavorable or the animal has not responded to veterinary care, it should be humanely euthanized. Feedstuffs • Maintain records of pesticides on pasture or crops • Create quality control program for incoming feedstuffs • Analyze suspect feedstuffs prior to use • Do not feed ruminant-derived protein sources per FDA • Support feeding of by-product/co-product ingredients with sound science 14 Practice Good Feed Room Hygiene • Don’t store agrochemicals, fertilizers and other non-feed items in the feed room • Keep feed dry and free from mold • Rotate inventory to keep feed fresh • Be very cautious with rodenticides • Do not use pesticide containers to store feed or feed cattle • Don’t ever feed floor sweepings to cattle 17 Feed Additives and Medications • Keep records for at • Use only FDAleast 2 years approved medicated • Assure all additives feed additives in are withdrawn at ration proper time • Use FDA current • Strictly adhere to Good Manufacturing medication Practices (cGMPs) withdrawal times to • Extra-label use of avoid violative feed additives is residues 18 prohibited Feed Additives and Medications • What falls into the feed additives and medications – Ionophores – Rumensin and Bovatec – Antibiotics – Aureomycin – Usually in purchased feeds • You must have a permit to mix the most concentrated forms Feed Additives and Medications • Monitor every withdrawal time to avoid residues • Identify treated individuals or groups Feed Storage and Handling • Store and handle feeds to prevent contamination of feeds and to insure safety of beef and milk products produced – Decrease moisture – Birds and rodents – Clean feeding area and water supply – Feed using clean equipment--I.E. To prevent Johne’s Disease– wash tractor tires, buckets, etc after handling manure and before feeding cattle Injectable Animal Health Products • Always follow label requirements • Products labeled for subcutaneous (SQ) administration should preferably be administered in the neck region • Products cleared for SQ, Intravenous (IV), Intranasal (IN) or oral administration are recommended • Products with low dosage rates are recommended and proper spacing of injections should be followed • All products labeled for intramuscular use shall be given in the neck region only (no exceptions, regardless of age) • All products can cause tissue damage when injected IM. Therefore all IM use should be avoided if possible. • No more than 10 cc of product is administered per IM injection site Judiciously Use Antibiotics • Select and use antibiotics carefully • Use laboratory results to select antibiotics • Avoid antibiotics important for humans as first line therapy • Limit antibiotic use to sick or “high risk” animals • Avoid combination therapy unless evidence to support decision • Sub-therapeutic antibiotic use is discouraged 9 Veterinarian Consultation • At a minimum invite your Veterinarian to your farm or livestock operation on an annual basis • Establishes valid Veterinary-Client-Patient Relationship (VCPR) – Vet better understand your production management & goals – Better assist you in making recommendations – Confidence that you’ll follow prescription labels – Diagnosis of disease challenges can be quicker Product Selection • Use Only Animal Health Products Approved for Cattle Production • Not all injectables are the same, reference should be given to products that • Use a lower dosage • Recommend SQ administration • Are less reactive once applied Injection Site Management • Since the first National Beef Quality Audit the incidence of injection site lesions has decreased from 22.3% (1991) to less than 3% (2000) Injection site lesions • Blemish Caused by IM Injection too Close to Shoulder The problem is being found in approximately 15 to 20% of steaks cut from the front of the Chuck Roll (NAMP 115). Injection Site Lesions • Decrease tenderness up to 3 inches from lesions • Result of an injection such as clostridial bacterins, antibiotics, and vitamins administered IM • Most lesions are scar tissue, but sometimes are active abscesses • Contaminated needles and syringes contribute to the problem Caution- Human Safety Concerns • Wear protective clothing/gloves when handling chemicals • Prostaglandin products (Lutalyse, Estrumate) should not be handled by pregnant women; this product can be absorbed through the skin • Micotil injections should use one handed technique; if self-injected it will likely cause death in humans Before Using a Drug • Read the label – Label includes the sheet that is inside the box with the product, not just what is on the bottle label or box. – Warning for withdrawal time noted, recorded • Record Serial & Lot Numbers – Needed for product failure, reporting adverse reaction, etc… • Record Expiration Date Example of Package Insert Information 13 Drug Classes • Over the Counter (OTC) • Prescription • Feed additives Over-the-Counter (OTC) • Products you can purchase online, at local farm store, etc… • Must be used in accordance to the label unless you have a written prescription • Examples: LA200, Penicillin Prescription Drugs • MUST have a valid Veterinary-Client-Patient Relationship (VCPR) • Require a prescription to obtain • Use the correct product for the disorder • BQA encourages Judicious use of Antimicrobials Extra Label Drug Use (ELDU) • “Off-Label” use • Veterinarian may decide to use either an OTC or Prescription Drug differently than as labeled – Examples may include different dosage, different route of administration, different purpose • MUST have a written prescription from the Vet and MUST have appropriate Withdrawal Time Established by the Vet – Often longer Withdrawal Time • CAN NOT prescribe use of FEED ADDITIVES different from the label – Not Even a Vet 6 animals are slaughtered for food. Exceeding recommended dose, or number of days treatment, or 10 ml per injection site may result in antibiotic residues beyond the withdrawal period. Net Contents: 100 ml Distributed by: Kentucky Animal Health Withholding Times Example of Label for Extra – Label Drug Quantity of Contents Use Name of Distributor LABEL PROVIDED BY VETERINARIAN FOR “EXTRA-LABEL”USE Name & Address of Veterinarian Veterinarian____________Phone_________ Address_________Date______Exp_______ Owner/Farm_______________ID#________ Active ingredients_____________________ Cautionary Statements Instructions for Use Indications___________________________ ____________________________________ Directions: Give___________cc’s/bolus/oz. ________times each day for ______days. Prescribed withholding time____________ Hours of milk withhold/Send samples Y/N; Days slaughter withhold/ Appropriate drug tag. Prescribed Withholding Times Properly Handling Vaccines Practice good sanitation • Separate needles should be used for filling the syringes and injecting the animals • Do not draw from a bottle with a needle that was in an animal – Get a new needle • Do not remove the needle from the syringe leaving the needle in the bottle Transfer Needle Springer Magrath Co. “Great tool for transferring diluent to vaccine on modified live vaccines. Stick transfer needle in sterile diluent first then stick in vaccine. Vacuum on vaccine will transfer over the diluent.” • http://www.dairypharm.com/servlet/ DisplayCatalog?key=100020 $1.08 (does not come with a container) • http://westernranchsupply.com/body .php3?cat_id=1&sub_id=104 MGRMTN $ 2.00 MLV Vaccine Care • Reconstitute only what is used in 1 hr • Use a transfer needle • Do not shake, but swirl to mix • Reconstituted vaccines should not be stored for use on another day, not effective Properly Handling Vaccines • Keep them cool during transport, use cooler or insulated bag with cold pack • Do not put them on the dash of the truck • Put them in the back of the refrigerator, not the door • Have a Cooler and cold packs for use at the chute • Avoid freezing the product as well Does Your Refrigerator Keep Vaccines at the Proper Temperature? • In a recent study over 50% of on farm refrigerators surveyed did not maintain the needed temperature(35 to 45F) more than 35% of the time Univ. of Arkansas 2009 Selecting Appropriate Needle • Gauge- diameter of needle – 14 to 20 gauge depending on animal size, route of administration, & product – Large enough to protect against breakage – Large enough to handle the characteristics of the product – No larger than necessary 5 & 10 Selecting Appropriate Needle • Length – ¾” to 1 ½” will suffice in most cases – Shorter needle for subcutaneous injections • ¾” to 1 inch – Longer needle for intramuscular (IM) • 1” for calves & 1 ½” for cows or bulls – Intravenous 1 ½” Table 2-1. Determining proper needle gauge based on the route of administration, animal size, and viscosity1 of fluid. SQ Injection (¾ to 1 inch long needle) IM Injection (1 to 1½ inch long needle) Animal Size (lb) 300700 <300 Fluid Viscosity1 >700 IV Injection (1½ inch long needle) Animal Size (lb) Animal Size (lb) 300700 300700 <300 Needle Gauge >700 <300 Needle Gauge >700 Needle Gauge Thin 18 18-16 16 20-18 18-16 18-16 18-16 16 16-14 Thick 18-16 16 16 18 16 16 16 16-14 16-14 Select the needle to fit the cattle size (the smallest practical size without bending). 1 An example of a thin viscosity fluid: saline; thick: oxytetracycline Avoid Breaking Needle – Properly restrain the animal – Avoid plastic hubs, select aluminum to minimize risk of breaking – IF you break off a needle in an animal, MUST retrieve it OR eliminate the animal from entering food / rendering channels 15 Change Needles—IF…. • Bends • Contacts manure, dirt or irritating chemicals • Needle point becomes burred (dropped syringe, hit chute, etc…) • Becomes dull or contaminated (every 1 to 15 head) • Between cattle with known blood-borne infectious disease (anaplasmosis, leukosis) Proper Use of Syringes • Disposable syringes are recommended over multi-dose syringes • Remove air from syringe after drawing • Sterilize syringes and needles properly Boil Do Not Use Disinfectants in or on syringes/needles for vaccine or medicine injections 11 Automatic Syringes • Genesis Instruments Mini-Cartridge® Automatic Syringe System – Recommend 35 ml/cc syringes (red) – Disposable barrel eliminates cleaning Vet Concepts Producers- Edwards Agri-Sales 800-235-2038 http://www.genesisinstruments.com/ General Syringe & Needle Care • Separate syringes for antibiotics & vaccines • Label syringes – Keep from drawing vaccine into antibiotic syringe • Properly dispose of used needles – Sharps Container – Hard plastic container (ie. Used laundry detergent container) – Do not throw them directly into trash 16 Manage Needles And Syringes • Separate needles should be used for filling syringes and injecting animals. • Change needles after about 10 injections (depending on biosecurity plan). • Replace bent or burred needles. • Disposable syringes are recommended instead of multiple-dose syringes. Do Not Combine Animal Health Products • Use combination products when possible to minimize number of injections. • Mixing two different vaccines WILL NOT produce one that will protect against both diseases. • Mixing unlike products can destroy the effectiveness of both products. If you administer 2 products give them at least 4 inches apart. Site Selection • CLEAN injection site, Avoid Wet Hides • Never inject any product IM behind the slope of the shoulder »use the neck only • Choose SQ when product allows • Never give more than 10cc of any product in one location, less if product directs 7 I.M. & SQ IM SQ Intramuscular Subcutaneous (under skin) Space injections a hand width apart Courtesy of Ohio State University 3 &4 Courtesy of Dr. Ron Gill, Texas A&M Practice Good Sanitation • Use boiling water to clean syringes used for MLV. Don’t use disinfectants or soap on inside portion of syringe. • Make sure the vaccine site is clean. • Avoid injecting into damp or wet cattle or manure covered areas. 11 Implant Cattle Properly • Properly restrain animals • Clean implant needle with disinfectant (tray and moist sponge to lay gun on) • Never sacrifice careful implantation technique for speed • Sanitation is very important Biosecurity • System of management procedures to prevent or reduce the risk of introducing disease into your operation • Directly affects BQA if it poses a public health risk with residues or disease causing pathogens • Indirectly if the disease impacts the quality or the subsequent treatment of the disease negatively effects quality • Test and quarantine replacements for at least 2 weeks but prefer 4 weeks • Disinfect equipment • Load and unload at the edge of the farm • Be careful when you return from visits to stockyards • Be careful when you help neighbors that are having a disease outbreak • Control visitors Written Records Herd Health Plan • A good health plan will decrease the risk of food safety and beef quality defects • A year round management calendar is highly recommended – Dates for major herd activities – Dates for the different vaccinations/treatments – Dates for breeding soundness in bulls Why are treatment Records Important? • Documentation of what was done • Written reminder of withdrawal time (and allowable marketing date) • Extra-label drug use • Residue violations • Proof of drugs used 20 Record Keeping • Keep records for at least 2 years for – Pasture/crop pesticides – Feed and drug additives – Health processing – Individual animal treatment 8 Treatment records • Individual and group treatment records should include – Animal ID (or group identification if group processing) – Treatment type – Treatment date – Treatment dose – Prescribed withdrawal time – Product used with serial/lot number and expiration date – Route of administration – Location of injections – Name of person administering treatment Feed Records • Keep a label on each lot of bagged feed • On bulk commercial feeds ask for invoices including – – – – Date Amount Lot/Batch number Signatures of person delivering and receiving the feed • On bulk commodities keep source information Processing/Treatment and Records • All cattle (fed and beef or dairy market cows/bulls) shipped to harvest will be checked by appropriate personnel to ensure that animals that have been treated have met label or prescription withdrawal times for all animal health products administrated • All processing and treatment records should be transferred with the cattle to next production level. • Prospective buyers must be informed of any cattle that have not met withdrawal times Written Records on “Paper” which are kept for at least 2 years KY-BQA Read and follow the label! Use common sense and do things right! Questions?