Technology's Effects in Organizations

advertisement

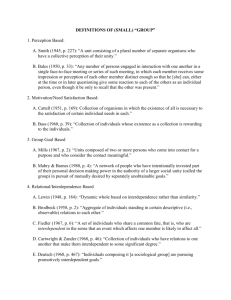

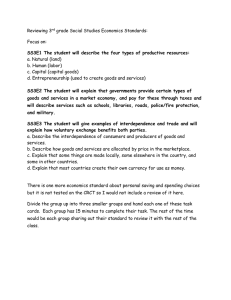

Task Interdependence: Thompson’s three types of technology • Mediating •Pooled interdependence • Long-linked •Sequential interdependence • Intensive •Reciprocal interdependence 9- 1 Thompson’s Classification of Interdependence and Management Implications Form of Interdependence Demands on Horizontal Communications, Decision Making Pooled (bank) Low communication Client Sequential (assembly line) Client Medium communication Reciprocal (hospital) Client High communication Type of Coordination Required Priority for Locating Units Close Together Standardization, rules, procedures Divisional Structure Low Plans, schedules, feedback Task Forces Mutual adjustment, cross-departmental meetings, teamwork Horizontal Structure Medium High Routine and Nonroutine Tasks and Organizational Design Structural characteristic Nature of technology Routine tasks Nonroutine tasks Standardization High Low Mutual adjustment Low High Specialization Individual Joint Formalization High Low Hierarchy of authority Tall Flat Decision-making authority Centralized Decentralized Overall structure Mechanistic Organic 9- 3 Technical Complexity: Woodward’s Theory Some kinds of technology are more complex and difficult to control than others because some are more difficult to program than others. Technology is said to be programmed when procedures can be specified in advance to make tasks standardized and predictable. 9- 4 Technical Complexity and Organization Structure Technical Low Structural Characteristics Small-Batch and Unit Technology Complexity Mass Production Technology High Continuous-Process Technology Levels in the hierarchy 3 4 6 Span of control of CEO 4 7 10 Span of control of firstline supervisor 23 48 15 Ratio of managers to nonmanagers 1 to 23 1 to 16 Relatively flat, with narrow span of control Relatively tall, with wide span of control 1 to 8 Approximate shape of organization Type of structure Organic Cost of operation High 9- Very tall, with very narrow span of control Mechanistic Organic Medium Low 5 Process Choice at a Bakery Advanced Manufacturing Technology Computer-aided design Computer-aided materials management Just-in-time inventory systems Computer-integrated manufacturing 10 - 7 Relationship of Computer-Integrated Manufacturing Technology to Traditional Technologies Flexible Manufacturing Small batch NEW Customized Mass Customization CHOICES PRODUCT FLEXIBILITY Mass Production Continuous Process Standardized Small Source: Based on Jack Meredith, “The Strategic Advantages of New Manufacturing Technologies For Small Firms.” Strategic Management Journal 8 (1987): 249-58; Paul Adler, “Managing Flexible Automation,” California Management Review (Spring 1988): 34-56; and Otis Port, “Custom-made Direct from the Plant.” Business Week/21st Century Capitalism, 18 November 1994, 158-59. BATCH SIZE Unlimited Differences Between Manufacturing and Service Technologies Manufacturing Technology 1. 2. Service Technology 1. 2. 3. 4. 5. 6. 7. 8. Intangible product Production and consumption take place simultaneously Labor and knowledge intensive Customer interaction generally high Human element very important Quality is perceived and difficult to measure Rapid response time is usually necessary Site of facility is extremely important 3. 4. 5. 6. 7. 8. Tangible product Products can be inventoried for later consumption Capital asset intensive Little direct customer interaction Human element may be less important Quality is directly measured Longer response time is acceptable Site of facility is moderately important Service: Product and Service: Product: Airlines, Hotels,Consultants, Healthcare, Law firms Fast-food outlets, Cosmetics, Real estate, Stockbrokers, Retail stores Soft drink companies, Steel companies, Auto manufacturers, Sources: Based on F. F. Reichheld and W. E. Sasser, Jr., “Zero Defections: Quality Comes to Services,” Harvard Business Review 68 (September-October 1990): 105-11; and David E. Bowen, Caren Siehl, and Benjamin Schneider, “A Framework for Analyzing Customer Service Orientations in Manufacturing,” Academy of Management Review 14 (1989): 75-95.